Floor system formed by cold bending type steel combination beam

A technology of cold-formed steel and composite beams, applied in the direction of floor slabs, building components, building structures, etc., can solve the problems of large proportion of shear connectors, reducing the actual use height of floors, and small operating space, saving engineering construction. Time and labor costs, increased floor operation space, and fast on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

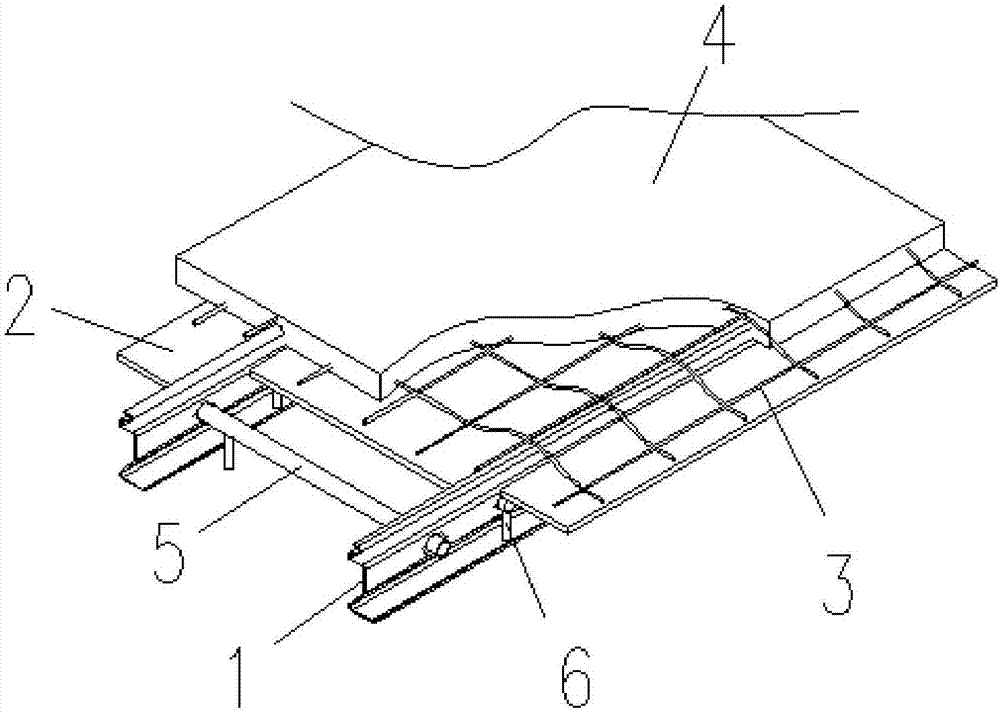

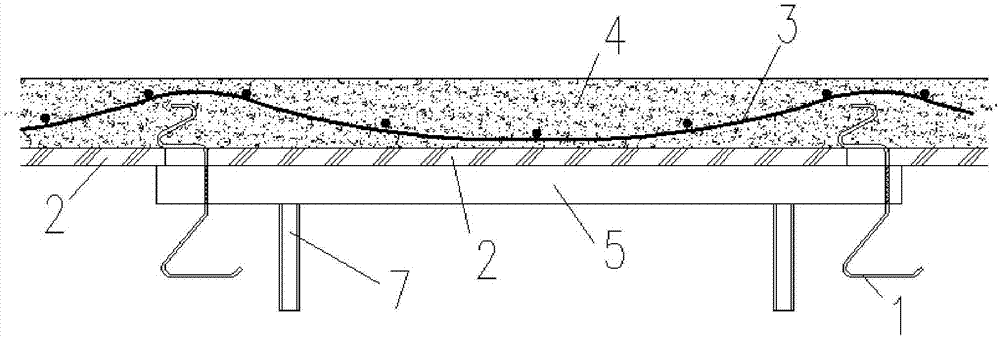

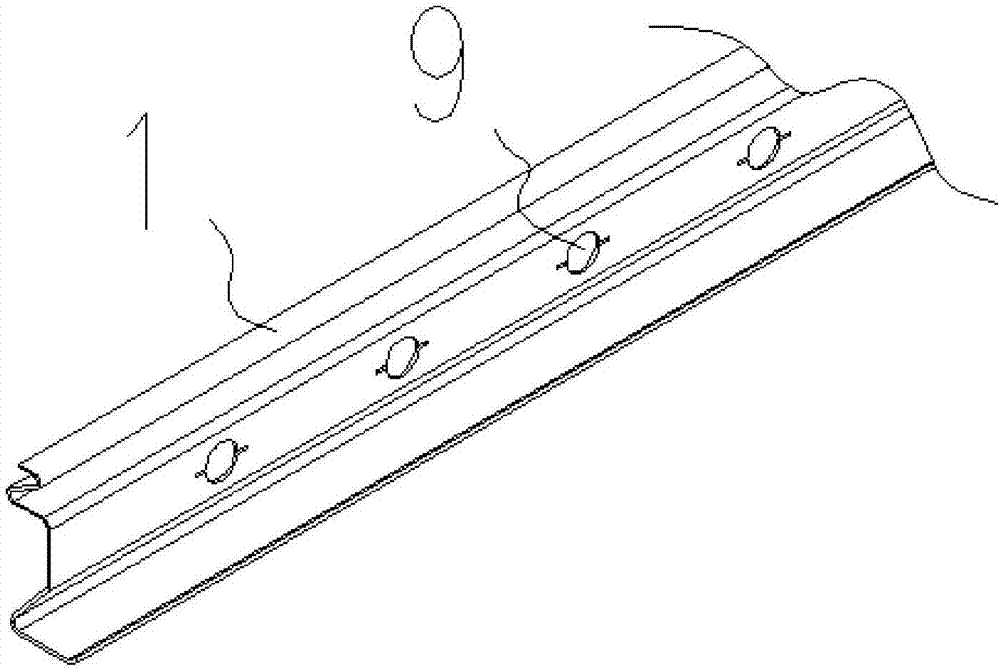

[0016] Such as Figure 1 to Figure 3 As shown, a floor system composed of cold-formed steel composite beams includes cold-formed steel 1, floor template 2 and floor concrete layer 4; two cold-formed steels 1 are arranged in parallel, and the The inner side of the room is provided with a long supporting rod 5, and the outer side is provided with a short supporting rod 6, forming a group of cold-formed steel; Fixed; the floor concrete layer 4 is provided with a floor reinforcement mesh 3, and the floor reinforcement mesh 3 is arranged in an arc-shaped structure, located on a group of cold-formed steel; the cross-section of the cold-formed steel 1 is a multi-curved surface structure, and a plurality of sets of connecting holes 9 are arranged along the length direction; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com