Beam-to-column connections for square steel tube columns

A technology of beam-column joints and square steel pipes, which is applied in construction, building construction, etc., can solve problems that are difficult to implement, and achieve the effects of improving construction efficiency, reducing on-site welding workload, and improving joint ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

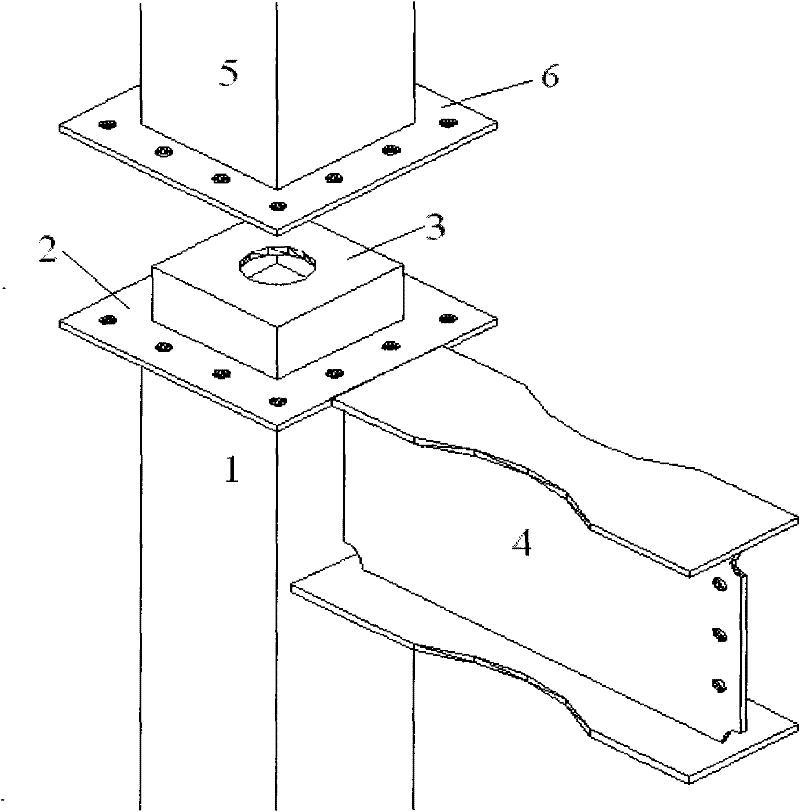

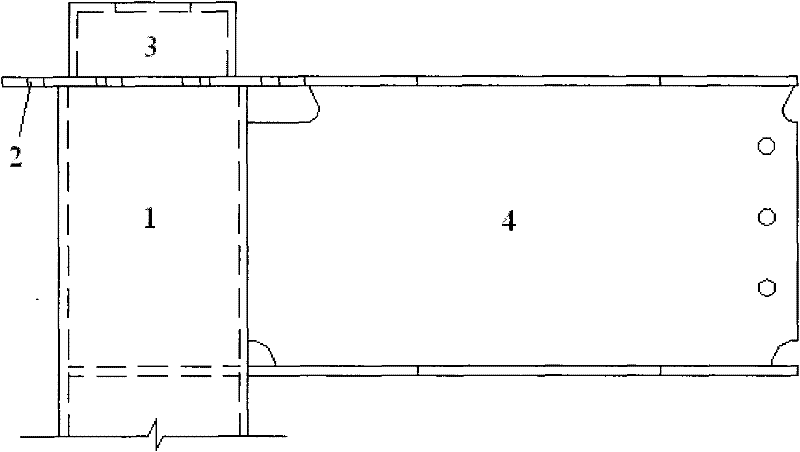

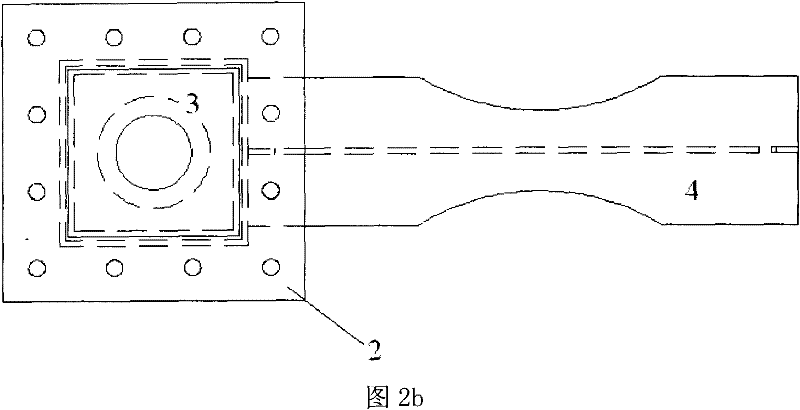

[0013] A beam-column joint suitable for a square steel pipe column, comprising: a lower square steel pipe column 1 and an upper square steel pipe column 5, a dog-bone short I-steel cantilever 4 is arranged on the lower square steel pipe column 1, The end of the upper square steel pipe column 5 is connected with a lower flange 2, and the end of the upper square steel pipe column 5 is connected with an upper flange 6 that can match the lower flange 2. Holes match the interpolation section 3 with transverse stiffeners, and the upper square steel pipe column 5 is sleeved on the interpolation section 3, and the lower flange 2 and the upper flange 6 are fastened and connected by bolts. There is a gap of 2-3 mm between the outer side of the interpolation section and the inner side of the square steel pipe column.

[0014] After the upper square steel pipe frame column 5 is hoisted in place, it is temporarily fixed after being socketed with the present invention through the node inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com