A new type of full-tube panel high-efficiency fuel-fired gas-fired boiler

A gas-fired boiler and tube panel technology, which is applied in steam boilers, steam generation, lighting and heating equipment, etc., can solve the problems of complex on-site manufacturing process, tube sheet cracks, difficult to enlarge, etc., and achieves easy disassembly, maintenance, and overhaul cycles. Short, easily normalized effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be described in more detail below in conjunction with the accompanying drawings.

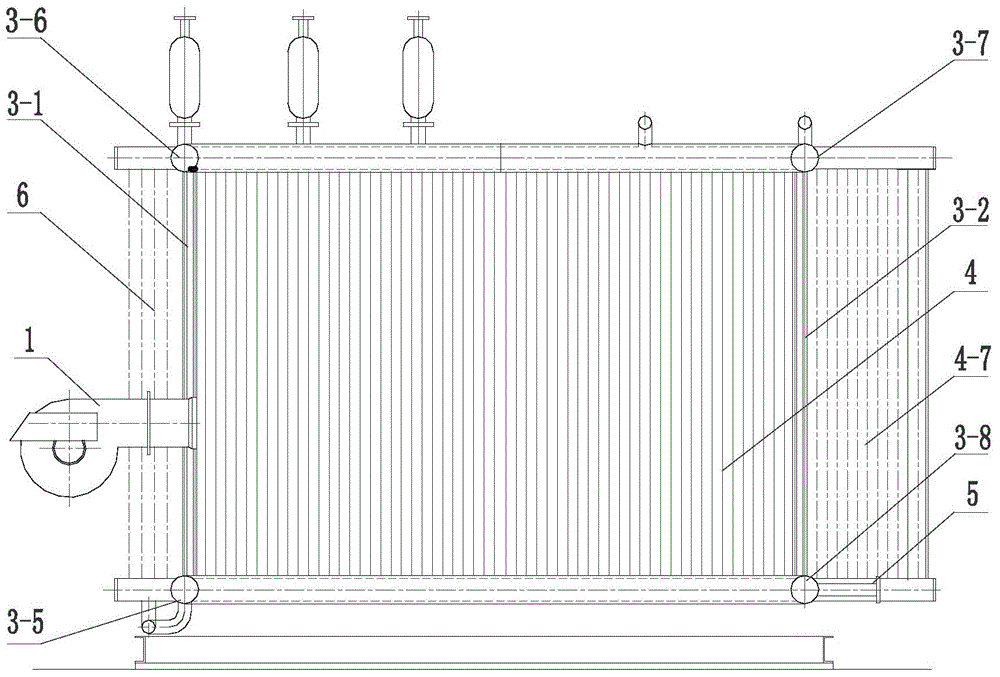

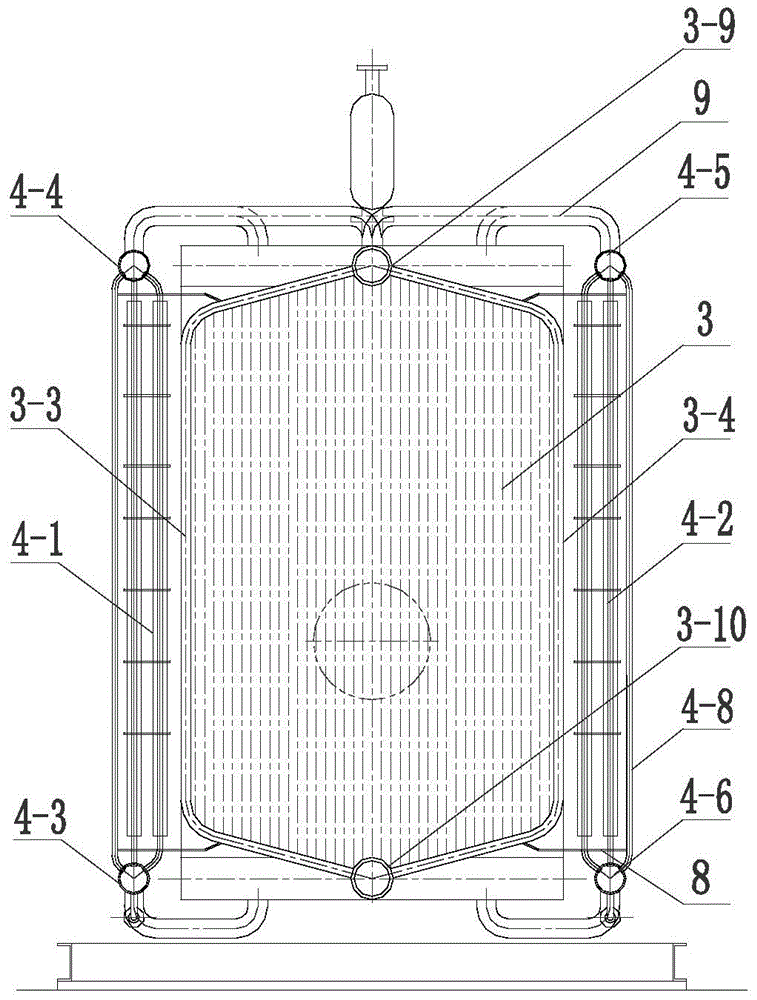

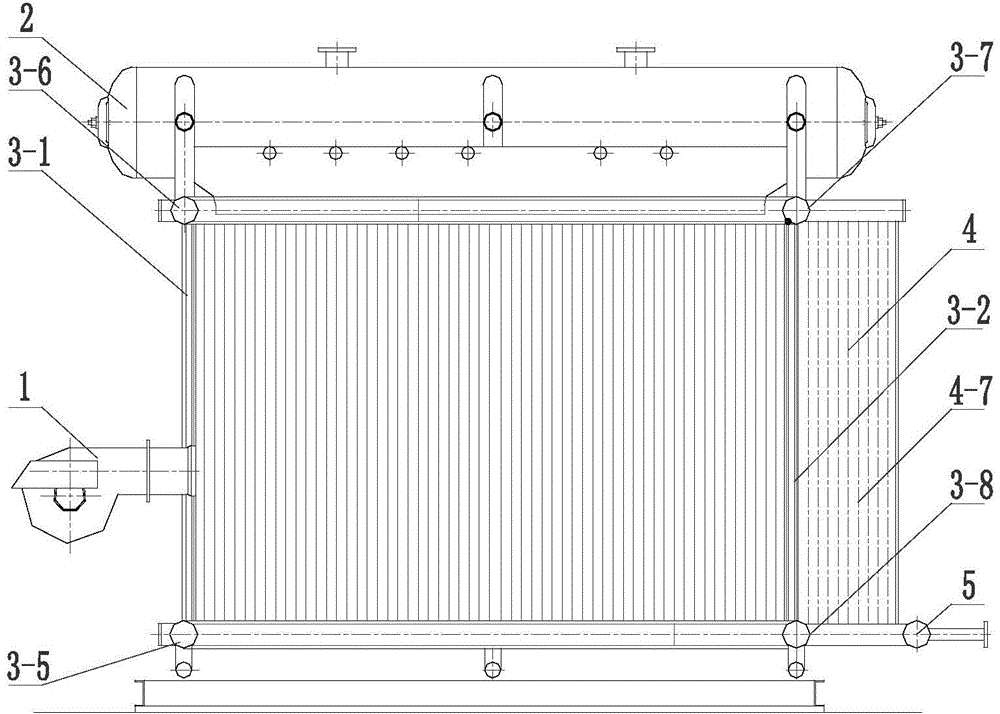

[0031] Such as figure 1 and figure 2 As shown, the present invention is a novel full-tube-panel high-efficiency fuel-fired gas boiler, which includes a radiation heat exchange membrane water-cooled wall tube panel structure 3 and a convective heat exchange tube bundle type tube panel structure 4. The radiation heat exchange membrane water-cooled wall The tube-panel structure 3 includes a front wall membrane water cooling wall 3-1, a rear wall membrane water cooling wall 3-2, a left wall membrane water cooling wall 3-3, a right wall membrane water cooling wall 3-4 and a front wall membrane water cooling wall 3-4. The burner 1 on the wall membrane type water cooling wall 3-1, the front wall membrane type water cooling wall 3-1, the rear wall membrane type water cooling wall 3-2, the left wall membrane type water cooling wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com