Mechanically anchored connection node structure between concrete filled steel tube columns and reinforced concrete beams

A technology for reinforced concrete beams and concrete-filled steel tubular columns is applied in the field of mechanically anchored connection node structures, which can solve problems such as weakening of steel tubular columns, and achieve the effects of fast construction speed, clear force relationship, and reduced welding workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

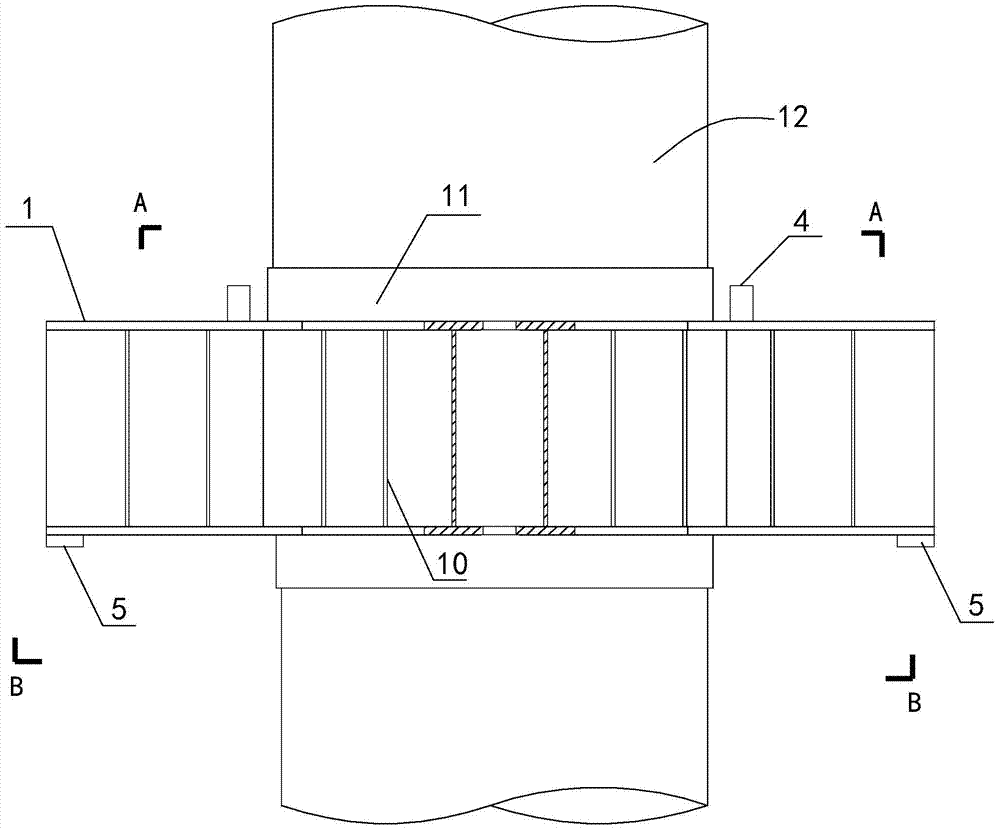

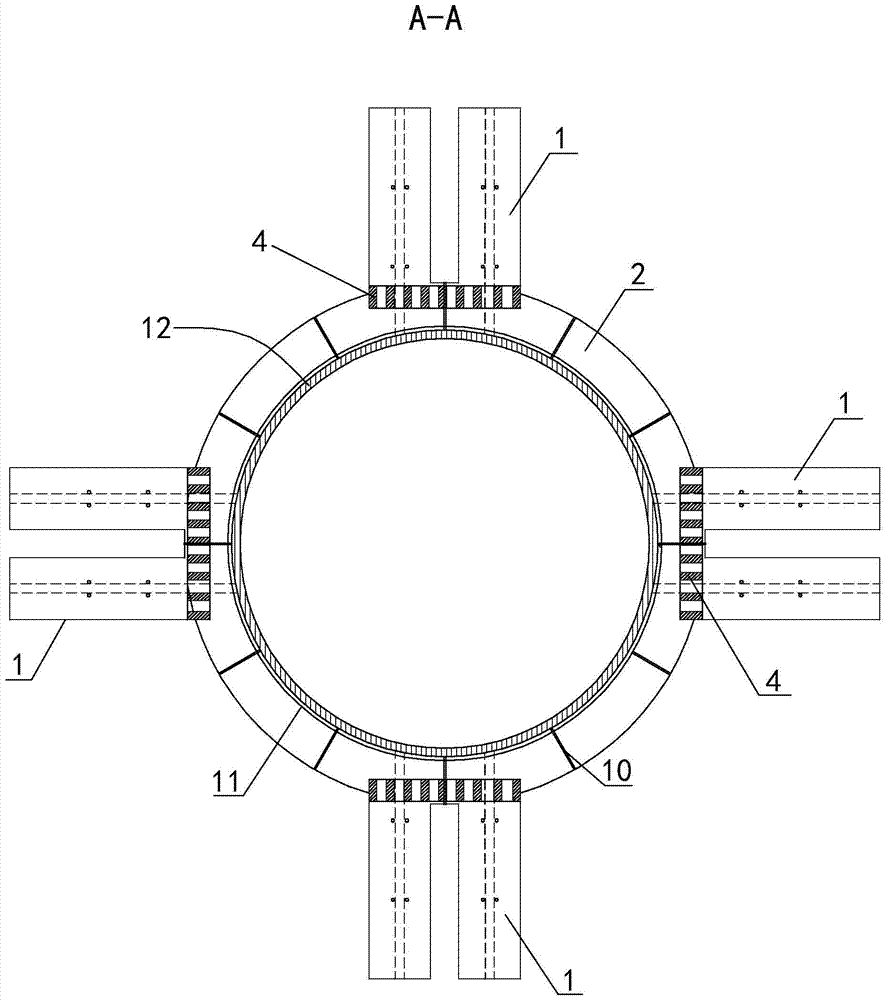

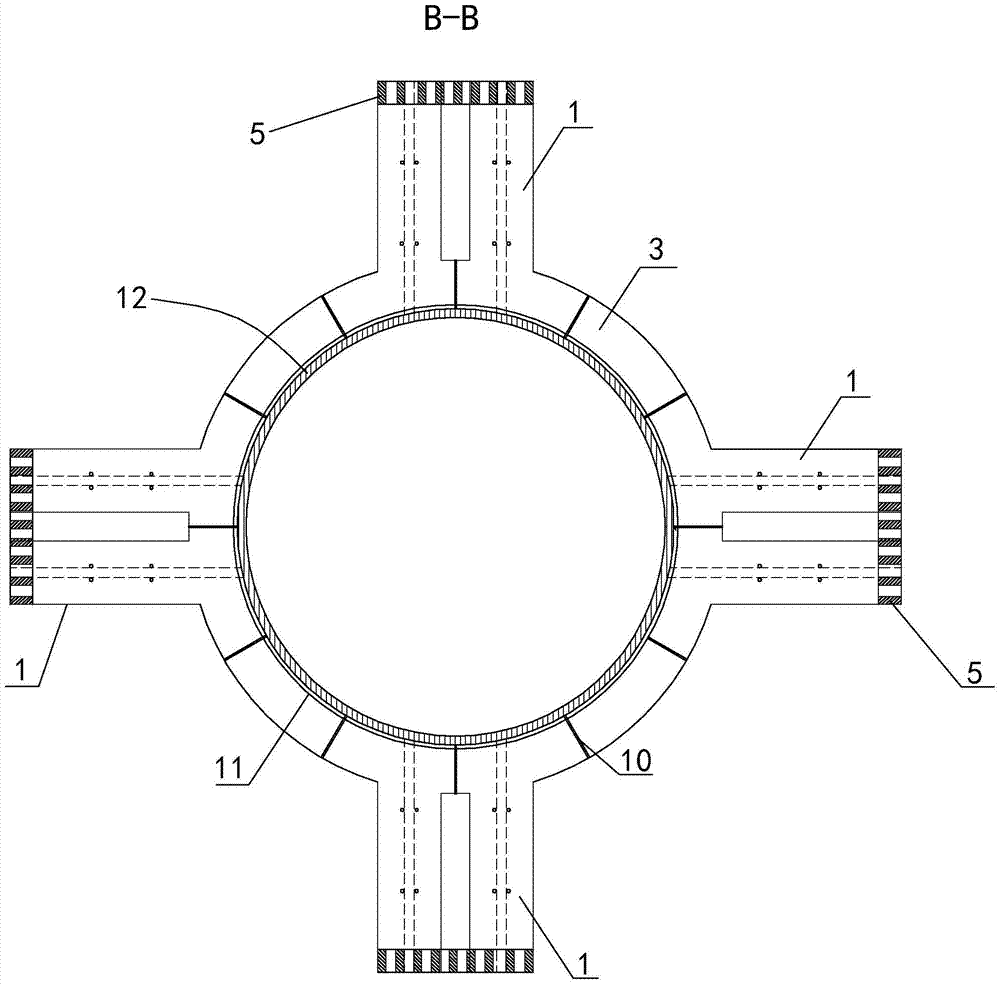

[0043] Such as Figure 1 to Figure 9 The mechanically anchored connection node structure between the concrete-filled steel tube column and the reinforced concrete beam is shown. Plates and connecting anchors.

[0044] The steel pipe column 12 is a vertical column, the beam gluten 6 and the beam bottom bar 7 are multiple horizontal beam longitudinal bars, the steel corbel 1 is four pairs of I-beams, and the steel corbel 1 has upper and lower flanges, Four pairs of I-beams are evenly arranged around the steel pipe column 12, each pair of steel corbels 1 is composed of two steel corbels 1 arranged in parallel, and the eight steel corbels 1 have the same structure and are all 700mm in length.

[0045] Since the beam reinforcement and the corbel are mechanically overlapped, the length of the steel corbel is taken as 0.6 times the anchorage length of the beam reinforcement. Considering that the diameter of the general beam reinforcement is less than 32 mm, the length of the steel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com