Reinforced structure of hinges on the a-pillar of the body

A technology for strengthening structures and pillars, applied to superstructures, subassemblies of superstructures, vehicle components, etc., can solve problems that affect the life safety of occupants in the vehicle, large displacement of the doors, and inability to open the doors, so as to reduce the failure of opening Risk, safety protection, and improvement of the effect of car door drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

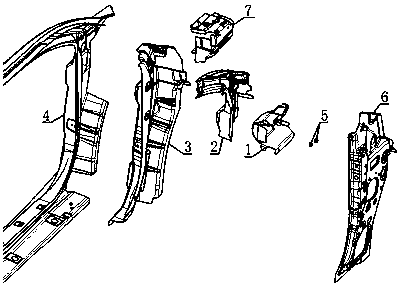

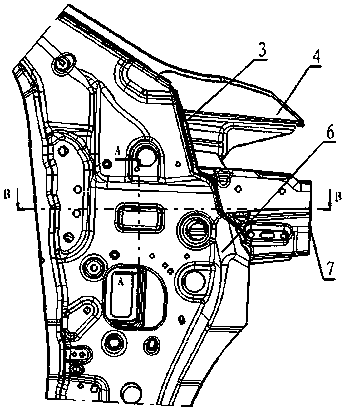

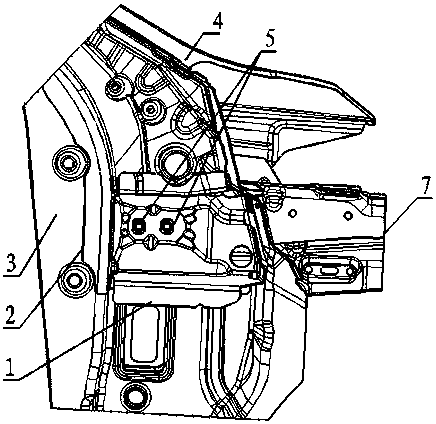

[0025] see Figure 1 to Figure 11 As shown, the A-pillar upper hinge reinforcement structure includes A-pillar upper reinforcement 2, A-pillar lower reinforcement 3, A-pillar upper hinge reinforcement 1, side wall outer panel 4, A-pillar inner panel 6 and side wall reinforcement Front connecting plate assembly 7. A column upper hinge reinforcement 1 includes a bottom plate and a top plate located above the bottom plate, the outer side of the bottom plate and the outer side of the top plate are connected by an outer side wall plate, and the middle part of the outer side wall plate bulges outward to form a first raised structure 11. A triangular rib is provided at the connection between the outer end surface of a protruding structure 11 and the side wall of the first protruding structure, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com