Steel plate and production method thereof

A production method and steel plate technology, which is applied in the field of steel plate rolling, can solve the problems affecting the production rhythm and yield, large head and tail shear loss, and low production efficiency, so as to improve the edge drop of cold rolling and reduce the cold rolling reduction Ratio, increase the effect of hot rolling reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

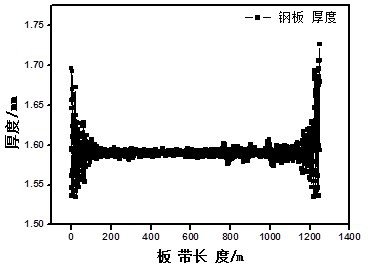

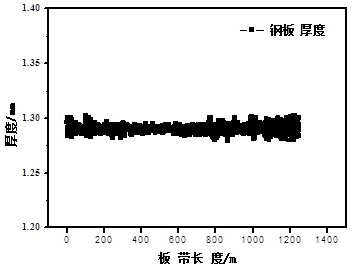

[0021] In the hot rolling process, the tapping temperature of the slab is 1220-1240 °C, the heating time is 180-240 min, the compensation temperature of the edge of the steel plate and the finishing temperature are shown in Table 2. , The finishing mill stand adopts CVC rolls, which are controlled by micro-waves. After the steel plate is rolled, laminar cooling is performed, and the rear half of the laminar flow section is heated. The compensation temperature and coiling temperature of the head and tail are shown in Table 2. After the coil is coiled, it is slowly cooled to room temperature.

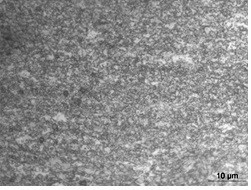

[0022] In the pickling process, the rolling mill is a CVC five-stand six-high continuous rolling mill. The crowns of the work rolls of the F1-F5 stands are shown in Table 3. The rolling reduction ratio and the F1-F5 stand reduction ratio in the pickling process are shown in Table 3. After the thickness of the steel plate is 0.8 ~ 2.5mm, the steel plate is rolled to the thickness of the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com