Patents

Literature

51results about How to "Achieving fine grain strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum-based material and preparation method thereof

InactiveCN109706350AHigh hardnessImprove wear resistanceFoundry mouldsMetallic material coating processesWear resistantAlloy substrate

The invention discloses an aluminum-based material. Aluminum nitride, zirconium oxide and tantalum oxide particles are uniformly distributed in an aluminum alloy substrate, MoS2, Al2O3 and SiC are distributed on part of a surface layer of the aluminum alloy substrate, the hardness of aluminum nitride, zirconium oxide and tantalum oxide is high, the hardness and wear-resisting performance of the substrate are significantly improved, and fluorinated graphite powder can improve the anti-friction property. The surface of the substrate is coated with a Mn-Cr coating in a fusion mode to effectivelyimprove the wear-resisting performance and corrosion resistance of the alloy surface. The dispersion strengthening of strengthening phases of Si, Cu, Cr, Ni, Hf, Fe, Ag, Ca, Li, Ba and other elementsin the alloy improves the mechanical properties of the material. A preparation method enables mixed powder to be located in the center of a master alloy solution during casting through a method by adhering the mixed powder to a pure aluminum metal wire, the rapid diffusion and homogenization of micro powder particles is facilitated, the production efficiency is improved, wear-resistant materials are locally added by friction stir machining, and the material utilization ratio is improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

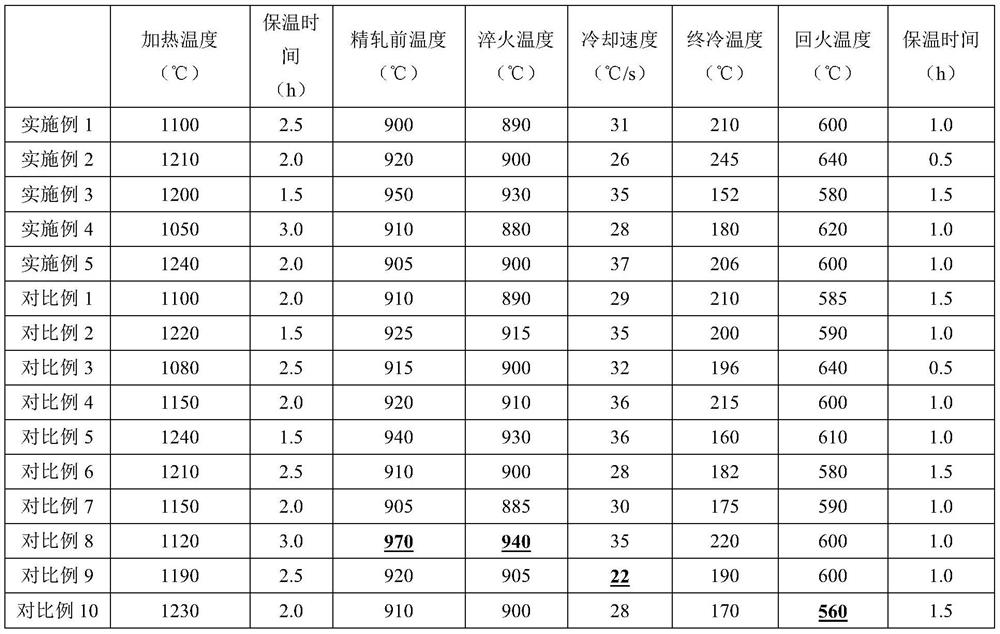

High-toughness weather-proof hot-rolled H-shaped steel for bridge structure with yield strength of 460 MPa and production method thereof

ActiveCN108754327AImprove uniformityIncreased sensitivityMetal rolling arrangementsTemperature controlChemical composition

The invention discloses a high-toughness weather-proof hot-rolled H-shaped steel for a bridge structure with yield strength of 460 MPa and a production method thereof. The hot-rolled H-shaped steel comprises the following chemical components by weight: C: 0.08-0.11, Si: 0.30-0.45, Mn: 1.30-1.50, P: <=0.020, S: <=0.015, Cr: 0.50-0.65, Ni: 0.30-0.40, Cu: 0.30-0.40, V: 0.075-0.095, Nb: 0.015-0.025, Alt: 0.015-0.030 and the balance Fe and trace residual elements. By means of reasonable composition proportion, press distribution and temperature control rolling, the fine grain strengthening, precipitation strengthening and phase transformation strengthening mechanisms as well as deformation and penetration control are utilized, and direct air cooling is conducted after hot rolling to obtain a complex phase structure of ferrite + bainite + pearlite; the mechanical property can reach the level that ReL is not less than 460MPa, Rm is not less than 570MPa, A is not less than 20%, KV2 is not lessthan 150J under 40oC, and the corrosion rate is not more than 50% compared with that of Q345B.

Owner:MAANSHAN IRON & STEEL CO LTD

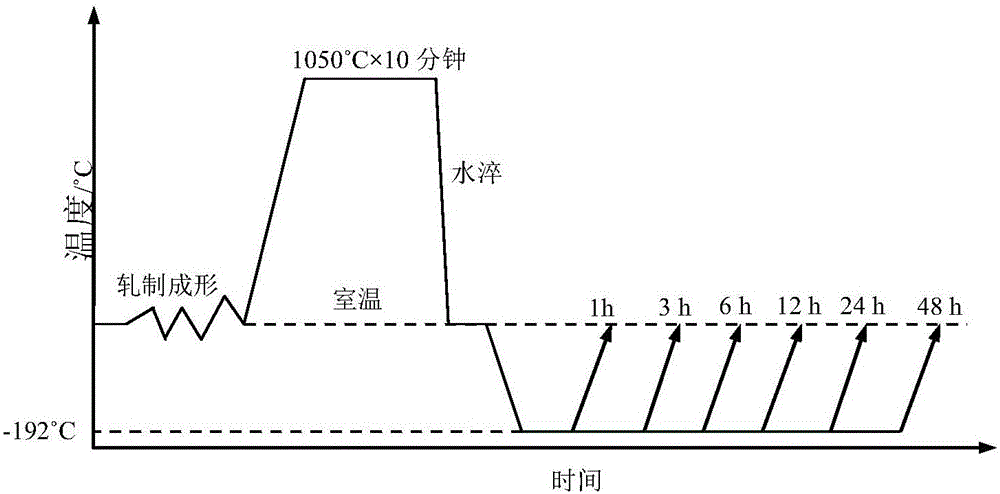

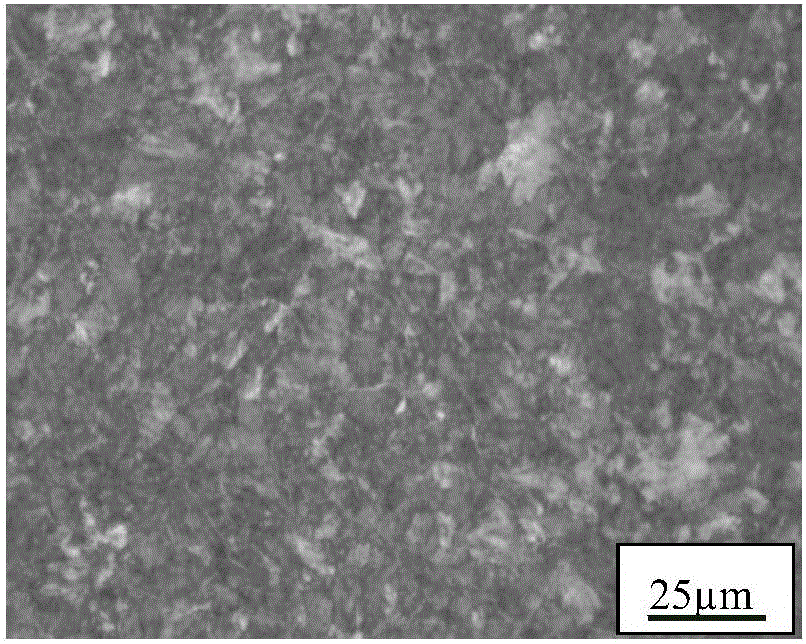

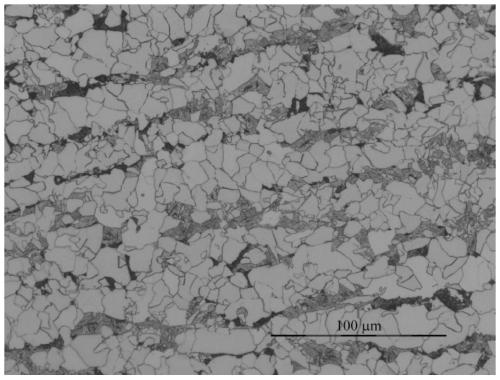

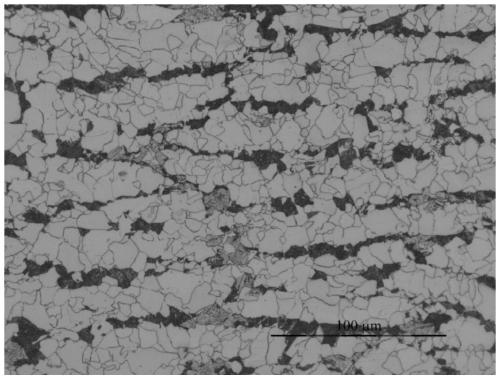

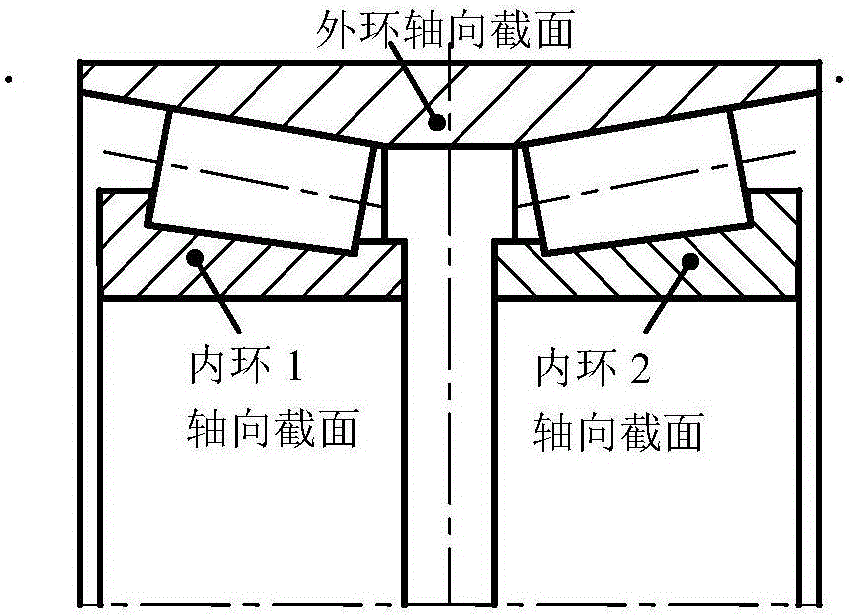

Rolling-deformation thermal treatment method for improving performance of bearing ring

InactiveCN106086381AIncrease dislocationIncrease crystal defects such as substructureFurnace typesHeat treatment furnacesCrystallographic defectMechanical property

The invention relates to a rolling-deformation thermal treatment method for improving performance of a bearing ring. The rolling-deformation thermal treatment method comprises the steps of carrying out roll forming on a bearing ring blank to break crystal grins, generating a lot of crystal defects like dislocation and substructures inside the material, and enlarging recrystallization nucleation positions; then, carrying out quenching treatment, dynamic recrystallization nucleation, solid state phase change and dispersion strengthening, and refining the crystal grains to improve the distribution uniformity of the crystal grins; and decreasing the content of retained austenite in the bearing ring through cold treatment, so as to improve the strength, rigidity, toughness and structure stability of the bearing ring considering the problems that the structure quickly cooled through oil quenching or water quenching has retained austenite with a relatively high content, and the retained austenite with the relatively high content influences the size accuracy stability and reduces the strength, rigidity, plasticity and fatigue crack propagation resistance of the bearing ring. According to the rolling-deformation thermal treatment method, the fineness uniformity, mechanical property and size stability of the bearing ring structure are remarkably improved.

Owner:WUHAN UNIV OF TECH

Composite material and preparation method thereof

InactiveCN109929986AHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingSilicon oxideBoron nitride

The invention discloses a composite material. Boron nitride particles, silicon oxide particles, tungsten trioxide particles and molybdenum disulfide particles are uniformly distributed in an aluminumalloy matrix, wherein the antifriction property can be improved through the molybdenum disulfide particles. The surface of the matrix is provided with three-layer gradient deposition layers, so that the wear resistance and the hardness of the alloy surface can be effectively improved. Dispersion strengthening is realized through strengthening phases of elements such as Zn, Sr, Ho, Cu, Au, Mg, Pd,Si, Al, Ni, W and Fe in an alloy, so that the mechanical property of the material is improved. The invention further discloses a preparation method of the composite material. According to the preparation method, a ceramic layer is formed through laser deposition, aluminum oxide particles can be driven to grow in the deposition layers, the hardness and the wear resistance are further improved by combining ultrasonic surface rolling, through the ceramic surface of the composite material, the composite material simultaneously achieves the characteristics of ceramic high temperature resistance andmetal low temperature resistance, so that the composite material can be applied to the field of machining of parts requiring the high temperature resistance and the low temperature resistance simultaneously, and the surface nitriding process can enhance the corrosion resistance of the composite material.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Recrystallizing high-strength titanium alloy and preparation method thereof

The invention provides a recrystallizing titanium alloy and a preparation method thereof. The high-strength titanium alloy is prepared from the following components of 4.5 to 6.0% of Al (aluminum), 3.7 to 4.7% of Sn (stannum), 0.75 to 2.0% of Mo (molybdenum), 0.2 to 0.35% of Si (silicon), 0.6 to 1.2% of Nd (neodymium), 5 to 50% of Zr (zirconium) and the balance of Ti (titanium). The recrystallizing high-strength titanium alloy has the advantages that after alloying, the crystal lattice is distorted due to the adding of the Zr element, the number of nucleation points is increased in the nucleation process due to the defects, the density of nucleation is increased, the refining function of crystal grains is realized, and the refining of crystals is reinforced; proofed by experiment results,compared with the contrast alloy with yield strength of 880MPa and the tensile strength of 1020MPa, the recrystallizing high-strength titanium alloy has the yield strength of 963 to 1130MPa and the tensile strength of 1100 to 1280MPa, and maintains the equivalent elongation rate.

Owner:YANSHAN UNIV

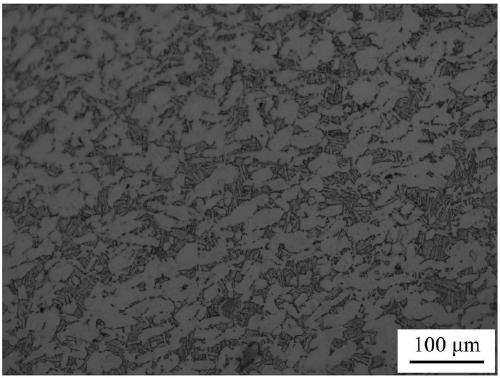

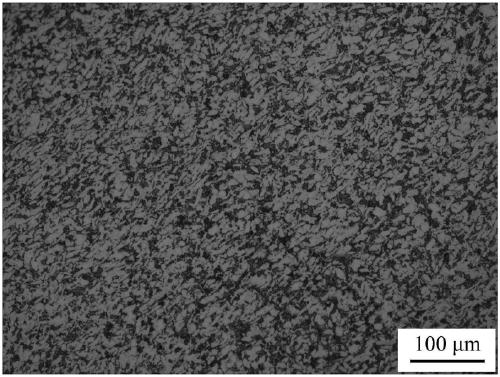

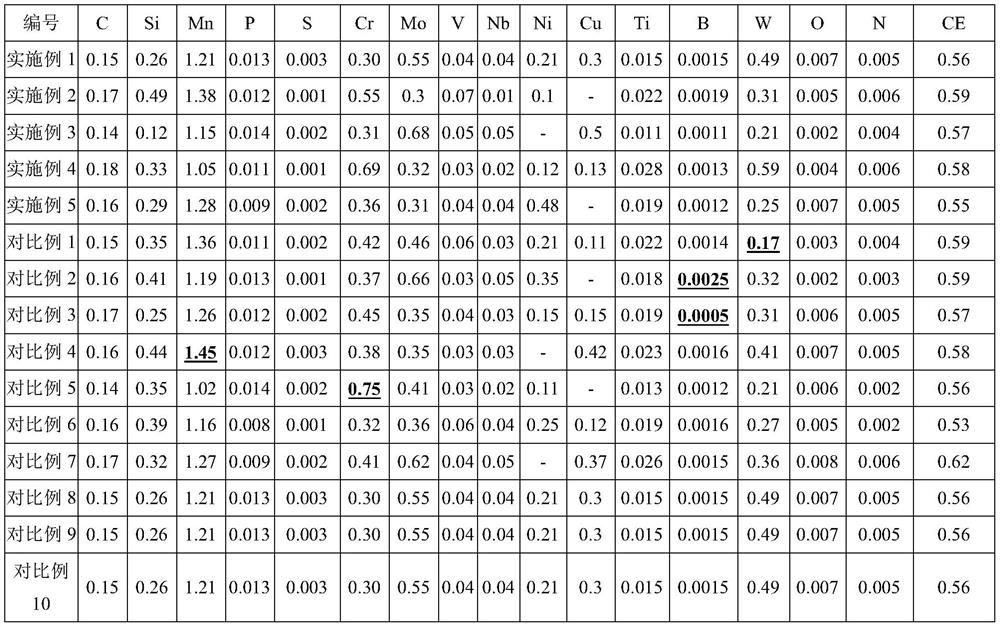

Ultrahigh-strength seamless steel tube with excellent weldability and manufacturing method thereof

The invention discloses an ultrahigh-strength seamless steel tube with excellent weldability. The ultrahigh-strength seamless steel tube comprises the following chemical elements of, by mass, 0.14% to0.18% of C, 0.1% to 0.5% of Si, 1.0% to 1.4% of Mn, 0.3% to 0.7% of Cr, 0.3% to 0.7% of Mo, 0.2% to 0.6% of W, 0.03% to 0.07% of V, 0.01% to 0.05% of Nb, 0.01% to 0.03% of Ti, 0.001% to 0.002% of B,at least one of 0.1% to 0.5% of Cu and 0.1% to 0.5% of Ni and the balance Fe and other inevitable impurities. In addition, the invention further discloses a manufacturing method of the ultrahigh-strength seamless steel tube with the excellent weldability. The ultrahigh-strength seamless steel tube is high in strength, good in toughness, excellent in welding performance and very suitable for high-strength engineering structures.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength titanium alloy and preparation method thereof

ActiveCN108913948AImprove mechanical propertiesHigh specific strengthSolution treatmentRoom temperature

The invention provides a high-strength titanium alloy and a preparation method thereof. The high-strength titanium alloy comprises, by mass, 4.5%-5.5% of Al, 3.5%-4.5% of Mo, 3.5%-4.5% of Cr, 1.5%-2.5% of Sn, 10%-50% of Zr and the balance Ti. According to the high-strength titanium alloy and the preparation method thereof, the content of all the elements is strictly controlled, and the mechanicalproperty of the titanium alloy is improved; the Cr element is added, therefore, a beta phase is stabilized, and the room-temperature strength of a titanium alloy matrix can be significantly improved;the Al element greatly improves the stability of an alpha phase and increases the beta-alpha conversion temperature, the uniform and fine alpha phase can be conveniently obtained after quenching in the solution treatment process, and the specific strength of the titanium alloy can be significantly improved; and in addition, lattice distortion can be caused due to addition of the Zr element, the defects can cause nucleation point increasing and nucleation density increasing in the nucleation process, the grain refinement effect is achieved, and then fine crystal strengthening is achieved.

Owner:YANSHAN UNIV

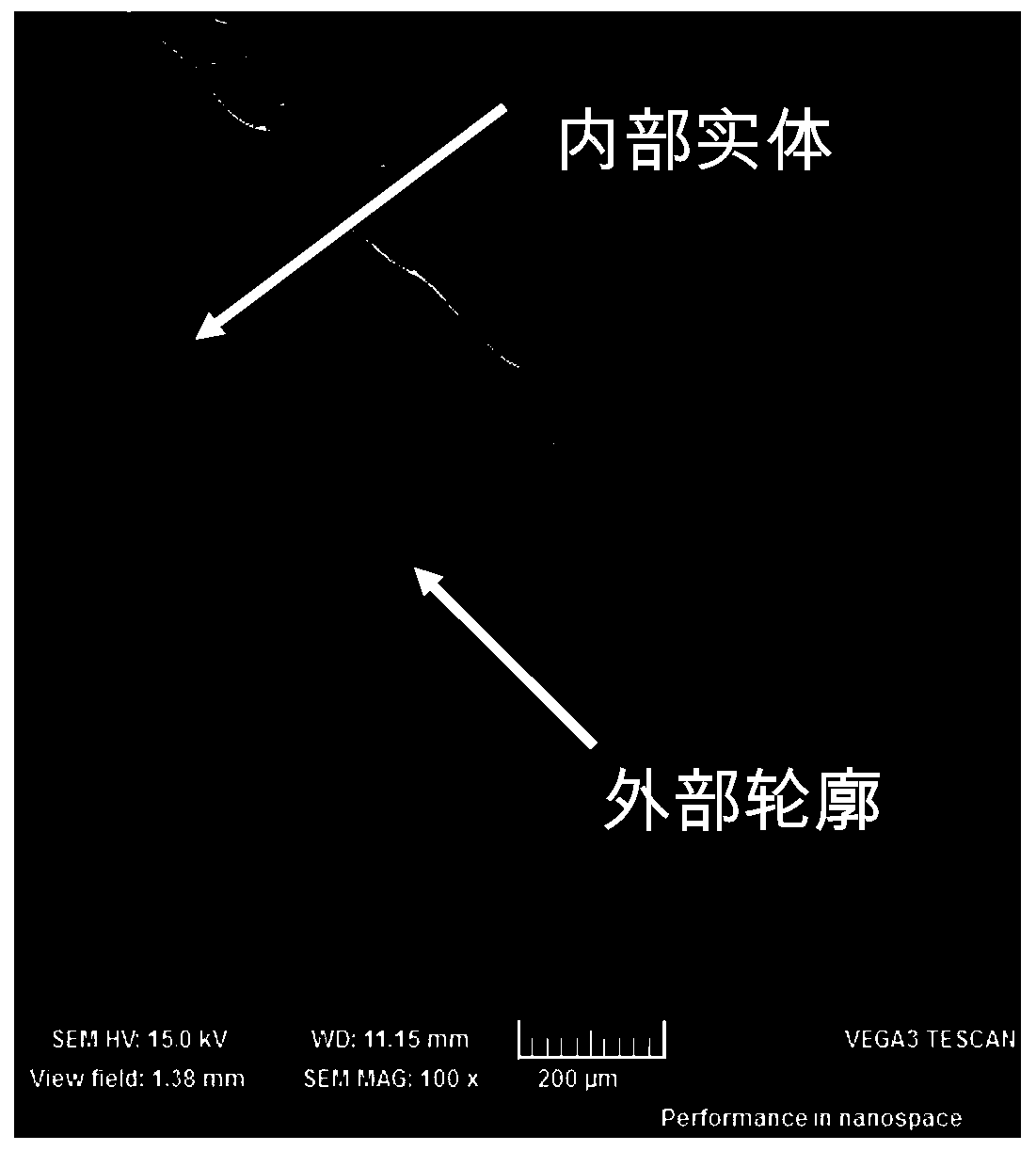

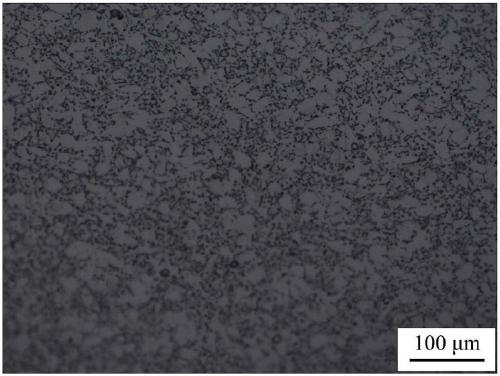

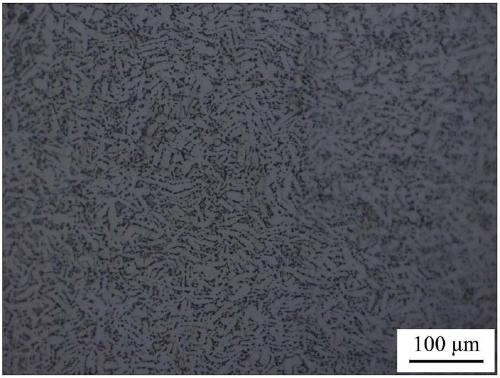

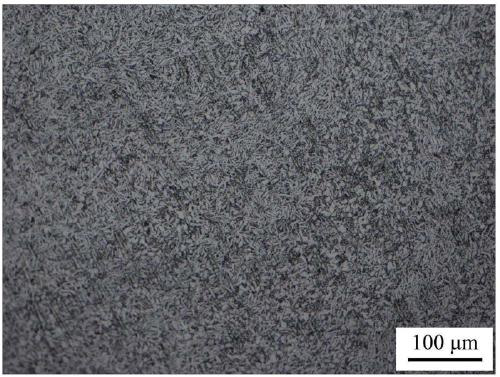

Laser additive manufacturing method for synergistically improving surface precision and strength of titanium alloy

InactiveCN110523984ASynergistically improve surface accuracySynergistically enhance surface strengthAdditive manufacturing apparatusIncreasing energy efficiencyScan lineLaser scanning

According to the laser additive manufacturing method for synergistically improving the surface precision and strength of the titanium alloy, the forming structure is adjustable, the surface is smoothand clean, the surface is self-strengthened, and extra surface treatment and other procedures are not needed. The method comprises the following steps: uniformly and continuously pre-paving Ti6Al4V alloy powder on a forming cabin substrate of laser additive manufacturing equipment, and printing and forming layer by layer to obtain a Ti6Al4V alloy test piece; when each layer is printed and formed,using laser beams to adjacently scan line by line to form an internal solid plane, after forming the internal solid plane, performing laser scanning of a contour along the edge of the internal solid plane to form an external contour, and finish forming of the printing layer; repeating the forming process of the printing layers until laser additive manufacturing forming of the Ti6Al4V alloy test piece is completed, wherein the laser power for printing internal solid plane is not less than the laser power for printing the external contour, and the scanning speed for printing the internal solid plane is not greater than the scanning speed of the printing external contour.

Owner:SHANGHAI AIRCRAFT DESIGN & RES INST COMML AIRCRAFT OF CHINA +1

High-strength titanium alloy and preparation method thereof

The invention provides a high-strength titanium alloy and a preparation method thereof. The high-strength titanium alloy comprises 0.2 to 0.4% of Mo, 0.6 to 0.9% of Ni, (0,50%] of Zr and the balance of Ti. According to the high-strength titanium alloy, by alloying, the element Mo, the element Ni and the element Zr are added into matrix titanium. In the alloy, adding of the Zr element can cause lattice distortion, the defects can cause increase of nucleation points in the nucleation process, and density increase of nucleation takes a grain refining effect so as to realize fine-grain strengthening. An experiment result shows that the high-strength titanium alloy provided by the invention has yield strength of 621 to 816MPa and tensile strength of 712 to 920MPa, and keeps a considerable levelof elongation percentage.

Owner:YANSHAN UNIV

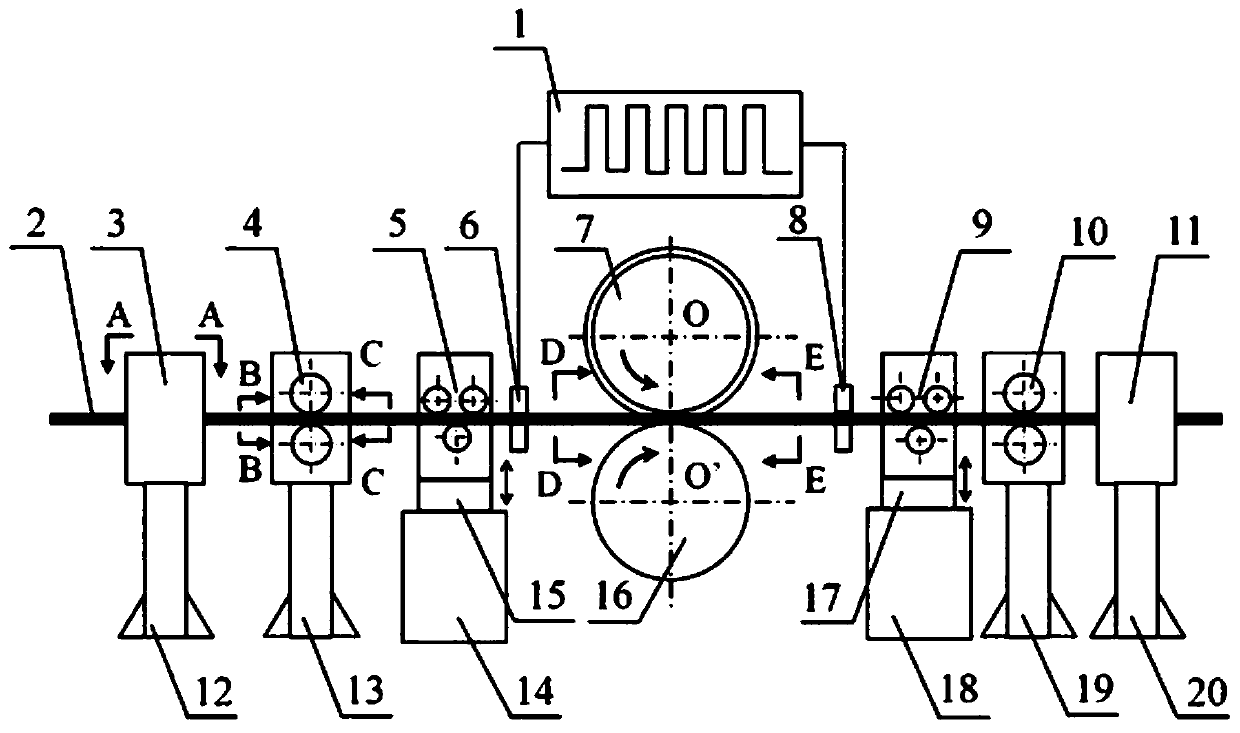

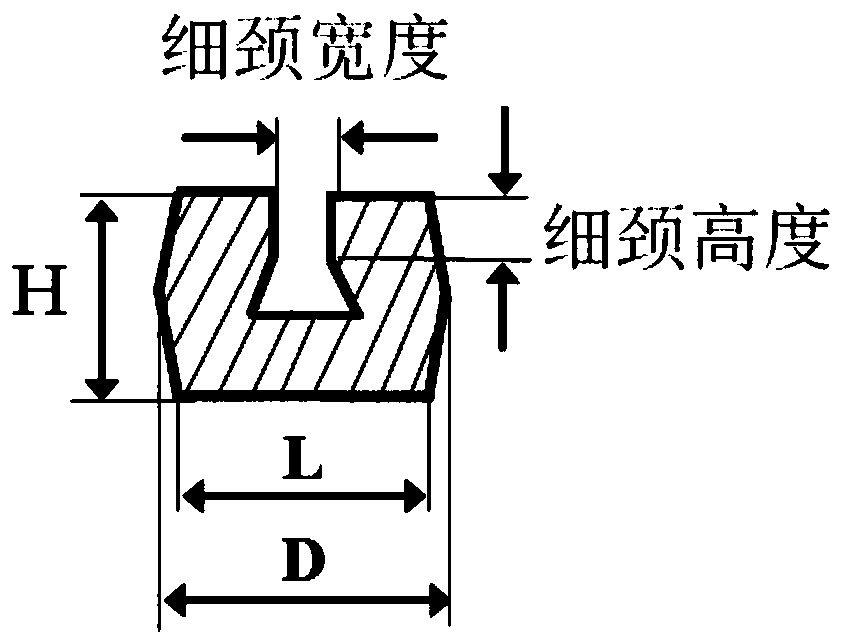

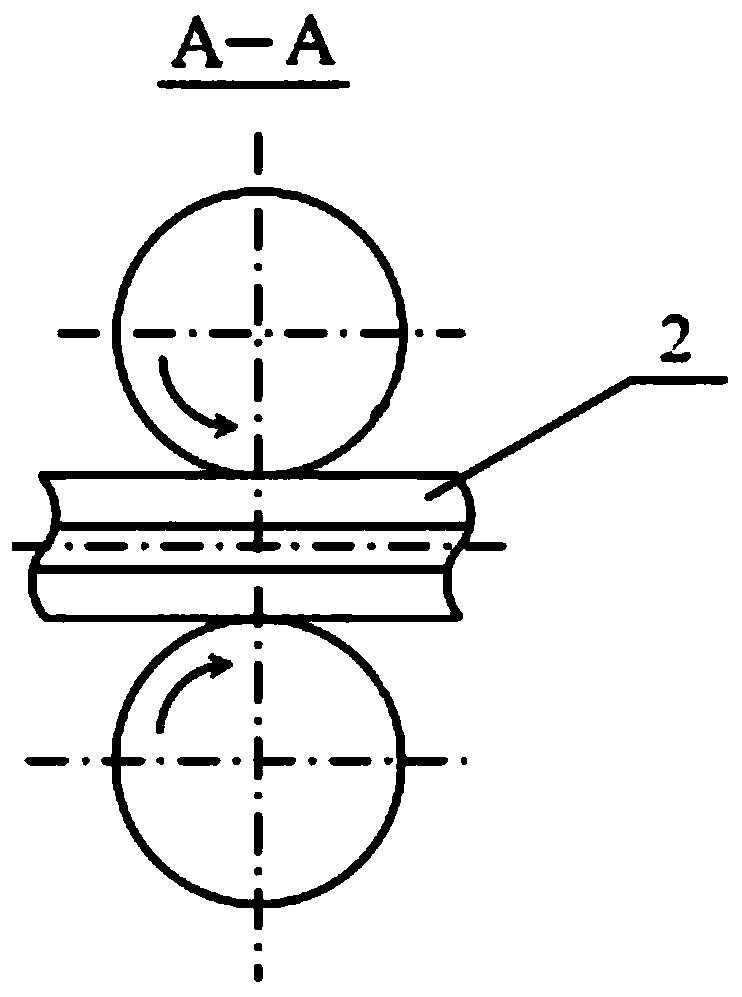

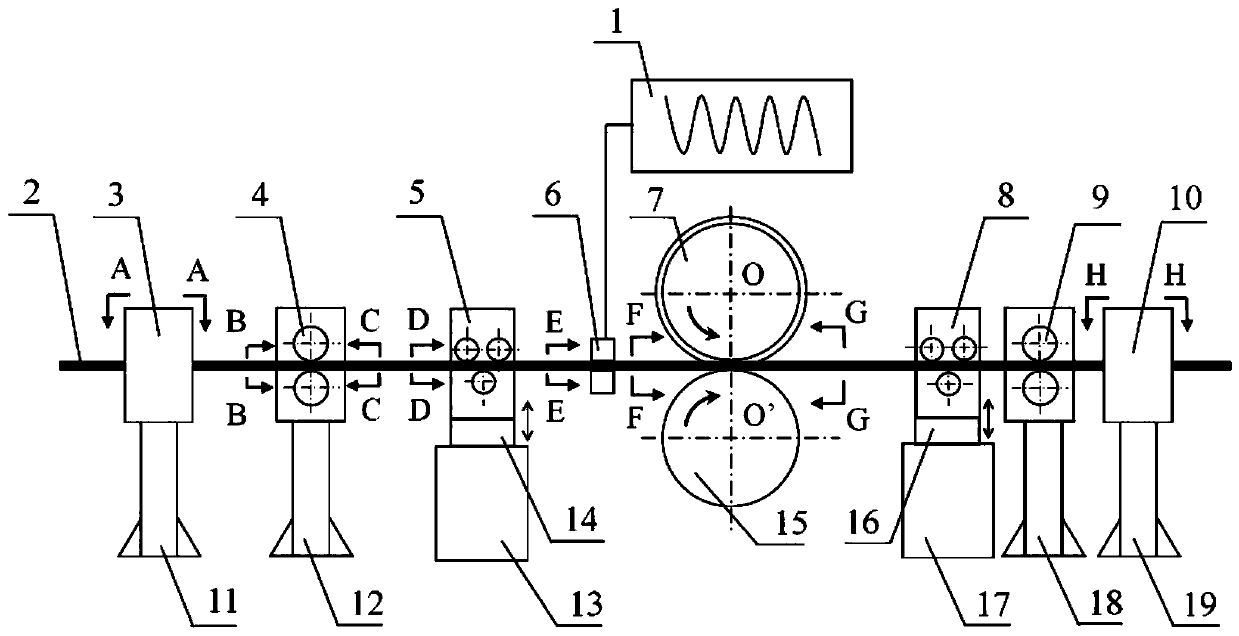

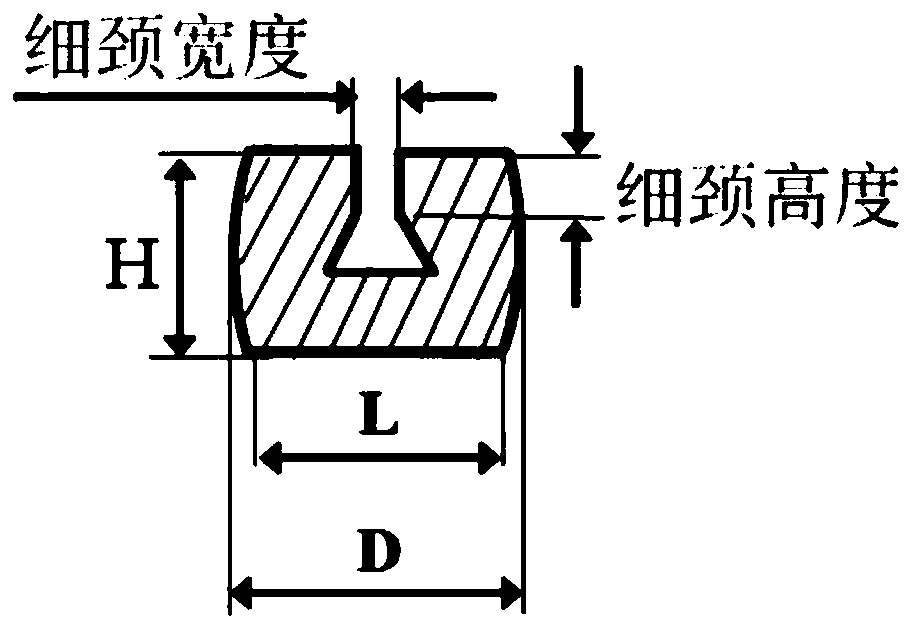

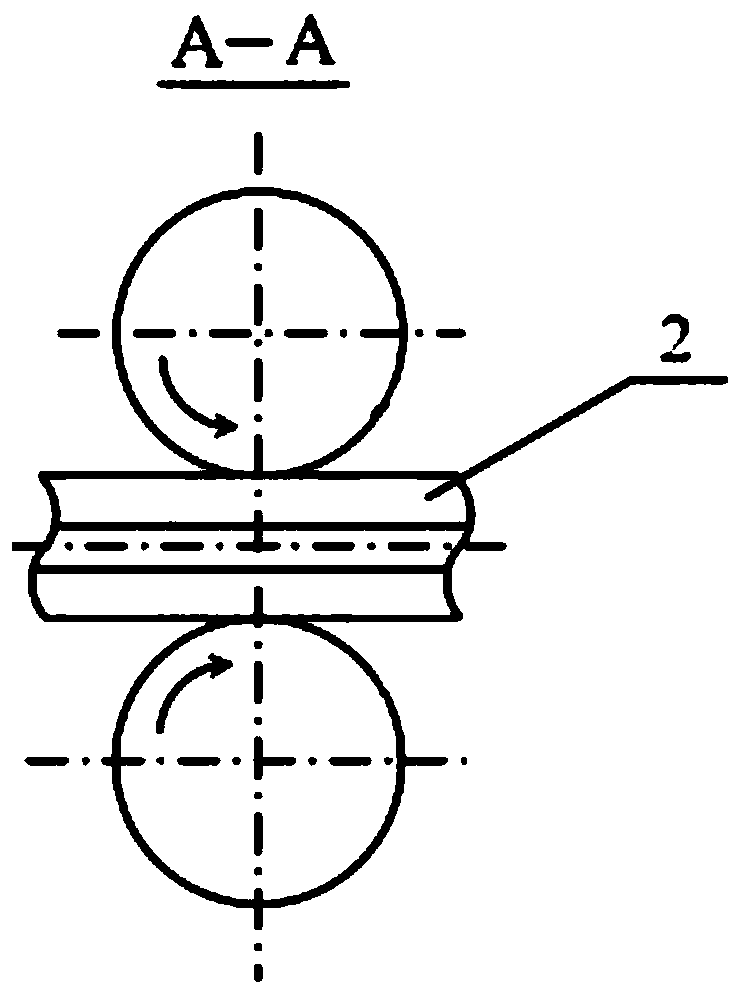

Ultrasonic and pulse current mixing auxiliary wedge-shaped cavity profile rolling line and rolling process

PendingCN111136104AAchieving Restorative HealingReduce deformation resistanceGuiding/positioning/aligning arrangementsRollsUltrasonic vibrationBrush

The invention relates to the technical field of groove profile rolling, in particular to an ultrasonic and pulse current mixing auxiliary wedge-shaped cavity profile rolling line and a rolling process. The ultrasonic and pulse current mixing auxiliary wedge-shaped cavity profile rolling line is characterized in that a left horizontal alignment roller, a pre-rolling roller, a left ultrasonic vibration roller, a left electric brush, a roller set, a right electric brush, a right ultrasonic vibration roller, a right height alignment roller and a right horizontal alignment carrier roller are sequentially arranged along the rolling line, the left horizontal alignment roller and a right horizontal alignment roller are composed of a left roller and a right roller which are horizontally arranged, the pre-rolling roller and the right height alignment roller are composed of an upper roller and a lower roller which are vertically arranged, the left ultrasonic vibration roller and a right ultrasonic vibration roller are composed of an upper roller and a lower roller which are vertically arranged, and the roller set is composed of an upper roller and a lower roller which are vertical arranged; the ultrasonic vibration module is connected with the left ultrasonic vibration roller and the right ultrasonic vibration roller, and drives the left ultrasonic vibration roller and the right ultrasonic vibration roller to vibrate ultrasonically; and the left electric brush and the right electric brush are connected with a pulse current source. The rolling difficulty of a wedge-shaped cavity profile is reduced, the rolling efficiency is improved, and the size precision and the surface finish of the wedge-shaped cavity profile are improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Tough corrosion-resistant titanium alloy and method for preparing same

The invention provides tough corrosion-resistant titanium alloy and a method for preparing the same. The tough corrosion-resistant titanium alloy comprises, by weight, 5.56-6.75% of Al, 0.08-0.14% ofRu, 3.5-4.5% of V, higher than 0% and lower than or equal to 50% of Zr and the balance Ti. The tough corrosion-resistant titanium alloy and the method have the advantages that the strength and the corrosion resistance of the tough corrosion-resistant titanium alloy can be improved by means of alloying, infinite solid solution can be formed by the Zr and the Ti, and accordingly solid solution can be strengthened; the Zr is negative in initiating passive potential as compared with the Ti, and still can be passivated even in environments under weak oxidization conditions, accordingly, the capacity of generating dense oxidation films on surfaces can be improved, and the corrosion resistance of the surfaces can be enhanced; the stability of alpha phase can be greatly improved by the element Al,the beta-alpha transition temperatures can be greatly increased by the element Al, tiny alpha phase can be obtained after the tough corrosion-resistant titanium alloy is quenched, and fine grains canbe strengthened; the trace element Ru is added into the tough corrosion-resistant titanium alloy, and accordingly the corrosion resistance of the tough corrosion-resistant titanium alloy can be improved.

Owner:YANSHAN UNIV

A kind of high-toughness weather-resistant hot-rolled H-shaped steel for bridge structures with a yield strength of 460mpa and its production method

ActiveCN108754327BImprove uniformityReduce sensitivityMetal rolling arrangementsTemperature controlChemical composition

The invention discloses a high-toughness weather-proof hot-rolled H-shaped steel for a bridge structure with yield strength of 460 MPa and a production method thereof. The hot-rolled H-shaped steel comprises the following chemical components by weight: C: 0.08-0.11, Si: 0.30-0.45, Mn: 1.30-1.50, P: <=0.020, S: <=0.015, Cr: 0.50-0.65, Ni: 0.30-0.40, Cu: 0.30-0.40, V: 0.075-0.095, Nb: 0.015-0.025, Alt: 0.015-0.030 and the balance Fe and trace residual elements. By means of reasonable composition proportion, press distribution and temperature control rolling, the fine grain strengthening, precipitation strengthening and phase transformation strengthening mechanisms as well as deformation and penetration control are utilized, and direct air cooling is conducted after hot rolling to obtain a complex phase structure of ferrite + bainite + pearlite; the mechanical property can reach the level that ReL is not less than 460MPa, Rm is not less than 570MPa, A is not less than 20%, KV2 is not lessthan 150J under 40oC, and the corrosion rate is not more than 50% compared with that of Q345B.

Owner:MAANSHAN IRON & STEEL CO LTD

Ultrasonic wave and induced current mixed auxiliary wedge-shaped cavity sectional material rolling line and rolling process

PendingCN111136102ASoften fastGood formabilityGuiding/positioning/aligning arrangementsRollsEngineeringUltrasonic vibration

The invention relates to the technical field of wedge-shaped cavity sectional material rolling, in particular to an ultrasonic wave and induced current mixed auxiliary wedge-shaped cavity sectional material rolling line and a rolling process. A left horizontal calibration roller, a pre-rolling roller, a left ultrasonic vibration roller, a heating coil, an upper roller, a lower flat roller, a rightultrasonic vibration roller, a right height calibration roller and a right horizontal calibration carrier roller are sequentially arranged along the rolling line, the left horizontal calibration roller and the right horizontal calibration roller are composed of a left roller and a right roller which are arranged in the horizontal direction, the right height calibration roller is composed of the upper roller and a lower roller which are arranged in the vertical direction, the left ultrasonic vibration roller and the right ultrasonic vibration roller are composed of the upper roller and the lower roller which are arranged in the vertical direction, the upper roller and the lower flat roller are arranged up and down in the vertical direction, an ultrasonic vibration module is connected withthe left ultrasonic vibration roller and the right ultrasonic vibration roller and drives the left ultrasonic vibration roller and the right ultrasonic vibration roller to vibrate ultrasonically, andthe heating coil is connected with an induction current source. According to the ultrasonic wave and induced current mixed auxiliary wedge-shaped cavity sectional material rolling line and the rollingprocess, the processing forming performance is improved, the processing forming difficulty is reduced, the sectional material size precision and smoothness are improved, and the processing energy consumption is reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

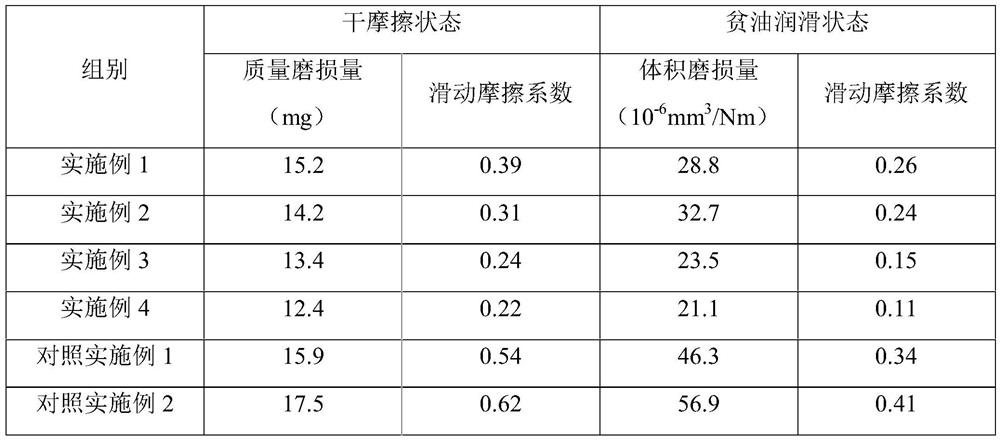

Wear resisting material and preparation method thereof

ActiveCN109868386AImprove wear resistanceImprove surface wear resistanceAnodisationOxide ceramicMicro arc oxidation

The invention discloses a wear resisting material. Aluminum nitride, aluminum oxide, molybdenum disilicide and graphite powder particles are uniformly distributed in an aluminum alloy basal body; a composite micro-arc oxidation layer is distributed on the surface of the aluminum alloy basal body; the aluminum nitride, the aluminum oxide and the molybdenum disilicide are high in hardness to prominently improve the hardness and the wear resistance of the material; and through graphite powder, the antifriction can be improved. Through the composite micro-arc oxidation layer on the surface, the alloy surface wear resistance and corrosion resistance can be effectively improved. Strengthening phases of such elements as Sn, Ru, Sr, Lu, Cu, Mn, Mg, Mo and Fe in an alloy are in dispersion strengthening to improve mechanical performances of the material. In a preparation method, through a mode of attaching mixed powder on a pure aluminum metal wire, the mixed powder is positioned in the center of mother alloy liquid during casting, so that the quick dispersion and the homogenization of micropowder particles are facilitated, and the production efficiency is improved; and micro-arc oxidation film forming parameters and conditions are optimized, so that the hardness and the smoothness degree of oxide ceramic films are improved, the film thickness is reduced, and the wear resistance of the material is effectively improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

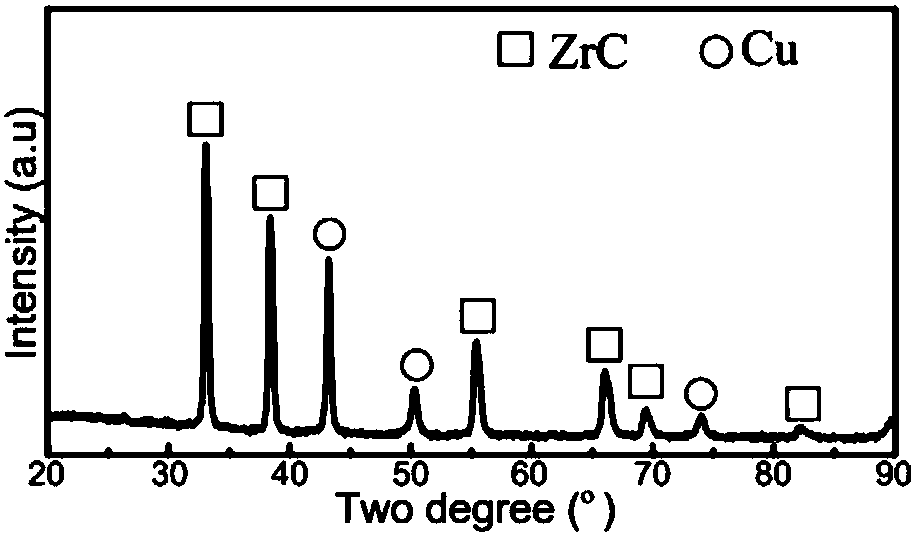

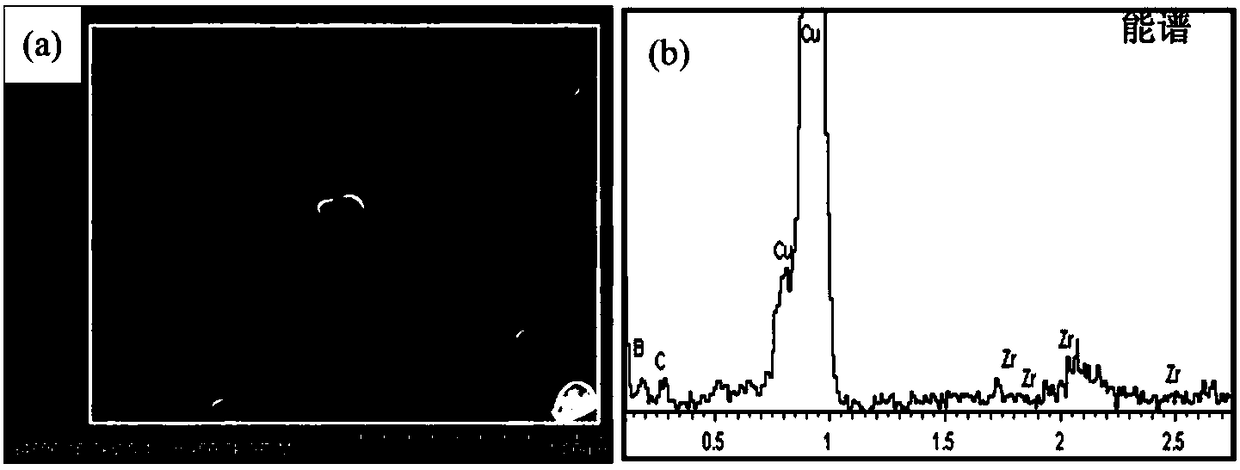

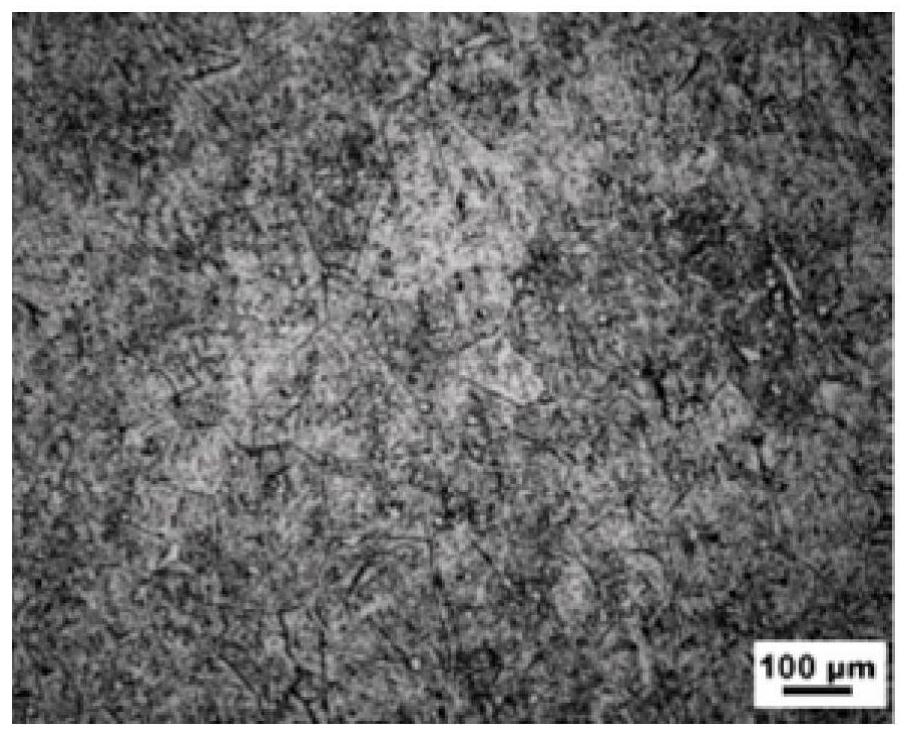

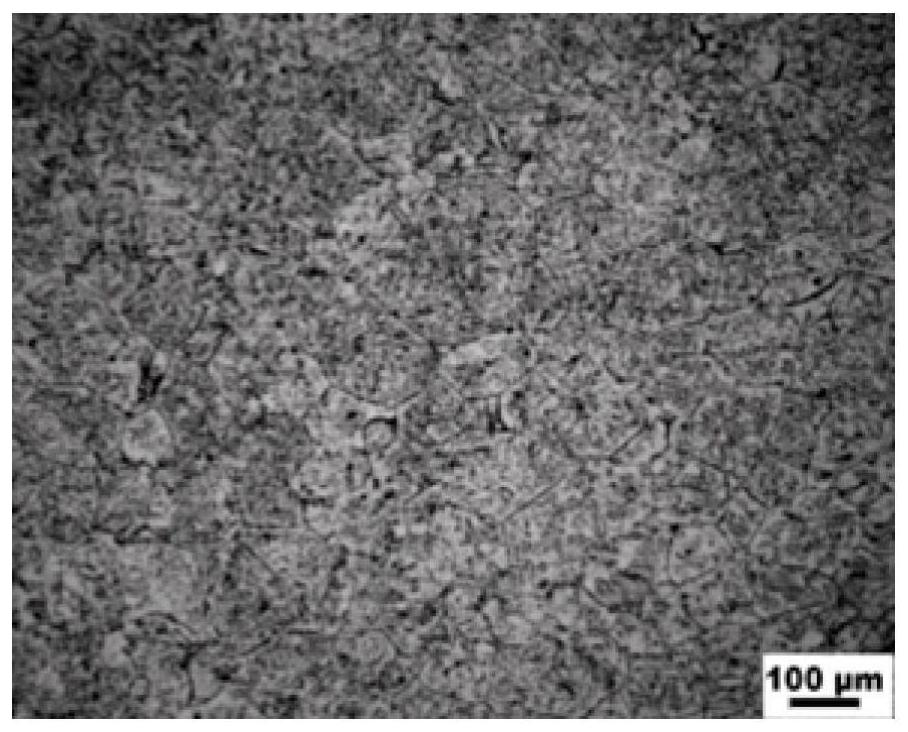

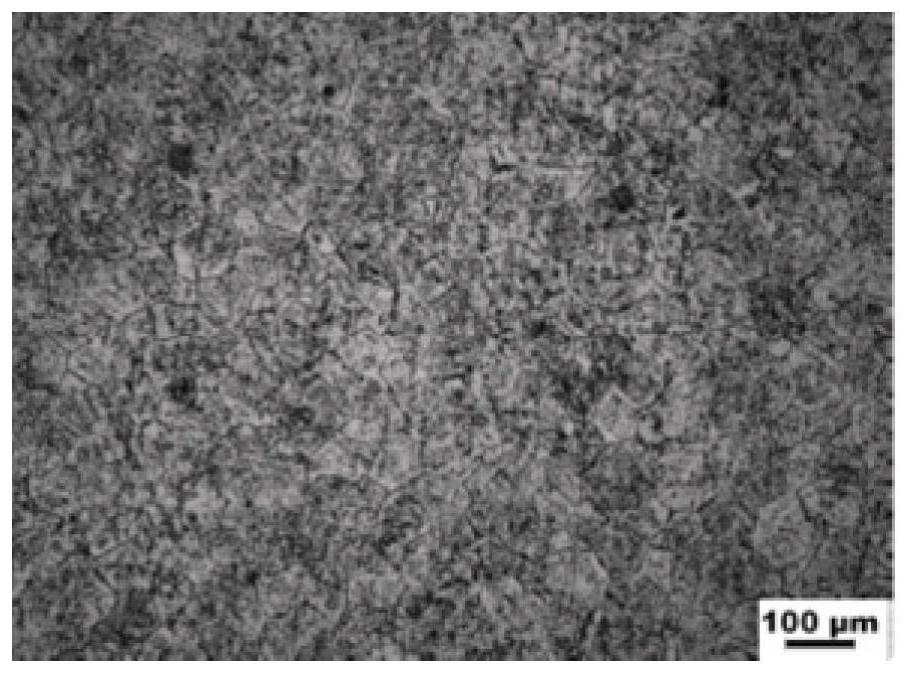

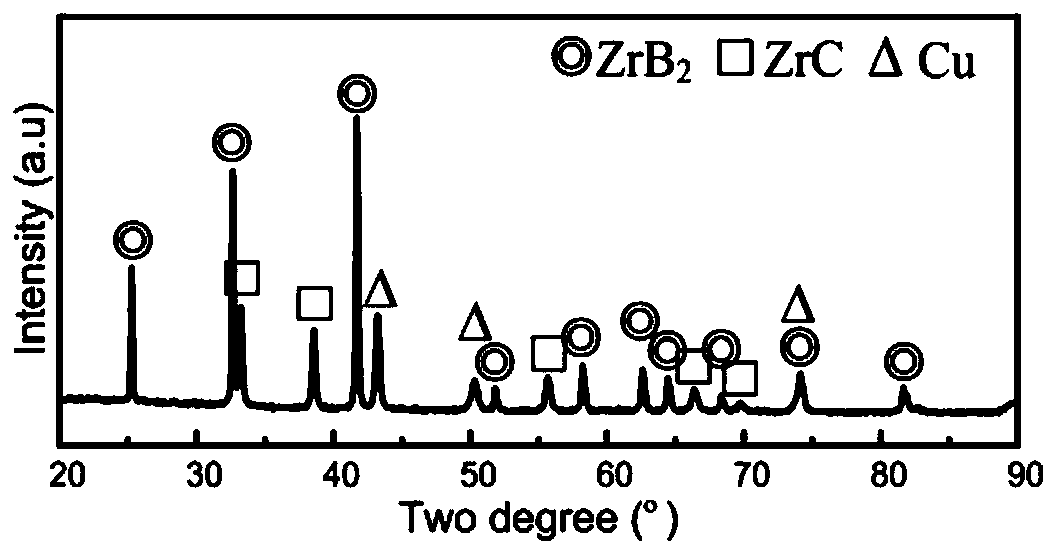

Preparation method of ultra-fine zirconium carbide particle dispersed and strengthened copper-based composite materials for spot-welding electrode

ActiveCN108531767AImprove mechanical propertiesSimple preparation processSelf-propagating high-temperature synthesisUltra fine

The invention belongs to the preparation field of copper-based composite materials for welding electrode, and discloses a preparation method of ultra-fine zirconium carbide particle dispersed and strengthened copper-based composite materials for spot-welding electrode. The preparation method comprises the following steps that cold press molding of uniformly mixed Cu-Zr-C powder is carried out, then powder compact is put into a self-propagating high temperature synthesis device to ignite to obtain ultra-fine ZrC powder body containing Cu, and a mixture of oxygen-free copper and the ultra-fine ZrC powder body containing Cu are smelted in a vacuum melting furnace and magnetic stirring is carried out, so that ultra-fine ZrC particle dispersed and strengthened copper-based composite materials are prepared. The preparation method has the characteristics of being low in cost, simple in techniques, high in production efficiency, tiny in ZrC size, uniform in distribution and the like.

Owner:温岭工联工量刃具科技服务有限公司

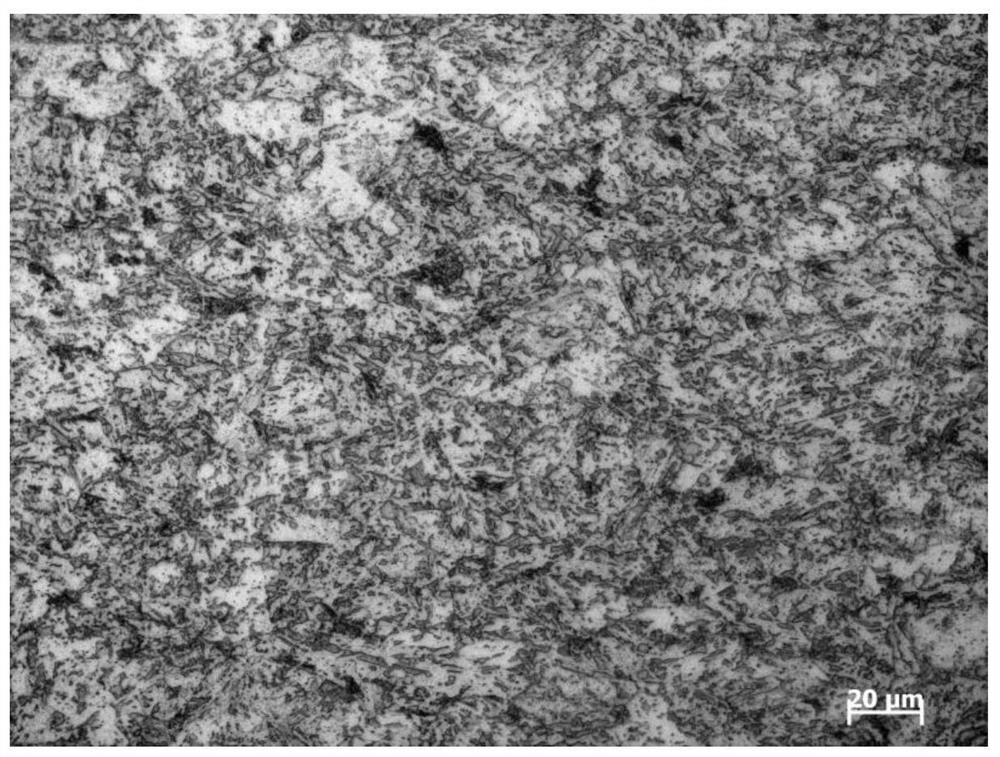

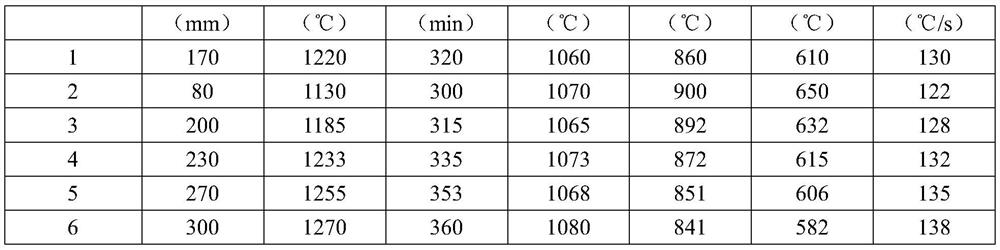

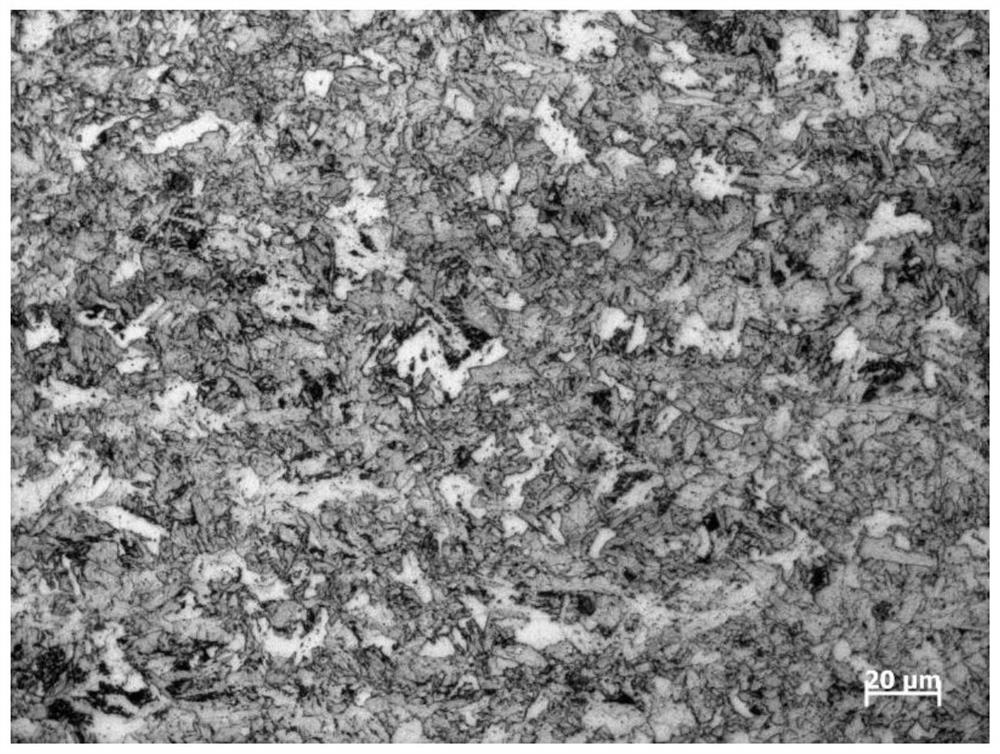

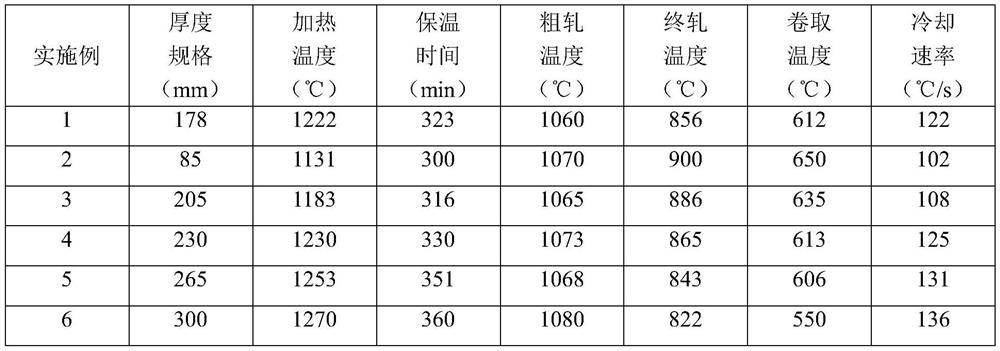

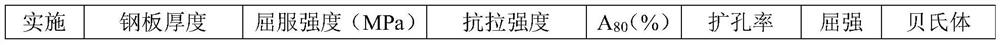

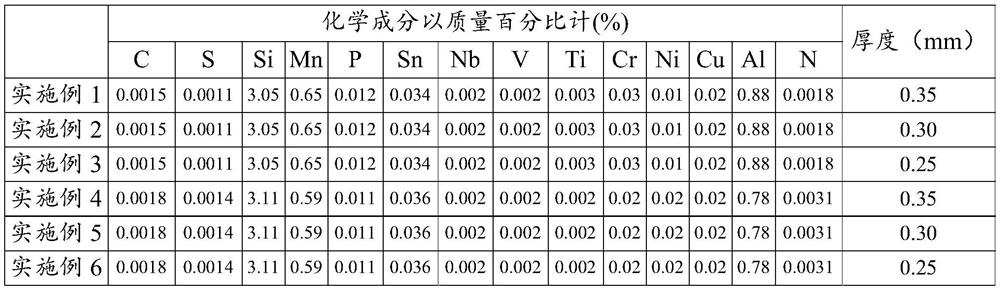

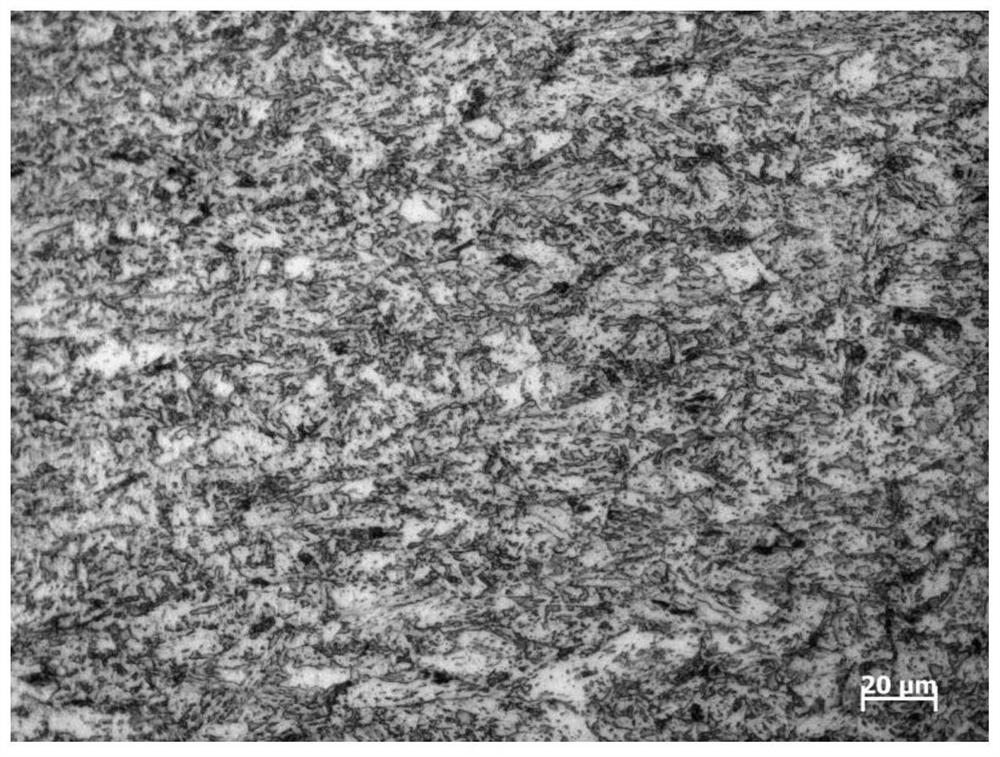

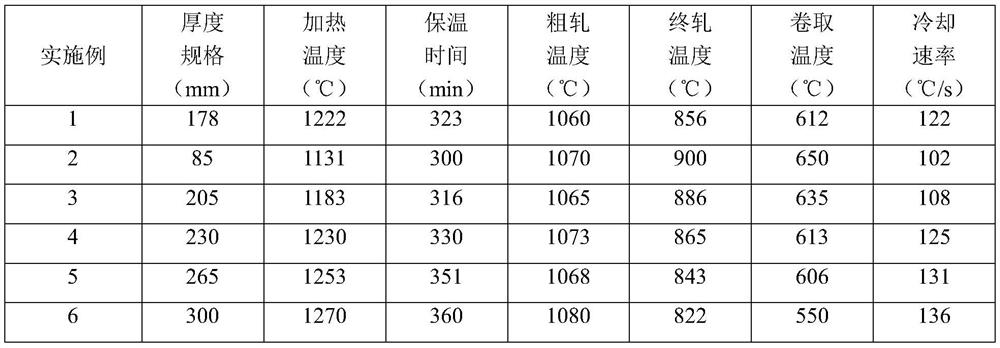

900MPa-grade hot-rolled and pickled complex-phase phase steel with low yield ratio and high hole expansion rate and production method of 900MPa-grade hot-rolled pickling complex phase steel

ActiveCN113549823AFine grain strengtheningWith precipitation strengtheningRare-earth elementSlow cooling

The invention relates to hot-rolled and pickled complex-phase steel, in particular to 900 MPa-grade hot-rolled and pickled complex-phase steel with a low yield ratio and a high hole expansion rate and a production method of the 900 MPa-grade hot-rolled and pickled complex-phase steel. The steel comprises the following chemical components of, in percentage by weight, 0.085%-0.162% of C, 0.08%-0.85% of Si, 1.15%-2.50% of Mn, 0.10%-0.30% of Al, 0.10%-0.75% of Cr, 0.08%-0.65% of Mo, 0.025%-0.070% of Nb, 0.030%-0.155% of Ti, 0.0020%-0.0050% of B, 0.010%-0.060% of rare earth elements La + Ce, P less than or equal to 0.020%, S less than or equal to 0.007% and the balance Fe and inevitable impurities. The method comprises the following steps that (1), a continuous casting slab with the thickness of 80-300mm is put into a heating furnace to be heated to be 1130-1270 DEG C; (2), the initial rolling temperature of rough rolling is not higher than 1080 DEG C, the thickness of an intermediate billet is 25-50 mm, the finish rolling temperature is 840-900 DEG C, the thickness of a finished product is 1.8-5.3 mm, and the total reduction rate is larger than or equal to 85%; (3), after finish rolling, front-section rapid continuous laminar cooling and curling are adopted; (4), after being curled, the steel plate immediately enters a slow cooling cover to be slowly cooled, and a steel coil is taken out and air-cooled to the room temperature; and (5), pickling is carried out . The steel has ultrahigh strength and good formability, and is suitable for manufacturing automobile structural parts, reinforcing parts and safety parts; and the steel has excellent anti-fatigue performance, welding performance and cold forming performance.

Owner:ANGANG STEEL CO LTD

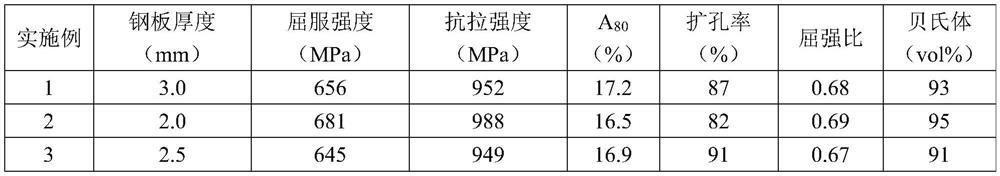

800MPa-grade hot-rolled complex-phase steel and production method thereof

InactiveCN113481436AAchieving fine grain strengtheningRealized with fine grain strengtheningTemperature control deviceWork cooling devicesLaminar coolingHeating furnace

The invention relates to steel for manufacturing automobile structures, in particular to 800MPa-grade hot-rolled complex-phase steel and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.055%-0.112% of C, 0.08%-0.40% of Si, 1.15%-2.02% of Mn, 0.10%-0.30% of Al, 0.10%-0.62% of Cr, 0.0020%-0.0050% of B, 0.015%-0.056% of V and / or 0.030%-0.145% of Ti, less than or equal to 0.020% of P, less than or equal to 0.007% of S and the balance of Fe and inevitable impurities. The method comprises the following steps that (1) a continuous casting sheet billet with the thickness of 80-300 mm is placed in a heating furnace, and the temperature is kept for 5-6 hours; (2) a controlled rolling means is adopted, the rough rolling temperature is not higher than 1080 DEG C, the thickness of an intermediate billet is 25-50 mm, the finish rolling temperature is controlled, the thickness of a finished product is 2.0-5.0 mm, and the total reduction rate is larger than or equal to 80%; (3) after finish rolling, front-section rapid continuous stream cooling is adopted, and coiling is conducted; and (4) after being coiled, a steel plate immediately enters a slow cooling cover to be slowly cooled to 120 DEG C or below, the slow cooling speed is not larger than 15 DEG C / h, and a steel coil is taken out and air-cooled to the room temperature. The steel has high strength and good formability, and is suitable for manufacturing automobile structural parts, reinforcements and safety parts.

Owner:ANGANG STEEL CO LTD

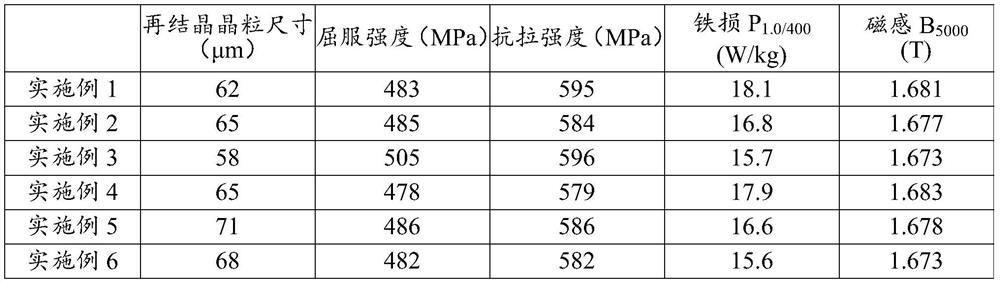

Non-oriented silicon steel for new energy driving motor and production method of non-oriented silicon steel

ActiveCN114196887AImprove magnetismIncrease magnetic inductionTemperature control deviceMetal rolling arrangementsElectric machineNew energy

The invention discloses non-oriented silicon steel for a new energy driving motor and a production method of the non-oriented silicon steel. The silicon steel is prepared through the steps of steelmaking, continuous casting, hot rolling, normalizing, acid pickling, preheating-free single-rack cold rolling, annealing, cooling, coating and finishing in sequence, Cu, Cr, Ni, Nb, V and Ti are not added in the steelmaking process, and the silicon steel comprises the chemical components of 2.95%-3.15% of Si, 0.75%-0.95% of Al, 4.6%-4.9% of Si + 2Al, 0.5%-0.7% of Mn, 0.03%-0.04% of Sn, smaller than or equal to 0.0025% of C and the balance iron; mn / S > = 380, and Al / N > = 200. According to the invention, the strength is improved while the magnetic performance is ensured, the problem of consideration of the magnetic performance and the strength in the prior art is solved, and the application requirement on a driving motor of a new energy automobile can be met.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

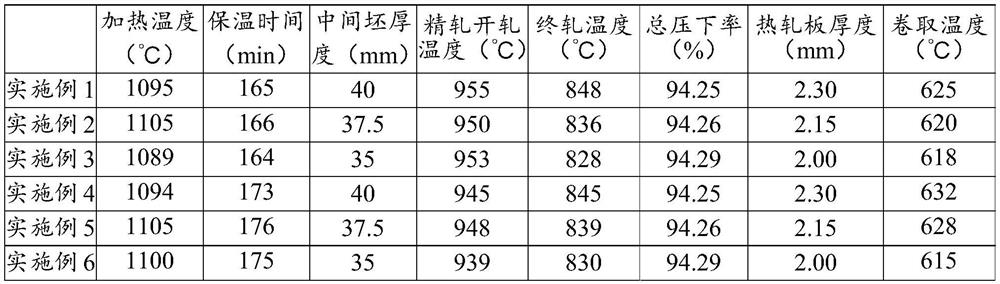

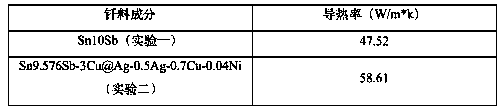

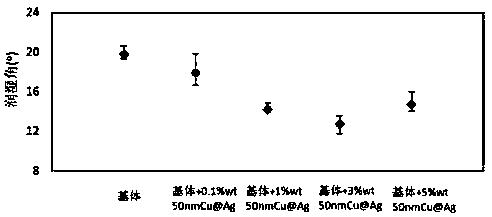

Micro-nano particle added composite soldering paste

InactiveCN109570814AEasy to oxidizeSolve the problem of more pores in welded jointsWelding/cutting media/materialsSoldering mediaMicro nanoMicro nanoparticles

The invention discloses micro-nano particle added composite soldering paste, belongs to the technical field of lead-free composite brazing filler metal, particularly relates to micro-nano wrapping particle added enhanced tin-antimony-series composite soldering paste and a preparing method thereof, and mainly solves the problems that Sn-Sb series brazing filler metal in high-temperature brazing filler metal at present is poor in wettability, thermal conductivity and mechanical performance, and application and popularization of the Sn-Sb series brazing filler metal are limited. The novel composite soldering paste is mainly characterized in that compared with SnSb series soldering paste, wettability is good, and mechanical performance is excellent. The brazing filler metal is composed of 1%-5% of Cu@Ag core-shell particles and 95%-99% of SnSb, the Sn-Sb soldering paste serves as a base body, and reinforced phase Cu@Ag particles are added for achieving. The method comprises the steps thatfirstly, the Cu@Ag core-shell particles are prepared; secondly, scaling powder is prepared; and thirdly, the composite soldering paste is prepared through the Cu@Ag core-shell particles and the Sn-Sbseries soldering paste in a mechanical mixing manner. According to the composite soldering paste, the microstructure of welding spots is refined, and the wettability and shearing strength of the brazing filler metal are greatly improved. The micro-nano particle added composite soldering paste is used for preparing Sn-Sb series composite brazing filler metal which is composite brazing filler metalconforming to the development tendency of the electronic industry.

Owner:HARBIN UNIV OF SCI & TECH

Forming technological method for high-ferrum bearing ring with metal flow lines distributed along roller path

The invention relates to a forming technological method for a high-ferrum bearing ring with metal flow lines distributed along a roller path. The method includes the following steps that S1, heading, blind hole punching and the like are used for hot forging so that a high-ferrum conical bearing ring blank can be manufactured, and then common hot rolling is conducted on a precision hot rolling mill to preset a near-shape conical high-ferrum conical bearing inner ring forged piece and an outer ring forged piece; S2, a roller mold is replaced on the precision hot rolling mill to perform precision near-shape hot rolling, a high-ferrum conical bearing ring roller path molded surface is formed, and accordingly an annular forged piece with the metal flow lines distributed along the roller path can be formed; S3, deformation heat treatment is immediately conducted on the precision hot rolling-formed high-ferrum bearing ring with the metal flow lines distributed along the roller path; and S4, the high-ferrum bearing ring subjected to hot rolling forming and deformation heat treatment is ground, ultra-precision subsequent machining is also performed, and accordingly the high-ferrum bearing ring piece with the required geometric accuracy can be obtained. By the adoption of the method, the high-ferrum bearing ring roller path can be formed directly, so that the metal flow lines are distributed along the roller path, and the phenomena that the material utilization rate is reduced due to high working allowance cutting and the metal flow lines are cut off through cutting machining are avoided.

Owner:WUHAN UNIV OF TECH

Near-alpha-phase high-strength-and-toughness titanium alloy and preparation method thereof

InactiveCN108913943APlay the effect of grain boundary strengtheningAchieving fine grain strengtheningNucleationTitanium alloy

The invention provides a near-alpha-phase high-strength-and-toughness titanium alloy and a preparation method of the near-alpha-phase high-strength-and-toughness titanium alloy. The near-alpha-phase high-strength-and-toughness titanium alloy comprises 2.5-3.5% of Al, 2.0-3.0% of V, 0.001-0.08% of Pd, no more than 50% of Zr and the balance of Ti. The addition of Zr can lead to lattice distortion. As results of the defects, in the nucleation process, the number of nucleating points increases, the nucleation density increases as well, grain refining can be conducted, and therefore fine-grain strengthening is achieved. Experimental results show that the yield strength and tensile strength of the near-alpha-phase high-strength-and-toughness titanium alloy increase by 34% and 35.9% respectively,and the rate of elongation remains appropriate.

Owner:YANSHAN UNIV

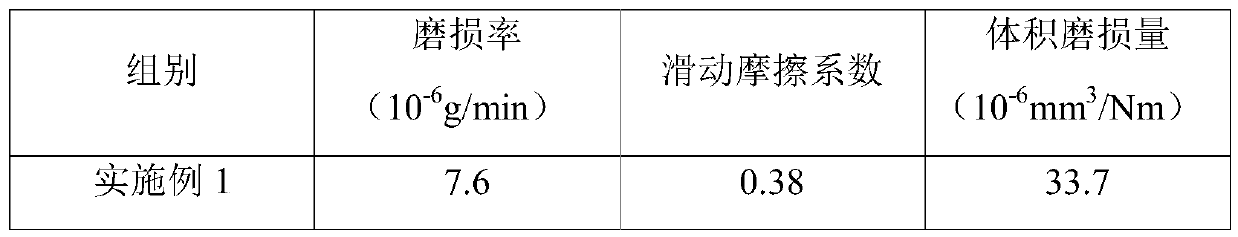

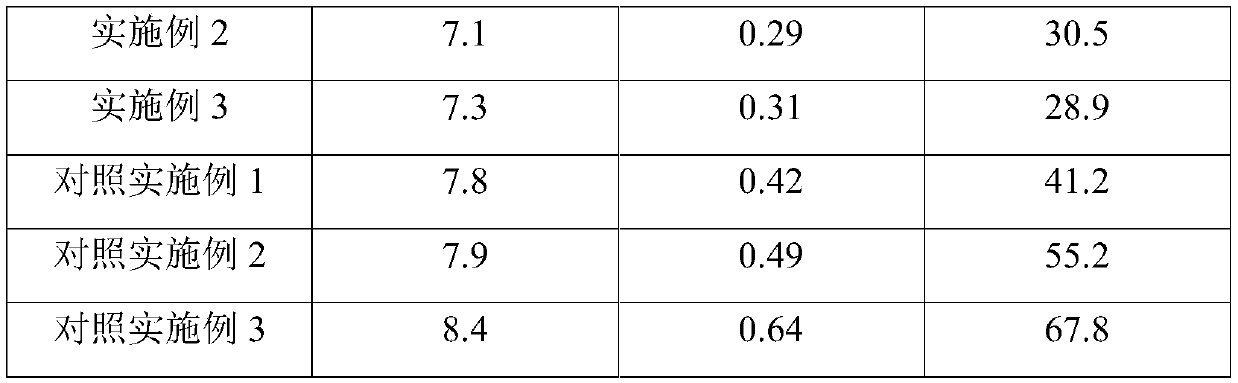

Low-wear-rate material and preparation method thereof

InactiveCN109852851AReduce the phenomenon of agglomeration and segregationPromote growthLiquid/solution decomposition chemical coatingChemical vapor deposition coatingChemical platingNiobium

The invention discloses a low-wear-rate material. Titanium nitride, titanium oxide, nickel oxide and niobium diselenide mixture particles are evenly distributed in an aluminum alloy substrate, a nickel-cobalt clad layer and a diamond coating are distributed on the surface of the aluminum alloy substrate, the hardness of titanium nitride and nickel oxide is high, the hardness and the low-wear-rateperformance of the material are remarkably improved, and the anti-wear performance can be improved due to titanium oxide and niobium diselenide. By means of the composite coatings on the surface, thewear rate of the alloy surface can be effectively reduced, and the hardness can be effectively improved. Strengthening phases of Dy, P, Bi, Sn, Nb, Cr, Fe, Zn, Pt, Th and other elements in alloy are in dispersion strengthening. In a preparation method, mixed powder adheres to aluminum-selenium metal wires, the mixed powder is located in the center of mother alloy liquid during casting, rapid diffusion and homogenization of micro-powder particles are facilitated, chemical plating and CVD film forming parameters and conditions are optimized, the hardness and the smooth degree of the coatings areimproved, the film thickness is reduced, and the low-wear-rate performance of the material is effectively improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

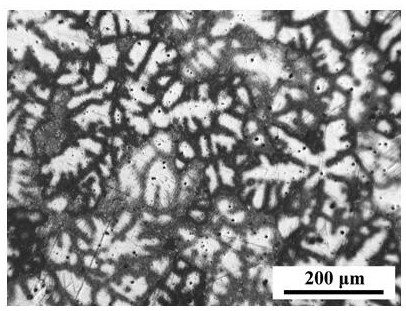

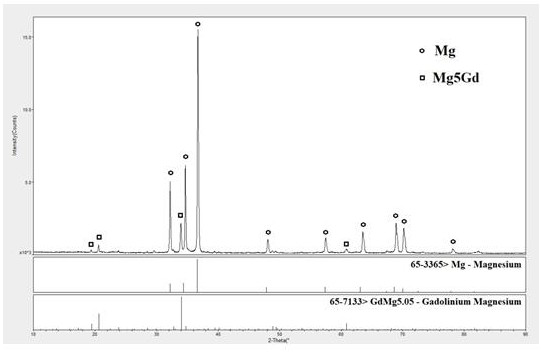

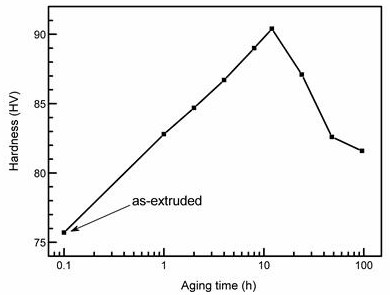

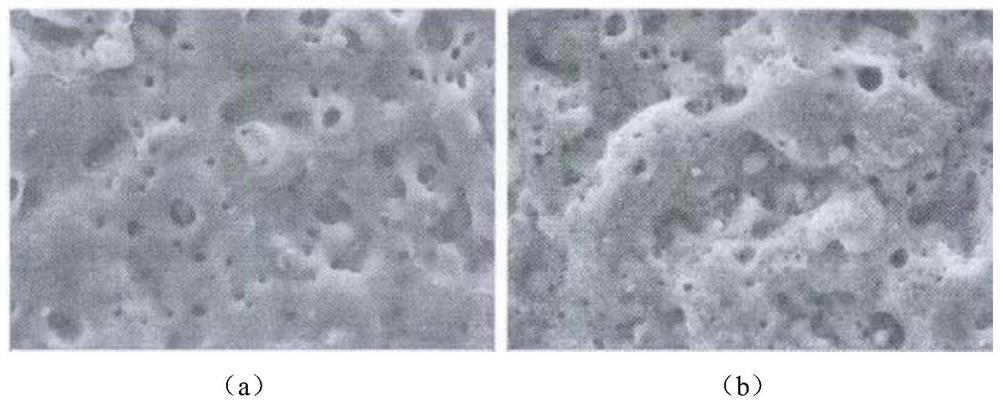

Mg-Gd alloy with low Gd content and preparation and heat treatment method thereof

ActiveCN113403515ALow densityReduce contentNuclear energy generationFurnace typesChemical compositionCrucible

The invention discloses a low-Gd-content Mg-Gd alloy and a preparation and heat treatment method thereof. The Mg-Gd alloy with the low Gd content is prepared from the following chemical components in percentage by mass: 2-5% of Gd, 2-5% of Li, 1-3% of Y, 1-2% of Nd, 0.2-0.6% of Zr and the balance of magnesium and inevitable impurities. The preparation method comprises the following steps of S1, preparing materials according to the proportion of the Mg-Gd alloy with the low Gd content; and S2, under the protection of SF6+CO2 gas, melting the alloy material in a resistance furnace and then refining for 2-4 minutes, then standing for 25-30 minutes in the resistance furnace and then casting into a metal mold to obtain a casting. The heat treatment method comprises the steps that the casting is put into a crucible, the crucible is put into a muffle furnace, the temperature is increased to 480-500 DEG C, then heat preservation treatment is conducted, and the heat preservation time is 2-4 hours; and after heat preservation is completed, the crucible is taken out and immediately quenched in water, and heat treatment is completed. The Li in the solid solution state is used for promoting the formation of an MgGd phase under the condition of low alloy content, and the content of Gd in the Mg-Gd alloy is reduced.

Owner:CHONGQING UNIV OF ARTS & SCI

A kind of wear-resistant material and preparation method thereof

The invention discloses a wear-resistant material, in which aluminum nitride, aluminum oxide, molybdenum disilicide, and graphite powder particles are evenly distributed in an aluminum alloy matrix, and a composite micro-arc oxidation layer is distributed on the surface of the aluminum alloy matrix, aluminum nitride, oxide Aluminum and molybdenum disilicide have high hardness, which can significantly improve the hardness and wear resistance of the material, and graphite powder can improve friction reduction. The composite micro-arc oxidation layer on the surface can effectively improve the wear resistance and corrosion resistance of the alloy surface. Sn, Ru, Sr, Lu, Cu, Mn, Mg, Mo, Fe and other elements in the alloy strengthen phase dispersion strengthening to improve the mechanical properties of the material. In the preparation method, the mixed powder is adhered to the pure aluminum wire, so that the mixed powder is located in the center of the master alloy liquid during casting, which is conducive to the rapid diffusion and homogeneity of the micro-powder particles, improves production efficiency, and optimizes the parameters of micro-arc oxidation film formation And conditions, improve the hardness and smoothness of the oxide ceramic film, reduce the film thickness, and effectively improve the wear resistance of the material.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

900MPa-grade hot-rolled complex-phase steel and production method thereof

ActiveCN113481435AFine grain strengtheningGrain refinementTemperature control deviceWork cooling devicesLaminar coolingHeating furnace

The invention relates to the technical field of hot-rolled complex-phase steel, in particular to 900MPa-grade hot-rolled complex-phase steel and a production method thereof. The 900MPa-grade hot-rolled complex-phase steel comprises the following components in percentage by weight: 0.070%-0.158% of C, 0.08%-0.85% of Si, 1.15%-2.50% of Mn, 0.10%-0.30% of Al, 0.10%-0.75% of Cr, 0.08%-0.65% of Mo, 0.0020%-0.0050% of B, 0.025%-0.070% of Nb and / or 0.030%-0.155% of V, less than or equal to 0.020% of P, less than or equal to 0.007% of S and the balance Fe and inevitable impurities. The production method comprises the following steps that (1) a continuous casting sheet billet with the thickness of 80-300mm is heated in a heating furnace, and the temperature is kept for 5-6 hours; (2) the initial rolling temperature of rough rolling is not higher than 1080 DEG C, the thickness of an intermediate billet is 25-50 mm, the finish rolling temperature is controlled, the thickness of a finished product is 2.0-5.0 mm, and the total reduction rate is larger than or equal to 80%; (3) after finish rolling, front-section rapid continuous laminar cooling is adopted, and coiling is conducted; and (4) after being coiled, the steel plate immediately enters a slow cooling cover to be slowly cooled to 140 DEG C or below, the slow cooling speed is not larger than 13 DEG C / h, and a steel coil is taken out and air-cooled to the room temperature. The 900MPa-grade hot-rolled complex-phase steel has ultrahigh strength and good formability, is suitable for manufacturing automobile components such as structural pieces, reinforcement pieces and safety pieces, and is particularly suitable for manufacturing bumpers and B pillar reinforcement pieces.

Owner:ANGANG STEEL CO LTD

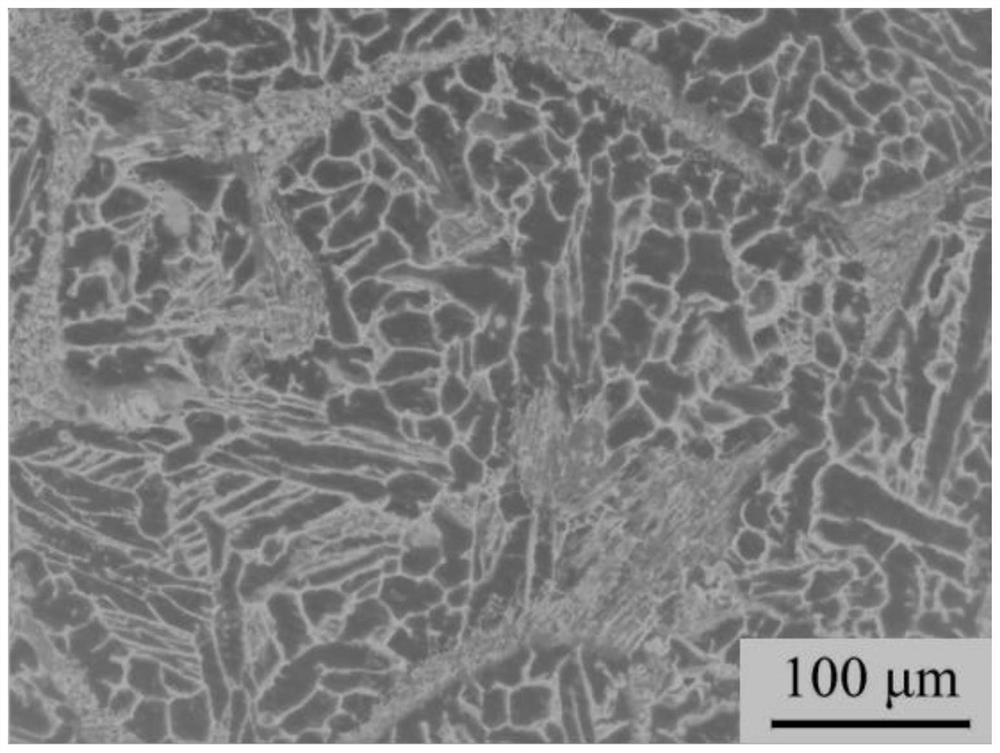

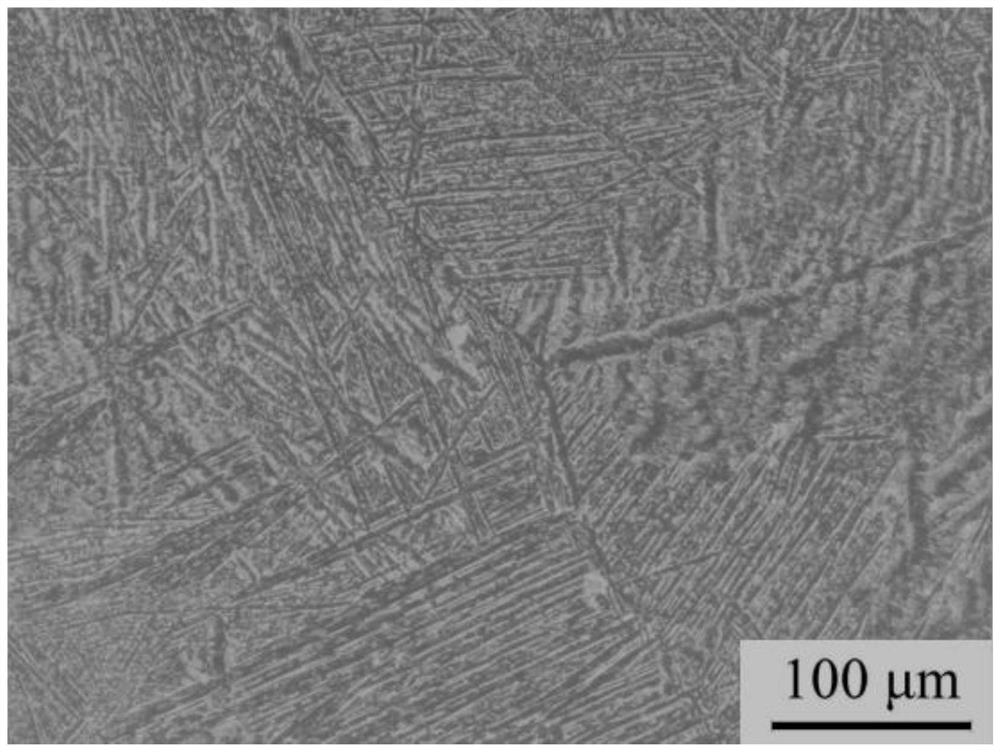

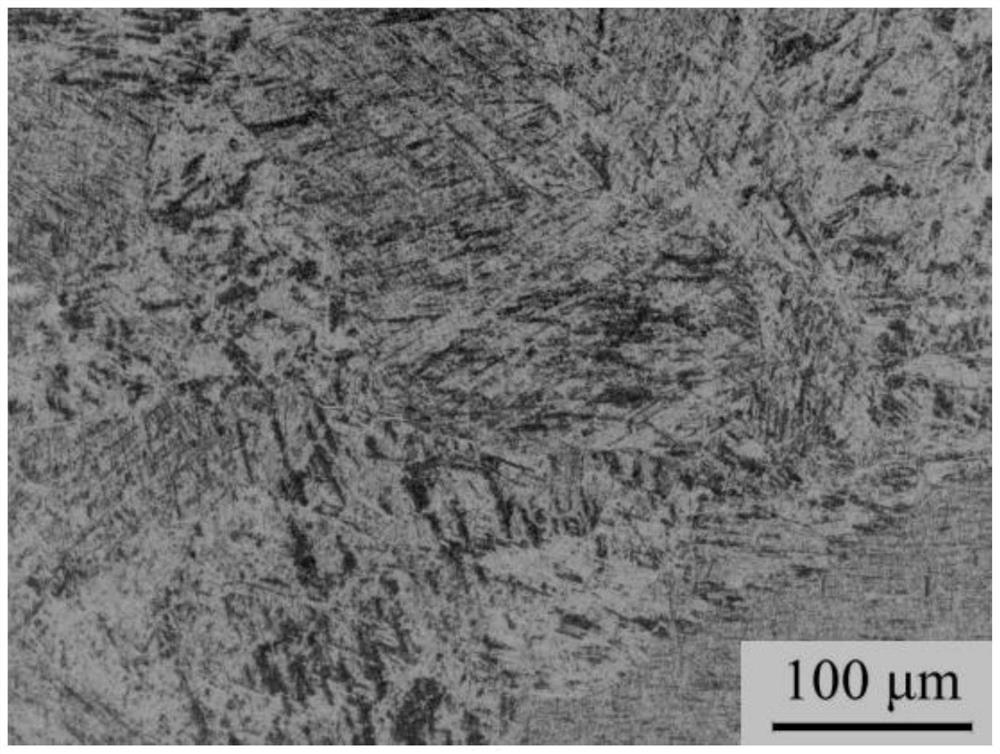

One-step synthesis method of ultrafine zirconium carbide-zirconium boride ceramic composite strengthened copper electrode material

The invention belongs to the field of preparation of copper-based composite materials for welding electrodes, and discloses a one-step synthesis method of an ultrafine zirconium carbide-zirconium boride ceramic composite strengthened copper electrode material, wherein the method comprises the steps: carrying out cold pressing of a uniformly mixed Cu powder, Zr powder and B4C powder into a prefabricated block, and then putting the Cu-Zr-B4C powder press blank and oxygen-free copper into a vacuum induction smelting furnace, pre-heating to promote a thermal detonation synthesis reaction of the press blank, then heating up to make oxygen-free copper molten, wrapping a reaction product, carrying out heat preservation, and stirring to prepare the zirconium carbide-zirconium boride ceramic reinforced copper-based composite material. The ultrafine zirconium carbide-zirconium boride ceramic composite strengthened copper electrode material is synthesized in one step, the production cost is reduced, the working procedures are simplified and the production efficiency is improved. At the same time, the ZrC-ZrB2 ceramic has small size, and uniform distribution is achieved in copper.

Owner:TAIZHOU UNIV +1

Aluminum alloy, preparation method thereof and die casting

The invention relates to an aluminum alloy which comprises the following components including 0.9%-1.4% of iron, 0.5%-0.9% of magnesium, 0.2%-0.5% of manganese, 0.15%-0.3% of silver, 0.2%-0.3% of scandium, 0.3%-0.5% of yttrium and the balance aluminum. The invention further relates to a preparation method of the aluminum alloy. The invention also relates to a die casting which is made of the aluminum alloy.

Owner:惠州市田宇中南铝合金新材料科技有限公司

High-strength titanium alloy and preparation method thereof

The invention provides a high-strength titanium alloy and a preparation method thereof. The high-strength titanium alloy is a Ti-Al-V-M high-strength titanium alloy and is composed of the following raw materials of, in percentage by mass, 5%-6% of Al, 1.0%-2.0% of V, 1%-1.5% of Mo, 0.5%-1.0% of Ni, 0.5%-1.0% of Sn, 0.5%-1.0% of Zr and the balance Ti. Experimental results show that compared with a contrast alloy obtained through the same treatment process, the yield strength of the alloy is improved by 9%-22.43%, and the tensile strength of the alloy is improved by 8.62%-34.71%.

Owner:YUNNAN TITANIUM IND

A kind of superfine zirconium carbide particles-zirconium boride rod crystal reinforced copper-based electrode material and its preparation method

The invention belongs to the field of preparation of copper-based composite materials for welding electrodes, and discloses an ultrafine zirconium carbide particle-zirconium boride rod crystal reinforced copper-based electrode material and a preparation method thereof: uniformly mixed Cu-Zr-B 4 C mixed powder was put into a high-temperature tubular atmosphere furnace and heated to 1250 °C to obtain Cu-containing ultrafine ZrC particles and ZrB 2 Rod crystal composite powder, followed by smelting oxygen-free copper and Cu-containing ultrafine ZrC‑ZrB in a vacuum melting furnace 2 Mixture of composite powders and applying magnetic stirring to prepare ultrafine ZrC particles‑ZrB 2 Rod grain reinforced copper-based electrode material. The method of the invention has the characteristics of low cost, simple process, high production efficiency, small reinforcement body, uniform distribution and the like.

Owner:JIUJIANG UNIV +1

A kind of tough and corrosion-resistant titanium alloy and preparation method thereof

ActiveCN108893632BImprove corrosion resistanceImprove stabilityTitanium alloyUltimate tensile strength

The invention provides tough corrosion-resistant titanium alloy and a method for preparing the same. The tough corrosion-resistant titanium alloy comprises, by weight, 5.56-6.75% of Al, 0.08-0.14% ofRu, 3.5-4.5% of V, higher than 0% and lower than or equal to 50% of Zr and the balance Ti. The tough corrosion-resistant titanium alloy and the method have the advantages that the strength and the corrosion resistance of the tough corrosion-resistant titanium alloy can be improved by means of alloying, infinite solid solution can be formed by the Zr and the Ti, and accordingly solid solution can be strengthened; the Zr is negative in initiating passive potential as compared with the Ti, and still can be passivated even in environments under weak oxidization conditions, accordingly, the capacity of generating dense oxidation films on surfaces can be improved, and the corrosion resistance of the surfaces can be enhanced; the stability of alpha phase can be greatly improved by the element Al,the beta-alpha transition temperatures can be greatly increased by the element Al, tiny alpha phase can be obtained after the tough corrosion-resistant titanium alloy is quenched, and fine grains canbe strengthened; the trace element Ru is added into the tough corrosion-resistant titanium alloy, and accordingly the corrosion resistance of the tough corrosion-resistant titanium alloy can be improved.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com