Non-oriented silicon steel for new energy driving motor and production method of non-oriented silicon steel

A technology of oriented silicon steel and driving motor, which is applied in metal rolling, temperature control, etc., can solve the problem of deteriorating the magnetic properties of non-oriented silicon steel, achieve the effects of reducing the thickness of iron oxide scale, low cost, and avoiding cracks and fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

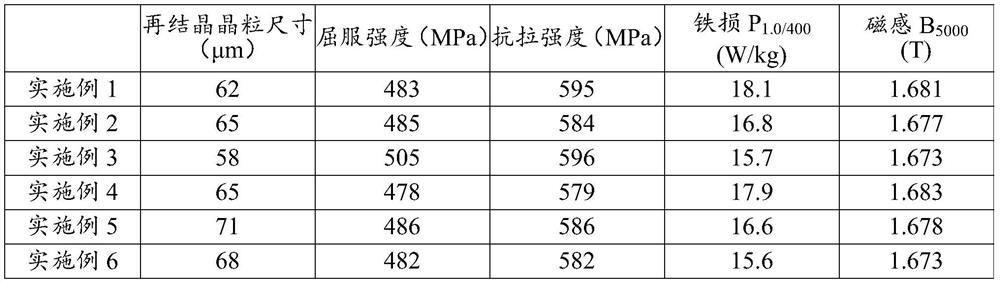

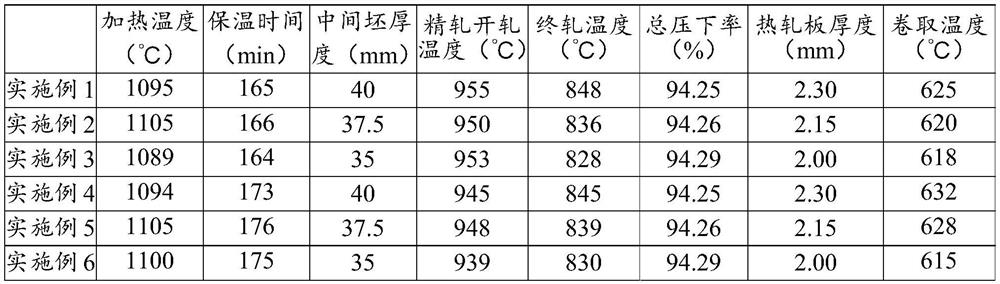

[0024] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

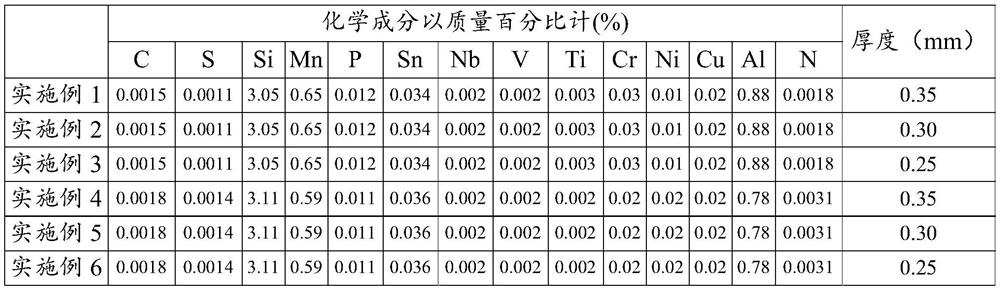

[0025] In the present invention, there is provided an outless silicon steel. The chemical ingredient of the no-to-rejection silicon steel comprises: Si: 2.95% ~ 3.15%, Al: 0.75% ~ 0.95%, Si + 2Al: 4.6% ~ 4.9%, Mn: 0.5% ~ 0.7%, SN: 0.03 % ~ 0.04%, CU ≤ 0.03%, CR ≤ 0.03%, Ni ≤ 0.03%, Cr + Ni + Cu ≤ 0.07%, NB ≤ 0.004%, V ≤ 0.004%, Ti ≤ 0.004%, NB + V + Ti ≤ 0.008%, C ≤ 0.0025%, P ≤ 0.015%, s ≤ 0.0015%, N ≤ 0.004%, C + S + N ≤ 0.007%, the rest is Fe and inevitable inclusion; and, Mn / s ≥ 380, Al / N≥200.

[0026] Among them, the role and effects of each element in the chemical composition are described below.

[0027] C, S, N, Cu, CR, Ni, Nb, V, Ti, and P: The increase in the content of these elements can result in a decrease in magnetic properties of no toilet silicon steel, including the increase in iron loss, and the magnetic induction strength is red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com