One-step synthesis method of ultrafine zirconium carbide-zirconium boride ceramic composite strengthened copper electrode material

A technology of ceramic composite and electrode material, which is applied in the field of preparation of copper-based composite materials for welding electrodes, can solve the problems of high price of ultrafine zirconium carbide-zirconium boride powder, etc., and achieves low cost, low price and low porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] One-step synthesis method of zirconium carbide-zirconium boride ceramic composite reinforced copper electrode material:

[0033] 1. Weighing: Cu powder with a particle size of ~0.5 μm, Zr powder with a particle size of ~45 μm, and B powder with a particle size of ~0.5 μm 4 C powder weighs the raw materials according to the molar ratio of 3.42:3:1, and the raw materials used are all commercial powders.

[0034] 2. Mixing: Mix the weighed Cu powder, Zr powder, B 4 C powder, as well as balls and milling jars are placed in a vacuum glove box, and after vacuuming to 5-10Pa, argon gas is flushed to normal pressure, and balls and powder are put into a ball milling jar in an inert gas environment, and then The sealed ball mill jar was put into the roller ball mill and mixed for 12 hours to obtain Cu-Zr-B 4 C mixed powder, wherein, the ball is ZrO 2 Grinding balls, the weight ratio of grinding balls to powder is 10:1, and the rotating speed of the ball mill is 60 rpm;

[003...

Embodiment 2

[0040] The one-step synthesis method of zirconium carbide-zirconium boride ceramic composite reinforced copper electrode material is the same as that of Example 1 except for the following.

[0041] In this example:

[0042] (1) Cu-Zr-B 4 C mixed powder Cu powder, Zr powder, B 4 C powder is weighed at a molar ratio of 1.28:3:1;

[0043] (2) Oxygen-free copper block and Cu-Zr-B 4 C powder compacts are placed in a vacuum melting furnace at a weight ratio of 399:1;

[0044] (3) The time of heat preservation and magnetic stirring is 30min;

[0045] (4) A zirconium carbide-zirconium boride ceramic composite reinforced copper electrode material with a content of 0.2 wt.% is obtained. The composite has a tensile strength of 287MPa and an electrical conductivity of 87% IACS.

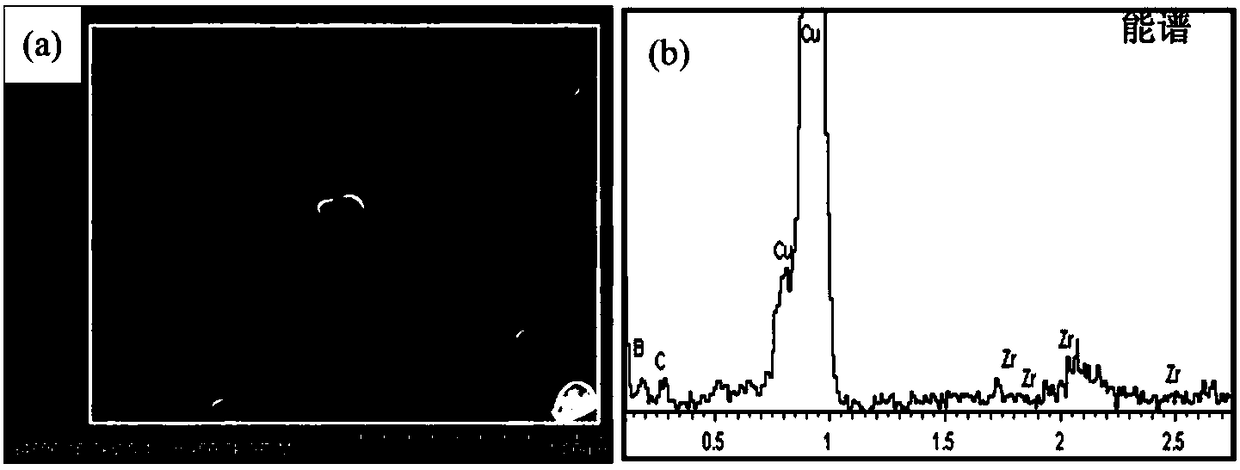

[0046] figure 1 Microstructure of 0.2wt.% zirconium carbide-zirconium boride ceramic composite strengthened copper electrode material after corrosion. Depend on figure 1 .a It can be seen that ultrafine ...

Embodiment 3

[0048] The one-step synthesis method of zirconium carbide-zirconium boride ceramic composite reinforced copper electrode material is the same as that of Example 1 except for the following.

[0049] In this example:

[0050] (1) Cu-Zr-B 4 The particle size of Cu powder in C mixed powder is 75 μm;

[0051] (2) Oxygen-free copper block and Cu-Zr-B 4 C powder compacts are placed in a vacuum melting furnace at a weight ratio of 59:1;

[0052] (3) The time of heat preservation and magnetic stirring is 30min, and the magnetic stirring current is 50A;

[0053] (4) A zirconium carbide-zirconium boride ceramic composite strengthened copper electrode material with a content of 1.0 wt.% is obtained. The composite has a tensile strength of 385 MPa and an electrical conductivity of 82% IACS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com