900MPa-grade hot-rolled and pickled complex-phase phase steel with low yield ratio and high hole expansion rate and production method of 900MPa-grade hot-rolled pickling complex phase steel

A hot-rolled pickling and low yield-strength ratio technology is applied in the field of hot-rolled and pickled multiphase steel with low yield ratio and high hole expansion ratio of 900 MPa and its production field, which can solve the problems of fatigue resistance, welding performance and cold forming performance. Ideal, does not meet the problems of high-strength forming steam, low tensile strength, etc., to achieve the effect of phase transformation strengthening, improving strength and toughness, and improving hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

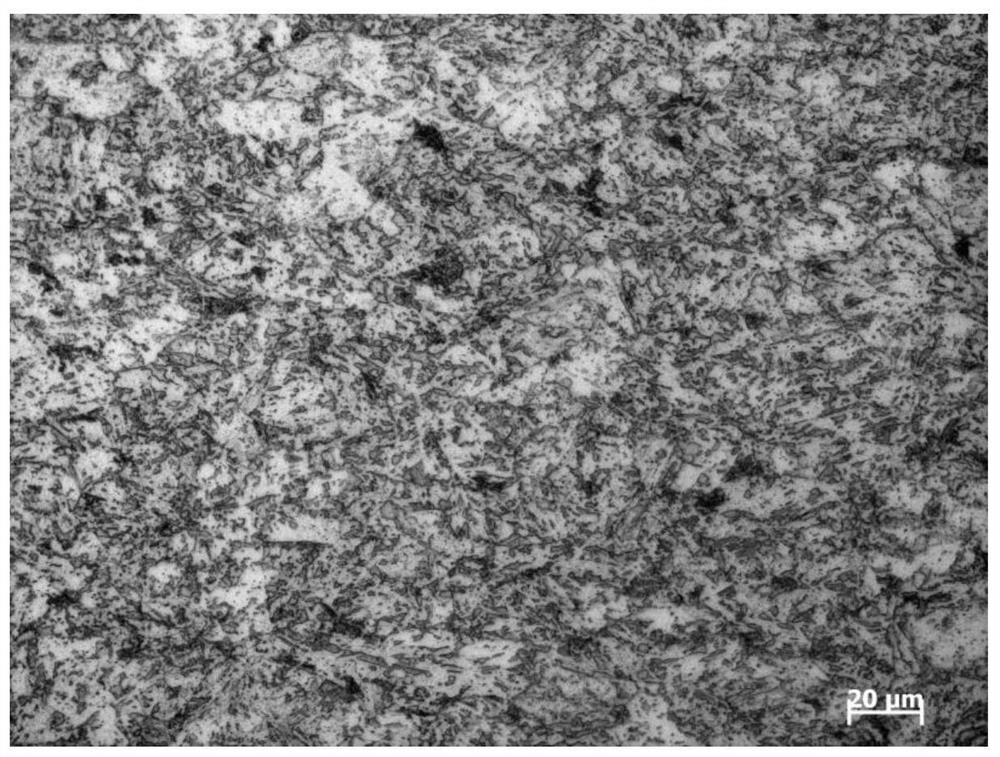

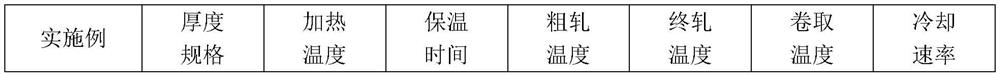

[0028] The invention discloses a 900MPa grade hot-rolled pickling multi-phase steel with low yield strength ratio and high hole expansion rate and a production method thereof. Those skilled in the art can refer to the content of this article to appropriately improve the process parameters to achieve. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and the relevant personnel can obviously make changes or appropriate changes and combinations to the method and application described herein without departing from the content, spirit and scope of the present invention to realize and Apply the technology of the present invention.

[0029] A 900MPa grade hot-rolled pickling multi-phase steel with low yield ratio and high hole expansion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com