Strengthened coating on surface of transmission component of agricultural machine and preparing method of strengthened coating

A transmission component and surface strengthening technology, which is applied in the direction of coating, metal material coating process, etc., can solve the problems of low hardness, poor wear resistance, and affecting service life, so as to improve mechanical properties, prevent fracture, and refine grains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

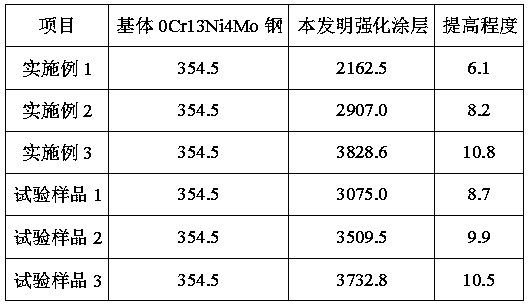

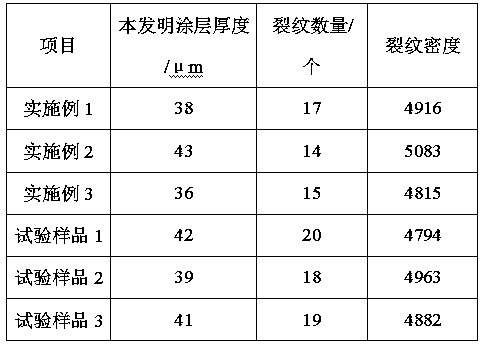

Examples

Embodiment 1

[0024] A surface strengthening coating for agricultural machinery transmission components, comprising the following raw materials in parts by weight: 10 parts of high-entropy alloy powder, 31 parts of hard alloy powder, and 46.5 parts of shape memory alloy powder, wherein the high-entropy alloy is Ni9Co31Cr30B15Fe7Si6.5Nd1 .5, the cemented carbide is Cr 3 C 2 +WC (Cr 3 C 2 +WC+Co) and ZrC, TiC, and the weight ratio of the former to the latter is 5:3, the shape memory alloy is a manganese-based alloy, including the following material components and the weight percentage of each component: aluminum 13.5% , chromium 2%, nickel 3%, iron 45%, silicon 5%, zirconium 2%, vanadium 1.8%, niobium 1.5%, and the rest is manganese.

[0025] A method for preparing a surface strengthening coating of an agricultural machinery transmission component, the specific preparation steps are as follows:

[0026] Step 1. Put the mechanically crushed high-entropy alloy powder, cemented carbide powde...

Embodiment 2

[0031] A surface strengthening coating for agricultural machinery transmission components, comprising the following raw materials in parts by weight: 12 parts of high-entropy alloy powder, 36 parts of cemented carbide powder, and 52 parts of shape-memory alloy powder, wherein the high-entropy alloy is NiCo23Cr17Fe8Ti5Al4.5Mn13 One or two of .5V4.6, Ni(11~15)TaAl8.3Nb4.1Hf7.2Zr11.8Ti0.5, the hard alloy is Cr 3 C 2 +WC (Cr 3 C 2+WC+Co) and ZrC, the shape memory alloy is a manganese-based alloy, including the following material components and weight percentages of each component: 15% aluminum, 6.5% chromium, 6% nickel, 43% iron, 6.5% silicon %, zirconium 2.3%, vanadium 2%, niobium 1.9%, and the rest is manganese.

[0032] A method for preparing a surface strengthening coating of an agricultural machinery transmission component, the specific preparation steps are as follows:

[0033] Step 1. Put the mechanically crushed high-entropy alloy powder, cemented carbide powder, and s...

Embodiment 3

[0038] A surface strengthening coating for agricultural machinery transmission components, comprising the following raw materials in parts by weight: 13.5 parts of high-entropy alloy powder, 40 parts of cemented carbide powder, and 59 parts of shape-memory alloy powder, wherein the high-entropy alloy is Ni(11 ~15) TaAl8.3Nb4.1Hf7.2Zr11.8Ti0.5, the hard alloy is Cr 3 C 2 +WC (Cr 3 C 2 +WC+Co) and NbC, TaC, the shape memory alloy is a manganese-based alloy, including the following material components and the weight percentage of each component: aluminum 17%, chromium 11%, nickel 9%, iron 41%, Silicon 8%, zirconium 2.5%, vanadium 2.2%, niobium 2.3%, and the rest is manganese.

[0039] A method for preparing a surface strengthening coating of an agricultural machinery transmission component, the specific preparation steps are as follows:

[0040] Step 1. Put the mechanically crushed high-entropy alloy powder, cemented carbide powder, and shape memory alloy powder with a partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com