Quaternary MAX phrase enhanced nickel base high temperature oxidation resisting composite material and synthetic method thereof

A technology for high-temperature anti-oxidation and composite materials, which is applied in the field of quaternary MAX phase reinforced nickel-based high-temperature anti-oxidation composite materials and their synthesis. , Excellent high temperature lubricating performance, the effect of improving high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

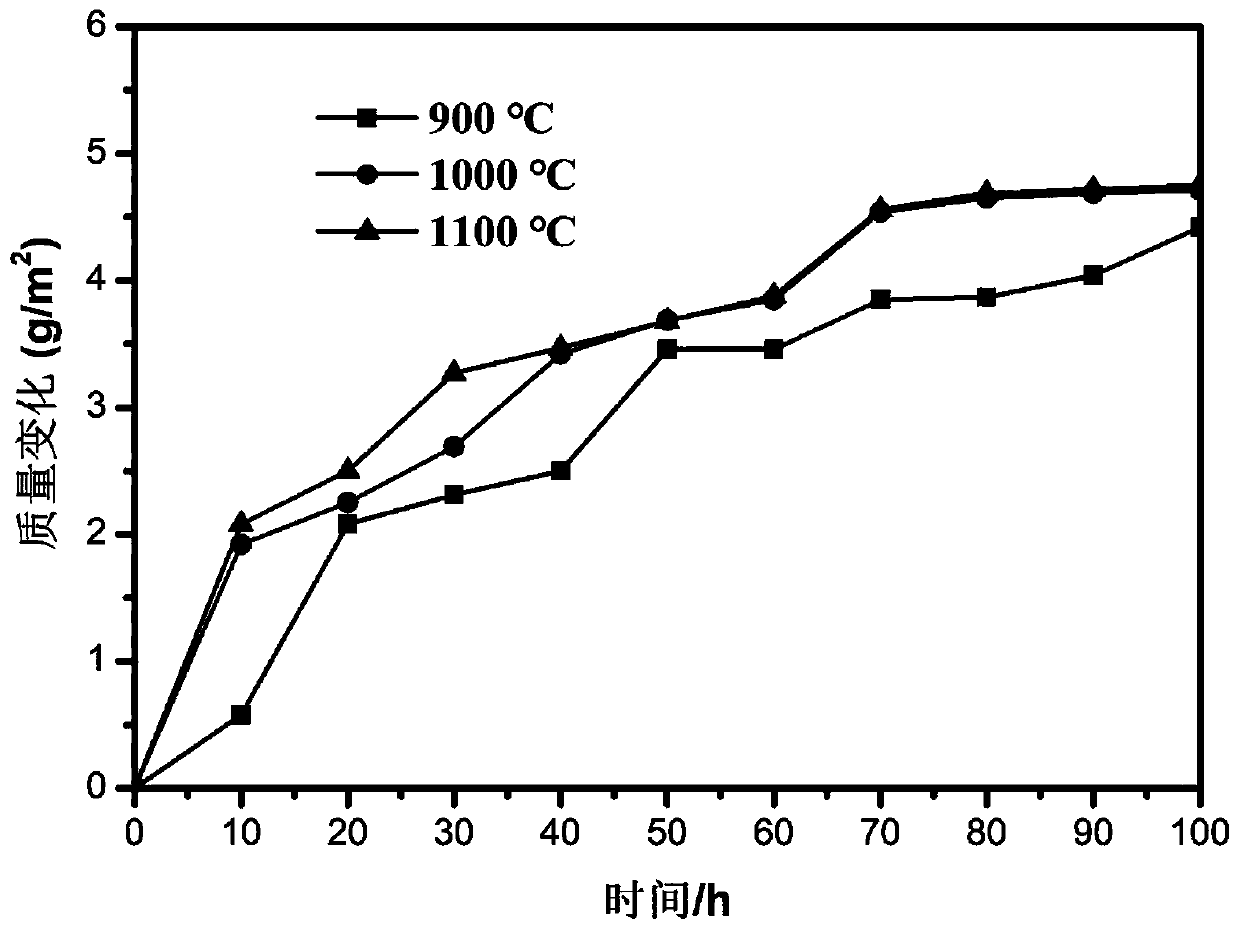

[0043] The NiAl material was prepared by hot pressing sintering technology, and the weighed powder was loaded into a graphite grinding tool. Before powder loading, a layer of graphite paper is laid on the wall of the graphite grinding tool to prevent the powder from sticking to the graphite grinding tool during the sintering process. The NiAl material prepared by hot pressing and sintering is dense and uniform. The composite exhibits excellent oxidation resistance under high temperature conditions. NiAl material is oxidized at 900°C, 1000°C, and 1100°C for 100 hours, respectively, and the oxidation weight gain per unit area is 4.42g / m 2 , 4.71g / m 2 , 4.75g / m 2 ,Such as figure 1 shown.

Embodiment 2

[0045] Preparation of homogeneously mixed nanostructured NiAl, Ti, Al and C powders by high energy ball milling

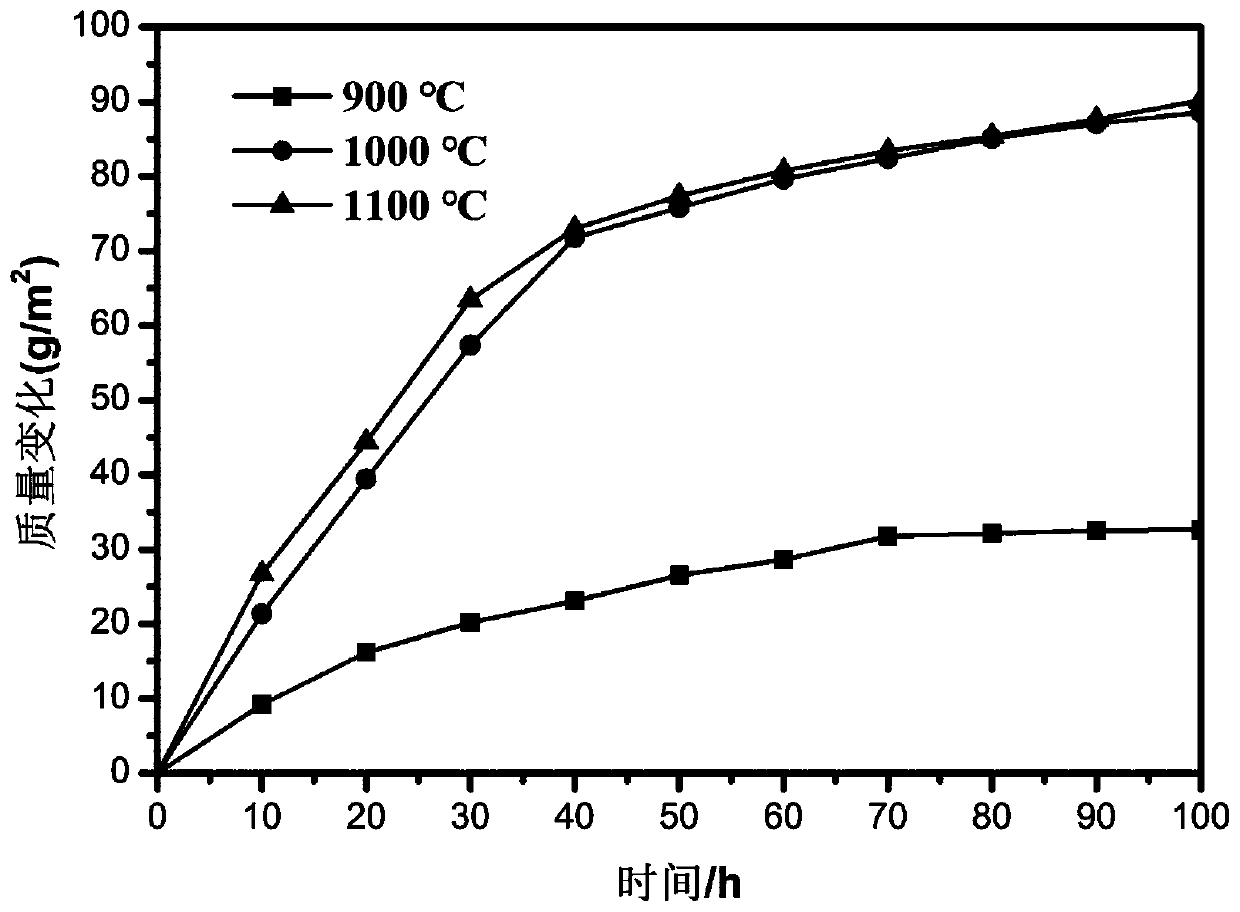

[0046] The powder weighed in proportion is put into a zirconia ball mill jar for high-energy ball milling to prepare a uniformly mixed nanostructure mixed powder, and then the mixed powder is loaded into a graphite mill. Before powder loading, a layer of graphite paper is laid on the wall of the graphite grinding tool to prevent the powder from sticking to the graphite grinding tool during the sintering process. The mixed powder with nanostructure has the effect of fine-grain strengthening, which can effectively improve the strength of composite materials. The Ti, Al and C powder added to the composite material can react in situ to form Ti during the high temperature vacuum sintering process 3 AlC 2 Phase, which has excellent high-temperature lubricating properties, can realize the high-temperature lubricating properties of composite materials. At the same time,...

Embodiment 3

[0048] Preparation of homogeneously mixed nanostructured NiAl, Cr, Ti, Al and C powders by high energy ball milling

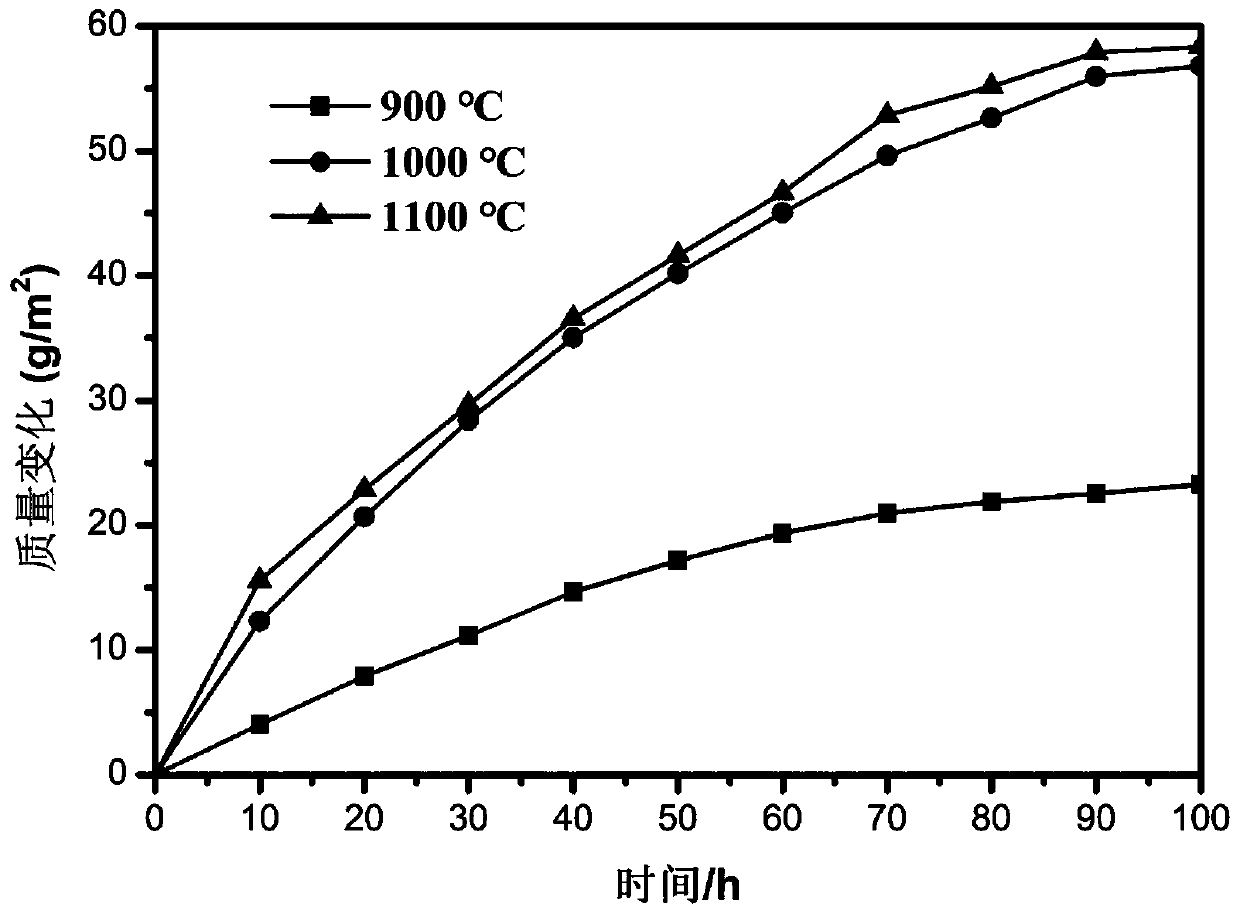

[0049] NiAl intermetallic compound powder is 75-90wt%, Cr powder, Ti powder, Al powder and C powder are 10-25wt%, and the molar ratio of Cr powder, Ti powder, Al powder and C powder is 2:1:1:2 , put the powder weighed in proportion into a zirconia ball mill tank for high-energy ball milling, the mass ratio of the ball to material is (6-15):1, the rotation speed is 200-300r / min, the ball milling time is 15-25h, and the prepared particle size 10-60nm, mixed homogeneous nano-structure mixed powder, then put the mixed powder into a graphite grinding tool, and cold-pressed at a pressure of 5-15MPa.

[0050] Before powder loading, a layer of graphite paper is laid on the wall of the graphite grinding tool to prevent the powder from sticking to the graphite grinding tool during the sintering process. The mixed powder with nanostructure has the effect of fine-grain st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com