Preparation method of nanostructure double metal oxide reinforced nial matrix composite material

A bimetallic oxide and composite material technology, which is applied in the field of preparation of nanostructured bimetallic oxide reinforced NiAl-based high-temperature high-strength lubricating composite materials, can solve problems such as poor wettability, achieve improved wettability, meet lightweight requirements, improve The effect of organizational structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

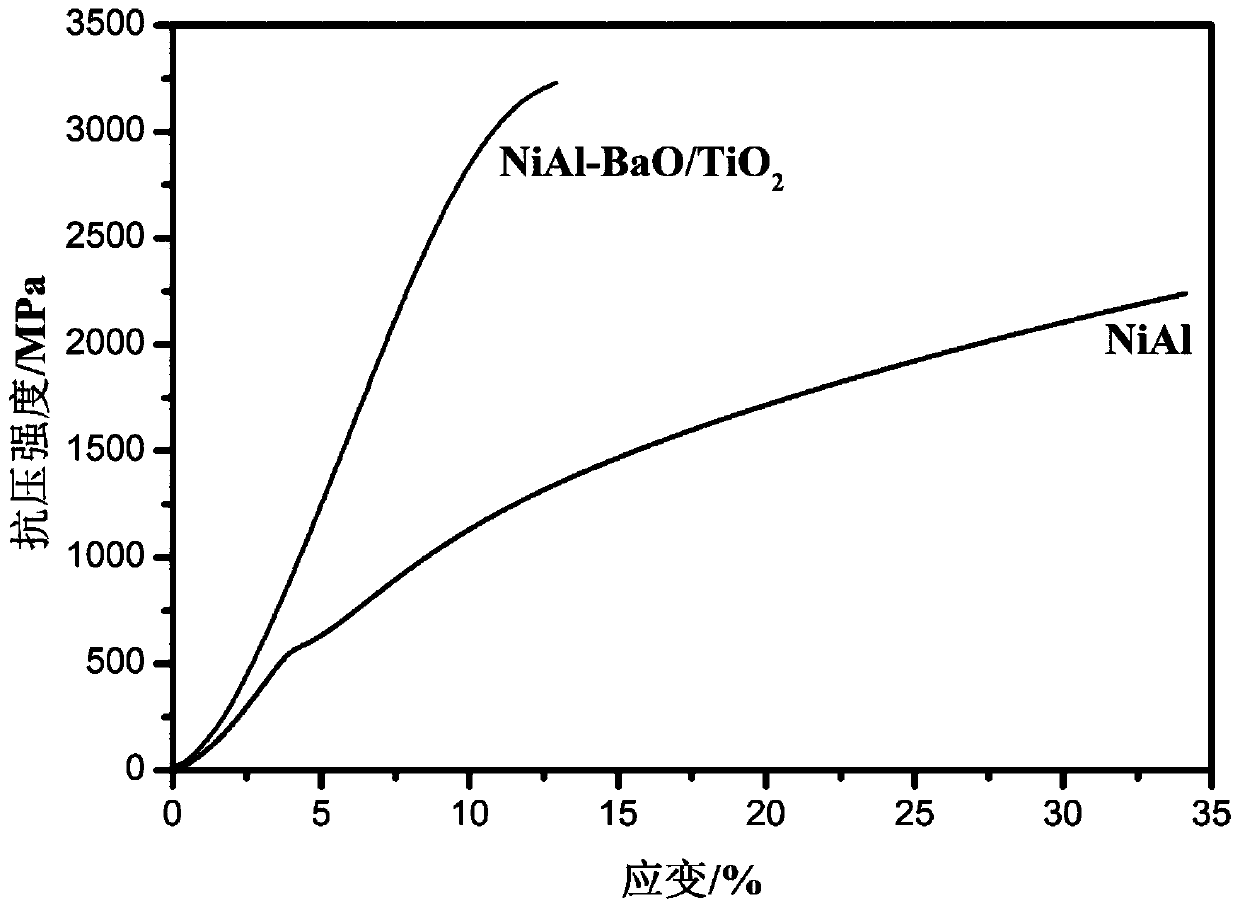

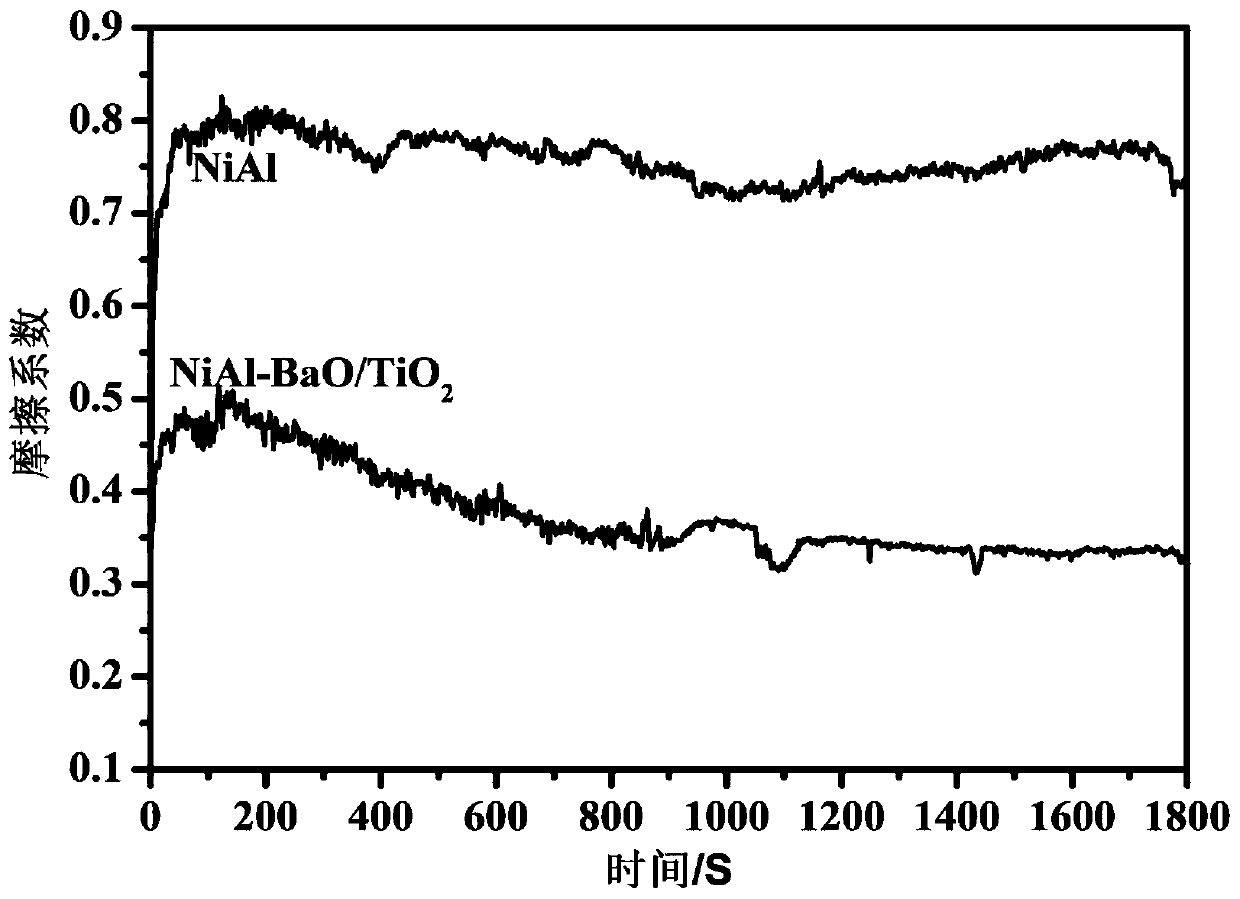

[0032] The invention discloses a method for preparing a nanostructured double metal oxide reinforced NiAl-based high-temperature, high-strength lubricating composite material. The nanostructured mixed powder is prepared by high-energy ball milling, and a nanostructured composite material with uniform phase distribution is successfully prepared. BaO and TiO are used 2 Reaction occurs during high temperature sintering to form BaTiO 3 The high-temperature solid lubricant realizes the high-temperature lubrication performance of the composite material, and at the same time, effectively improves the problem of poor wettability between the metal oxide and the NiAl matrix, significantly improves the microhardness and compressive strength of the composite material, and realizes Composite materials have high strength, light weight and high temperature lubrication performance. Specific steps are as follows:

[0033] S1. Mixed powder ratio and ball milling

[0034] Weigh the powder acco...

Embodiment 1

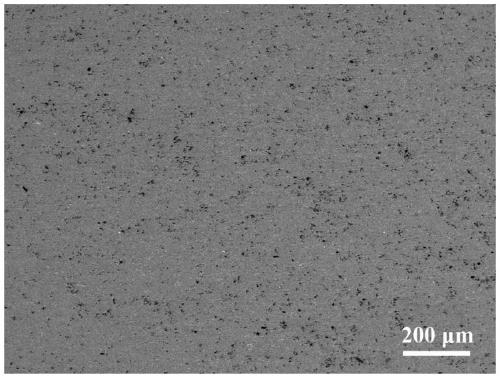

[0043] The method of high-energy ball milling is used to prepare a uniformly mixed nanostructure mixed powder; the mass percentage of 75% NiAl and 25% BaO / TiO 2 Put it into a zirconia ball mill tank for high-energy ball milling, the mass ratio of balls to materials is 8:1, the rotation speed is 200r / min, the ball milling time is 10h, the particle size of the mixed powder is 10nm, the drying temperature is 80°C, and the time For 1 h, prepare a homogeneously mixed nanostructure mixed powder, and then put the mixed powder into a graphite grinding tool.

[0044] Before powder loading, a layer of graphite paper is laid on the wall of the graphite grinding tool to prevent the powder from sticking to the graphite grinding tool during the sintering process. The mixed powder with nanostructure has the effect of fine-grain strengthening, which can effectively improve the strength of composite materials. BaO / TiO added to composites 2 On the one hand, the double metal oxide can effectiv...

Embodiment 2

[0048] The method of high-energy ball milling is used to prepare uniformly mixed nanostructure mixed powder. 85% NiAl and 15% BaO / TiO 2 Put it into a zirconia ball mill jar for high-energy ball milling, the mass ratio of the ball to material is 10:1, the rotation speed is 250r / min, the ball milling time is 15h, the particle size of the mixed powder is 30nm, the drying treatment temperature is 90°C, and the time for 1.5 h to prepare a homogeneously mixed nanostructure mixed powder, and then put the mixed powder into a graphite grinding tool.

[0049] Before powder loading, a layer of graphite paper is laid on the wall of the graphite grinding tool to prevent the powder from sticking to the graphite grinding tool during the sintering process. The mixed powder with nanostructure has the effect of fine-grain strengthening, which can effectively improve the strength of composite materials. BaO / TiO added to composites 2 On the one hand, the double metal oxide can effectively impr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com