FeCoCrNiMo-based high-entropy alloy composite material as well as preparation method and application thereof

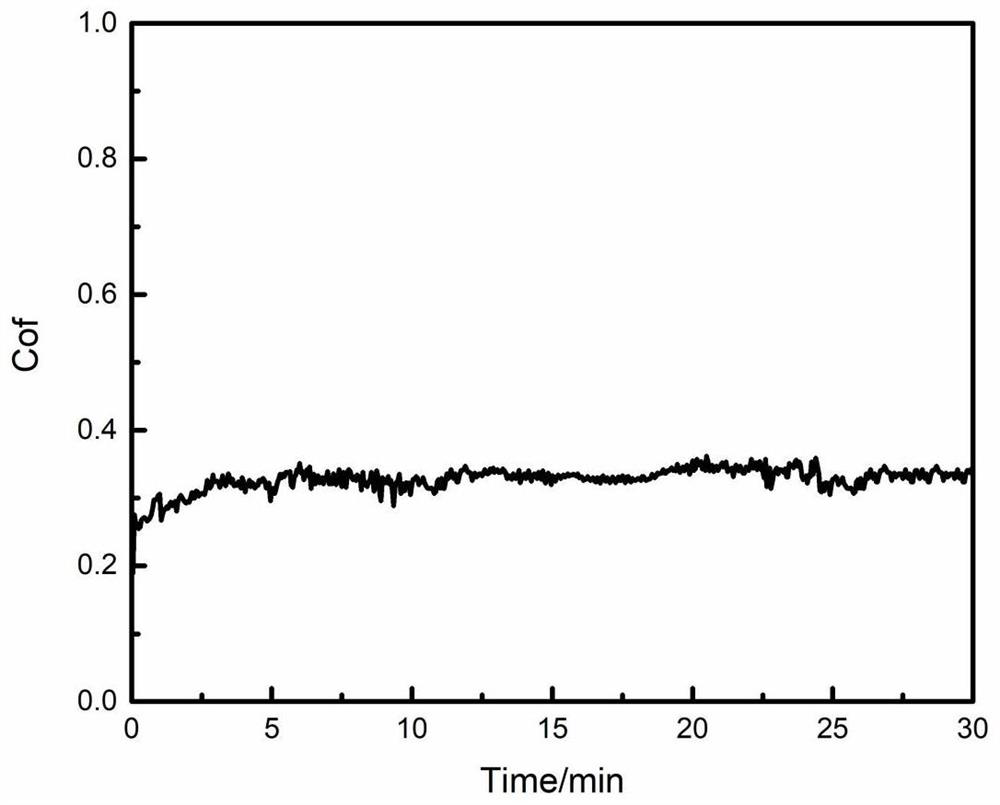

A high-entropy alloy and composite material technology is applied in the field of FeCoCrNiMo-based high-entropy alloy composite materials and their preparation, which can solve the problems of reduced material strength, poor bonding performance, and easy occurrence of a large number of micro-cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention provides a method for preparing an FECOCRNIMO-based high entropy alloy composite, including the following steps:

[0025] FECOCRNIMO high entropy alloy powder, Ti powder, Al powder and Ag powder were mixed, and the resulting mixture was subjected to discharge plasma sintering, solid solution and aging treatment to obtain FECOCRNIMO-based high entropy alloy composite.

[0026] In the present invention, if there is no special description, the required materials are commercially available goods well known to those skilled in the art.

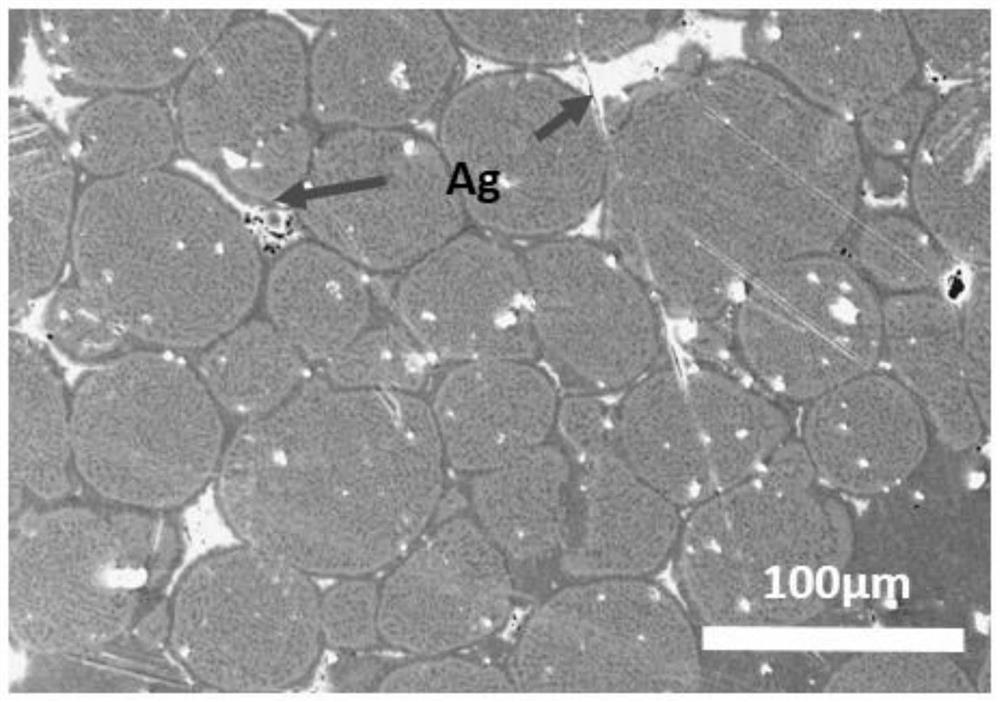

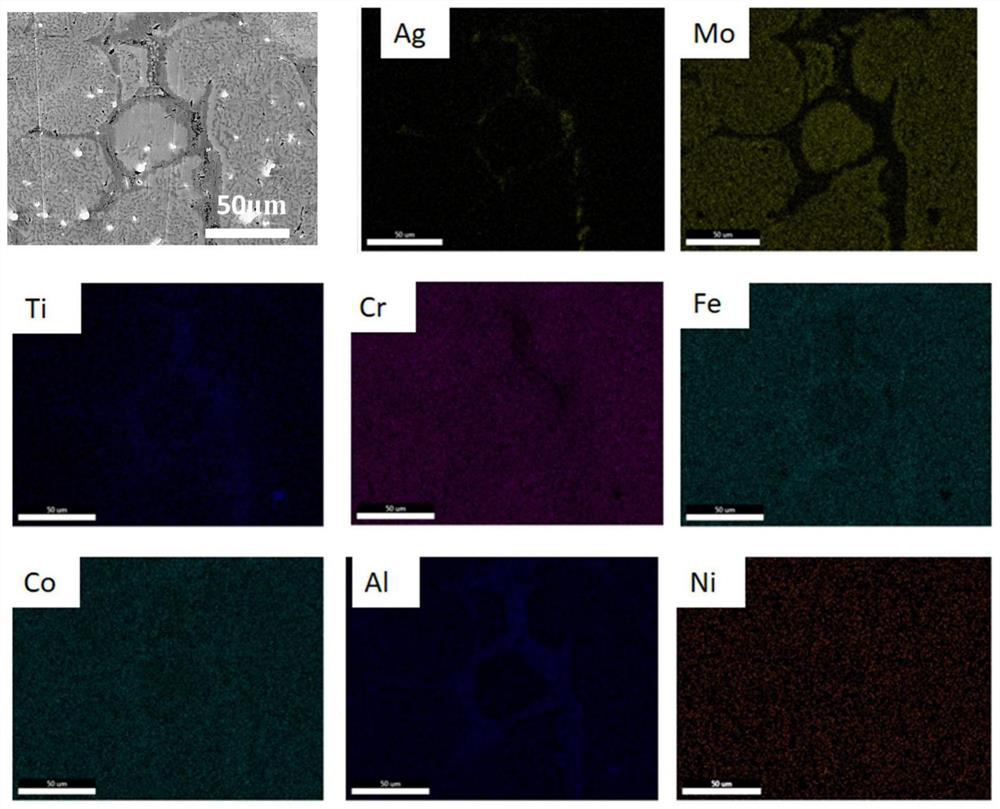

[0027] In the present invention, the particle size of the FECRNIMO high entropy alloy powder is preferably 65 to 100 μm; the particle size of the Ti powder is preferably 15 to 35 μm; the particle size of the Al powder is preferably 20 to 40 μm; the particle size of the Ag powder It is preferably 15 to 35 μm. The present invention has no particular limitation on the source of FECOCRNIMO high entropy alloy powder, Ti powder, ...

Embodiment 1

[0040] Add 90 FECOCRNIMO high entropy alloy powder, Ti powder 3 parts and Al powder 3 parts in 3 parts of 3 parts and AL powder. 2 O 3 In the ball mill, mixed for 20 h under the condition of rotation 300R / min; add 4 Ag powder to the resulting mixed powder, mixed with 5 h under the condition of 250 R / min; pour the mixed mixed mixture, load the graphite mold By discharging plasma sintering, under pressure of 30 MPa, the temperature is gradually warmed by room temperature to 950 ° C, 20 min, fuel to the room temperature, and the resulting composite is charged at 1 h, after air cooling, after 4 h at 850 ° C for 4 h Treatment to obtain FECOCRNIMO-based high entropy alloy composite.

Embodiment 2

[0042] According to the mass parts, 88 FeCoCrnimo high entropy alloy powder, Ti powder 4 parts and Al powder 3 parts were put in Al 2 O 3 In the ball mill, mixed for 18 h under the conditions of the rotational speed 280R / min; 5 parts of Ag powder was added to the resulting mixed powder, mixed under the condition of 200R / min, and mixed mixed mixed mixture, put graphite The mold is sintered by discharge plasma, at a pressure of 30 MPa, gradually warping from room temperature to 900 ° C, molded 15 min, fuel to the room temperature; the material prepared by discharge plasma sintering is 1 h at 1100 ° C, after air cooling, at 800 EtOAc EtOAc EtOAc EtOAc EtOAc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com