A fecocrnimo-based high-entropy alloy composite material and its preparation method and application

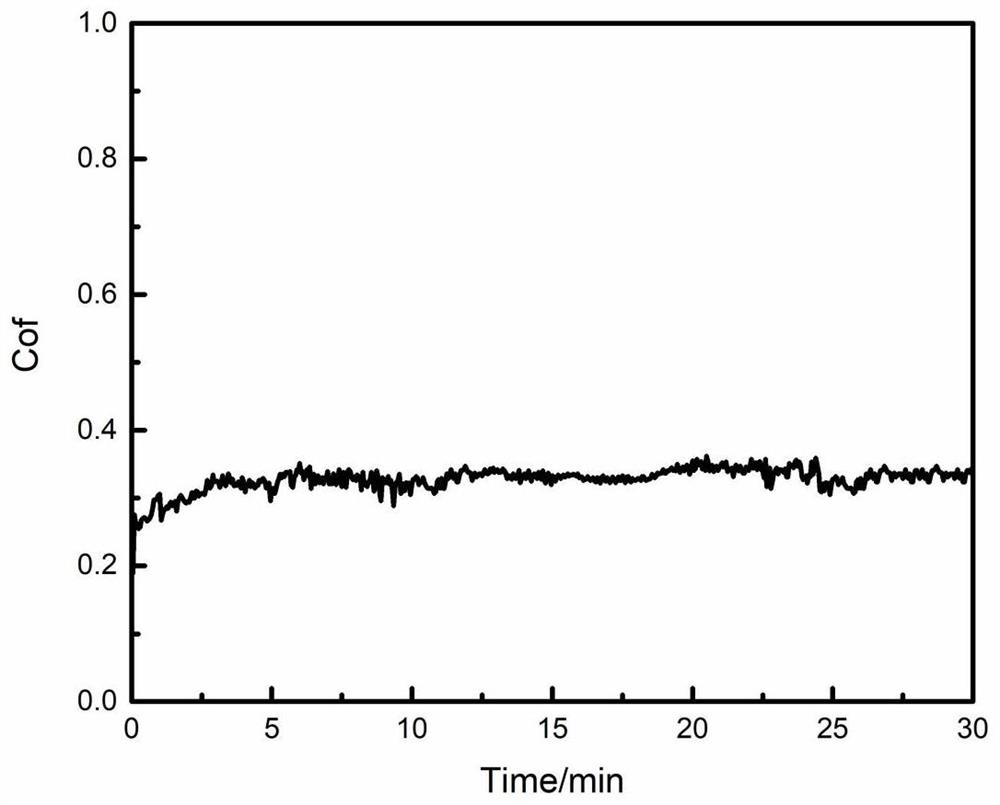

A high-entropy alloy and composite material technology, which is applied in the field of FeCoCrNiMo-based high-entropy alloy composite materials and their preparation, can solve the problems of reduced material strength, poor bonding performance, and a large number of microcracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a FeCoCrNiMo-based high-entropy alloy composite material, comprising the following steps:

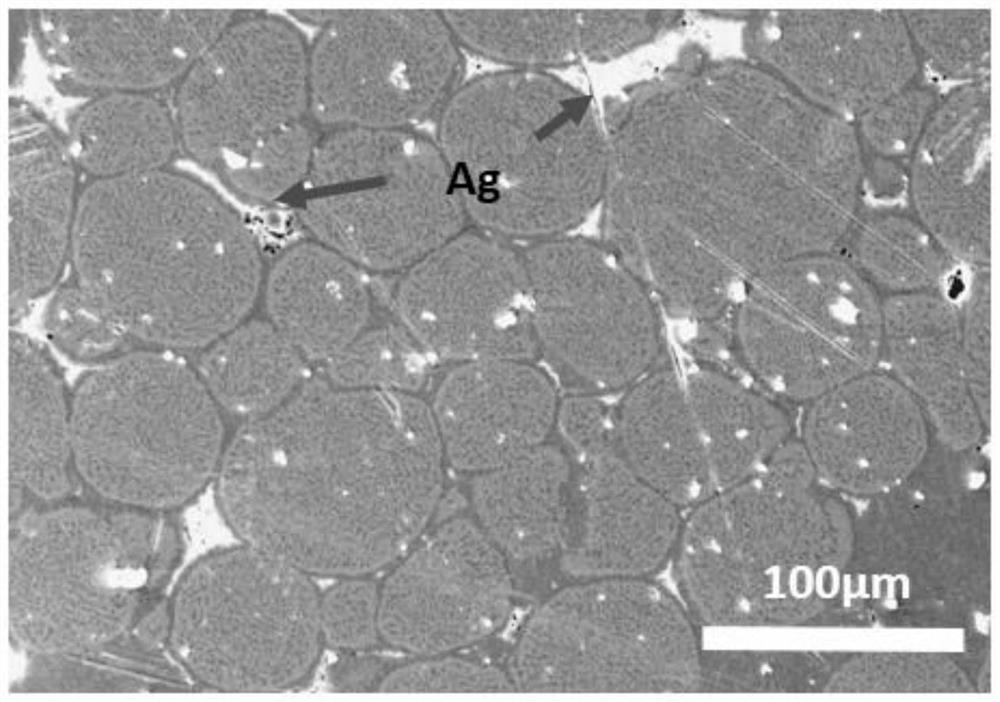

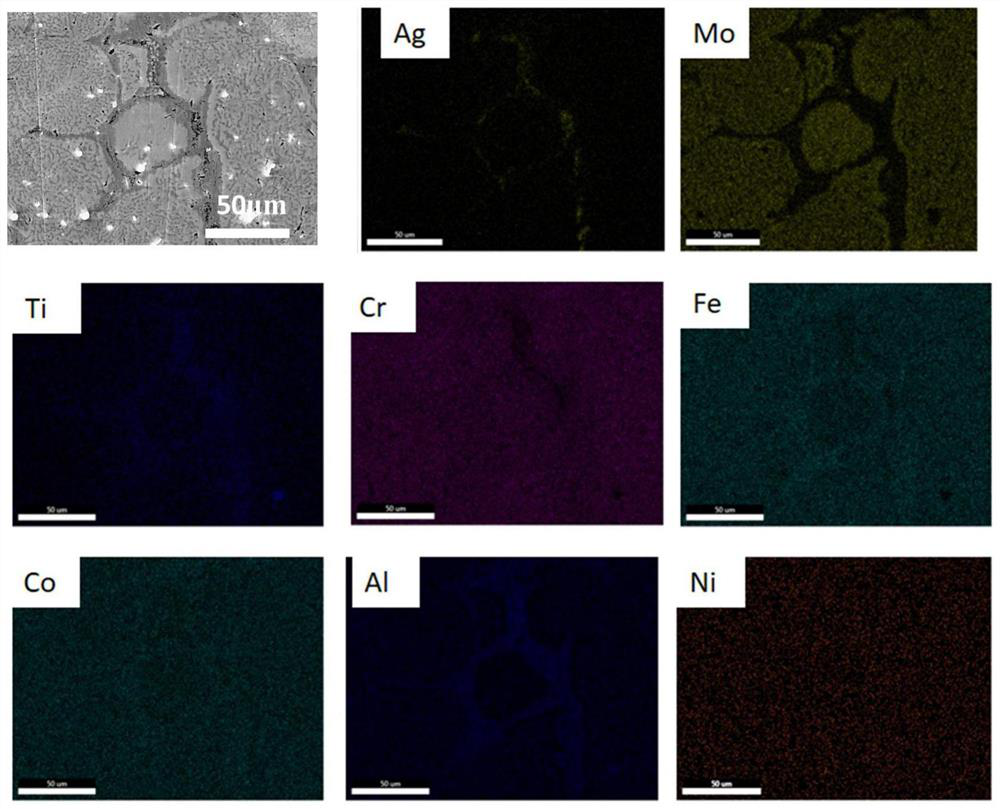

[0025] FeCoCrNiMo high-entropy alloy powder, Ti powder, Al powder and Ag powder are mixed, and the obtained mixture is sequentially subjected to spark plasma sintering, solution treatment and aging treatment to obtain FeCoCrNiMo-based high-entropy alloy composite material.

[0026] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0027] In the present invention, the particle size of the FeCoCrNiMo high-entropy alloy powder is preferably 65-100 μm; the particle size of the Ti powder is preferably 15-35 μm; the particle size of the Al powder is preferably 20-40 μm; the particle size of the Ag powder is Preferably it is 15-35 micrometers. In the present invention, the sources of the FeCoCrNiMo high-entropy alloy powder, ...

Embodiment 1

[0040] In parts by mass, put 90 parts of FeCoCrNiMo high-entropy alloy powder, 3 parts of Ti powder and 3 parts of Al powder into Al 2 o 3 In a ball mill, mix for 20 hours at a speed of 300r / min; add 4 parts of Ag powder to the resulting mixed powder, and mix for 5 hours at a speed of 250r / min; pour out the mixed material and put it into a graphite mold , through spark plasma sintering, under the pressure of 30MPa, the temperature is gradually raised from room temperature to 950°C, molded for 20min, and then lowered to room temperature for demoulding, and the obtained composite material is subjected to heat preservation treatment at 1000°C for 1h, and after air cooling, it is aged at 850°C for 4h treatment to obtain FeCoCrNiMo-based high-entropy alloy composites.

Embodiment 2

[0042] In parts by mass, put 88 parts of FeCoCrNiMo high-entropy alloy powder, 4 parts of Ti powder and 3 parts of Al powder into Al 2 o 3 In a ball mill tank, mix for 18 hours at a speed of 280r / min; add 5 parts of Ag powder to the resulting mixed powder, mix for 10 hours at a speed of 200r / min, pour out the mixed material, and put in graphite The mould, through spark plasma sintering, is gradually heated from room temperature to 900 ° C under a pressure of 30 MPa, molded for 15 minutes, and then lowered to room temperature for demoulding; the material prepared by spark plasma sintering is subjected to heat preservation treatment at 1100 ° C for 1 hour, and after air cooling, at 800 ℃ for 8h aging treatment to obtain FeCoCrNiMo-based high-entropy alloy composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com