Ultrahigh-strength seamless steel tube with excellent weldability and manufacturing method thereof

A technology for seamless steel pipes and manufacturing methods, applied in the field of ultra-high-strength seamless steel pipes and their manufacturing, capable of solving problems such as inapplicability, non-weldability, high-strength weight loss in the field of engineering structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

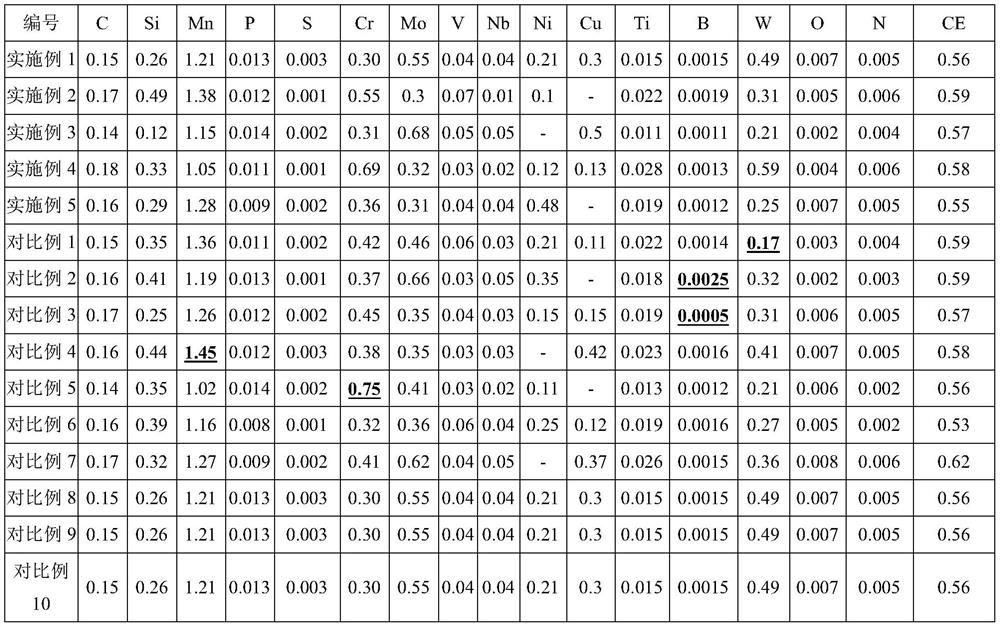

Embodiment 1-5 and comparative example 1-10

[0050] The ultra-high-strength seamless steel pipes of Examples 1-5 of the above-mentioned embodiments and the seamless steel pipes of Comparative Examples 1-10 were prepared by the following steps:

[0051] (1) Carry out electric furnace smelting according to the mass percentage of each chemical element shown in Table 1, and then cast the molten steel after smelting into a tube blank of φ178.

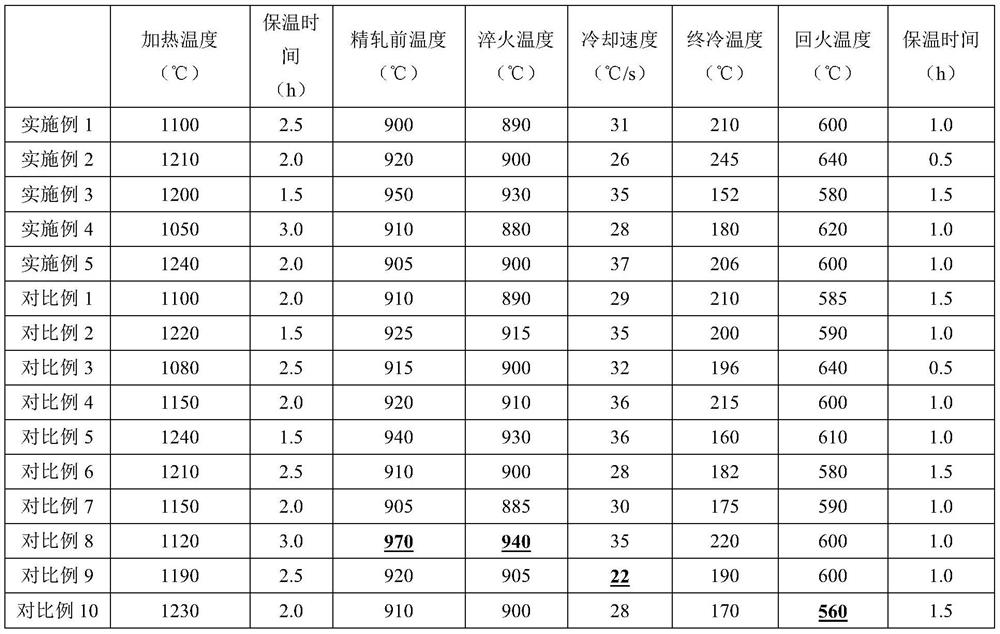

[0052] (2) Heat the tube billet to 1050-1250°C in a ring furnace and keep it warm for 1-3 hours. After it comes out of the furnace, it is pierced and hot-rolled into a blank tube. After the temperature reaches 900-950°C, it is finished rolling, and the finish rolling is φ121*11mm of seamless steel pipes.

[0053] (3) On-line quenching by using the waste heat after rolling: make the steel pipe pass through the cooling device for on-line quenching, the temperature of the on-line quenched steel pipe is controlled between 880-930°C, and when quenching, the steel pipe quickly passes through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com