Rolling-deformation thermal treatment method for improving performance of bearing ring

A cold treatment, bearing ring technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of reducing the dimensional accuracy of bearing rings, short service life, etc., to improve strength, reduce content, and eliminate mesh carbides. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0022] Take GCr15 bearing steel bearing ring as an example to improve mechanical properties and dimensional stability by rolling forming-heat treatment-cold treatment.

[0023] Step 1: Roll forming on the D56G90 CNC ring rolling machine to obtain deep groove ball bearing rings, such as figure 1 As shown, the microstructure of the bearing ring is refined by rolling forming, and crystal defects such as dislocations and substructures in the material are increased to significantly increase the recrystallization nucleation position, making preparations for increasing the dynamic recrystallization nucleation rate in the subsequent heat treatment;

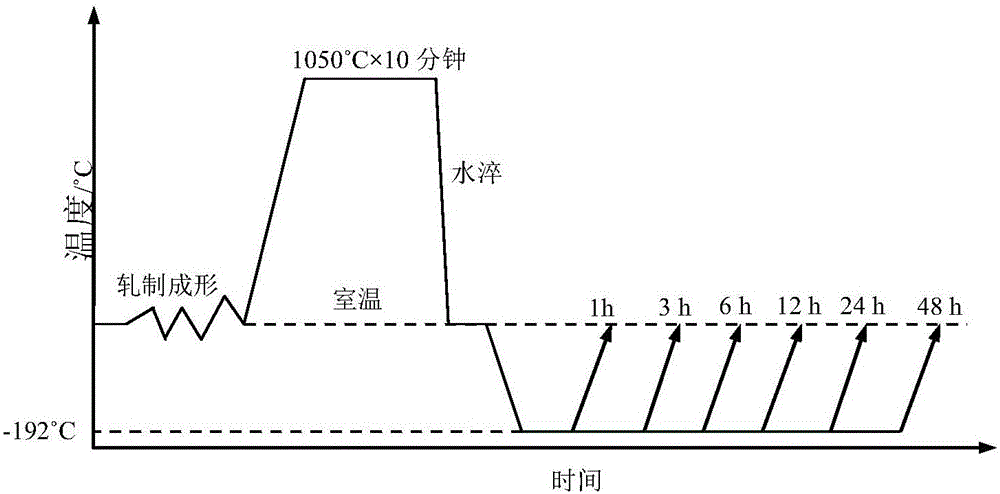

[0024] Step 2: Heat the rolled bearing ring to 1050°C to fully austenitize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com