Preparation method of ultra-fine zirconium carbide particle dispersed and strengthened copper-based composite materials for spot-welding electrode

A particle dispersion strengthening, copper matrix composite material technology is applied in the field of preparation of ultrafine zirconium carbide particle dispersion strengthening copper matrix composite materials for spot welding electrodes, which can solve the problems of high price of ultrafine zirconium carbide powder and reduce the preparation cost. , small size and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of ultrafine zirconium carbide particle dispersion strengthened copper matrix composite material for spot welding electrodes is as follows:

[0042] 1. Weighing: Weigh Cu powder with a particle size of ~0.5μm, Zr with a particle size of ~45μm, and graphite powder with a particle size of ~100nm in a molar ratio of 1.1:1:1. The raw materials used are all commercial powders.

[0043] 2. Mixing materials: Put the weighed Cu powder, Zr powder, C powder, and grinding balls and ball milling tanks into a vacuum glove box. After vacuuming to 5-10Pa, fill it with argon to normal pressure. Put the balls and powder into the ball mill jar in the gas environment, and then put the sealed ball mill jar into the roller ball mill and mix for 10 hours, wherein the balls are ZrO 2 Grinding balls, the weight ratio of the grinding balls to the powder is 10:1, and the rotating speed of the ball mill is 70 rpm;

[0044] 3. Molding: Put the Cu-Zr-C mixed powder into a stee...

Embodiment 2

[0051] A method for preparing a dispersion-strengthened copper-based composite material with ultrafine zirconium carbide particles for spot welding electrodes is the same as in Example 1 except for the following.

[0052] In this example:

[0053] (1) The rotating speed of ball mill is 50 revs / min; Apply the magnetic stirring current of 30A;

[0054] (2) Oxygen-free copper block and Cu-containing ultrafine ZrC powder are placed in a vacuum melting furnace at a weight ratio of 299:1;

[0055] (3) Obtain an ultrafine ZrC / Cu composite material with a ZrC content of 0.2wt.%. The tensile strength of the composite material is 302 MPa, and the electrical conductivity is 96% IACS.

Embodiment 3

[0057] A method for preparing a dispersion-strengthened copper-based composite material with ultrafine zirconium carbide particles for spot welding electrodes is the same as in Example 1 except for the following.

[0058] In this example:

[0059] (1) The speed of the ball mill is 60 rpm; the oxygen-free copper block and the ultrafine ZrC powder containing Cu are put into the vacuum melting furnace at a weight ratio of 59:1;

[0060] (2) The magnetic stirring time is 10min, and the magnetic stirring current is 30A;

[0061] (3) Obtain an ultrafine ZrC / Cu composite material with a ZrC content of 1.0wt.%. The composite has a tensile strength of 414 MPa and an electrical conductivity of 90% IACS.

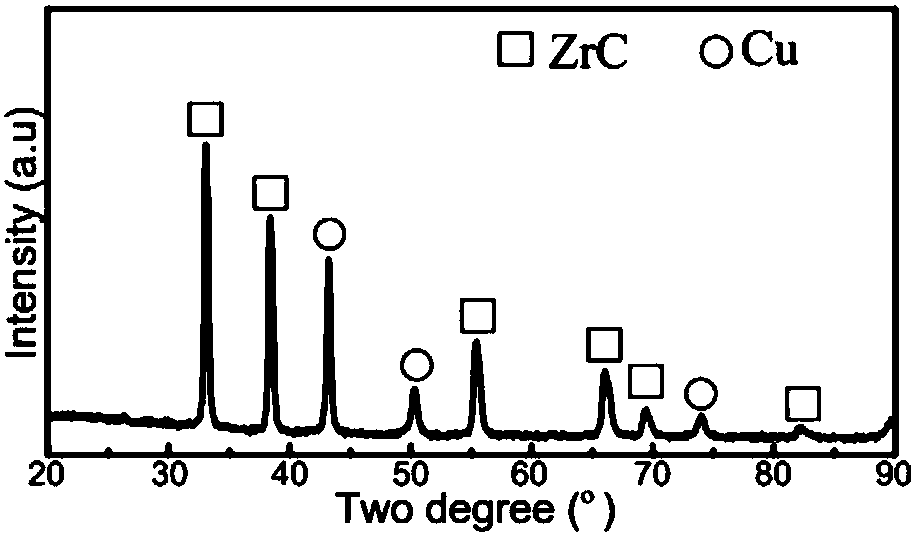

[0062] figure 1 It is the XRD detection result of Cu-containing ultrafine ZrC powder. From figure 1 It can be seen that the ultrafine ZrC powder containing Cu is only composed of two phases of ZrC and Cu, and no zirconia, unreacted Zr or C was detected, indicating that Zr and C we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com