Ultrasonic and pulse current mixing auxiliary wedge-shaped cavity profile rolling line and rolling process

A pulsed current and ultrasonic technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problem of increasing the thermal load, thermal deformation and corrosion risk of rolls and blank strips, increasing rolls and blank strips. The contact resistance of the material surface, the deterioration of the insulation performance of the power system, etc., can improve the machinability and forming performance, reduce the production cost and forming difficulty, and save the raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

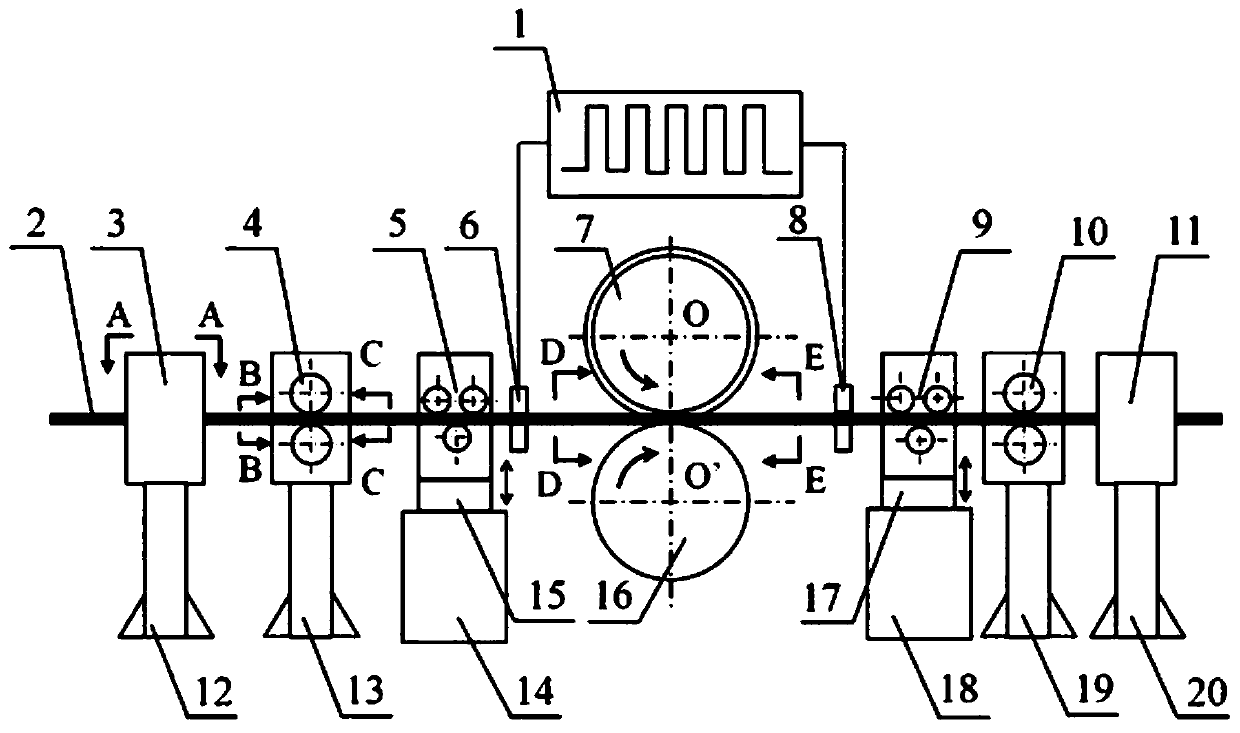

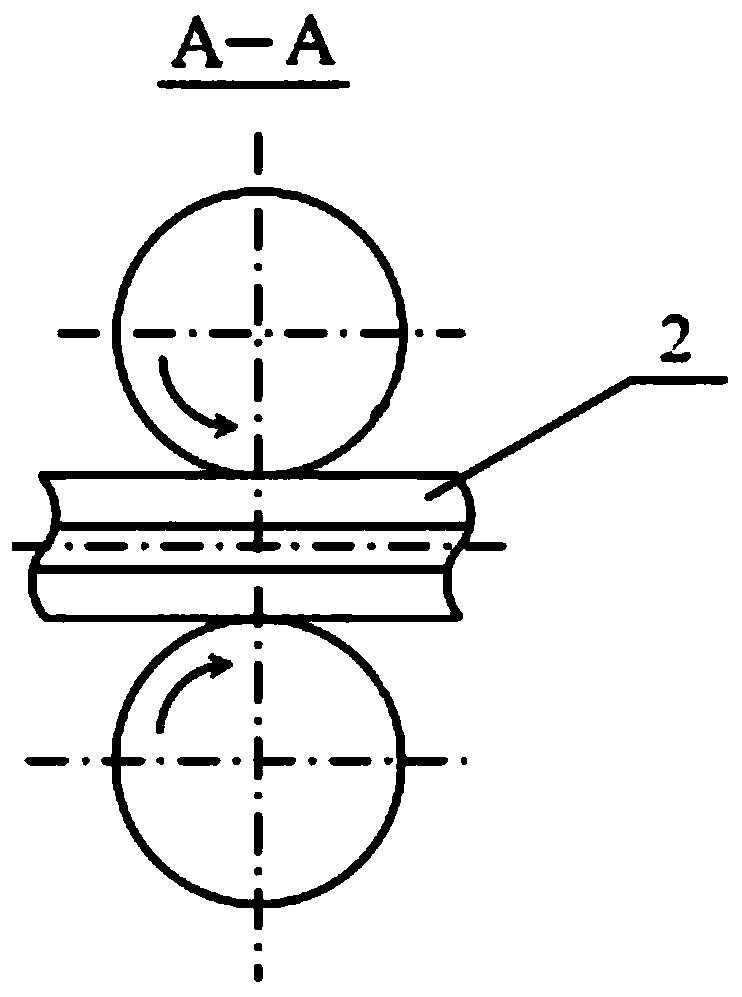

[0048] Such as figure 1 As shown, the ultrasonic and pulse current mixed auxiliary wedge-shaped cavity profile rolling line, along the rolling line, the left horizontal calibration roll 3, the pre-rolling roll 4, the left ultrasonic vibrating roll 5, the left brush 6, the roll group, the right Electric brush 8, right ultrasonic vibrating roll 9, right height calibration roll 10 and right horizontal calibration support roll 11. The left horizontal calibration roll 3 and the right horizontal calibration roll 11 are made up of horizontally arranged left and right rolls, the pre-rolling roll 4 and the right height calibration roll 9 are made up of vertically set upper and lower rolls, and the left ultrasonic vibrating roll 5 and the right ultrasonic vibrating roll 9 are composed of The upper and lower rollers arranged vertically form, and the roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com