Metal corrosion defect self-inspection healing repair method

A repair method and metal corrosion technology, applied in metal processing equipment, weather resistance/light resistance/corrosion resistance, measuring devices, etc., can solve the problems of increasing maintenance cycle and maintenance cost, and achieve the effect of average current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

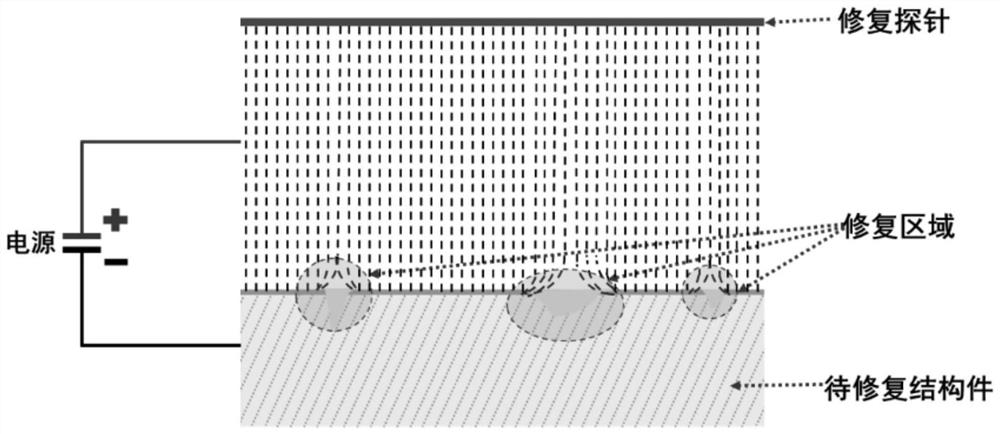

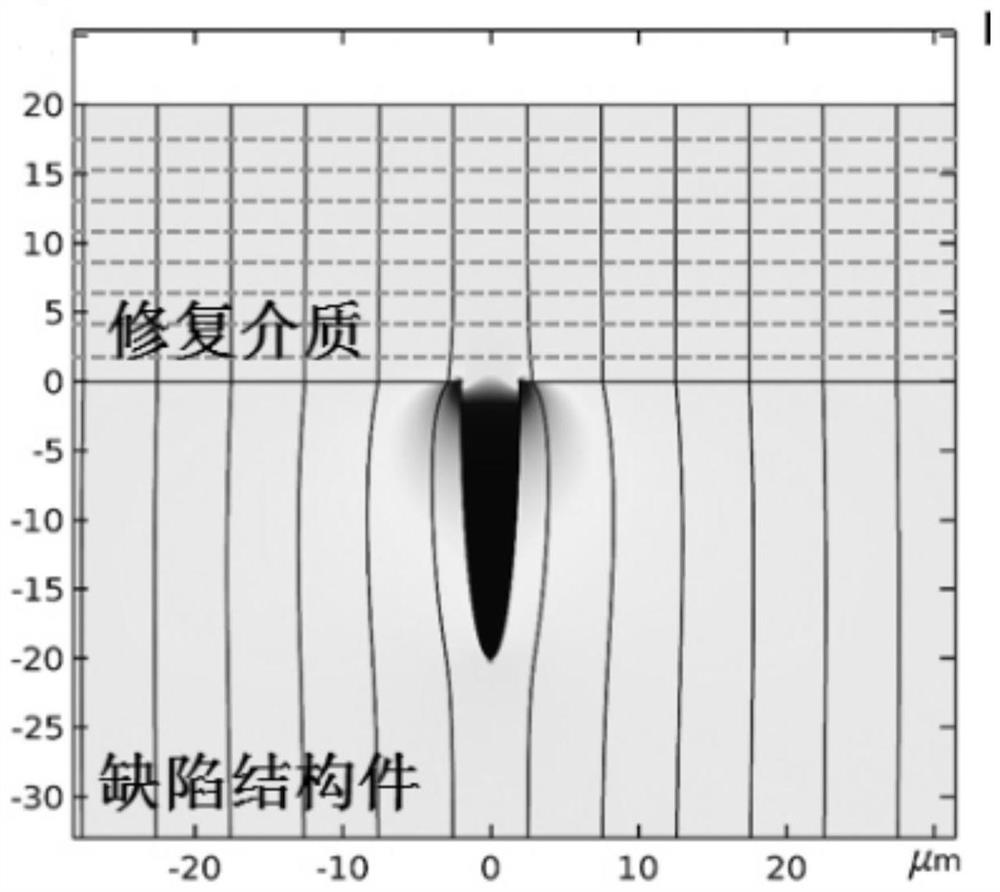

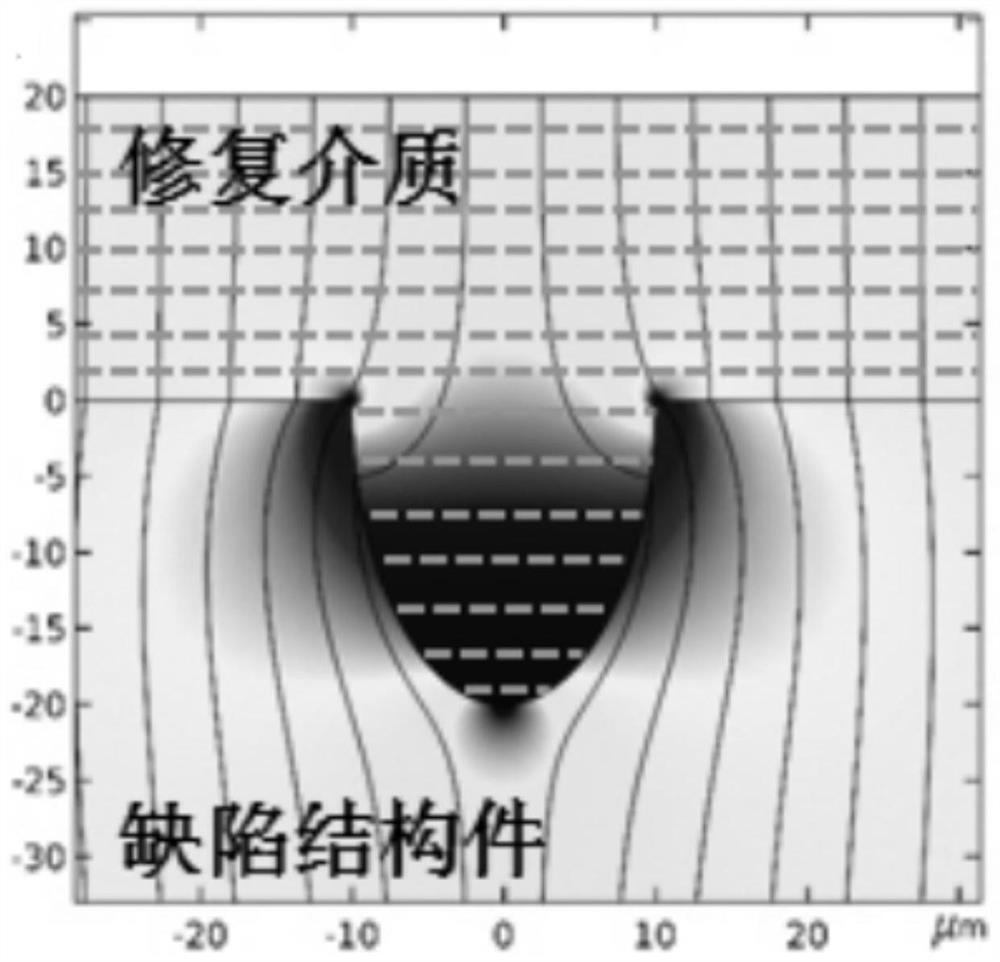

[0048] A repair method of self-detection and healing of metal corrosion defects is used to repair early pitting defects on the surface of stainless steel parts. The base material is 316L stainless steel. The embodiment includes the following steps: (1) Cleaning the surface of the defective workpiece, putting the workpiece to be repaired into alcohol and acetone for ultrasonic cleaning, removing surface impurities, and formulating a repair plan. (2) Select a suitable probe to carry out the restoration experiment, (3) Determine the environmental medium used for restoration, the restoration solution used in this example is 10M / L NaOH solution. (4) Detect and observe the position of the repaired surface. Figure 2-Figure 6 This is the cross-section simulation results of pitting defects with different depths and widths during the finite element simulation process of related 316L stainless steel pitting defects in this embodiment. from Figure 2-Figure 5 It can be seen that when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com