High-strength titanium alloy and preparation method thereof

A titanium alloy and high-strength technology, which is applied in the field of high-strength titanium alloys and their preparation, can solve the problems of short service life of titanium alloy aviation structures and difficulty in meeting industrial service standards in strength level, and achieve the effect of increasing yield strength and tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

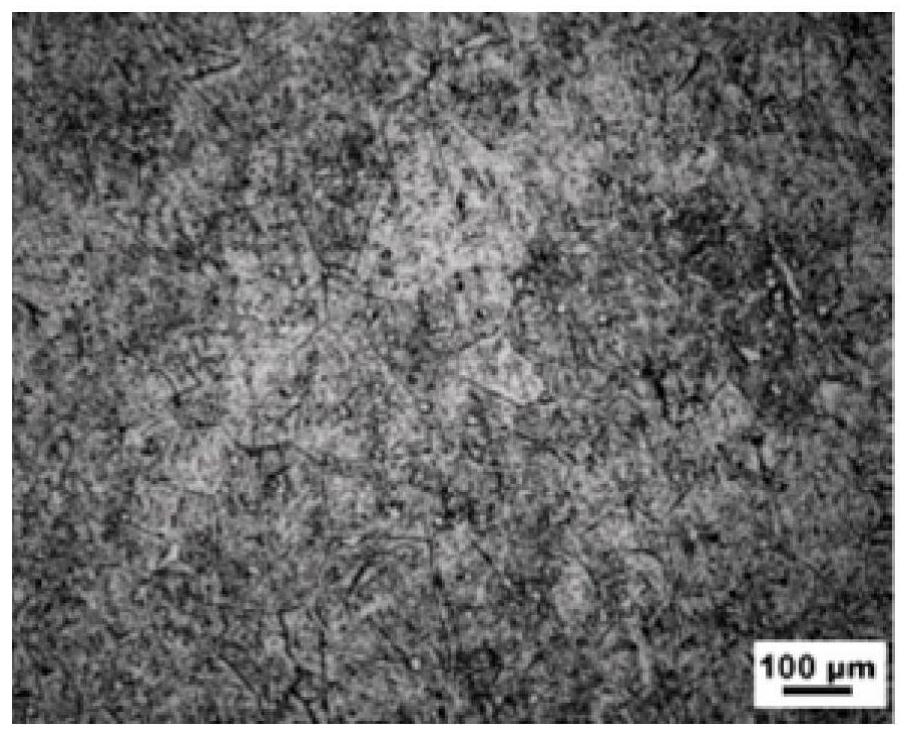

[0035] like figure 1 As shown, the Ti-Al-V-M high-strength titanium alloy of this embodiment, the titanium alloy is composed of the following raw materials by mass percentage: 6% Al, 2% V, 1.5% Mo, 0.5% Zr, The balance is Ti.

[0036] The Ti-Al-V-M high-strength titanium alloy of the present embodiment comprises the following steps:

[0037] (1) Preparation of raw materials

[0038] Prepare materials according to the above components, the purity of the raw materials is higher than 99 wt%, the surface of the above raw materials is polished to remove scale, and then ultrasonically cleaned with acetone and ethanol for 10 minutes, and then accurately weighed according to the mass fraction of each element for alloy melting .

[0039] (2) Alloy melting

[0040] Use a vacuum non-consumable electric arc furnace, place the cleaned raw materials in a water-cooled copper crucible, and place a piece of pure titanium ingot in one of the crucibles, use a mechanical pump to evacuate the ...

Embodiment 2

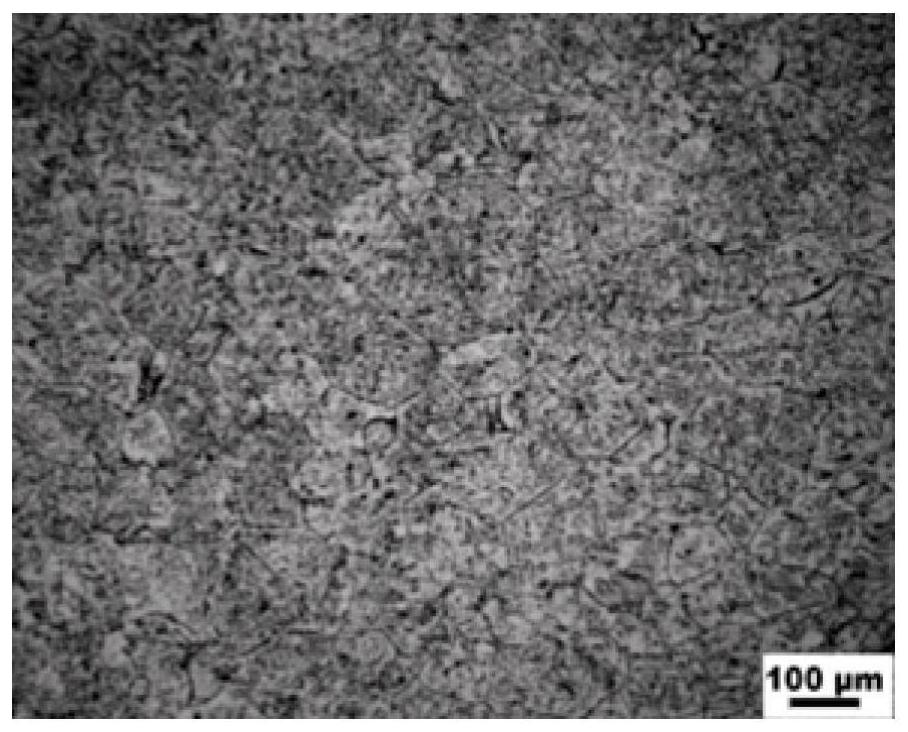

[0043] like figure 2 As shown, the Ti-Al-V-M high-strength titanium alloy of this embodiment, the titanium alloy is composed of the following raw materials by mass percentage: 6% of Al, 1.5% of V, 1.5% of Mo, 0.5% of Sn, 0.5% Zr, the balance is Ti.

[0044] The Ti-Al-V-M high-strength titanium alloy of the present embodiment comprises the following steps:

[0045] (1) Preparation of raw materials

[0046] Prepare materials according to the above components, and the purity of the raw materials is higher than 99 wt%. The surface of the above raw materials is polished to remove scale, and then ultrasonically cleaned with acetone and ethanol for 15 minutes, and then accurately weighed according to the mass fraction of each element for alloy smelting .

[0047] (2) Alloy melting

[0048]Use a vacuum non-consumable electric arc furnace, place the cleaned raw materials in a water-cooled copper crucible, and place a piece of pure titanium ingot in one of the crucibles, use a mech...

Embodiment 3

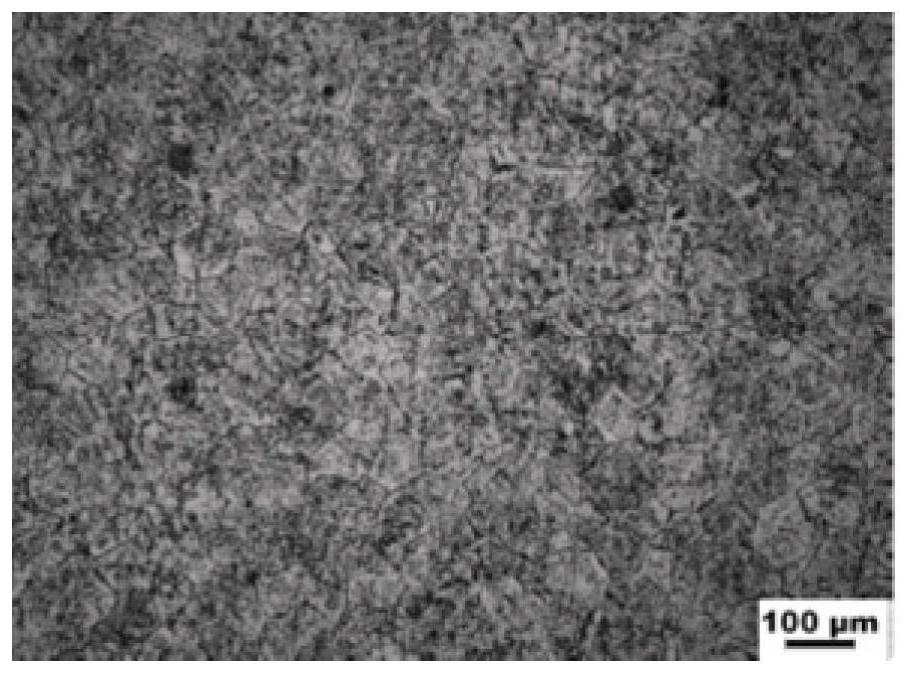

[0051] like image 3 As shown, the Ti-Al-V-M high-strength titanium alloy of this embodiment, the titanium alloy is composed of the following raw materials by mass percentage: 6% Al, 2% V, 1% Ni, 0.5% Sn, 0.5% Zr, the balance is Ti.

[0052] The Ti-Al-V-M high-strength titanium alloy of the present embodiment comprises the following steps:

[0053] (1) Preparation of raw materials

[0054] Prepare materials according to the above components, the purity of the raw materials is higher than 99 wt%, the surface of the above raw materials is polished to remove scale, and then ultrasonically cleaned with acetone and ethanol for 6 minutes, and then accurately weighed according to the mass fraction of each element for alloy melting .

[0055] (2) Alloy melting

[0056] Use a vacuum non-consumable electric arc furnace, place the cleaned raw materials in a water-cooled copper crucible, and place a piece of pure titanium ingot in one of the crucibles, use a mechanical pump to evacuat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com