Coating-free ocean atmospheric corrosion resisting high-strength bolt steel for bridge structure and manufacturing method

A technology for bridge structures and high-strength bolts, which is applied in the manufacture of high-strength bolt steels resistant to marine atmospheric corrosion, and the processing and manufacturing of high-strength bolts with bolt specifications M16-30mm weather-resistant. High cost of coating and other problems, to achieve the effect of excellent resistance to marine atmospheric corrosion and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention adopts 200mm 2 The rolling of continuous casting slabs to produce Φ16, 24 and 30mm straight bars has been applied, and the downstream bolt processing plants have made bolts and then quenched and tempered to obtain excellent performance.

[0018] 1, design steel chemical composition and corrosion resistance index I are shown in Table 1 in the specific embodiment;

[0019] 2. The hot-rolled material for high-strength bolts is used for high-speed rolling, and the rolling specification is

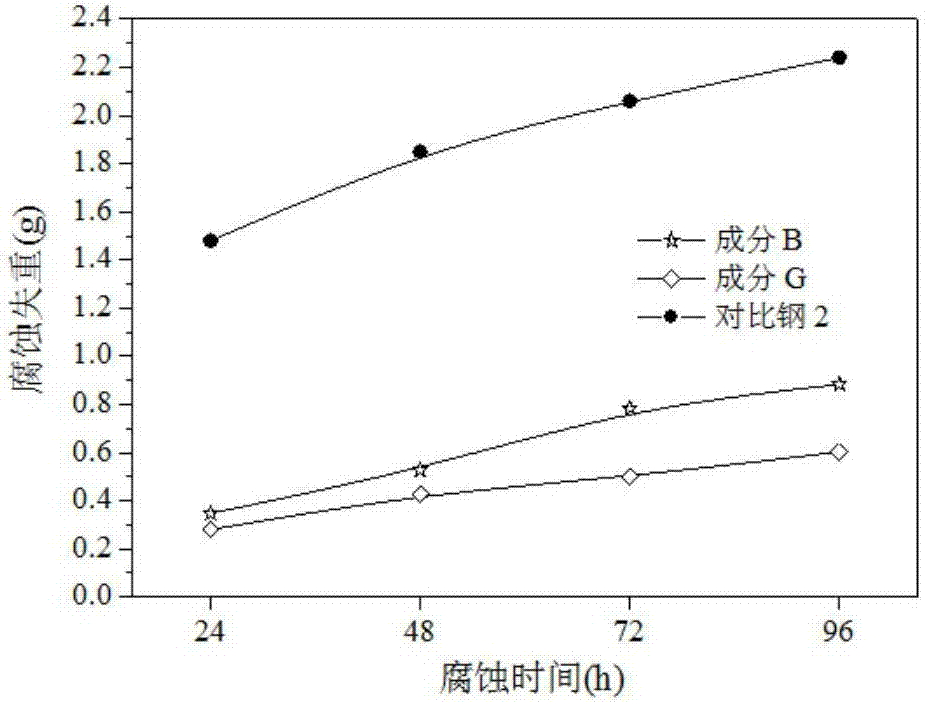

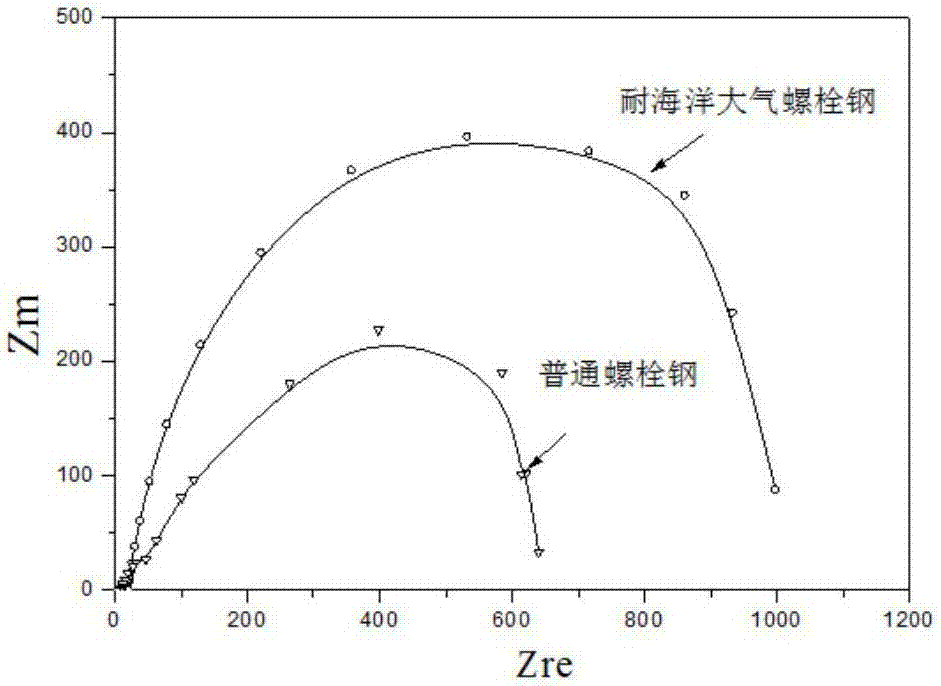

[0020] 3. After the bolts are made into bolts by the bolt processing plant, the quenching and tempering heat treatment process system: oil quenching at 880-920°C + tempering at 380-625°C. The mechanical properties and corrosion rate obtained after the optimized control of the heat treatment system of the rolled material are shown in Table 2. After being processed into M16-30 specification bolts by the user's bolt factory, the properties after quenching and temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com