Airtightness detection tool for castings

A technology of air tightness detection and tooling, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by detecting the appearance of fluid at the leakage point, etc., which can solve the problem of delaying production schedule, increasing production cost, oil leakage of parts or Air leakage and other issues can be reduced to reduce adjustment time, improve production efficiency, and reduce processing and assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention is further described below, but the scope of protection is not limited to the above.

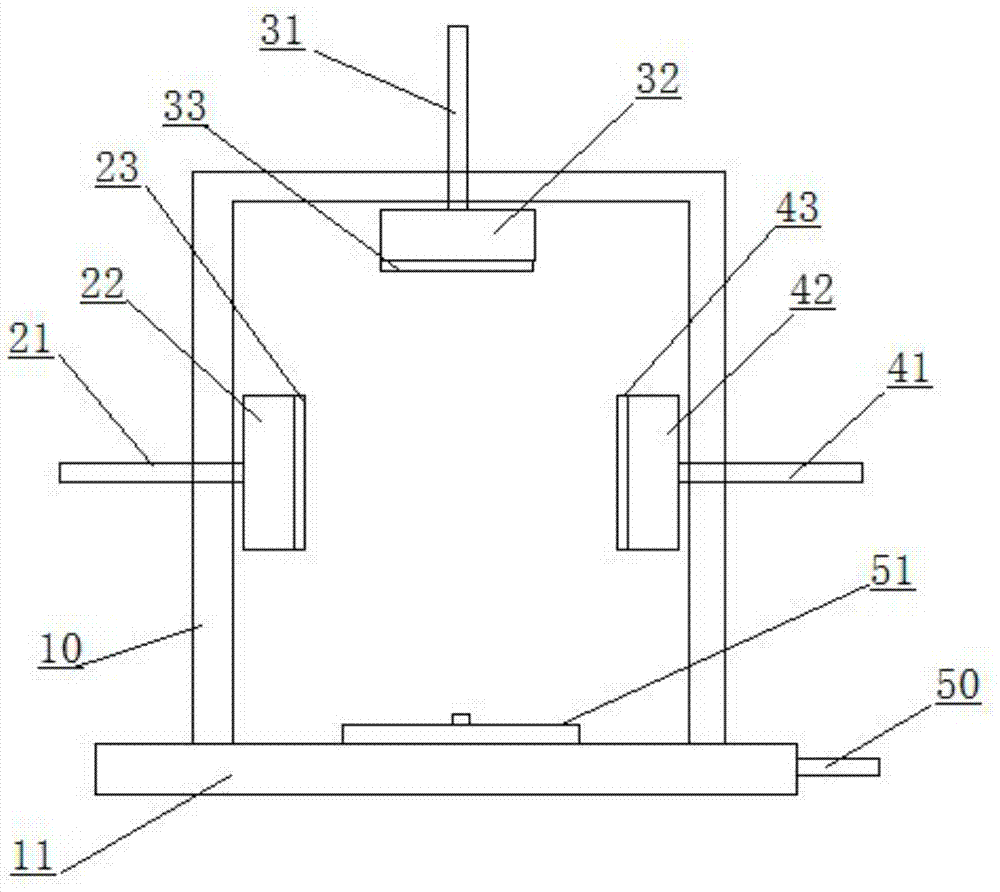

[0015] Such as figure 1 Shown is a casting air tightness testing tool; including bracket 10, base 11, trapezoidal screw A21, spacer A22, trapezoidal screw B31, spacer B32, trapezoidal screw C41, spacer C42, vent tube 50, of which bracket 10 It is an integrated structure with the base 11. The spacer block A22 is installed at the left end of the bracket 10 through the trapezoidal screw A21, and the spacer block A22 can move left and right under the spiral rotation of the trapezoidal screw A21; the spacer block B32 is installed on the bracket 10 through the trapezoidal screw B31 The top, and the spacer block B32 can move up and down under the spiral rotation of the trapezoidal screw B31; the spacer block C42 is installed on the right end of the bracket 10 through the trapezoidal screw C41, and the spacer block C42 can move left and right under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com