Dual-purpose continuous grinding machine for planar and angular stone lines

A stone and line technology, which is applied in the field of continuous mills, can solve problems such as poor mechanical strength, troublesome construction, and inability to grind stone lines at corners, and achieve the effects of reducing purchase costs, improving processing efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

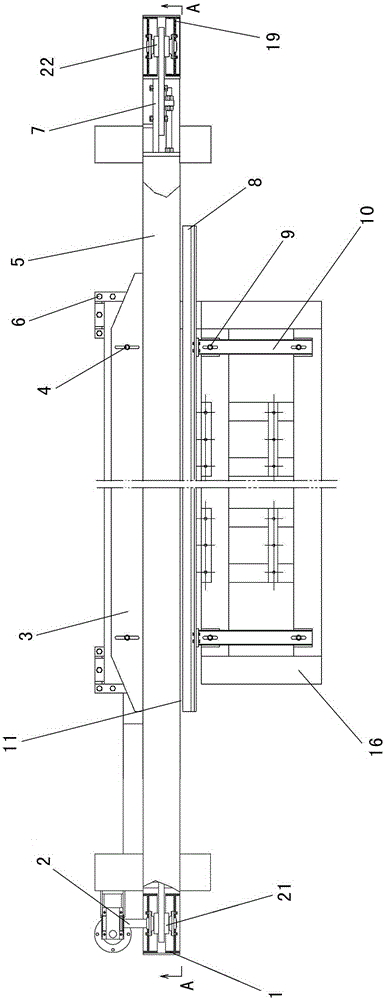

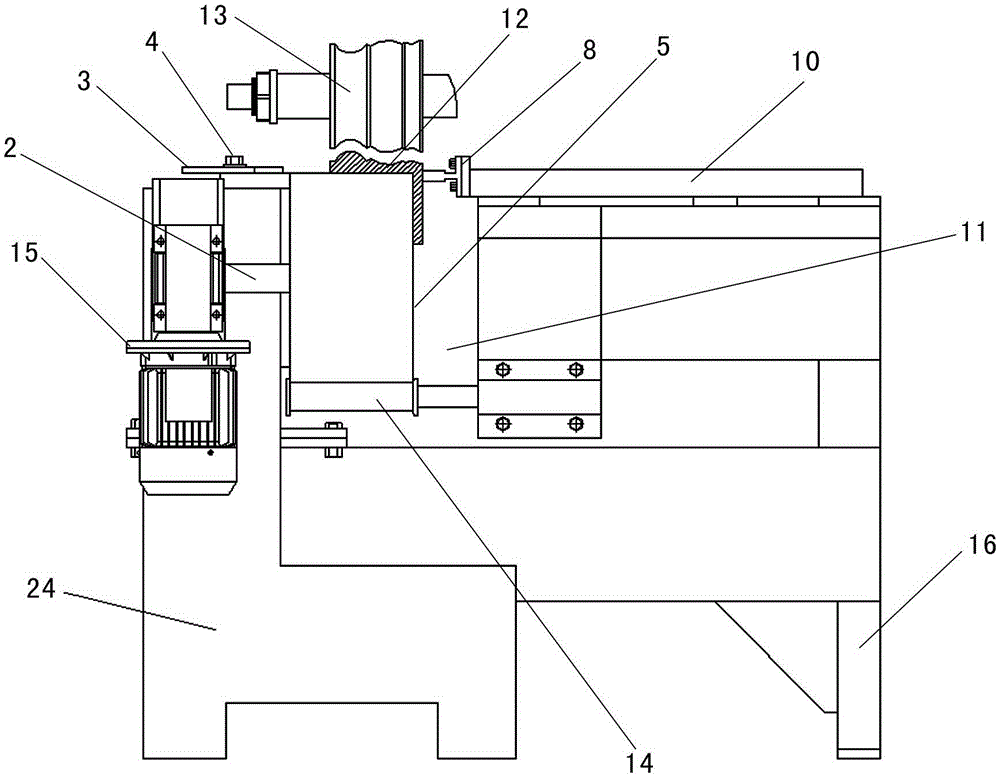

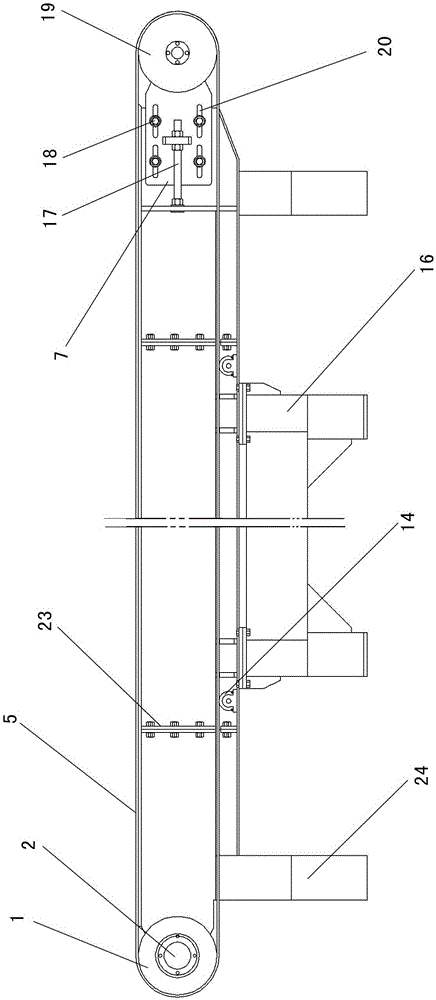

[0016] Referring to each figure, the existing conveyor belt type stone grinding machine is modified, and the corner stone positioning support plate 8 is arranged on the side opposite to the flat grinding adjustment support plate 3 of the conveyor belt, and the corner stone positioning support plate 8 and the conveyor belt 5 A drooping gap 11 is adjusted between them, so that the other side of the corner stone 12 can hang down in the gap 11, so that it is suitable for corner stone processing of various common sizes; a tension mechanism 7 is arranged on the driven wheel 19 to ensure The conveyor belt 5 can move well; the driving wheel rotating bearing 21 and the driven wheel rotating bearing 22 of the driving wheel 1 and the driven wheel 19 are all arranged between the upper and lower conveyor belts 5 respectively, so that the corner stone material 12 will not be affect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com