Dynamic absorber frequency testing method

A technology of a dynamic vibration absorber and a test method, which is applied to vibration measurement in solids, vehicle suspension/shock absorption mechanism testing, instruments, etc. Considering the temperature and other issues, the effect of improving R&D efficiency and shortening the time period of trial production and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

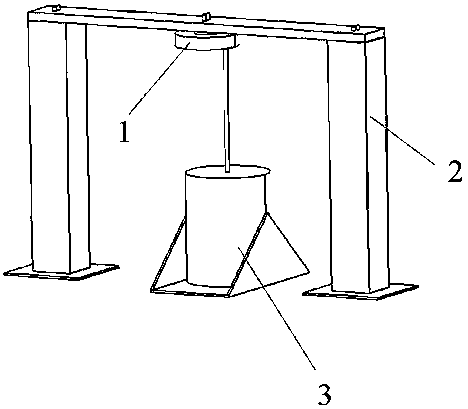

[0034] Example: see Figure 1 to Figure 10 .

[0035] A method for testing the frequency of a dynamic vibration absorber, the characteristic steps of which are as follows:

[0036] Step 1: Use the dynamic vibration absorber modal test bench 2 to simulate the boundary conditions of the dynamic vibration absorber on the vehicle, including temperature and excitation force, and test its comprehensive frequency response on the dynamic vibration absorber modal test bench 2 The function SUM, the operation steps are as follows:

[0037] (1) First determine the parts of the test vehicle that produce low-speed roar in the power transmission system, then determine the natural frequency of the parts, and assemble the dynamic vibration absorber 1 that needs to be tested and modulated at the parts;

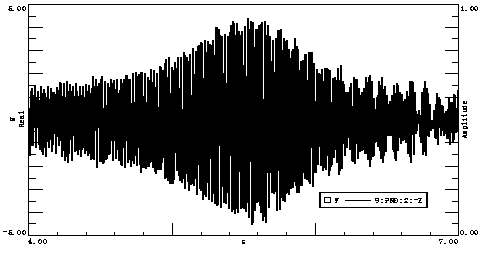

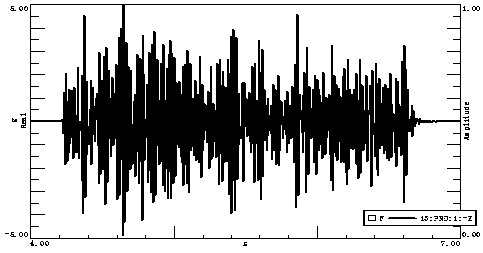

[0038] (2) An acceleration vibration sensor and a near-field temperature sensor are arranged on the dynamic vibration absorber 1 to collect the acceleration time-domain signal and near-field ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com