Fabricated floor structure module and manufacturing method thereof

A structural module and prefabricated technology, applied in the direction of floor slabs, building components, building structures, etc., can solve the problems of destroying the environmental protection and tidy environment of steel structure processing plants, increasing the complexity of transportation, and increasing the weight of transportation, so as to ensure deformation. Integrity and integrity of force transmission, avoidance of environmental problems, effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

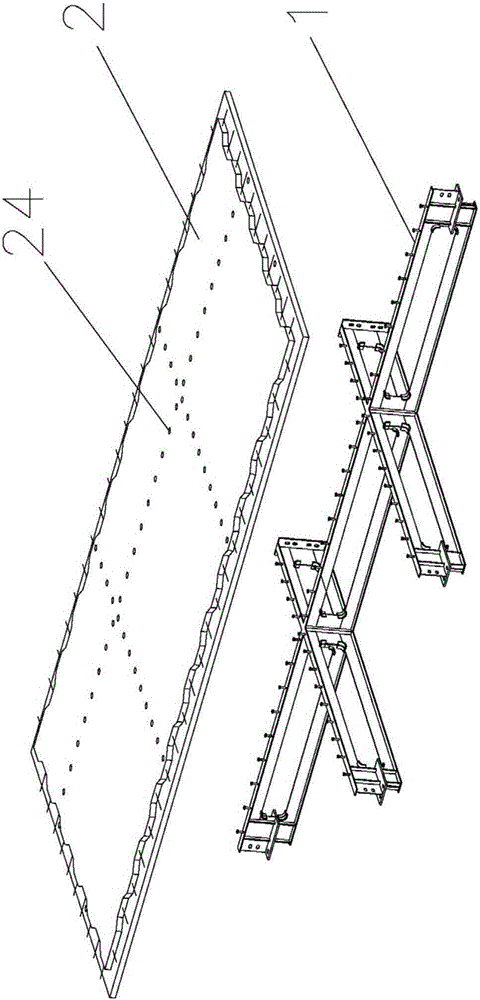

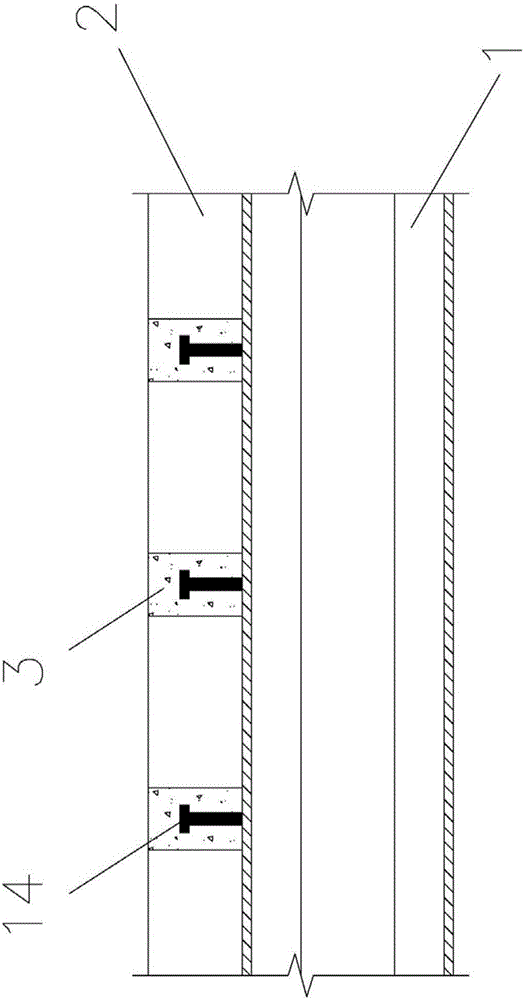

[0033] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention is an assembled floor structure module, which is composed of a hollow steel truss unit 1 and a prefabricated partially laminated floor 2.

[0034] Among them, the upper surface of the hollow steel truss 1 is provided with a number of shear bolts 14; the prefabricated partial laminated floor 2 is supported on the hollow steel truss 1, and there are several through holes 24 therethrough; the shear bolts The nails 14 are inserted into the through holes 23 of the prefabricated partially laminated floor 2; the micro-expansion concrete 3 is filled in the through holes 24, and the shear studs 14 are buried.

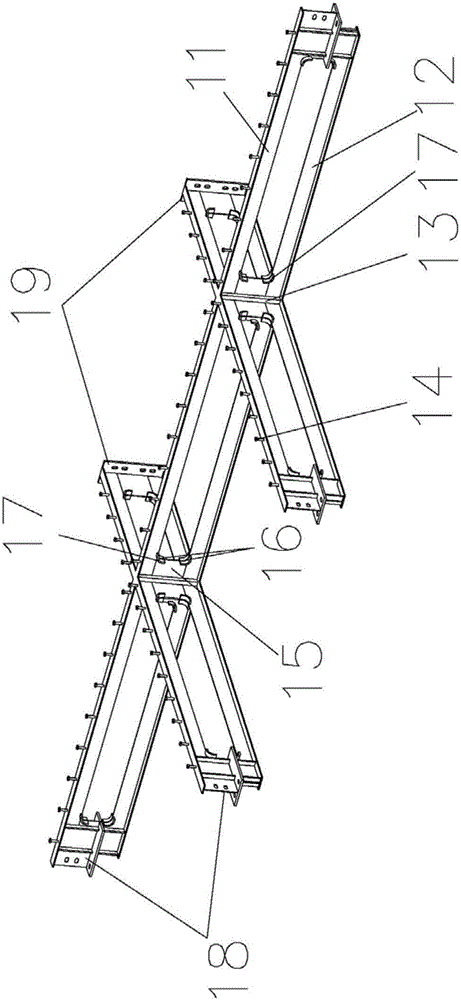

[0035] Further, the hollow steel truss unit 1 is composed of steel hollow truss intersections, and is manufactured in a steel structure processing factory. The steel hollow truss includes an upper chord 11, a lower chord 12 and a vertical web 13; the upper chord 11 and the lower ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com