Flame-retardant electrolyte for secondary lithium-sulfur battery and preparation method for flame-retardant electrolyte

A lithium-sulfur battery and electrolyte technology, applied in the field of secondary lithium-sulfur battery flame-retardant electrolyte and its preparation, can solve the problems of weakening battery safety, low boiling point, flammability, etc., and achieve improved cycle stability and rate Discharge capability, high-safety electrochemical performance, and the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

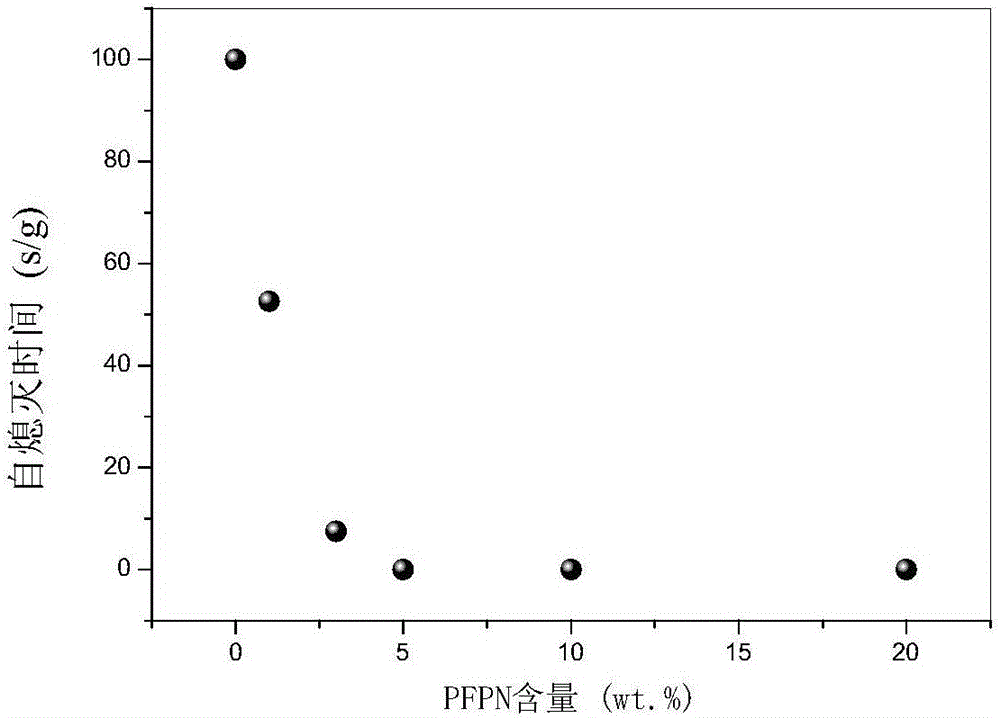

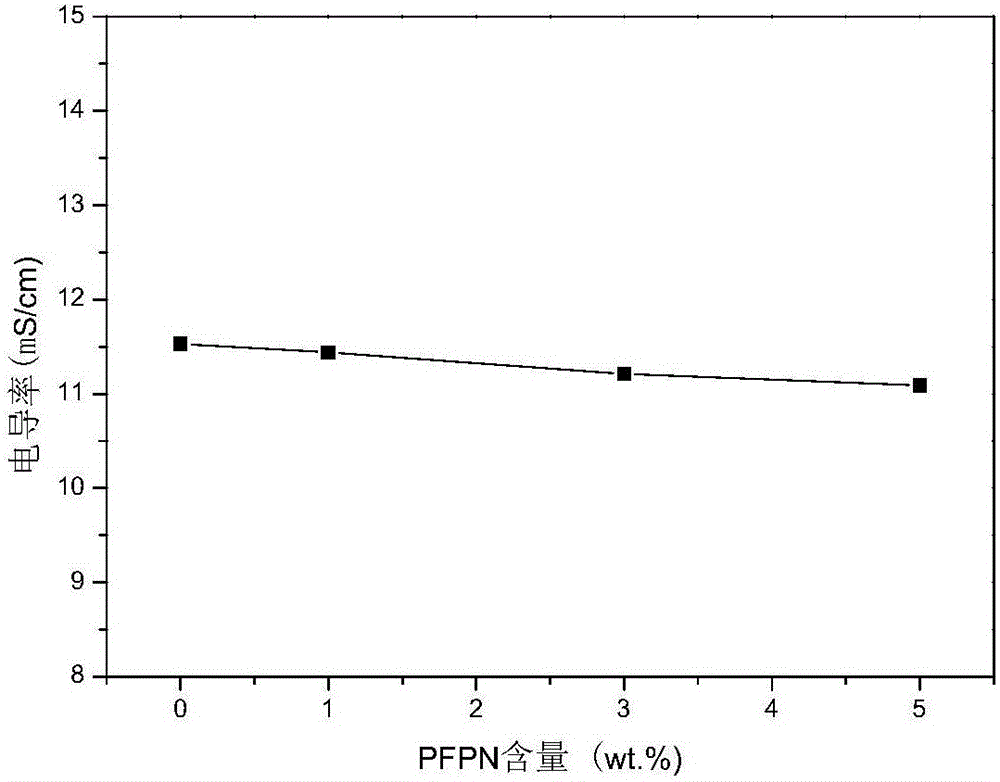

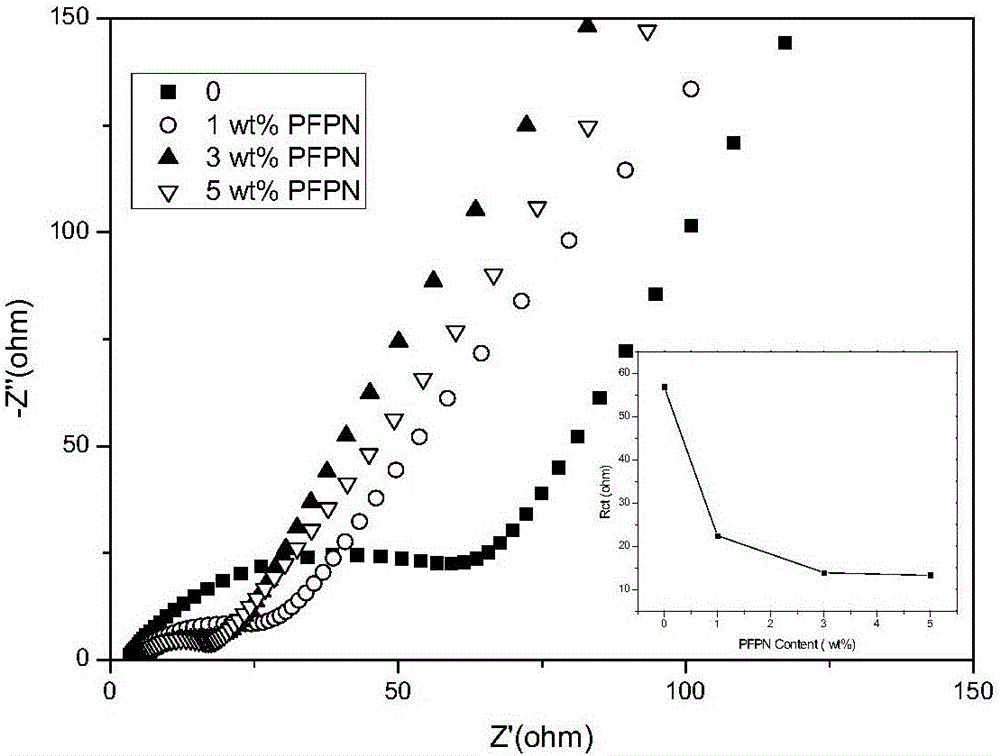

[0029] In the glove box, ethylene carbonate and ethyl methyl carbonate were uniformly mixed at a volume ratio of 1:1, LiPF6 was added to the mixed solvent, and stirred evenly to prepare an electrolyte solution with a concentration of 1mol / L. Add flame retardant ethoxyl (pentafluoro) cyclotriphosphazene to this electrolyte solution again, obtain flame retardant electrolyte solution, described flame retardant accounts for the mass percentage content of total weight of electrolyte solution to be respectively 0.1%, 1%, 3%, 5%, 10%, 20%.

Embodiment 2

[0031] Mix fluoroethylene carbonate, propylene carbonate and ethylene glycol diethyl ether uniformly in the glove box at a volume ratio of 1:1:1, and add LiN(FSO 2 ) 2 and LiN(CF 3 SO 2 ) 2 , and stir evenly to make an electrolyte solution with a concentration of 0.5mol / L. Add flame retardant propoxyl (pentafluoro) cyclotriphosphazene to this electrolyte solution again, obtain flame retardant electrolyte solution, the mass percent content of described flame retardant accounting for electrolyte total weight is respectively 0.1%, 1%, 3%, 5%, 10%, 20%.

Embodiment 3

[0033] Mix dioxane and diethylene glycol diethyl ether uniformly in a volume ratio of 1:1 in the glove box, and add LiBC to the mixed solvent 2 o 4 f 2 , and stir evenly to make an electrolyte solution with a concentration of 5mol / L. Then add the flame retardant phenoxy (pentafluoro)cyclotriphosphazene to the electrolyte to obtain a flame retardant electrolyte, and the mass percentage of the flame retardant to the total weight of the electrolyte is 0.1%, 1%, and 3% respectively , 5%, 10%, 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com