Electromagnetic auxiliary stamping incremental forming process for thin-wall curved-surface light alloy component

A light alloy, incremental forming technology, applied in the field of electromagnetic-assisted stamping incremental forming process of thin-walled curved light alloy components, can solve the problems of easy cracking, high sealing requirements, and large post-spin residual stress, etc., to achieve improved Microstructure uniformity and formability, good flexibility and expandability, and the effect of improving the forming limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

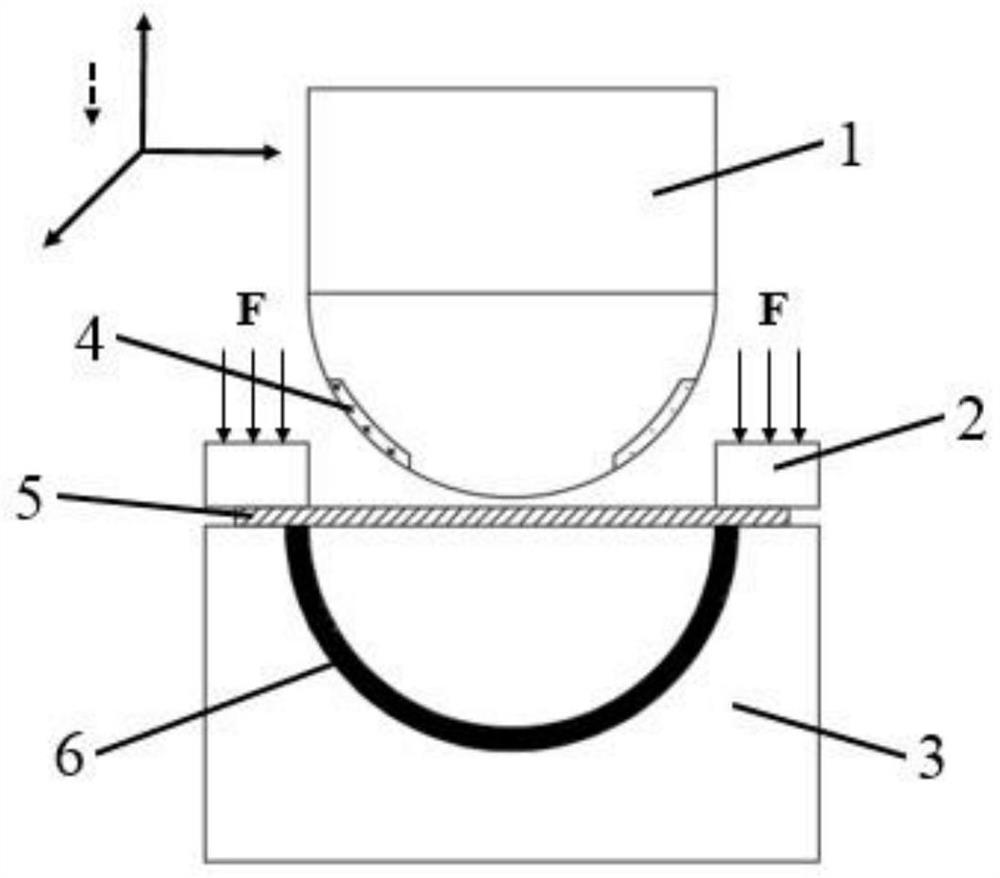

[0036] For the high-strength alloy after heat treatment, place it on the mold platform 3, fix it with the clamping system 2, move the punch 1 embedded with the driving forming coil 4 to make it go down until the punch 1 and the plate to be formed The material 5 is just in contact with each other, and it is pre-deformed by punch 1 as a whole, and the pre-deformation amount is 10-30% of the total deformation amount. In places where the local fluidity is not good, the capacitor bank is used to realize charging and discharging, so that the formed coil 4. With a pulse current of 20-100kA, the forming coil 4 embedded in the punch 1 is used to discharge to form a strong pulse Lorentz force, and the pre-deformed sheet is punched at high speed, so that the sheet to be formed 5 is locally deformed at a high speed , so as to complete the final shape of the part. If the final shape requirements of the parts are not met, the forming coil 4 can be discharged again to perform electromagnetic...

Embodiment 2

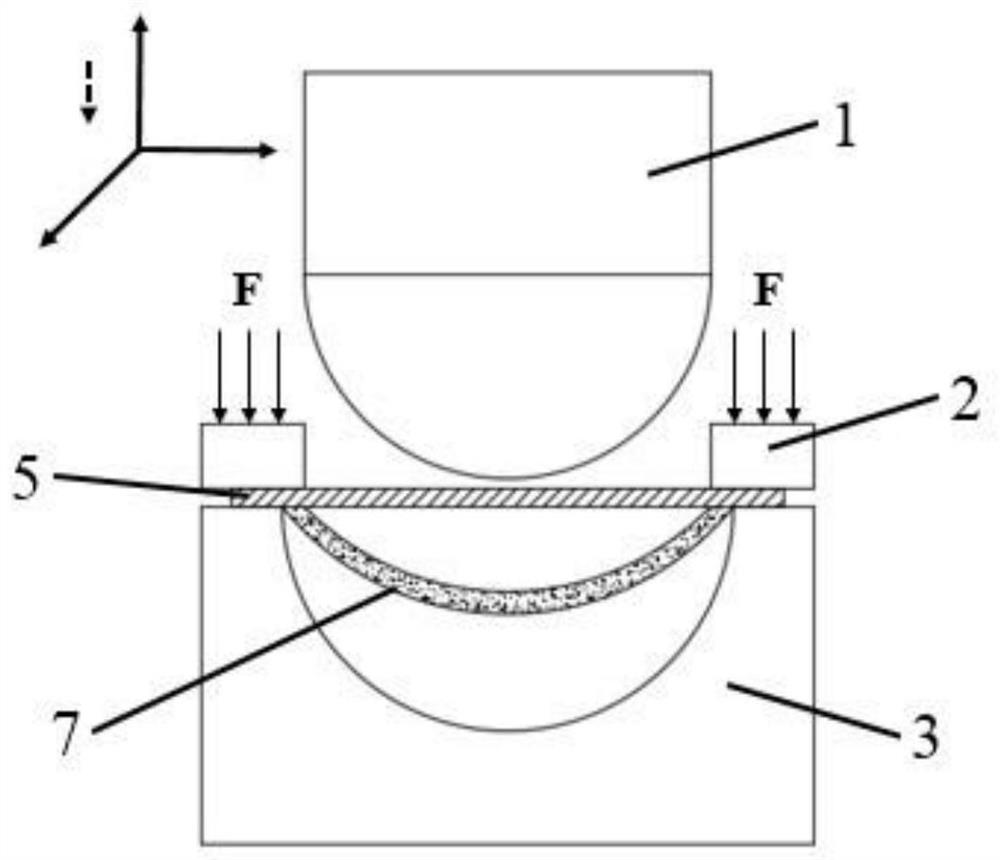

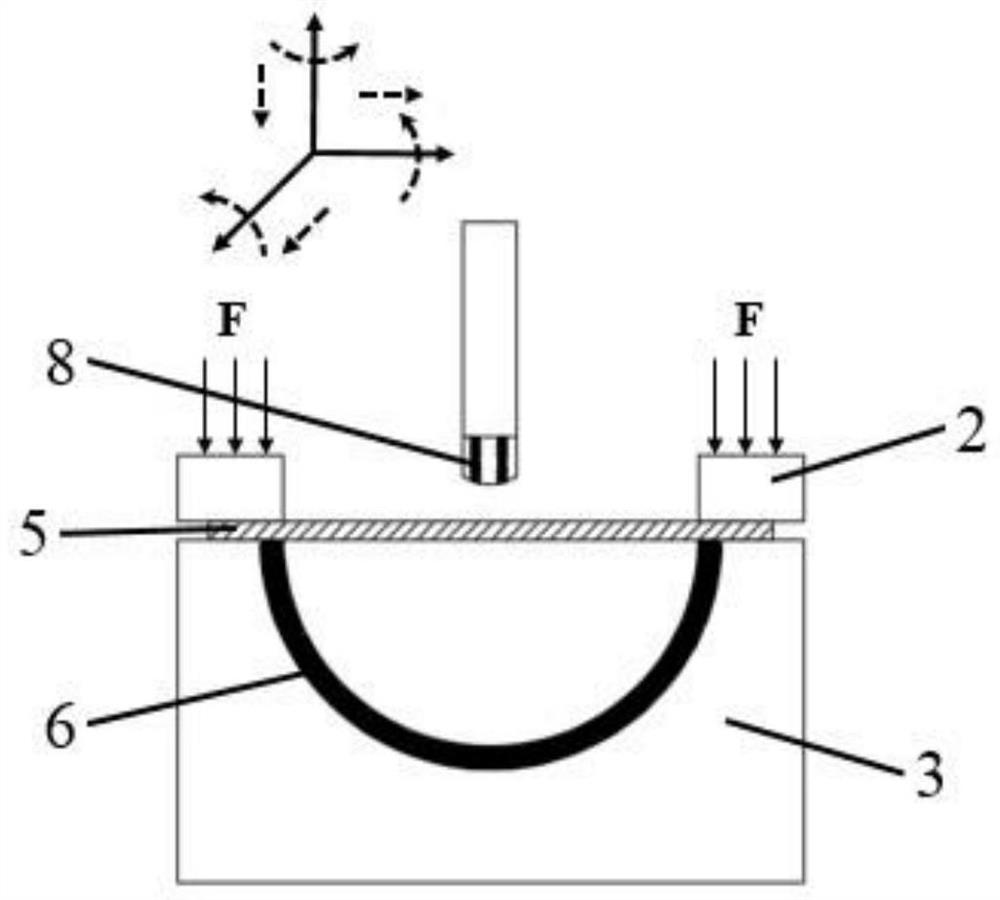

[0038] For the high-strength alloy after heat treatment, place it on the mold platform 3, fix it with the clamping system 2, move the punch 1 to make it go down, until the punch 1 and the sheet material 5 to be formed are just in contact with each other. Pre-deformed by punch 1 as a whole, the amount of pre-deformation is 10-30% of the total deformation, and the pre-stamped sheet 7 is obtained. The specific forming schematic diagram is shown in Fig. Replace it with one or more flexible coils 8 that can move and rotate along three axes. According to the preset trajectory, the flexible coils 8 are discharged along the trajectory in turn to form a strong pulse Lorentz force, and the pre-deformed sheet is stamped at high speed. , compared with the traditional punch 1, the flexible coil 8 is smaller in size and more flexible. It is gradually formed through multi-pass coil superposition and discharge until it meets the shape accuracy requirements of the part. The specific forming sch...

Embodiment 3

[0040]First, the overall stamping and pre-deformation, followed by solid solution single-stage aging or solid solution double-stage aging heat treatment, and then use the coil placed in the punch, or one or more small flexible follow-up coils, discharge to form a strong Lorentzian pulse Force, high-speed impact stamping the pre-deformed sheet, multi-pass electromagnetic progressive forming, until the shape accuracy requirements of the parts are met. The specific processing process of molding scheme three is as follows: Figure 4 shown.

[0041] Electromagnetic-assisted stamping progressive forming can actively control the local forming of the sheet to be formed by changing the layout and moving track of the driving forming coil. The strength and toughness of the alloy realize the integrated and precise forming tonality of large thin-walled curved surface components of light alloys.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com