Weather-resistant hot-rolled H-shaped steel with yield strength being 650 MPa or above and manufacturing method thereof

A technology with a yield strength of 650mpa, which is applied in the field of weathering hot-rolled H-beams with a yield strength of 650MPa and above for marine engineering and its manufacturing field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following specific examples are given to illustrate the present invention. It should be pointed out that the examples are only used to further illustrate the present invention, and do not limit the protection scope of the present invention, and non-essential modifications and adjustments made by others according to the present invention still belong to the protection scope of the present invention.

[0049] The continuous casting slabs in the following examples are all prepared according to the following process flow or the aforementioned process, and the processes not mentioned in the present invention can adopt the prior art.

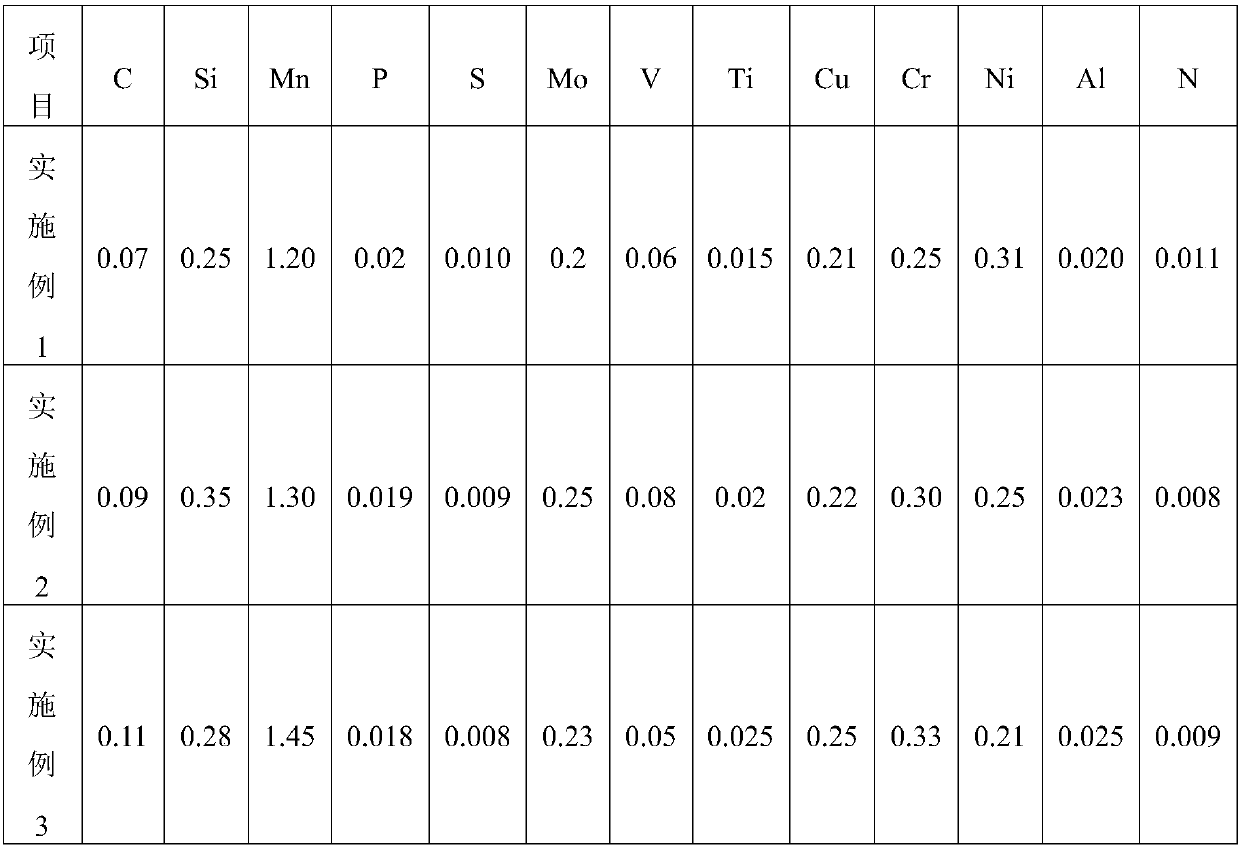

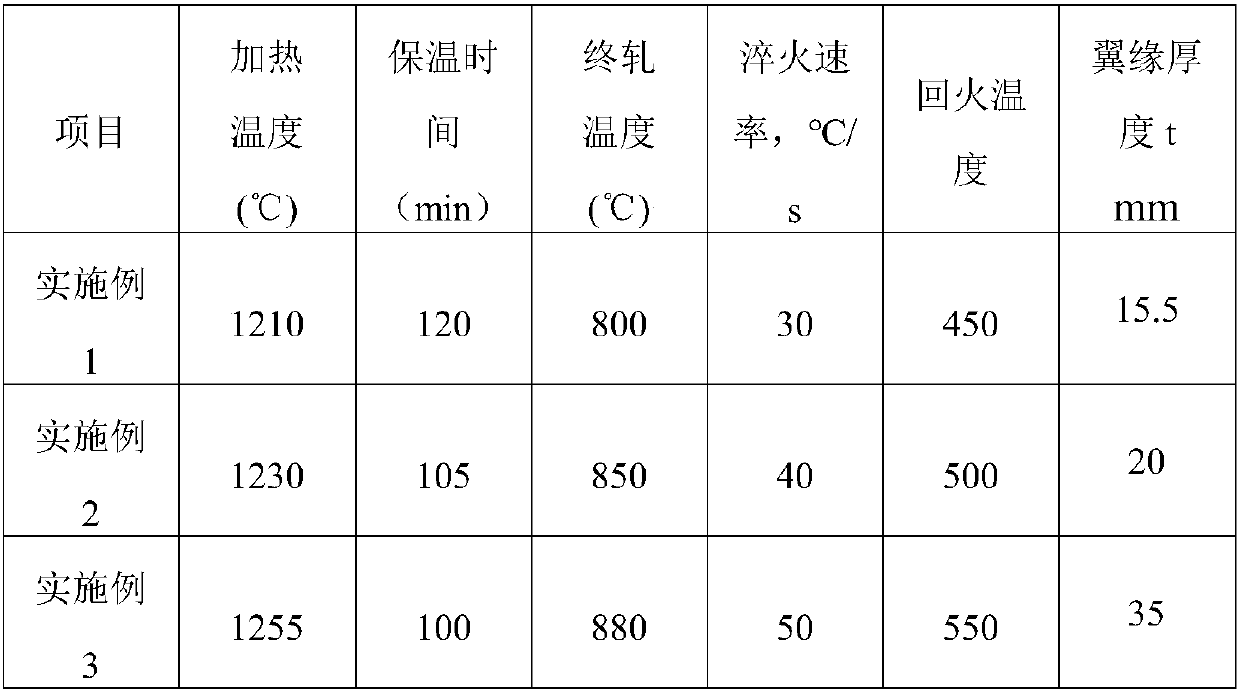

[0050] In the following examples, according to the set chemical composition range (Table 1), the chemical composition C, Si, Mn, S, P and Fe are used as raw materials for converter smelting, refining, continuous casting, and direct heating or soaking of the slab. The preparation steps of embodiment 1-3 are as follows:

[0051] 1. Pre-desul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com