Current-aided flexible pressing roll stretch-forming method for titanium alloy and pressing roll stretch-forming device

A pressing roller device and technology of titanium alloy, applied in the field of pressing roller drawing device and current-assisted flexible pressing roller drawing titanium alloy, can solve the problem of unsuitability for mass production, low heating efficiency of pressing roller drawing titanium alloy, and production process. Low efficiency and other problems, to achieve the effect of improving heating efficiency and energy utilization, simple structure and perfect function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

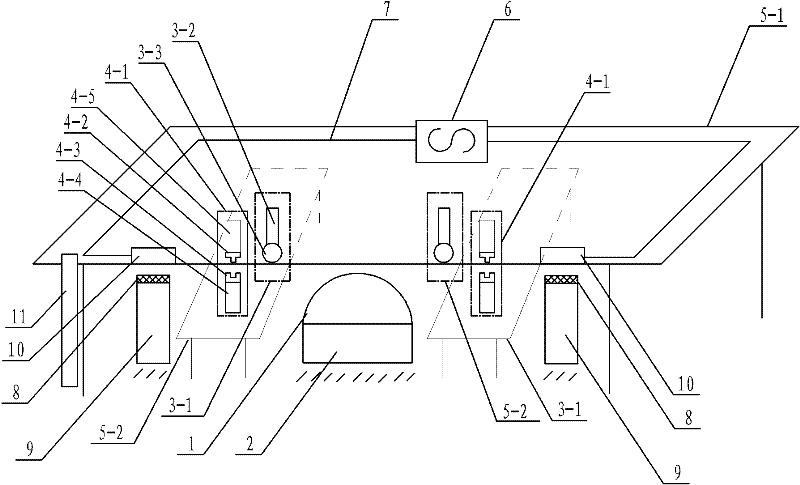

[0016] Specific implementation mode one: combine figure 1 Describe this embodiment, a kind of current-assisted flexible pressure roller drawing method of titanium alloy of this embodiment is as follows:

[0017] Step 1: Select a current of 1000A-20000A according to the cross-sectional size and resistance data of the billet to be formed;

[0018] Step 2: Place the outer edge of the blank to be formed between the electrode 10 and the insulating plate 8, the insulating plate 8 is kept insulated from the blank to be formed, and pressurize the blank to be formed through the lifting cylinder 9, so that the electrode 10 is in contact with the blank to be formed and The insulating plates 8 are in contact with each other. At this time, power on and heat, and the heating rate is 5-20°C / s;

[0019] Step 3: Measure the temperature of the billet to be formed in real time by the infrared thermometer 11, and adjust the output current of the power supply in real time according to its tempera...

specific Embodiment approach 2

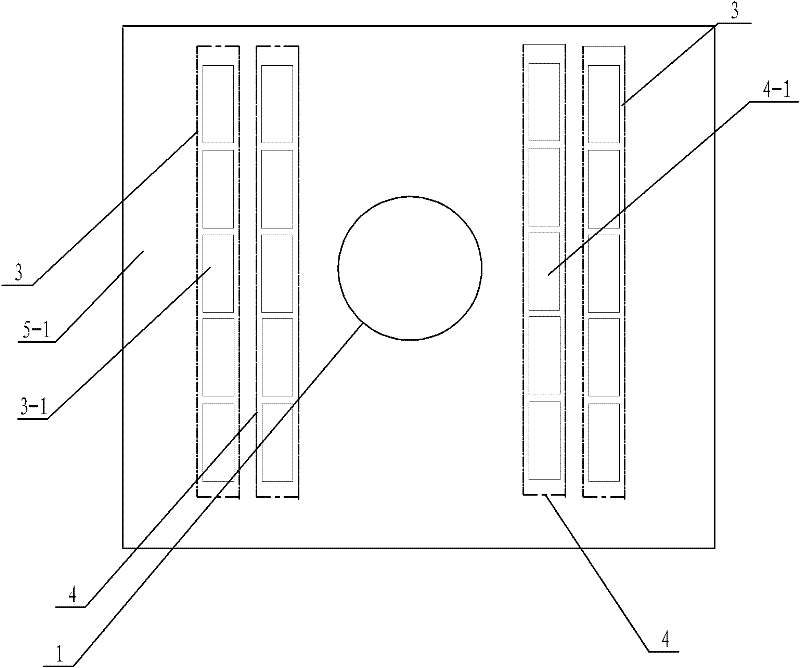

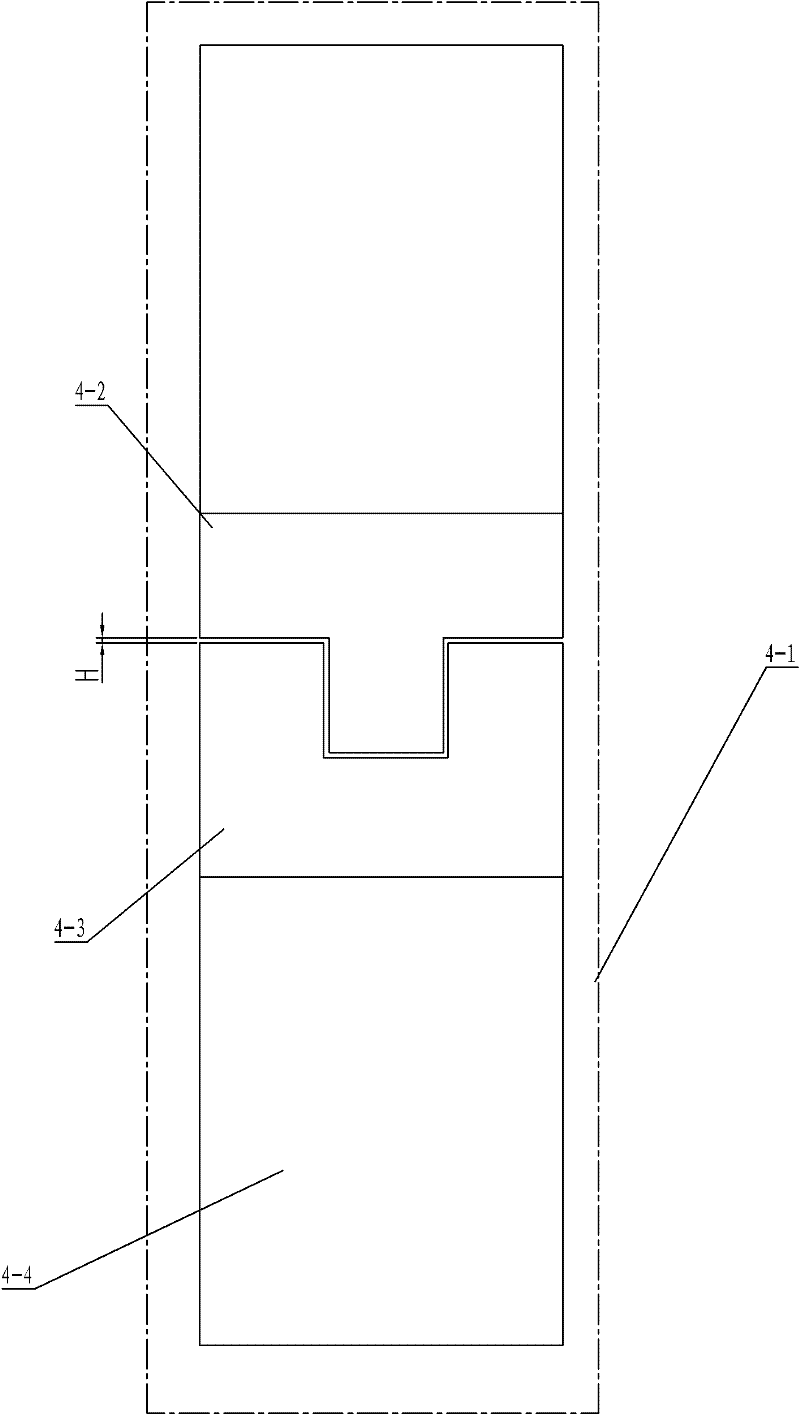

[0022] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment mode, a kind of device of current-assisted flexible pressure roller drawing titanium alloy of this embodiment mode, it comprises drawing die 1, support platform 2, upper workbench 5-1, lower workbench 5-2, two groups Pressing roller device 3 and two sets of edge-holding devices 4, the drawing die 1 is fixedly installed on the support platform 2, the upper working table 5-1 is arranged above the drawing die 1, and the lower working table 5-2 is arranged on the drawing die On both sides of 1, the pressure roller device 3 is arranged in a straight line on the upper workbench 5-1, and the pressure roller device 3 is located outside the drawing die 1, and the edge pressing device 4 is arranged on the upper workbench 5-1 and the lower workbench 5-2, and the edge-holding device 4 is arranged on the outside of the pressing roller device 3, the current-assisted flexible pressing roller...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 The present embodiment is described. The insulating plate 8 of the present embodiment is made of mica sheet, ceramic or asbestos rubber plate. With such setting, the insulation effect is good. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com