Porosity testing tool and testing method thereof

A technology for testing tooling and testing methods, which is applied in measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., and can solve problems such as poor accuracy of porosity testing, springback of electrode sheets or diaphragms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A test method for porosity, comprising:

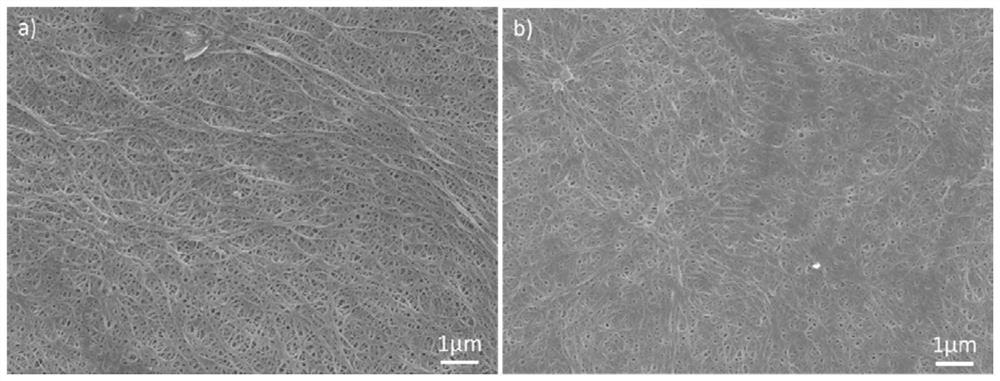

[0052] Take a fresh separator (referring to the separator that has not been assembled into a battery, the thickness is 14 μm, and the thickness of the PE base film is 9 μm, Al 2 o 3 The thickness of the ceramic layer is 3 μm, and the thickness of PVDF coated on both sides is 1 μm) as the sample to be tested, which is soaked in dimethyl carbonate (DMC) for 20 minutes, cleaned and dried. Fold the above-mentioned fresh septum in half, and ensure that the septum is flat.

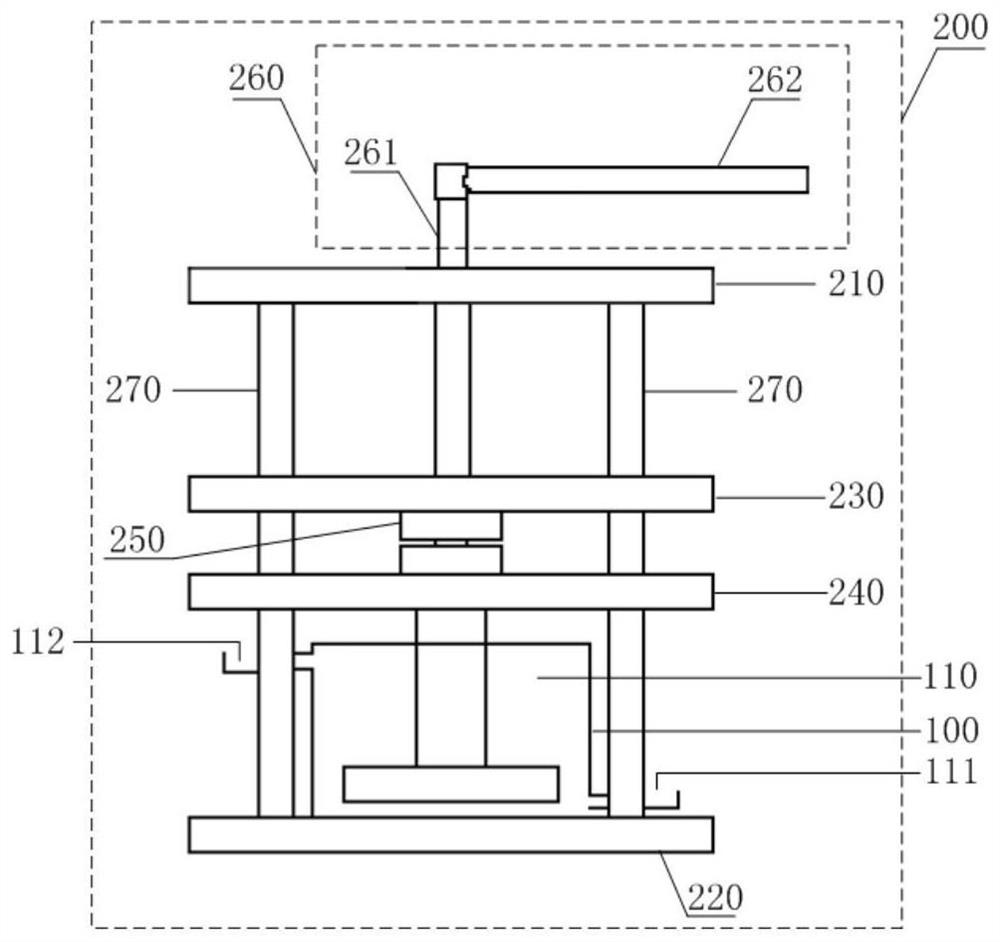

[0053] Such as figure 1In the schematic diagram of the porosity test tooling structure shown, the folded sample to be tested is placed in the chamber 110 of the liquid nitrogen quenching part 100, and pressure is applied through the torque wrench 260, and the pressure value is observed. When the applied pressure reaches 3000N, Keep it for 5 minutes. At this time, the porosity test tool shows that the pressure is 2542N. Continue to increase the pressure to make ...

Embodiment 2

[0057] The difference from Example 1 is that the applied pressure is 1000N.

Embodiment 3

[0059] The difference from Example 1 is that the applied pressure is 5000N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com