Press-formed product

A technology for stamping and forming products, applied in the field of stamping and forming products, can solve problems such as defects and decline in yield, and achieve the effects of suppressing springback, improving fuel efficiency, and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0138] The present invention will be described more specifically with reference to examples.

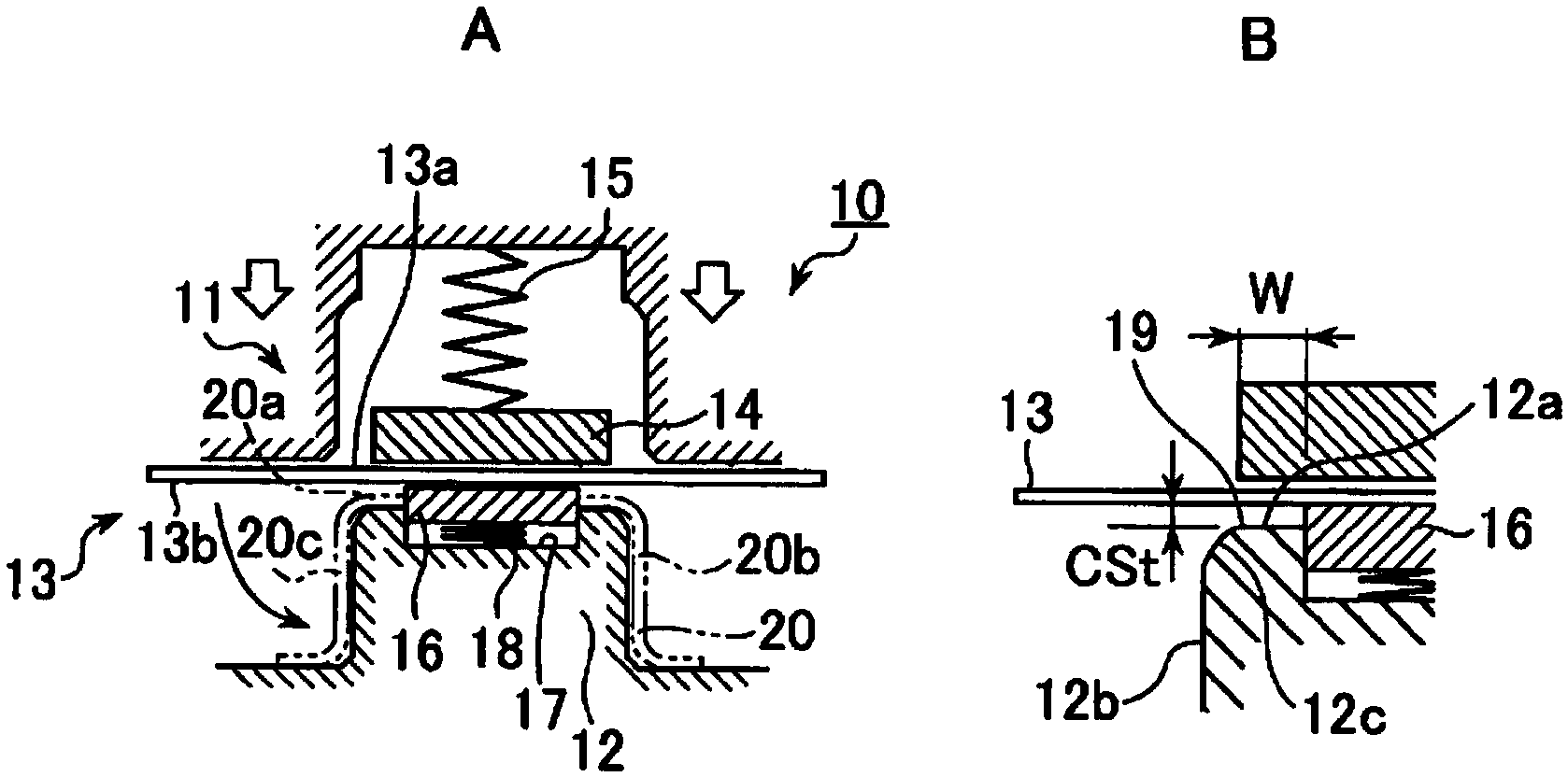

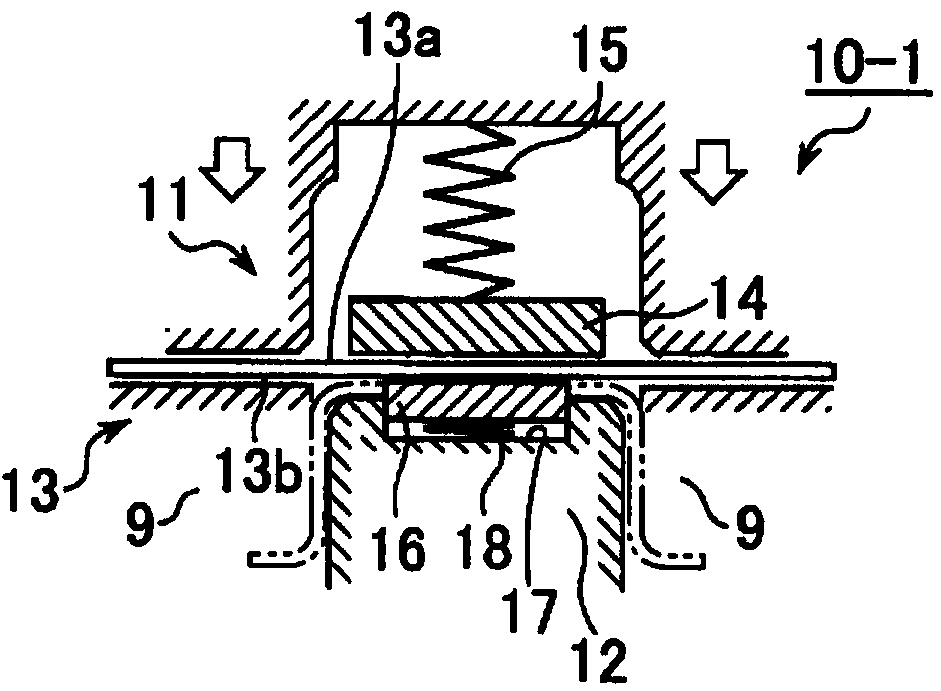

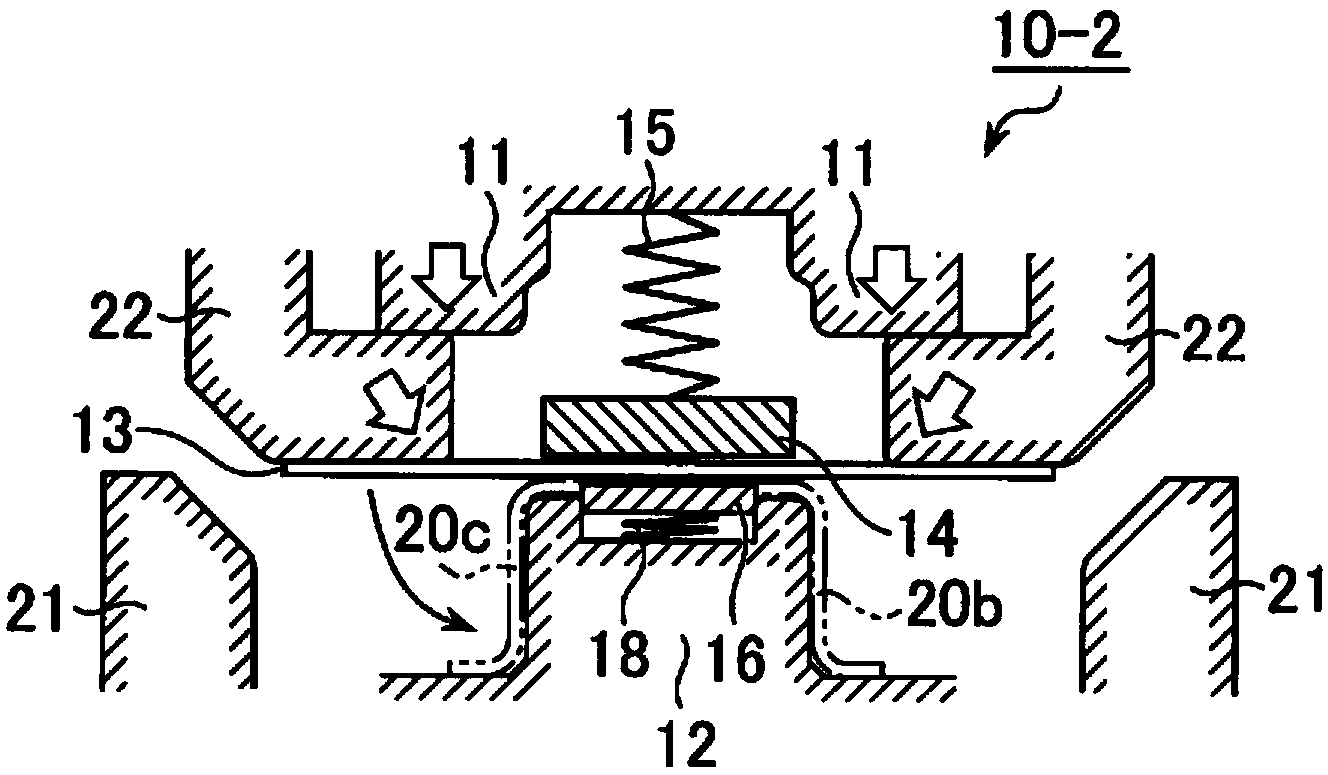

[0139] In this example, use image 3 The press forming apparatus 10 - 2 shown was used to verify the effect of press forming on the press formed product 20 of the present invention. The width of the punch 12 of the press forming apparatus 10 - 2 was 80 mm, the height was 60 mm, and the depth of the press forming apparatus 10 - 2 was 80 mm.

[0140] Figure 10 It is an explanatory diagram showing the cross-sectional shape of the main body 24 of the press-formed product 20 verified in this example.

[0141] The radius of curvature R1 of the part corresponding to the punch shoulder on the inner surface of the shoulder 24 c was set to 5 mm. The radius of curvature R2 of the flange part of the main body 24, which corresponds to the die shoulder, was set to 3.6 mm. The inner wall pitch L1 of the main body 24 was set to 80 mm, and the height H of the main body 24 was set to 50 mm.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com