A thin-wall metal bellows forming method based on shape memory polymer

A technology of memory polymer and metal bellows, which is applied in the field of pipe forming, can solve the problems of low production efficiency, complicated equipment, poor surface quality of formed parts, etc., and achieve the effect of improving surface quality, improving uniformity and preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

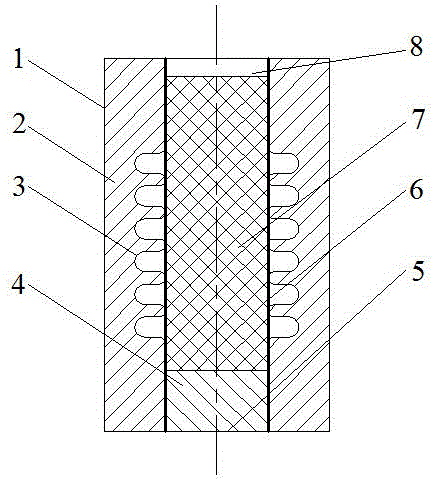

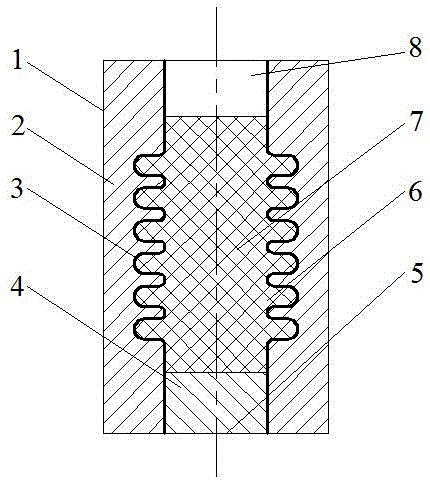

[0018] Specific implementation mode one: combine Figure 1~Figure 6 To illustrate, a shape memory polymer-based thin-walled metal bellows forming method in this embodiment is implemented in this way.

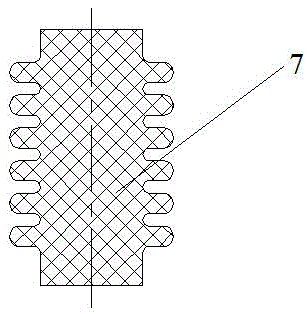

[0019] Step 1: Making a corrugated shape memory polymer 7: Making the outer contour of the shape memory polymer material with shape memory function into a corrugated shape consistent with the shape of the bellows to be formed.

[0020] Step 2: Make the forming die 1: first make the die blank, which is composed of two half-die blanks 2, and the two half-die blanks 2 are buckled and detachably connected; secondly, process on the inner wall of the die blank Corrugated ring cavity 3.

[0021] Step 3: Coating a release agent on the surface of the corrugated ring cavity 3 .

[0022] Step 4: Manufacturing the mandrel 5 : machining a counterbore on the central axis of one end face of the cylinder 4 and calling it the medium chamber 8 .

[0023] Step 5: Set the core mold 5 in the inne...

specific Embodiment approach 2

[0029] Specific embodiment 2: The thin-walled metal bellows finally produced in this embodiment has a number of corrugations N ranging from 3 to 40; the wall thickness is 0.2 mm to 0.5 mm, and the inner surface radius of the corrugated surface is 0.25 mm ~1.0mm. Other method steps are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: the release agents used in step three of this embodiment are all wax-free release agents. Other method steps are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com