Elevator provided with emergency braking device

An emergency braking and elevator technology, which is applied in transportation, packaging, elevators, etc., can solve the problems of buffer body loss of shock absorption, buffer body deformation change, lack of reproducibility, etc., to achieve convenient positioning, restrain rebound, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

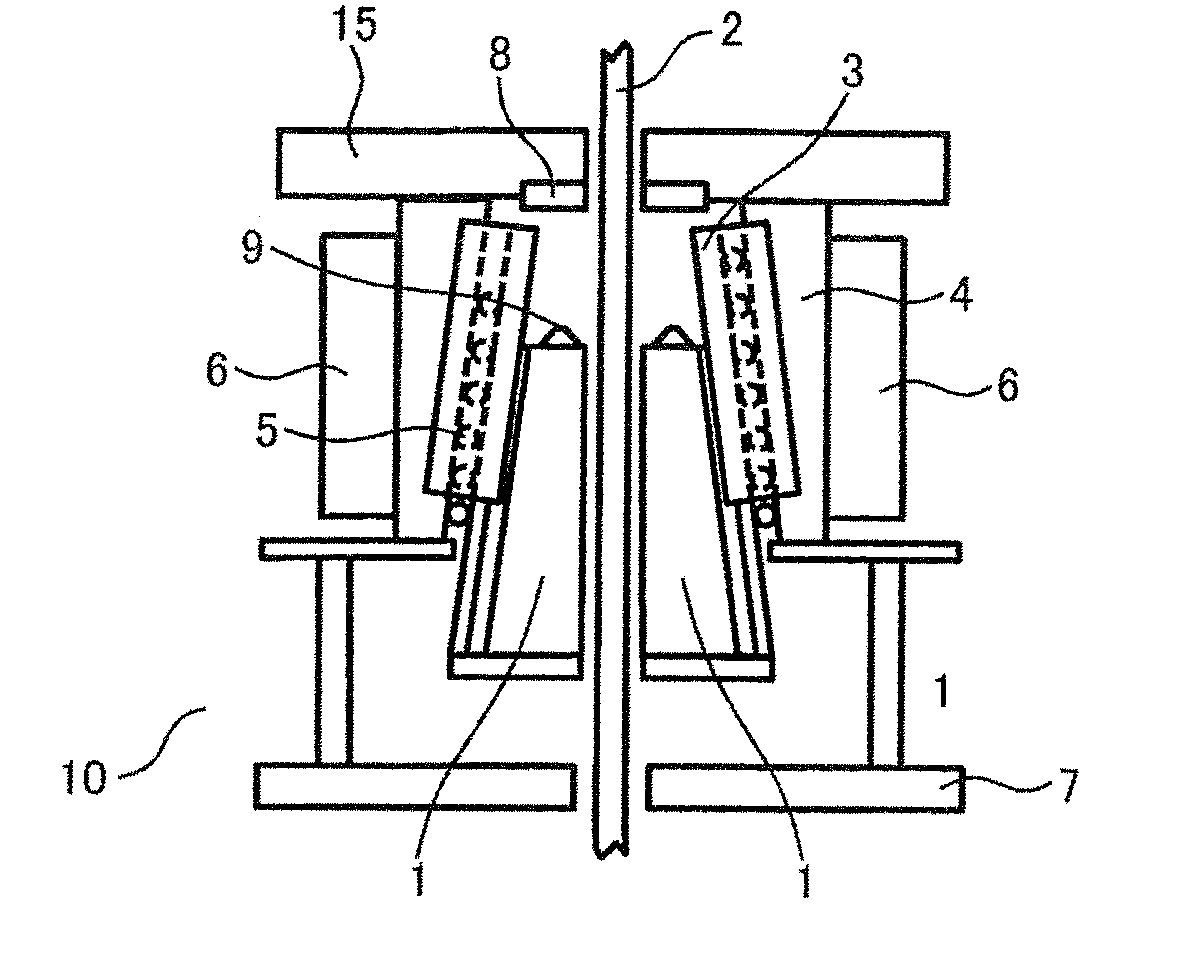

[0042] The emergency braking device in the elevator of the present invention will be described below with reference to the accompanying drawings.

[0043] figure 1 It is a longitudinal sectional view when the emergency braking device 10 is not operating (the elevator is running normally).

[0044] The emergency brake device 10 has a pair of brake shoes 1 arranged bilaterally symmetrically across the guide rail 2 , and the pair of brake shoes 1 are arranged substantially parallel to the guide rail 2 with a slight gap therebetween so as to sandwich the guide rail 2 .

[0045] The back surface of the brake shoe 1 opposite to the guide rail is a smooth inclined surface having a wedge shape that narrows upward.

[0046] In order to move the brake shoe 1 to a predetermined position, a guide member 4 for guiding the displacement of the brake shoe 1 is provided on the back surface of the brake shoe 1 .

[0047] The guide member 4 has a guide plate 3 and a roller 5. The inner side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com