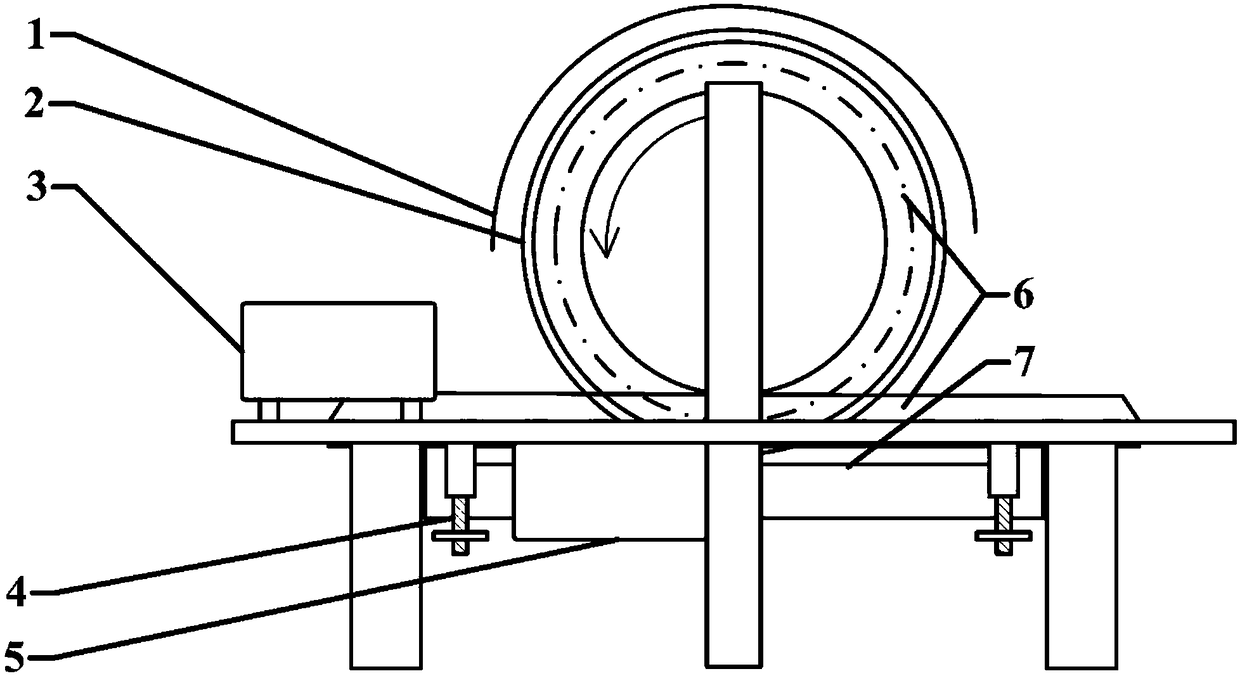

Large-deformation rolling technology based on asymmetric rolling equipment

An asymmetric rolling, large deformation technology, applied in metal rolling and other directions, can solve the problems of grain refinement sheet texture weakening, strong sheet texture, complex process and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The large deformation rolling process based on asymmetric rolling equipment in this embodiment, the specific steps are as follows:

[0030] (1) Select solid solution Al-7Mg-0.6Sc hard-to-deform aluminum alloy as rolling raw material, machined to 4.8×40×13cm 3 The standard rolling sample;

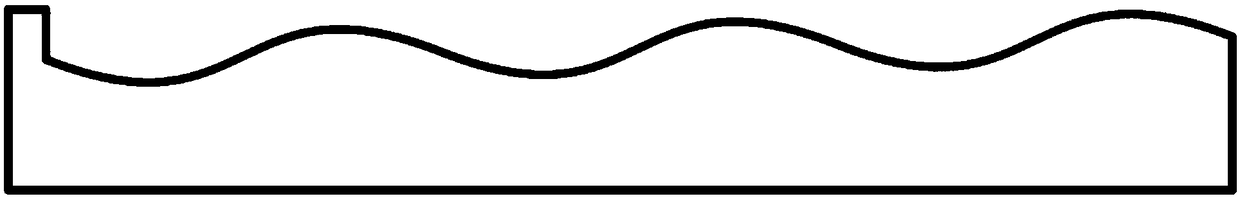

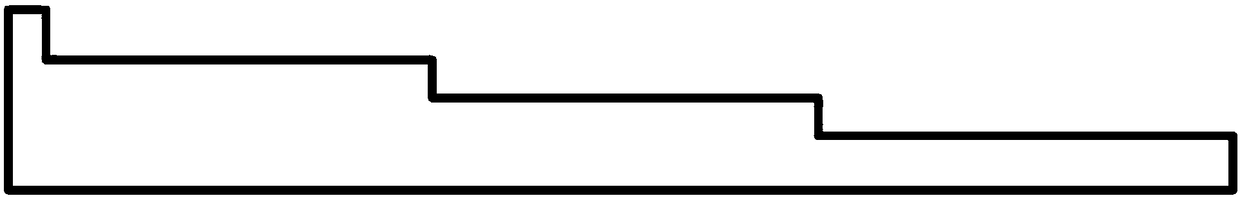

[0031] (2) Select the combined working bottom plate whose upper surface is a smooth plane with a thickness of 10mm, and the hardness of the bottom plate material is 55HRC;

[0032] (3) The rolling process is not heated;

[0033] (4) Place the sample on the feeding port of the combined bottom plate, and bring the sample into the roll inlet at a constant speed;

[0034] (5) The rolling process is completed in one pass, and the reduction in each pass is 80%;

[0035] (6) The grain size of the rolled sample is a mixture of large and small grains. The small grain size is 0.1-0.3 μm, and the large grain size is 200-500 μm. The yield strength is 319MPa, the tensile strength is 538MPa, and...

Embodiment 2

[0037] The large deformation rolling process based on asymmetric rolling equipment in this embodiment, the specific steps are as follows:

[0038] (1) Select solid solution Mg-9Al-1Zn (AZ91) magnesium alloy as rolling raw material, machined to 4.8×40×13cm 3 The standard rolling sample;

[0039] (2) Select the combined working bottom plate whose upper surface is a smooth plane with a thickness of 10mm, and the hardness of the bottom plate material is 55HRC;

[0040] (3) The heating temperature of the sample heating device is set to 350°C, the heating temperature of the roll is set to 100°C, and the heating temperature of the transmission belt is set to 100°C;

[0041] (4) The sample is placed in an incubator, and after the temperature is raised to the preset temperature, it is kept for 10 minutes;

[0042] (5) Take out the sample, place it on the working floor, and bring the sample to the entrance of the roll at a constant speed;

[0043] (6) The rolling process is only comp...

Embodiment 3

[0047] The large deformation rolling process based on asymmetric rolling equipment in this embodiment, the specific steps are as follows:

[0048] (1) Select the solid solution state Mg-9Al-1Zn-1Y (AZ91-1Y) magnesium alloy as the rolling raw material, and machine it into a standard rolling sample of 4.8×40×13cm3;

[0049] (2) Select the combined working bottom plate whose upper surface is a smooth plane with a thickness of 10mm, and the hardness of the bottom plate material is 55HRC;

[0050] (3) The heating temperature of the sample heating device is set to 350°C, the heating temperature of the roll is set to 100°C, and the heating temperature of the working base plate is set to 100°C;

[0051] (4) The sample is placed in an incubator, and after the temperature is raised to the preset temperature, it is kept for 10 minutes;

[0052] (5) Take out the sample, place it on the feeding port of the combined bottom plate, and bring the sample into the roll inlet at a constant speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com