Pressure control method for forming aluminum alloy covering part viscoelastic-plastic soft mode

A technology of pressure control and aluminum alloy, which is applied in the field of pressure control of soft mold forming of aluminum alloy cover parts, can solve the problems of high manufacturing cost, poor surface quality, thinning and cracking, etc., to improve surface quality, prevent cracking, and suppress return The effect of playing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

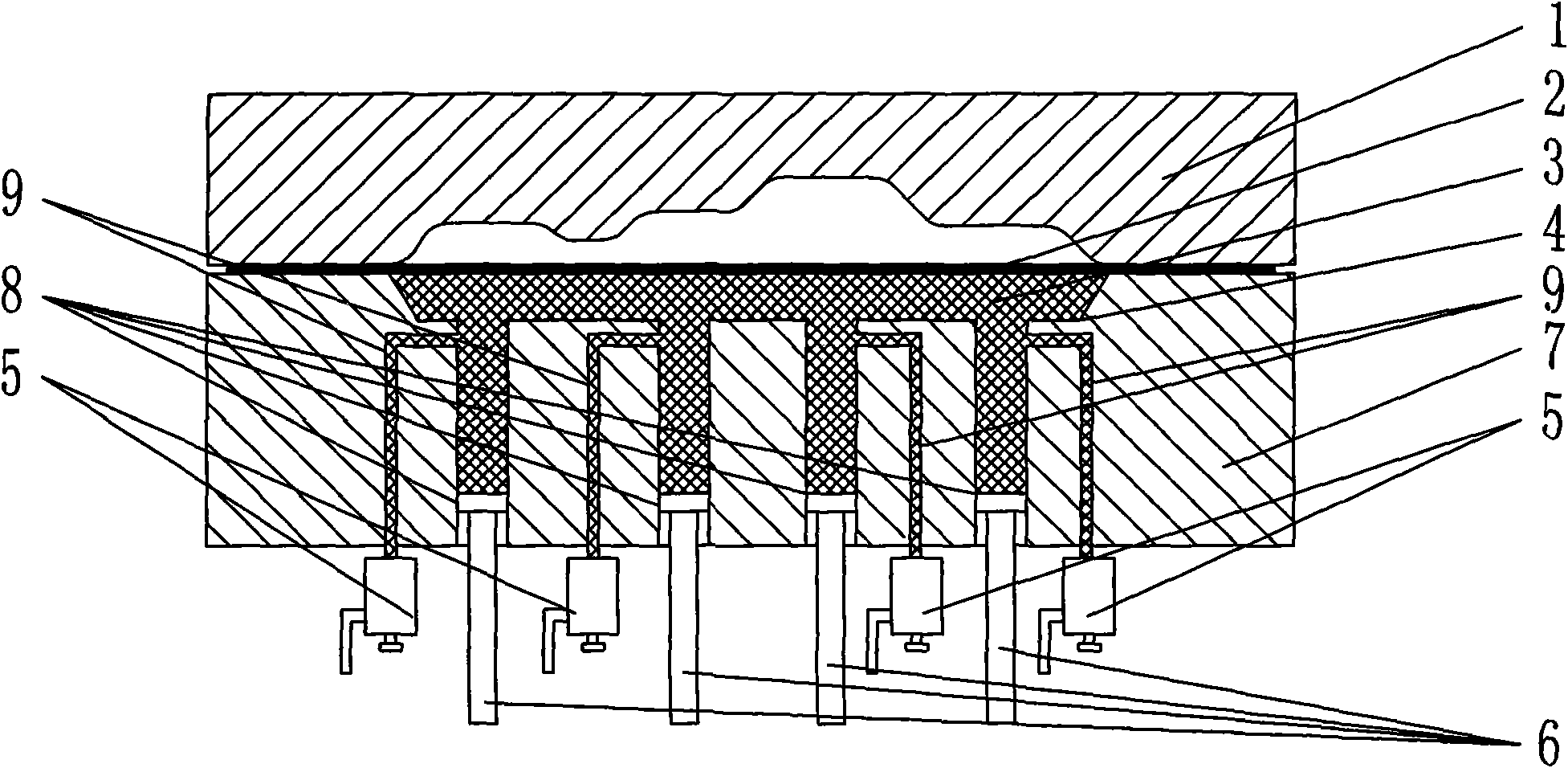

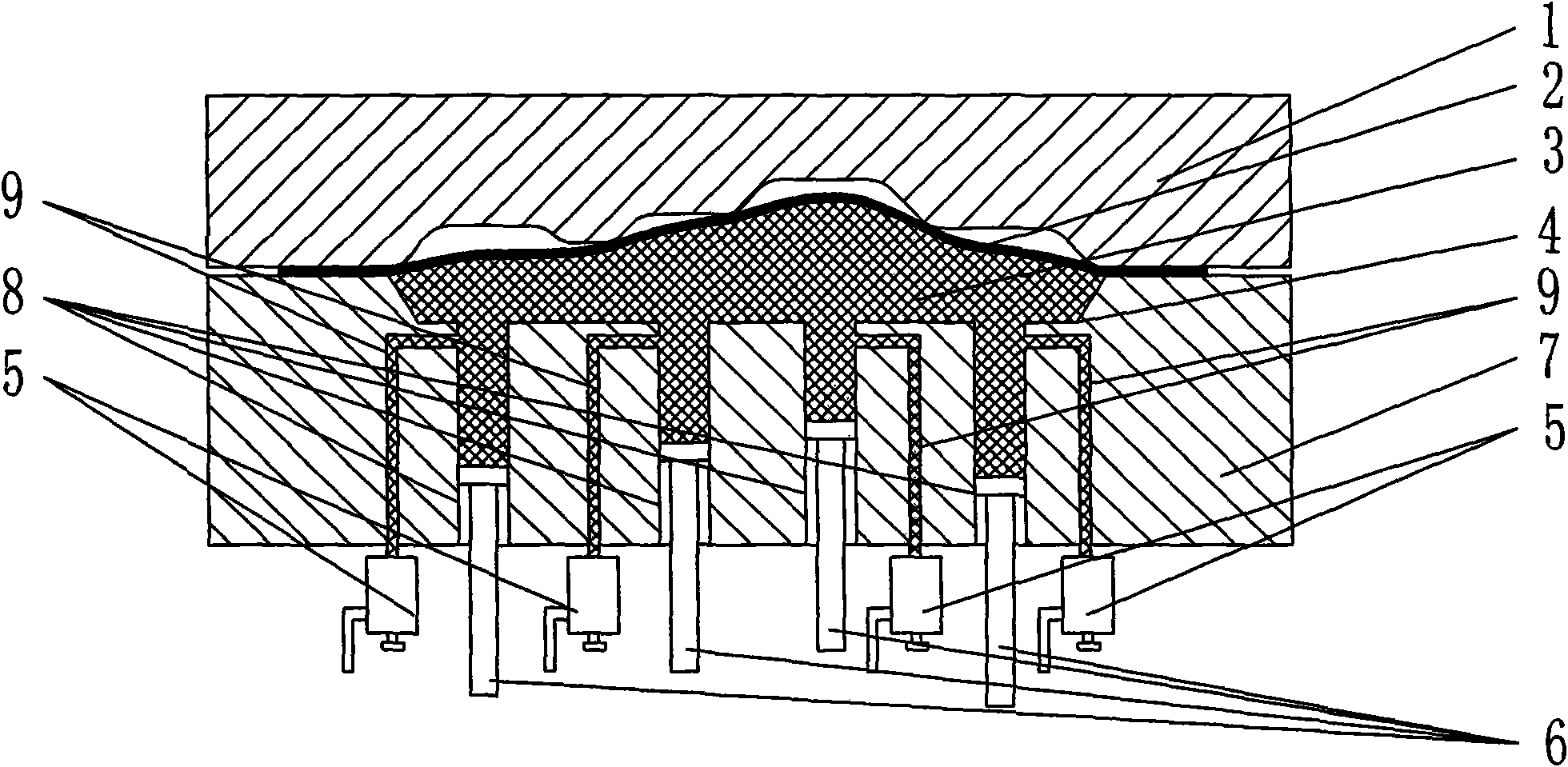

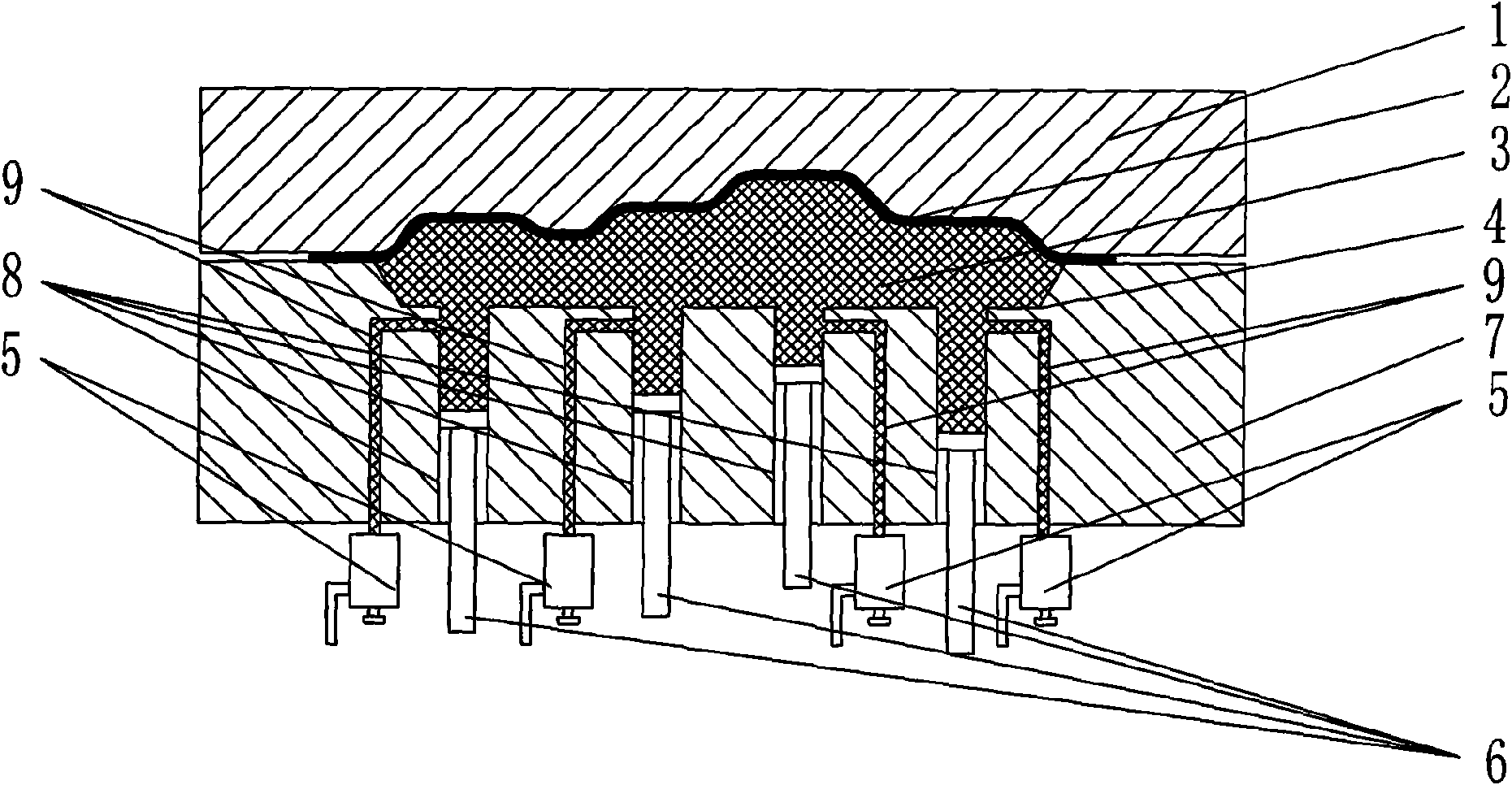

[0014] Specific implementation mode one: combine Figure 1 to Figure 4 To illustrate this embodiment, the steps of a pressure control method for viscoelastic-plastic soft mold forming of an aluminum alloy cover part in this embodiment are as follows:

[0015] Step 1: first mold the mold, then grind and polish the cavity surface of the concave mold 1 of the mold, apply a release agent on the surface of the upper mold cavity, and then set up a pressure chamber 4 on the upper end surface of the lower mold 7 of the mold, A plurality of piston movable chambers 8 and a plurality of overflow chambers 9 are provided on the bottom surface of the mold 7, the piston movable chambers 8 communicate with the pressure chamber 4, and the overflow chambers 9 communicate with the piston movable chambers 8;

[0016] Step 2: install a plurality of pistons 6 in the piston movable chamber 8, and install a plurality of overflow valves 5 at the outlet end of the overflow chamber 9;

[0017] Step 3: ...

specific Embodiment approach 2

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the release agent in step 1 of this embodiment is a wax-free release agent. The surface quality of the aluminum alloy cover is better, and it is easier to demould.

specific Embodiment approach 3

[0023] Specific embodiment three: The difference between this embodiment and specific embodiment one or two is: the viscoelastic plastic material 3 in step three of this embodiment has a molecular weight of 400000g / mol~600000g / mol, and a viscosity of 10000Pa·s~ 16000Pa·s polymer material, the state of the viscoelastic plastic material 3 is semi-solid. The viscoelastic-plastic material has better strain rate sensitivity, is more suitable for the change of stress in the deformation process of the aluminum alloy sheet, and better suppresses the springback of the aluminum alloy cover after forming.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com