Flexible die forming method with approximatively equal wall thickness for variable-diameter part

A technology of equal wall thickness and parts, applied in the field of soft mold forming of variable-diameter parts, can solve the problems of thinning wall thickness and uneven wall thickness distribution, and achieve easy sealing, improve wall thickness distribution uniformity, and good fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

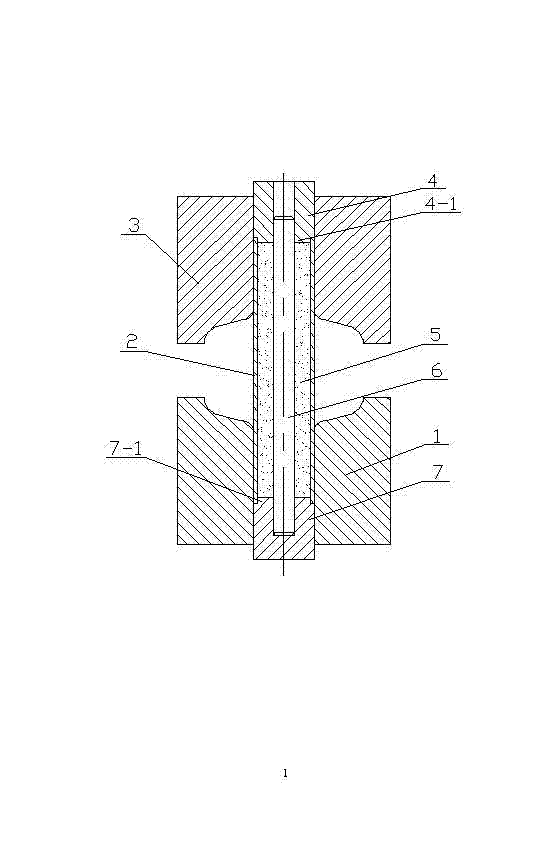

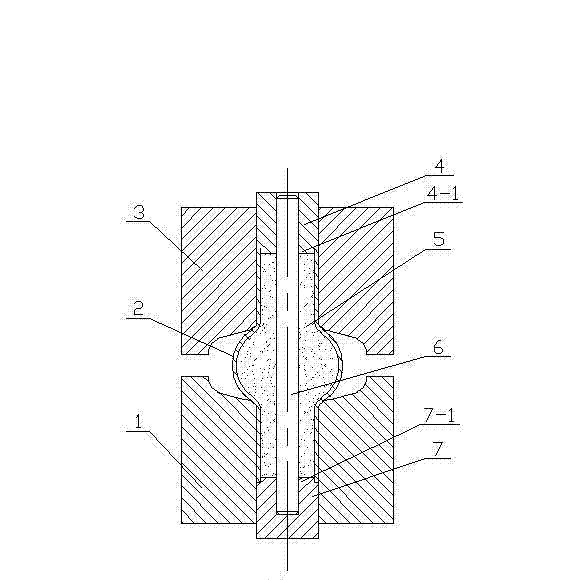

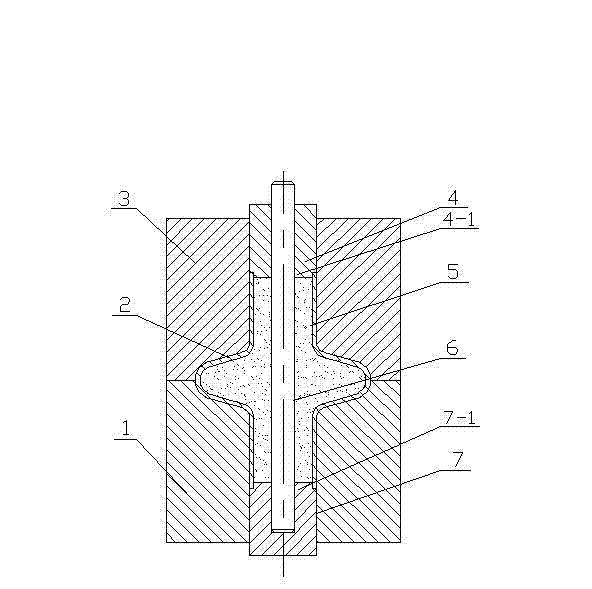

[0015] Specific implementation mode one: combine Figure 1-Figure 5 and Figure 7 To illustrate, a room-temperature forming method of a variable-diameter part with a near-equal wall thickness soft mold is completed by the following steps:

[0016] Step 1: The mold is composed of an upper mold 3 and a lower mold 1, and the cavity of the mold is composed of the cavity of the upper mold 3 and the cavity of the lower mold 1, and the tube blank 2 is installed on the cavity of the upper mold 3 and the lower mold 1 In the mold cavity, there is a distance between the upper mold 3 and the lower mold 1, the upper end of the lower plunger 7 is provided with an upper boss 7-1, the upper end of the lower plunger 7 is arranged in the cavity of the lower mold 1, and the The upper convex shoulder of the lower plunger 7 is in sealing contact with the lower end surface of the tube blank 2, and the upper boss 7-1 of the lower plunger 7 is pressed into the tube blank 2;

[0017] Step 2: Place a...

specific Embodiment approach 2

[0024] Embodiment 2: The viscoelastic plastic material 5 in step 3 of this embodiment is a polymer material with a molecular weight of 400000g / mol~600000g / mol and a viscosity of 10000Pa·s~16000Pa·s, the viscoelastic plastic material 5 The state of matter is semi-solid. The strain rate sensitivity of the viscoelastic plastic material is better, it is more suitable for the change of the stress during the deformation process of the shell, and it can better suppress the wrinkling that may occur during the forming process. Other method steps are the same as those in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: In step 6 of this embodiment, the wall thickness of the manufactured variable diameter part is 1-6mm. Other method steps are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com