Patents

Literature

57results about How to "Simplify the forming process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

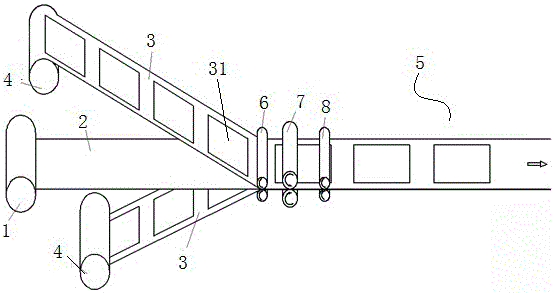

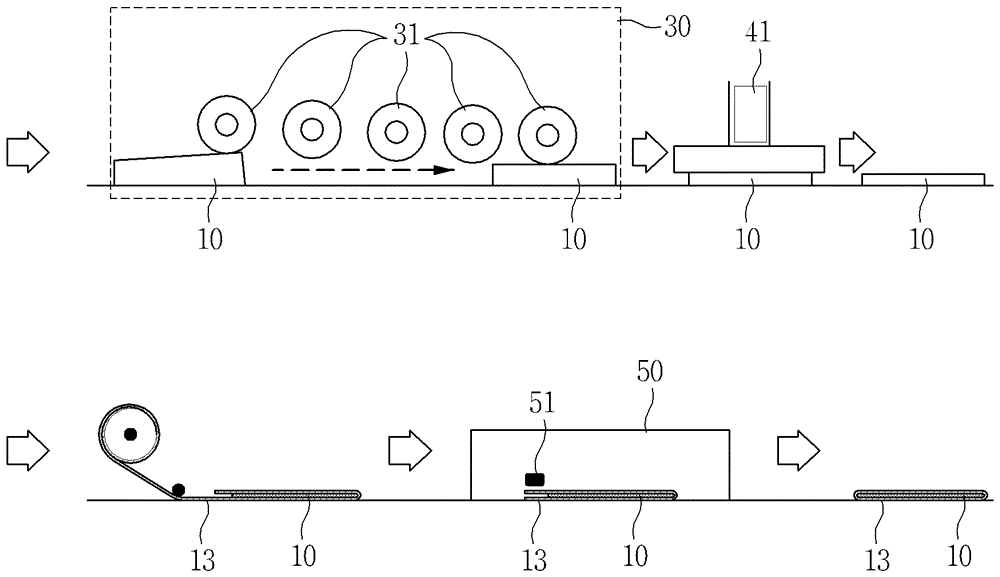

Method for preparing fuel cell membrane electrode with sealing frame

ActiveCN104617310ARealize continuous large-scale productionAvoid damageCell electrodesPolymer electrolytesPtru catalyst

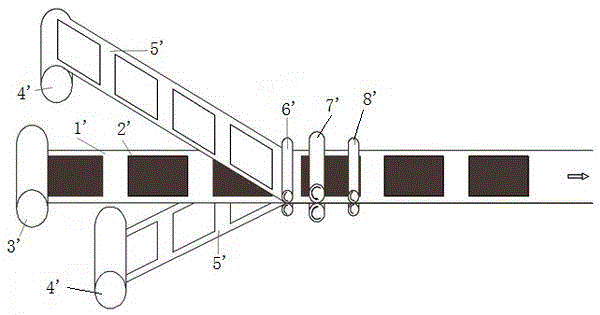

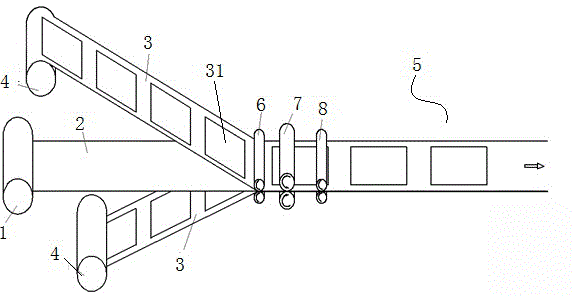

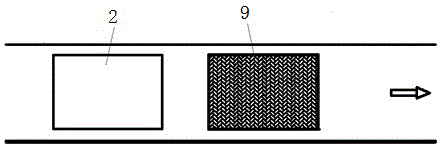

The invention discloses a method for preparing a fuel cell membrane electrode with a sealing frame. The process is simple and easy to realize. The method comprises the following steps: feeding a polymer electrolyte membrane and a sealing frame material with a layer of hot melt adhesive into a rolling device of a hot pressing platform, jointing the sealing frame material to edges of two sides of the polymer electrolyte membrane through heating rolling, and laminating a gas diffusion layer coated with a catalytic layer on two sides of the polymer electrolyte membrane so as to form a membrane electrode component. In the preparation process, a catalyst liquid is directly coated on the gas diffusion layer instead of the polymer electrolyte membrane, so that damage to a catalytic layer is reduced, the situation that later process is affected by swelling deformation of the membrane in the spraying process is avoided, the formation procedure can be simplified, continuous large-scale production of GDE and MEA can be conveniently achieved, and the production efficiency is greatly improved.

Owner:KUNSHAN SUNLAITE NEW ENERGY +1

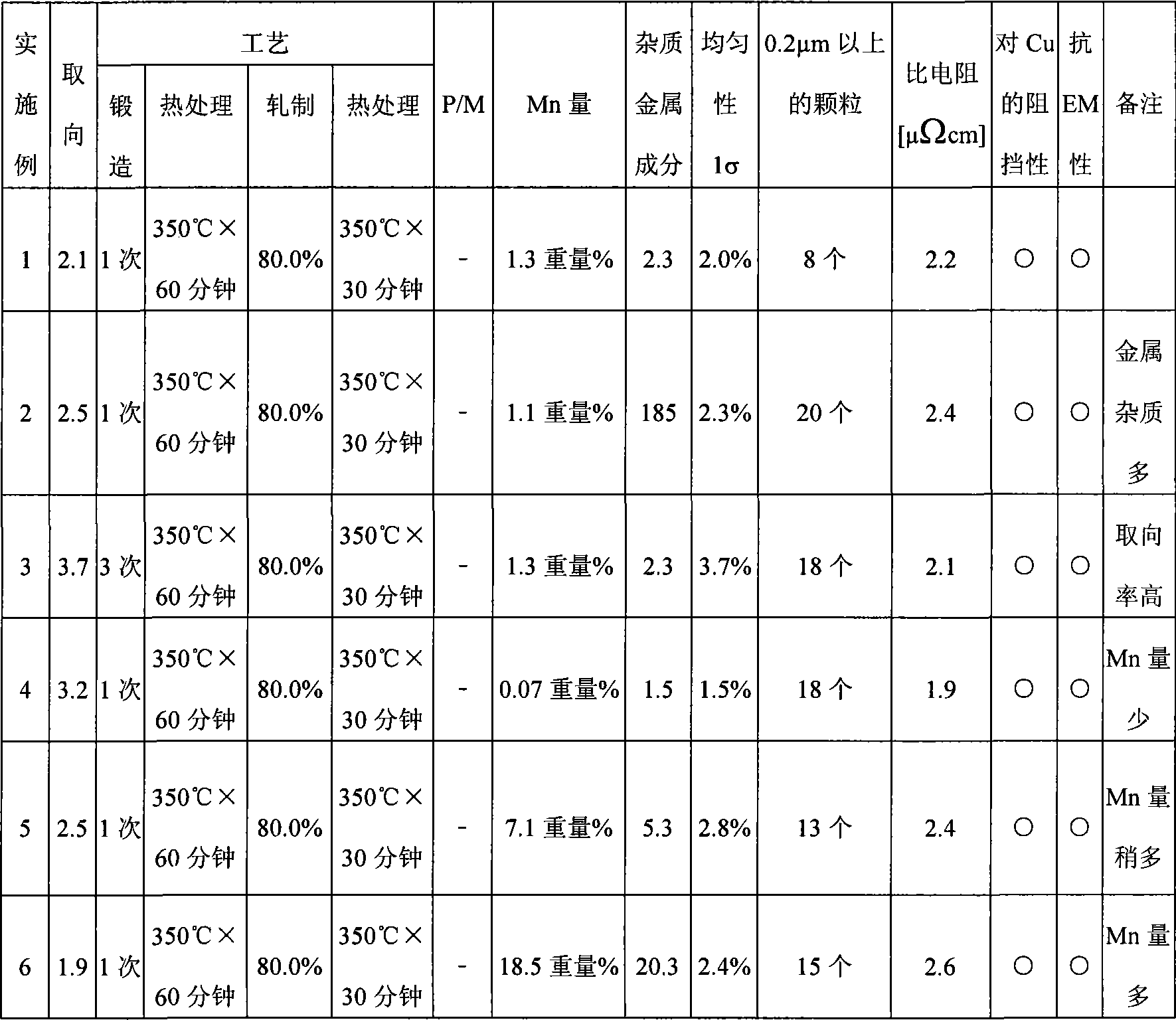

Cu-Mn alloy sputtering target and semiconductor wiring

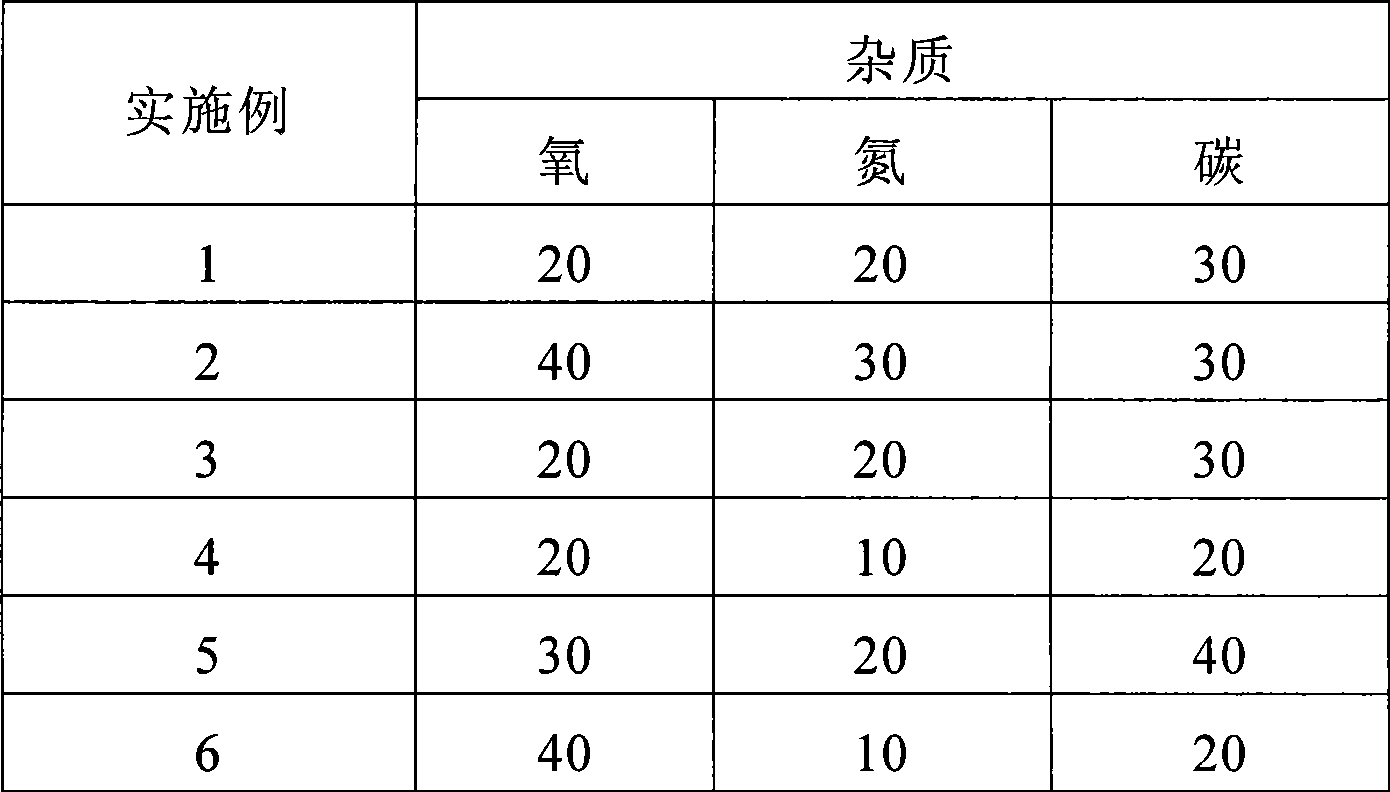

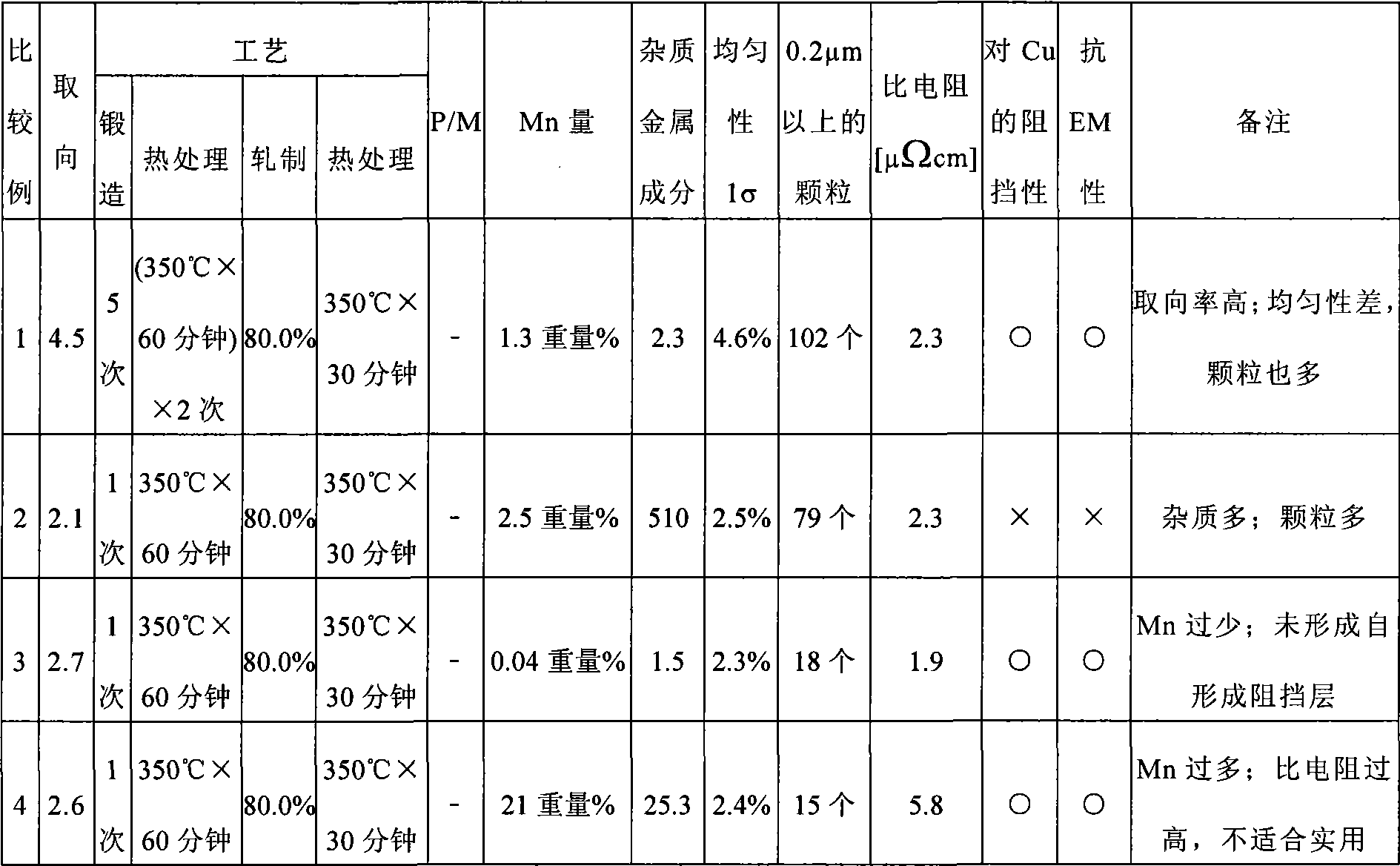

ActiveCN101473059AWith self-diffusion inhibition functionSimplify the forming processSemiconductor/solid-state device detailsSolid-state devicesSelf-diffusionImpurity

Owner:JX NIPPON MINING & METALS CORP

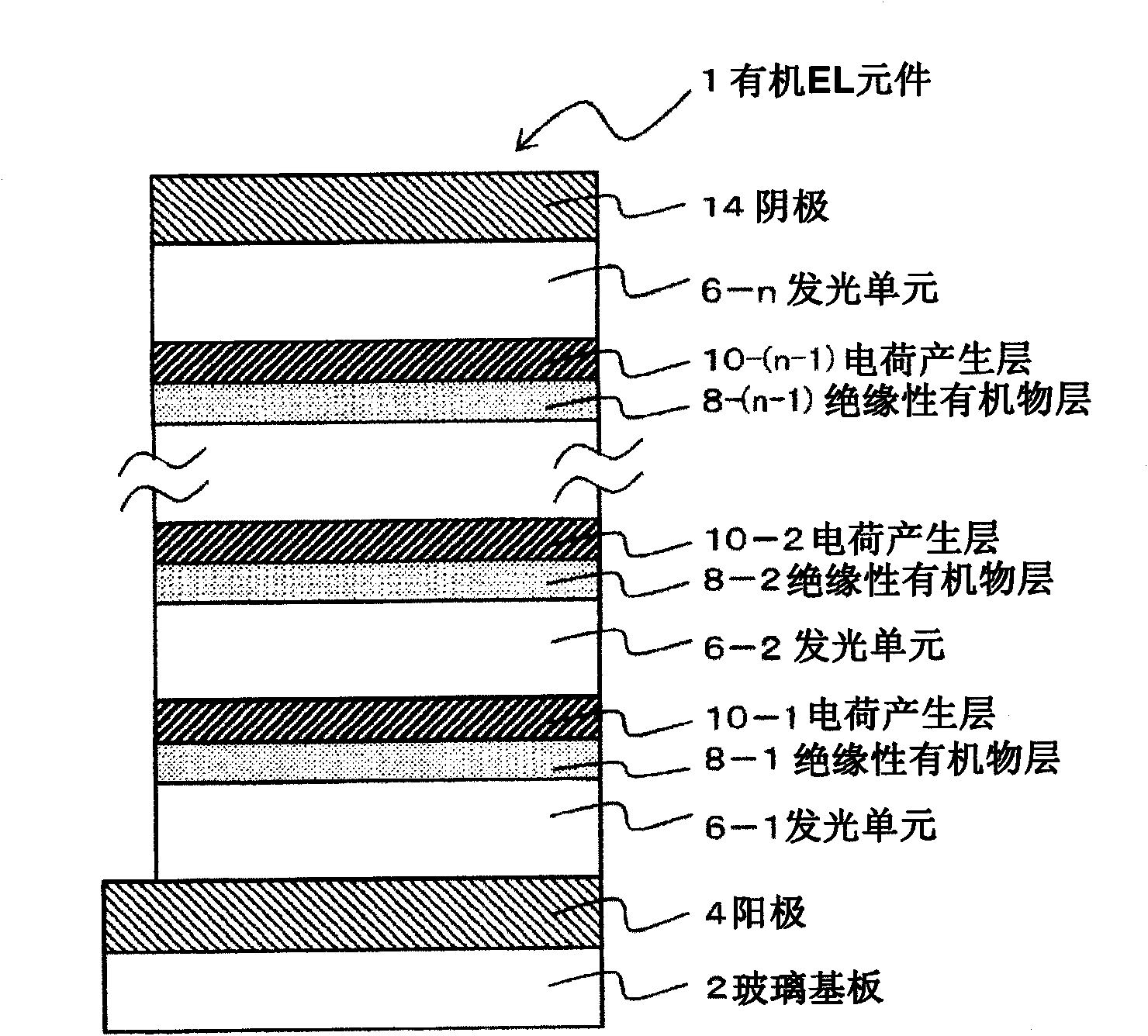

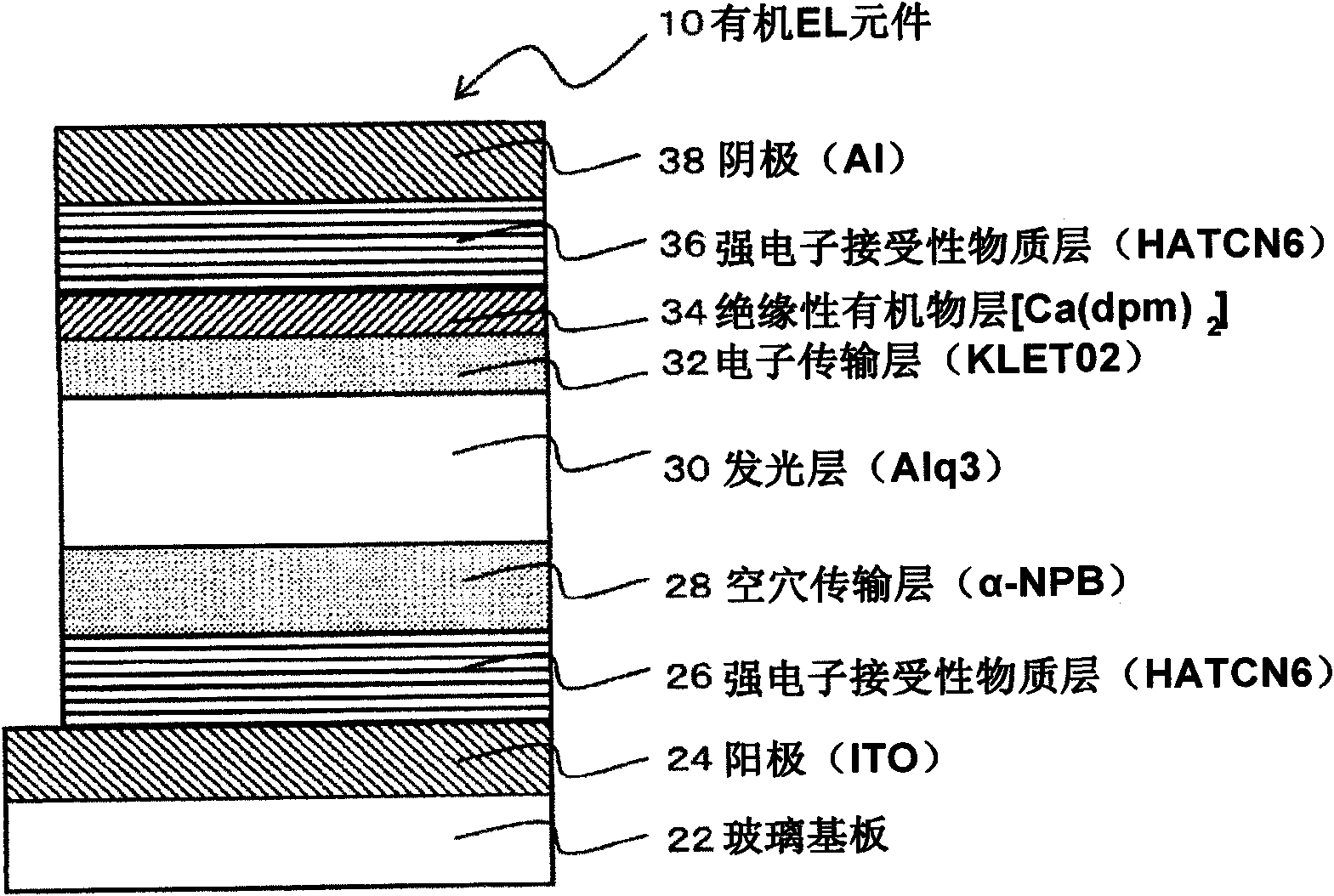

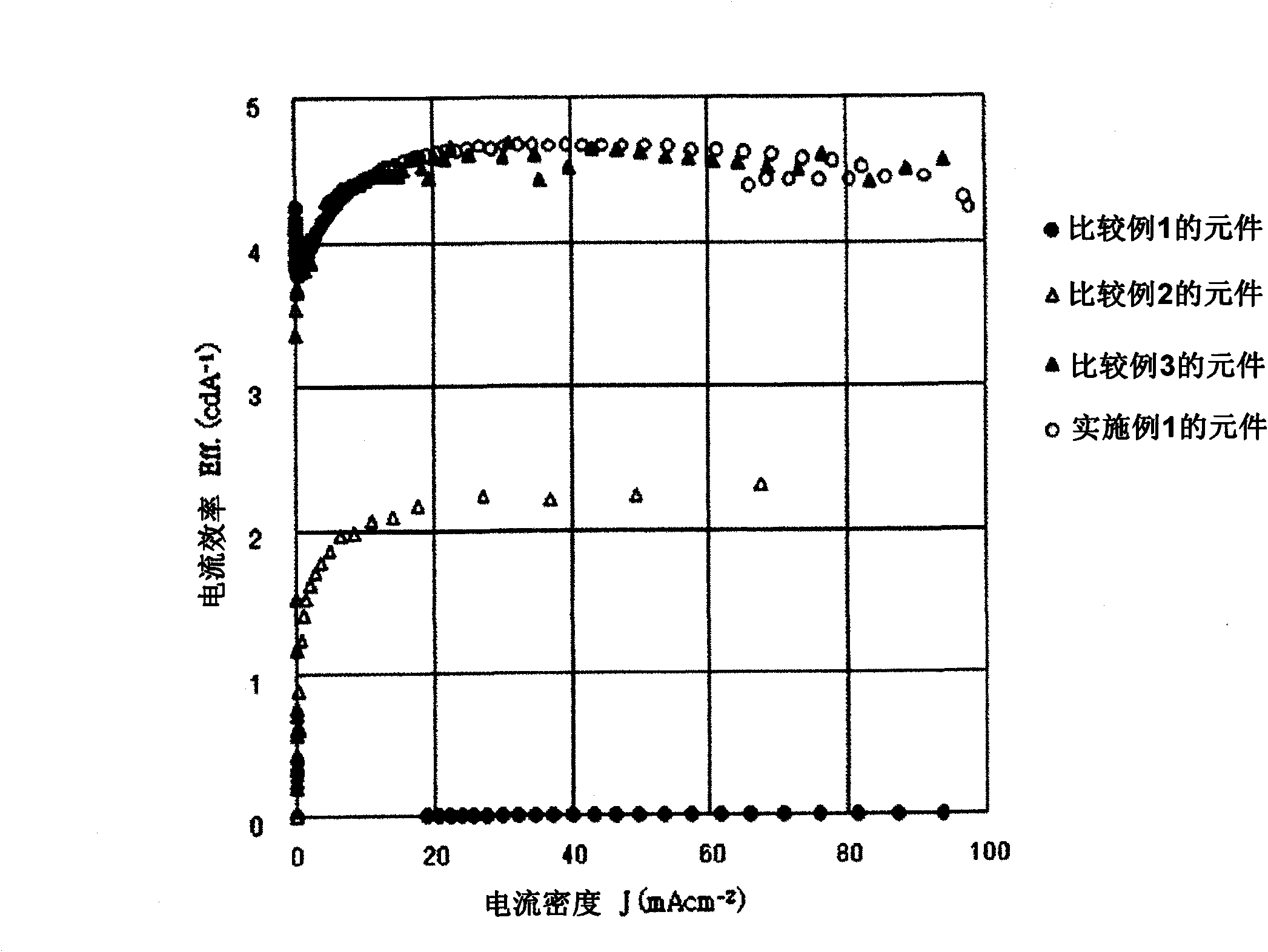

Organic electroluminescent element

InactiveCN102396296ASimplify the manufacturing processSimple forming processElectroluminescent light sourcesSolid-state devicesOrganic electroluminescenceLow-k dielectric

Provided is a structure of an organic EL element capable of reducing the product cost by drastically simplifying the fabrication process as compared with a conventional multi-photon organic EL element. An insulating organic layer having a low dielectric constant is interposed to smooth the transfer of electron charges between a strong electron-accepting material and an electron transport layer included in a charge generation layer of the conventional multi-photon organic EL element.

Owner:ASON TECH

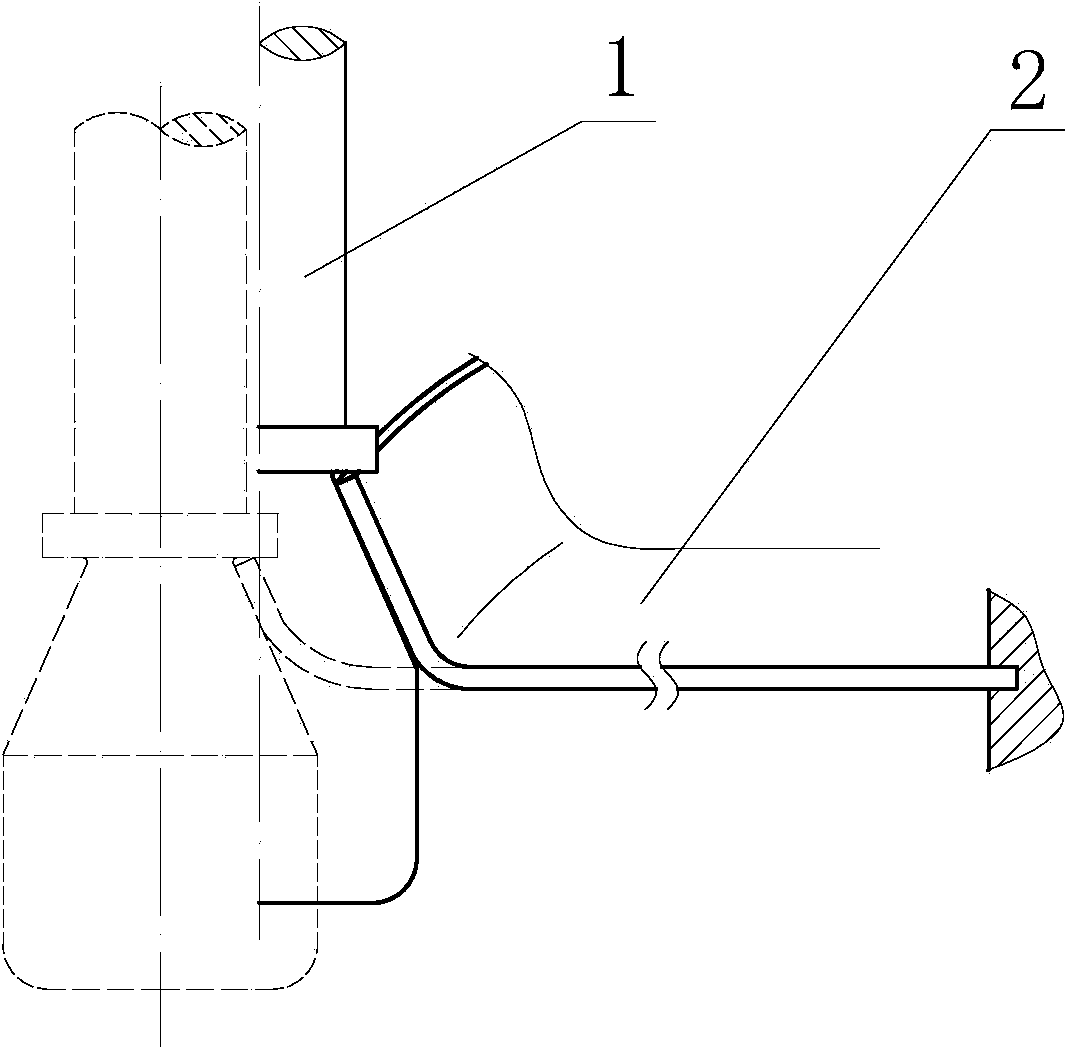

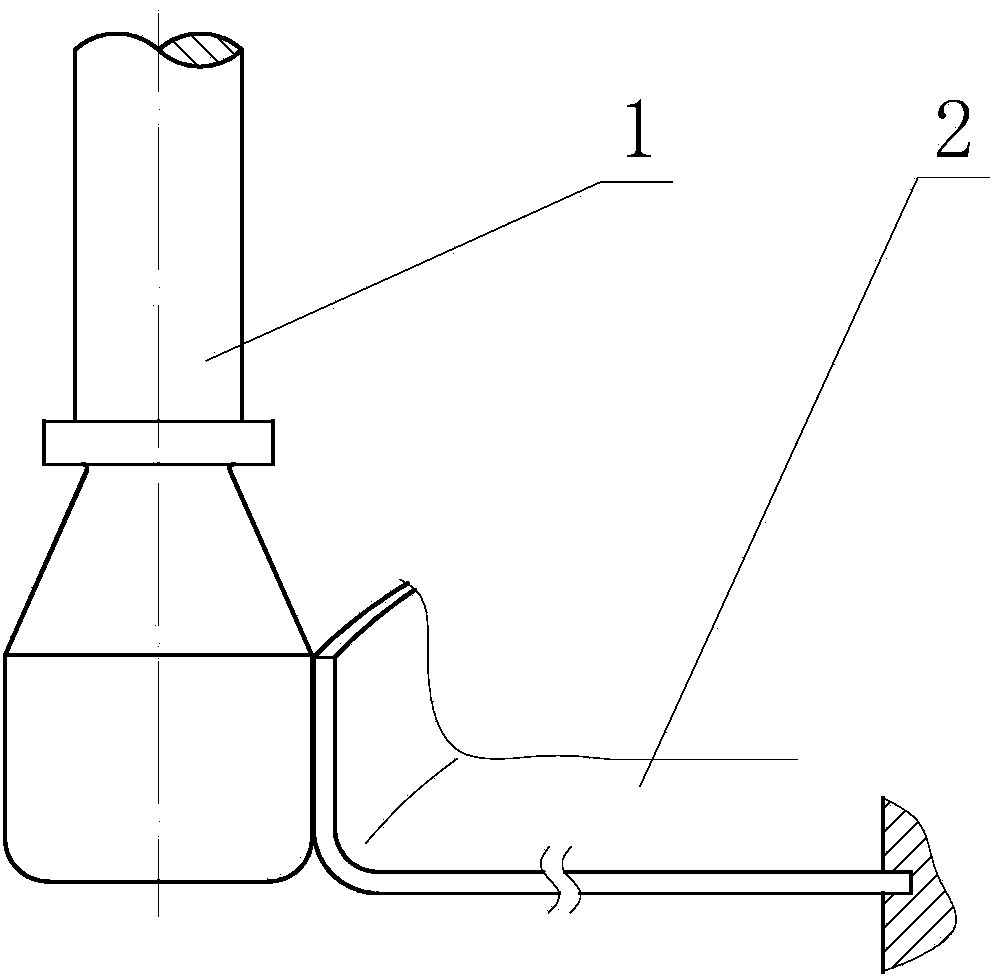

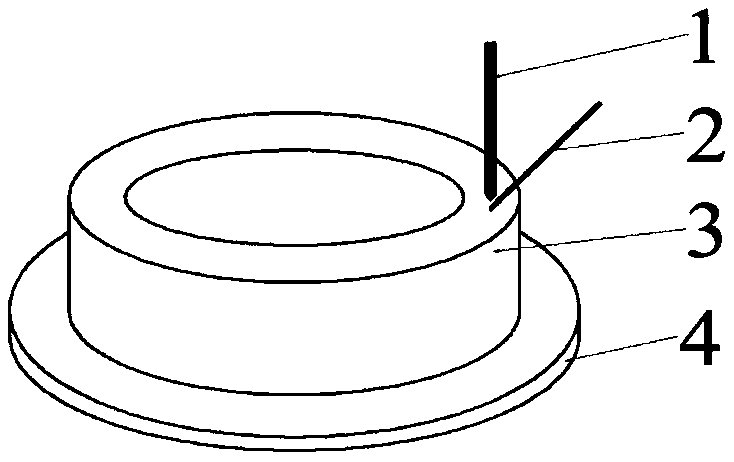

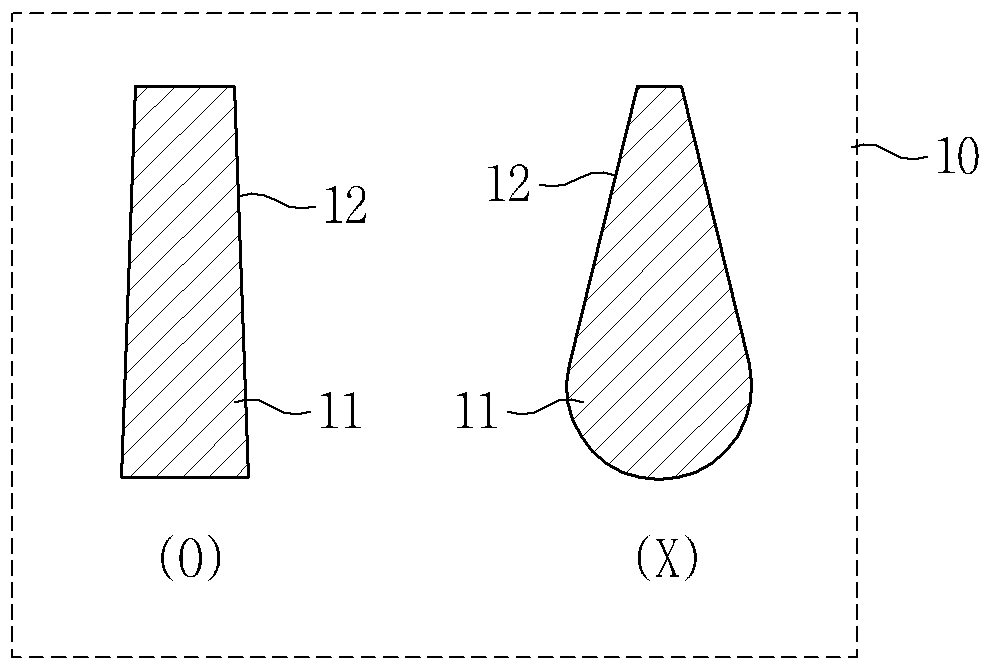

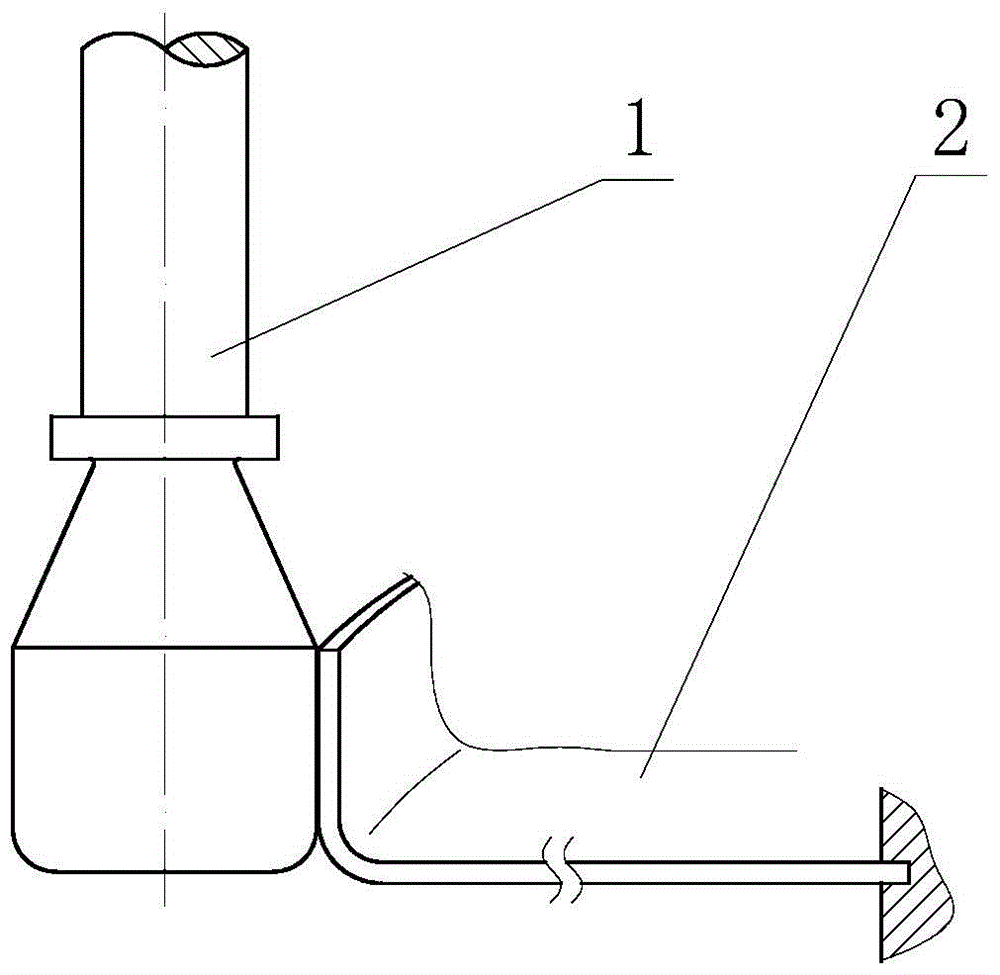

Tool head and method for controlling buckling deformation in thin plate die-free gradual edge turning process

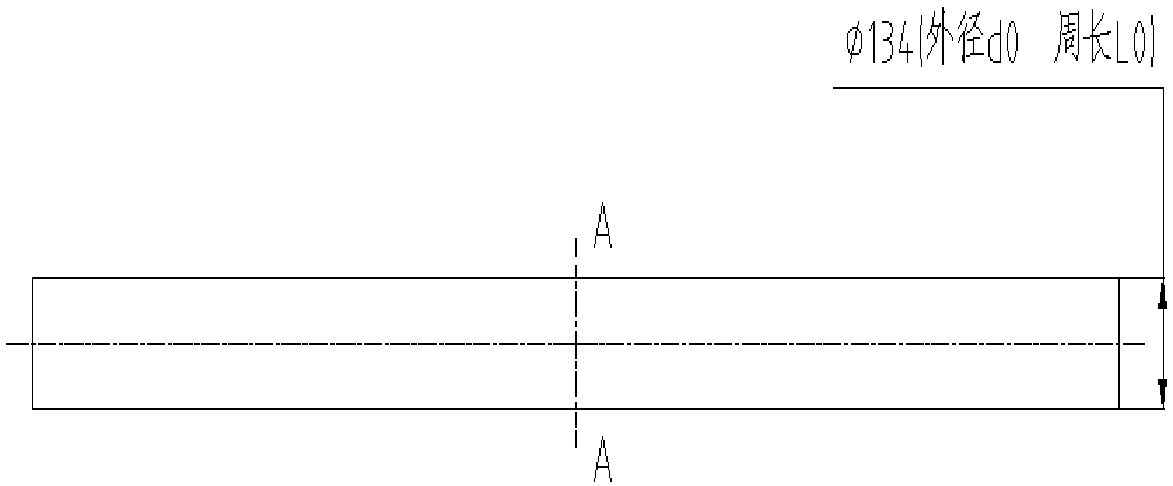

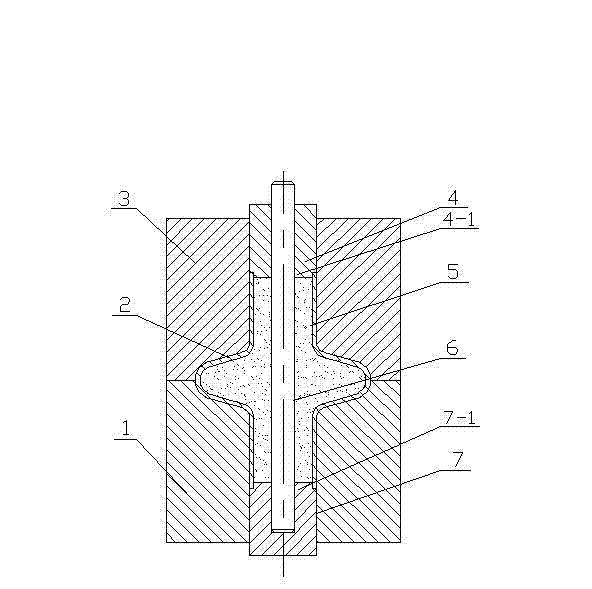

The invention discloses a tool head and method for controlling the buckling deformation in a thin plate die-free gradual edge turning process. A long cylindrical body is arranged at the upper end of the tool head. The lower end of the long cylindrical body is connected with a disc. The bottom face of the disc is connected with a big-end-down circular truncated cone. The diameter of the small end of the circular truncated cone is smaller than that of the disc. The large end of the circular truncated end is connected with a large cylindrical body, wherein the diameter of the large end of the circular truncated end is the same as the diameter of the large cylindrical body. The method includes the following steps that an inclined face of the circular truncated cone of the tool head makes contact with the edge of a plate material, and a gap of 2 mm to 3 mm is formed between the bottom face of the disc and the upper surface of the plate material; the tool head horizontally extrudes the edge of the plate material to make the plate material bent upwards till the plate material makes contact with the bottom face of the disc; the tool head moves along the periphery of the plate material so that the same deformation can happen to an edge to be turned; the tool head is lifted, the steps are repeatedly executed, and performing is completed; the edge to be preformed is shaped through the side wall of the large cylindrical body of the tool head, and a vertical turned edge is obtained. The tool head and method have the advantages that deformation of the plate material is controlled through the combination of the tool head and a program, the longitudinal upwarp in the die-free gradual edge turning forming process can be eliminated, and the tool head and method are easy to obtain and implement and feasible.

Owner:CHONGQING UNIV

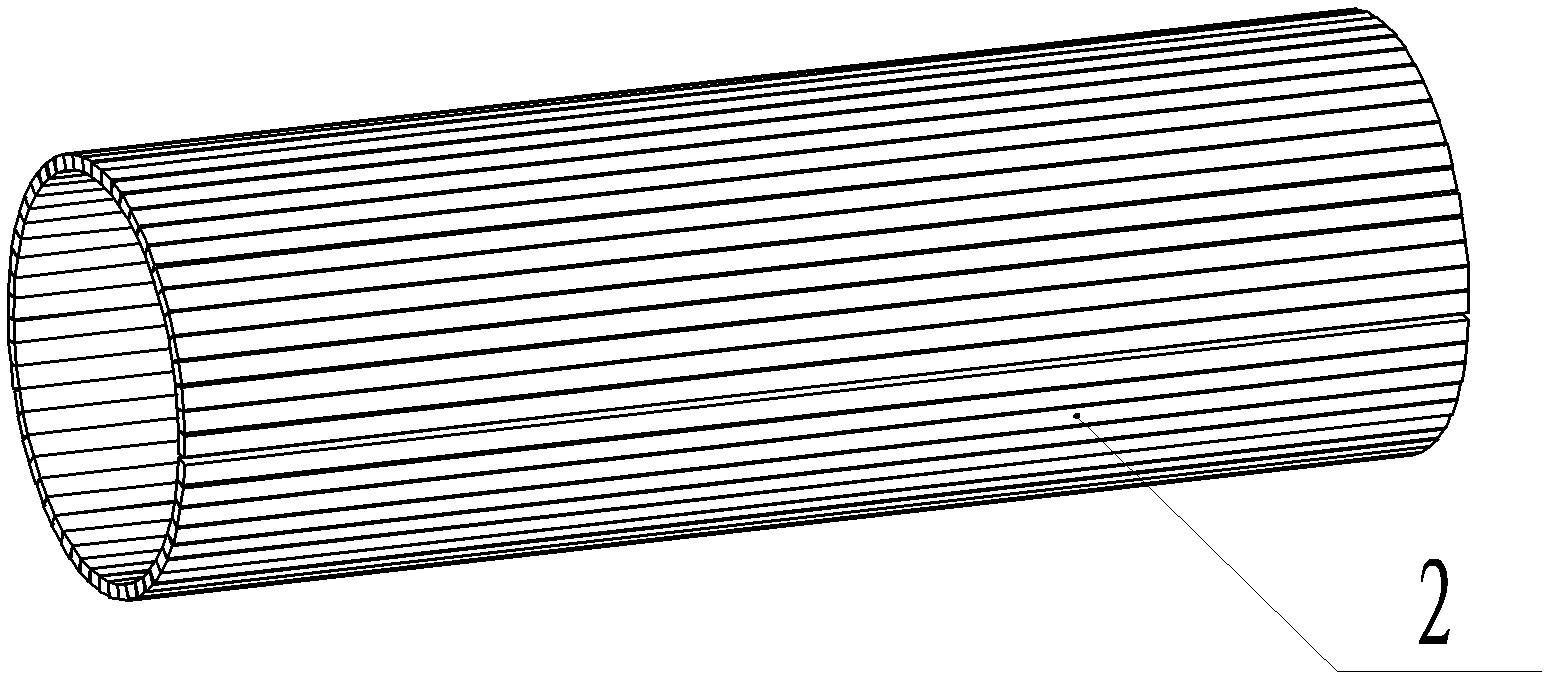

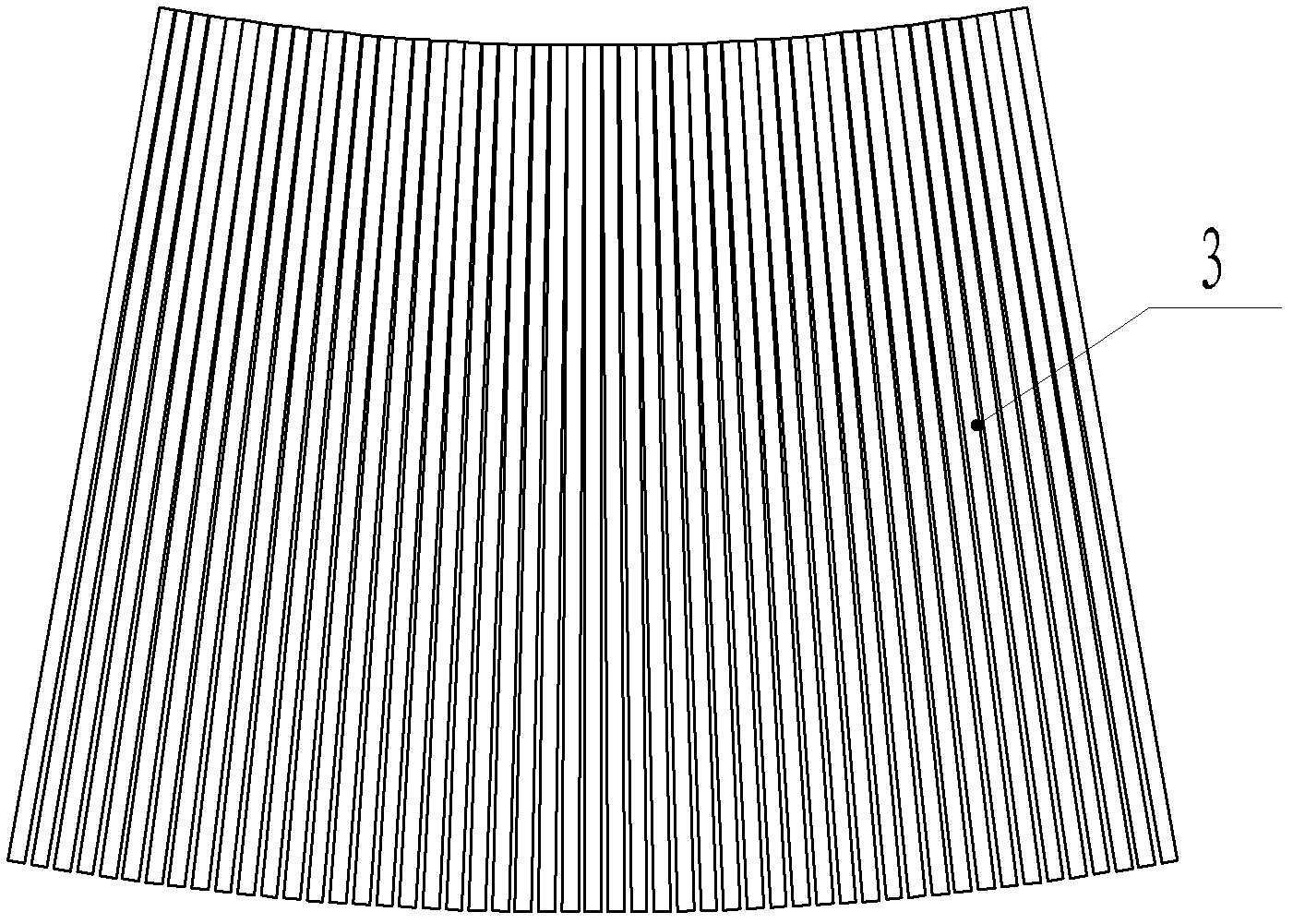

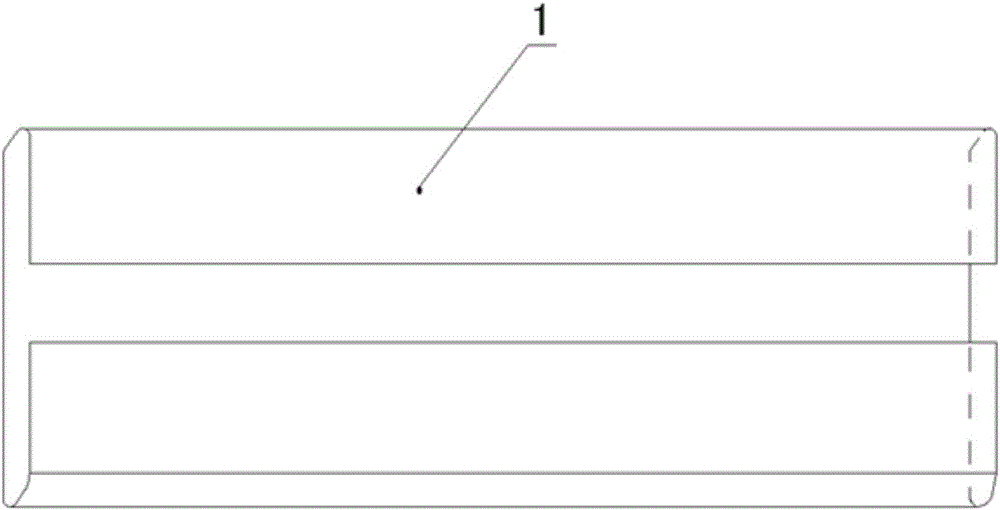

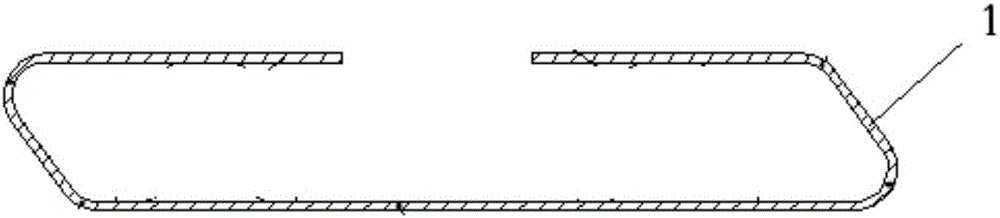

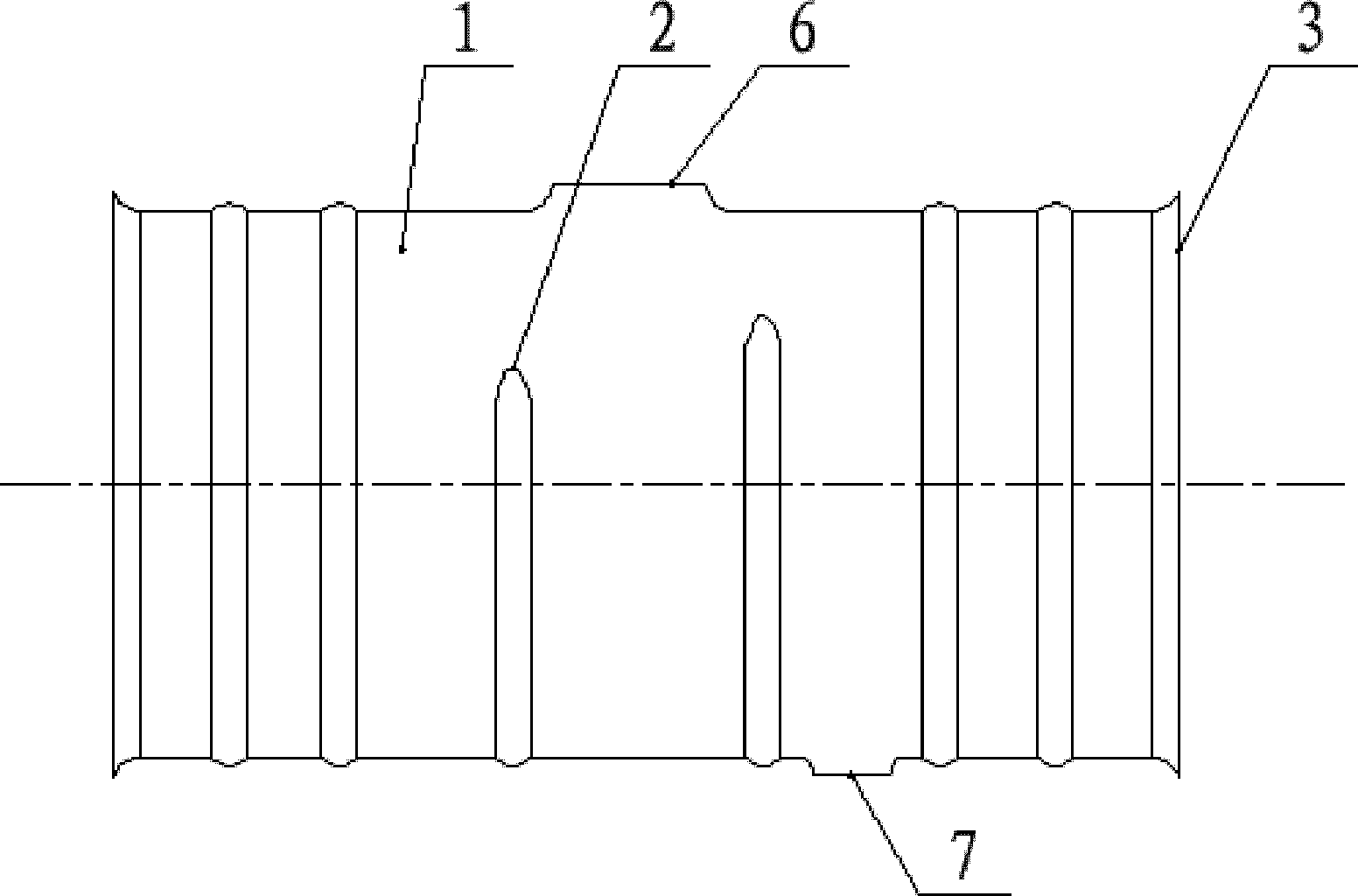

Sandwich composite pipe and rapid forming method thereof

ActiveCN102494238AShorten molding timeShorten the production cycleElongated constructional elementsSynthetic resin layered productsBiomedical engineeringRapid prototyping

The invention discloses a sandwich composite pipe and a rapid forming method thereof, which are mainly applied to electric power bearing pipe engineering. The sandwich composite pipe consists of an inner skin and an outer skin, wherein a sandwich layer is clamped between the inner skin and the outer skin. The sandwich composite pipe is characterized in that the sandwich layer is composed of an outline board which is formed by horizontally arranging and fixing a plurality of stripped materials into a whole. The forming method comprises the following steps of: forming the inner skin and the outer skin and paving the sandwich layer between the inner skin and the outer skin, wherein the sandwich layer is composed of the outline board which is formed by horizontally arranging and fixing a plurality of stripped materials into a whole. The forming steps of the outline board are as follows: (1) processing any one selected from a bamboo board, a cork wood, a foam material or an extruding and drawing rod into the stripped materials; and (2) juxtaposedly arranging several stripped materials on a plane and fixing into a row; compounding the inner skin, the outline board and the outer skin on a tubular die to form a pipe, and solidifying and forming. The sandwich composite pipe is light in weight, small in deformation amount, low in cost, rapid in forming and easy to popularize and apply.

Owner:北玻电力复合材料有限公司

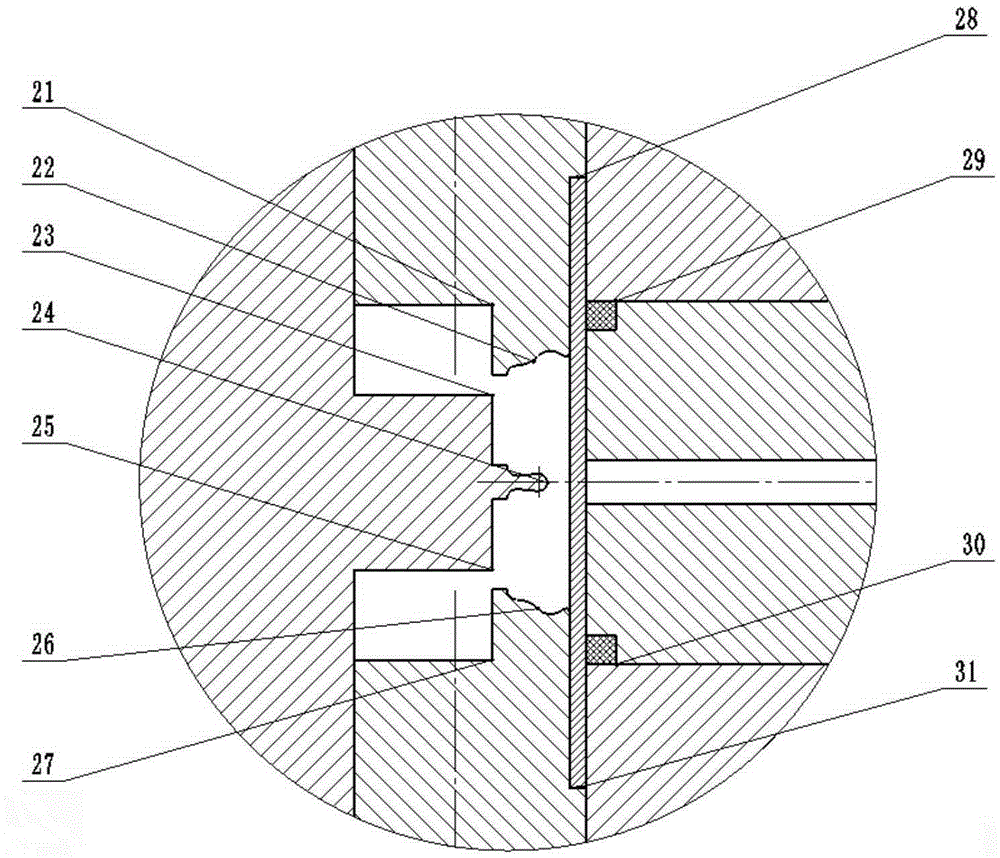

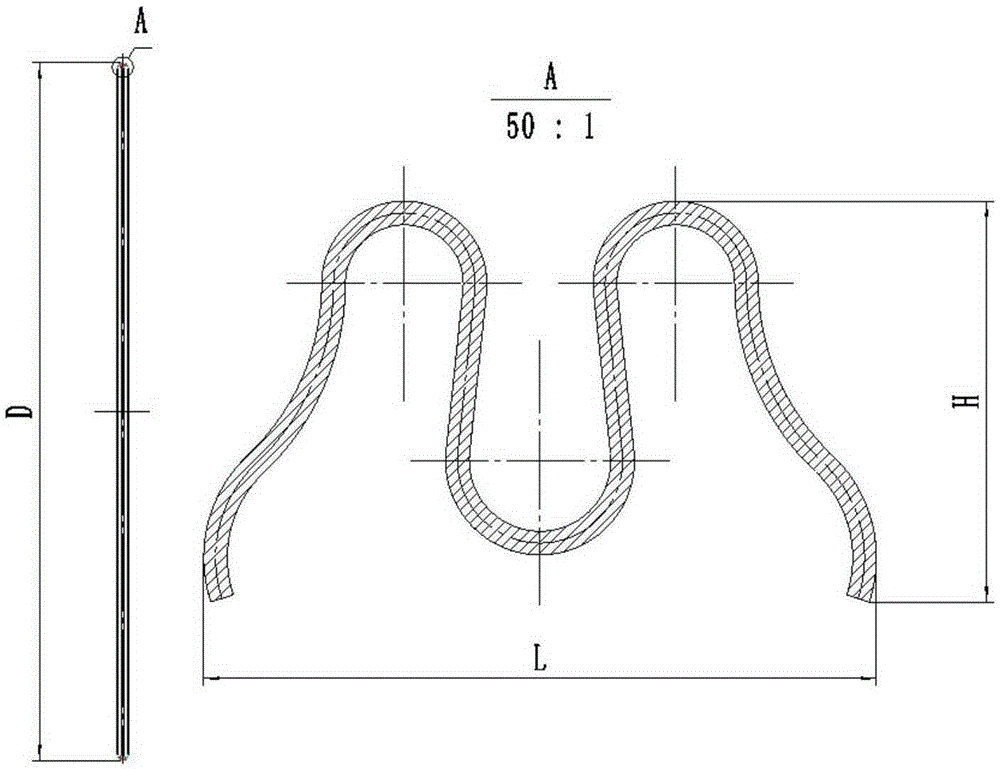

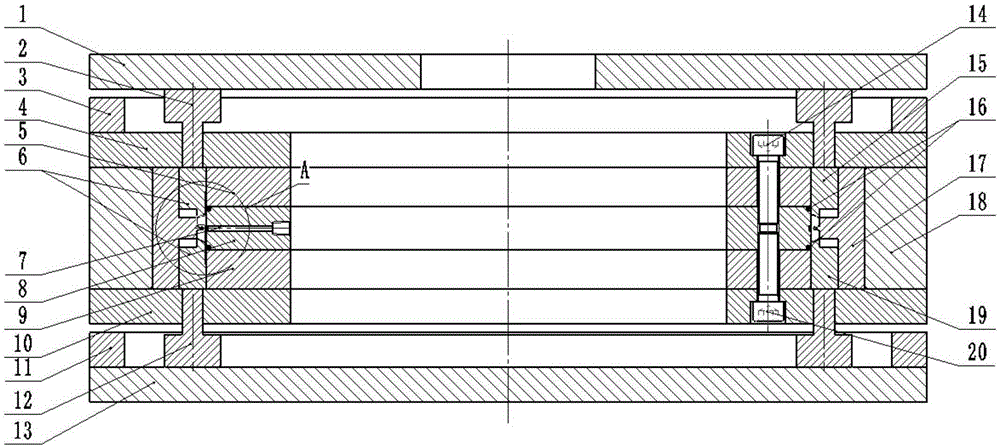

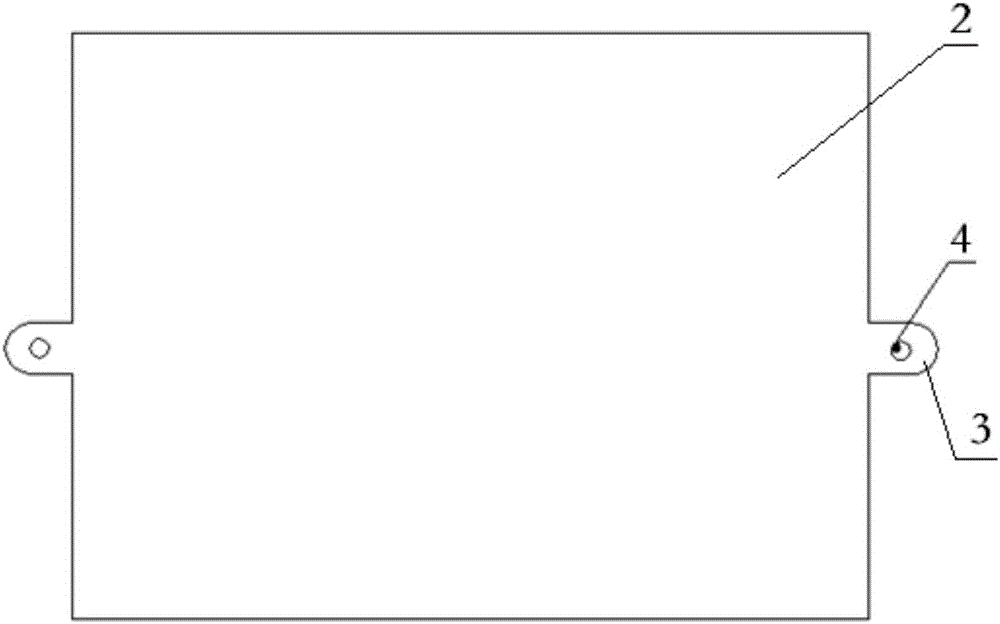

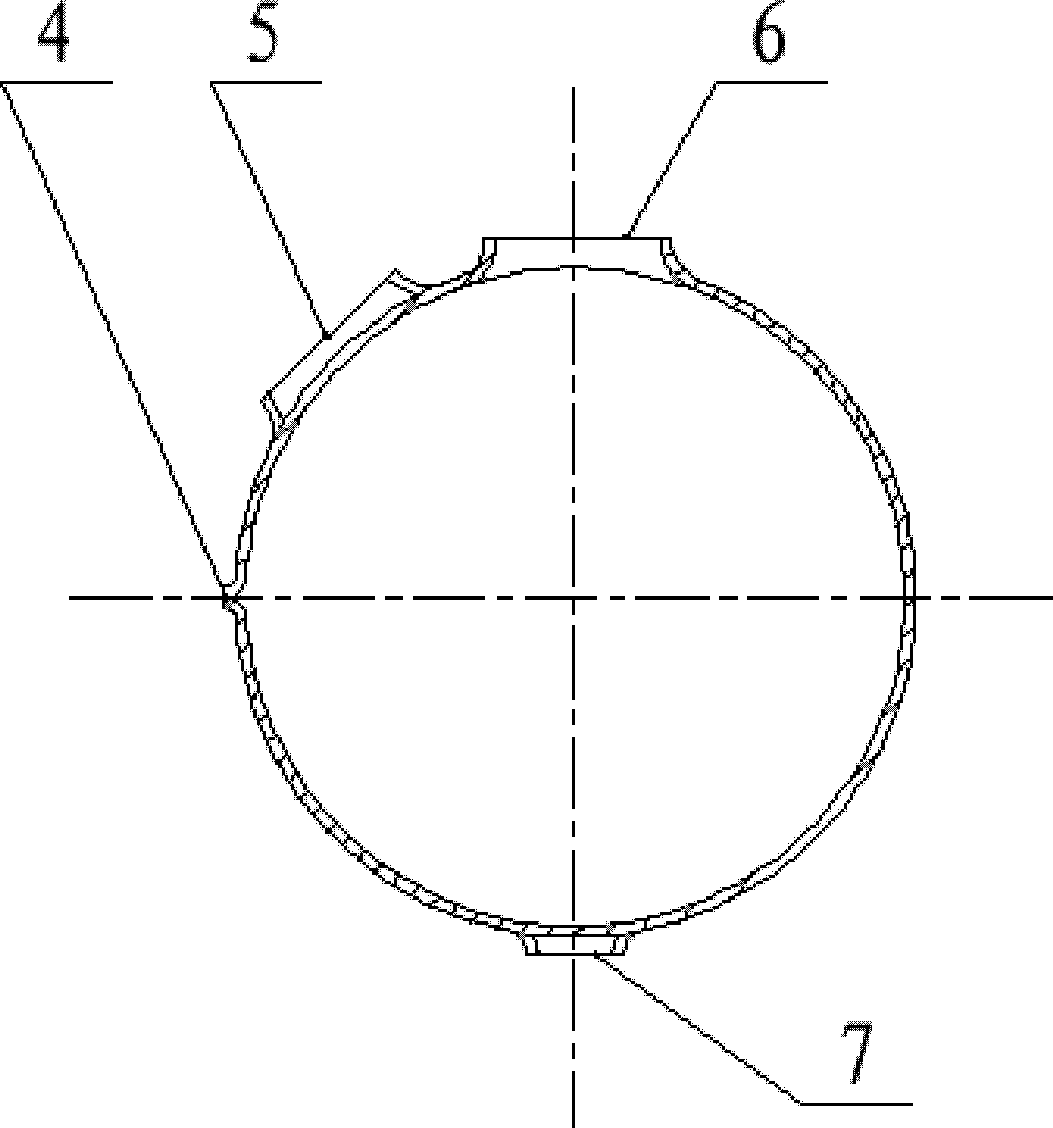

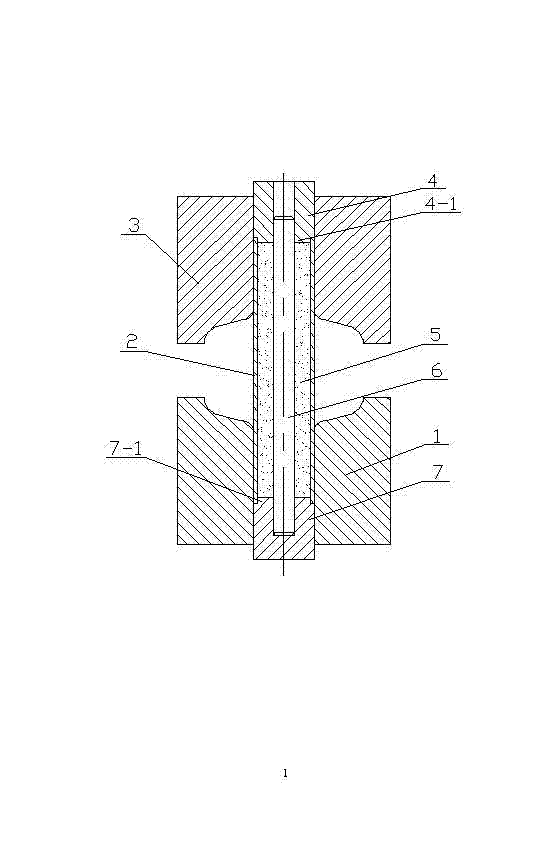

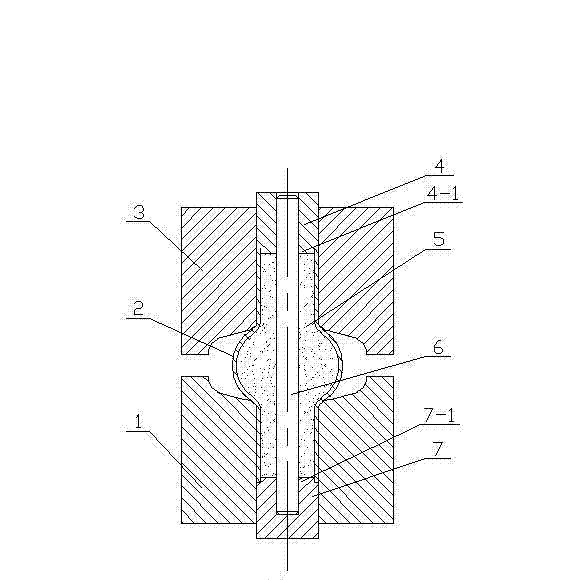

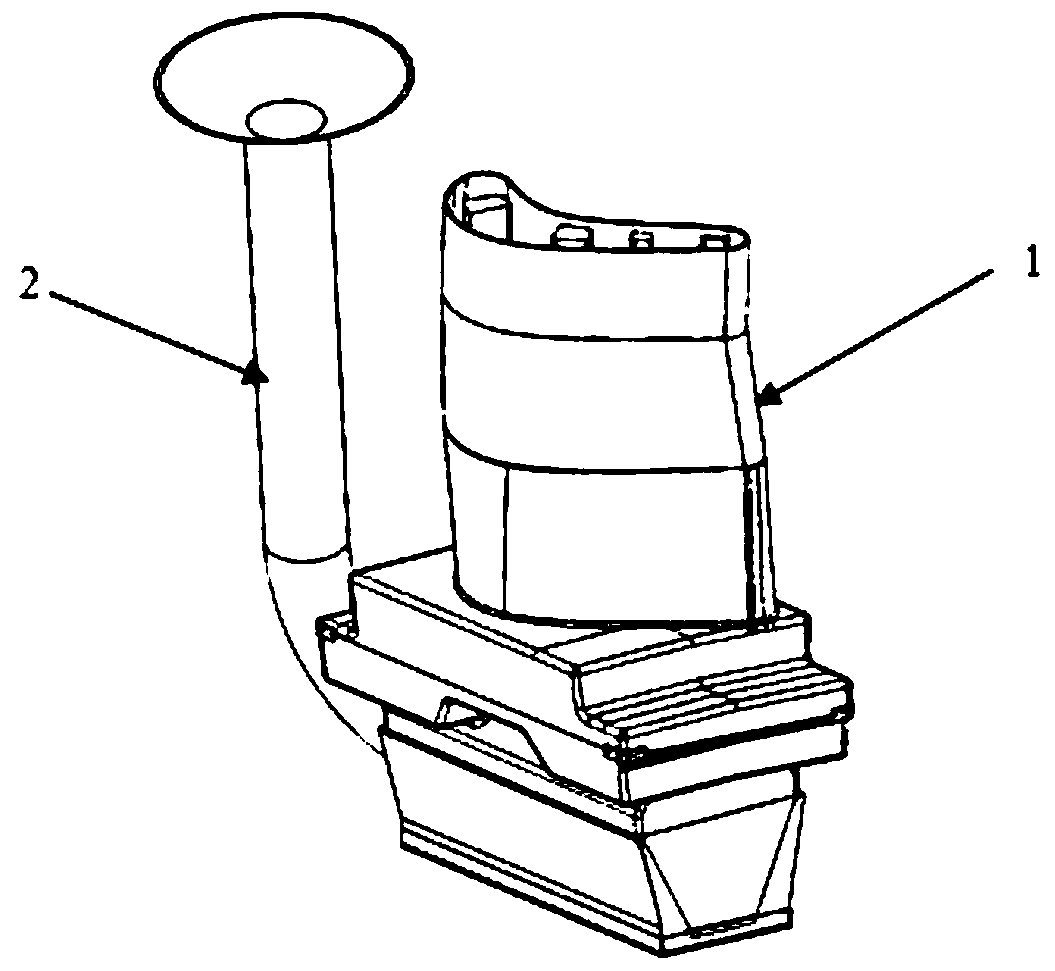

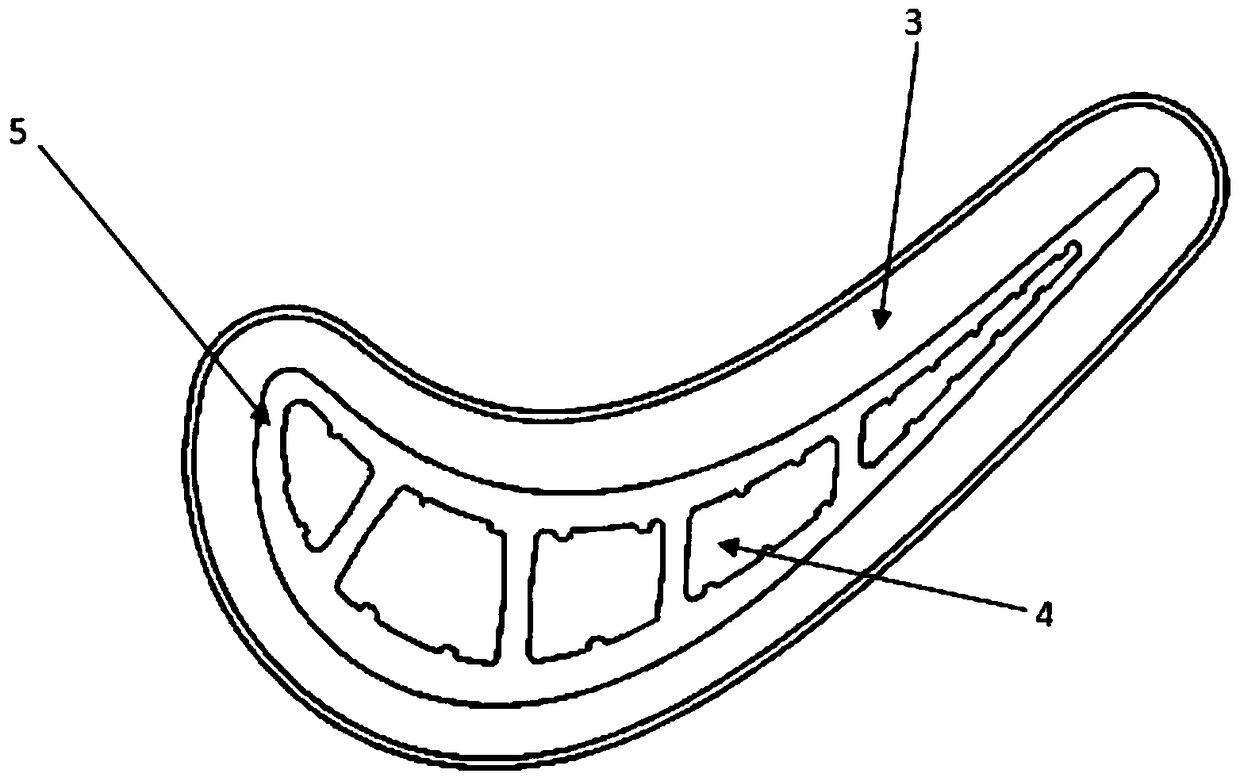

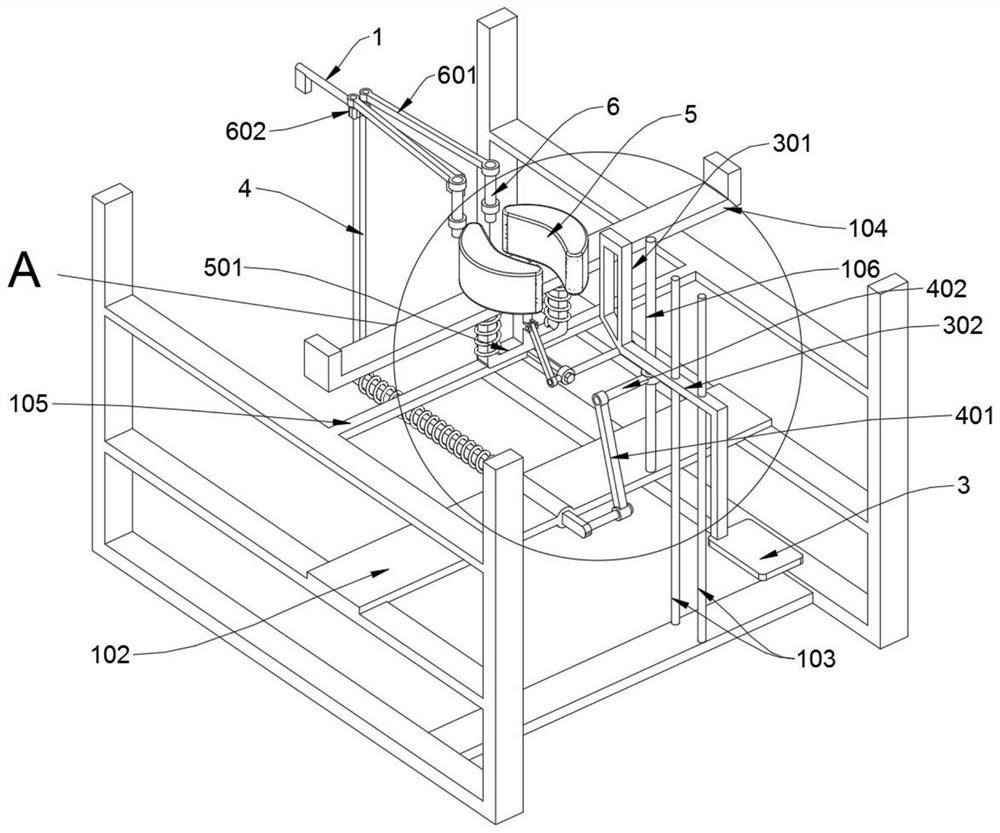

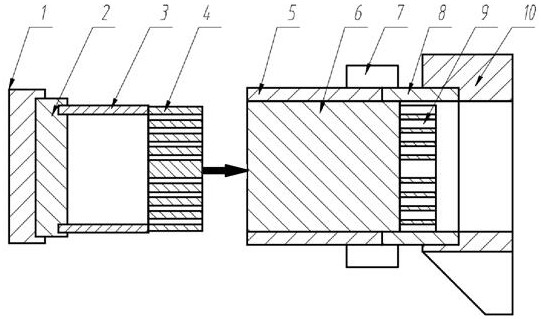

Single-pass integral molding device for M-shaped metal sealing ring

The invention provides a single-pass integral molding device for an M-shaped metal sealing ring. The single-pass integral molding device is characterized by comprising a bottom plate (13); a pressing plate (1), an upper feeding press block (2), an upper fixing plate (4), an upper sealing press block (5), a liquid chamber module (8), a lower sealing press block (9), a lower fixing plate (10) and a lower feeding press block (12) are sequentially arranged on the bottom plate (13) from top to bottom and are of an annular structure and consistent in axis; and the outer ring wall face of the upper sealing press block (5), the outer ring wall face of the liquid chamber module (8) and the outer ring wall face of the lower sealing press block (9) are flush with one another, and a movable mold (6), a middle mold (17) and an annular reinforced lantern ring (18) are sequentially arranged outwards from the outer ring wall faces, wherein the middle mold (17) is formed by two symmetrical half molds and of an annular structure, and the movable mold (6) is divided into a movable upper mold body (15) and a movable lower mold body (19).

Owner:中航空天发动机研究院有限公司

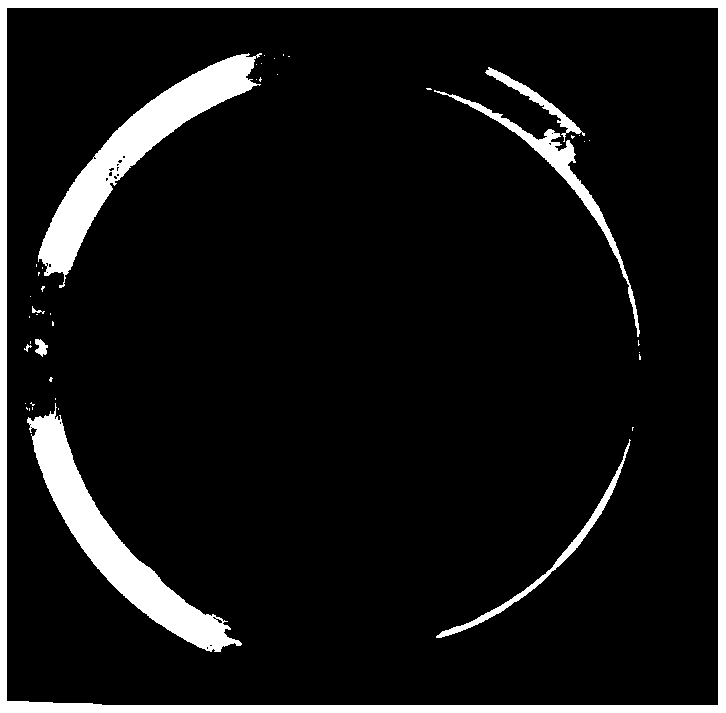

Electron beam fusing additive blank manufacturing and ring-rolling forming method for large-size metal annular piece

InactiveCN109434264AAvoid punchingImprove fatigue lifeAdditive manufacturing apparatusElectron beam welding apparatusManufacturing technologyRoll forming

The invention provides an electron beam fusing additive blank manufacturing and ring-rolling forming method for a large-size metal annular piece. According to the method, a precision ring-rolling technology and an electron beam fusing additive manufacturing technology are combined, a roller is used for rolling an electron beam additive manufactured blank for deformation, and thus precise and rapidforming of the high-performance annular piece is achieved. The prepared large-size metal annular piece has a fine and uniform deformed structure, the defects of an as-cast structure, pores, non-fusion and the like of an electron beam fusing additive manufactured blank part are eliminated, residual stress and distribution in the part are reduced and improved correspondingly, and stability and reliability of performance of the large-size metal annular piece prepared through electron beam additive manufacturing in the using process are remarkably improved. Meanwhile, by means of the method, forming procedures of the annular piece are greatly reduced, production efficiency is improved, and the production cost of the part is lowered.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

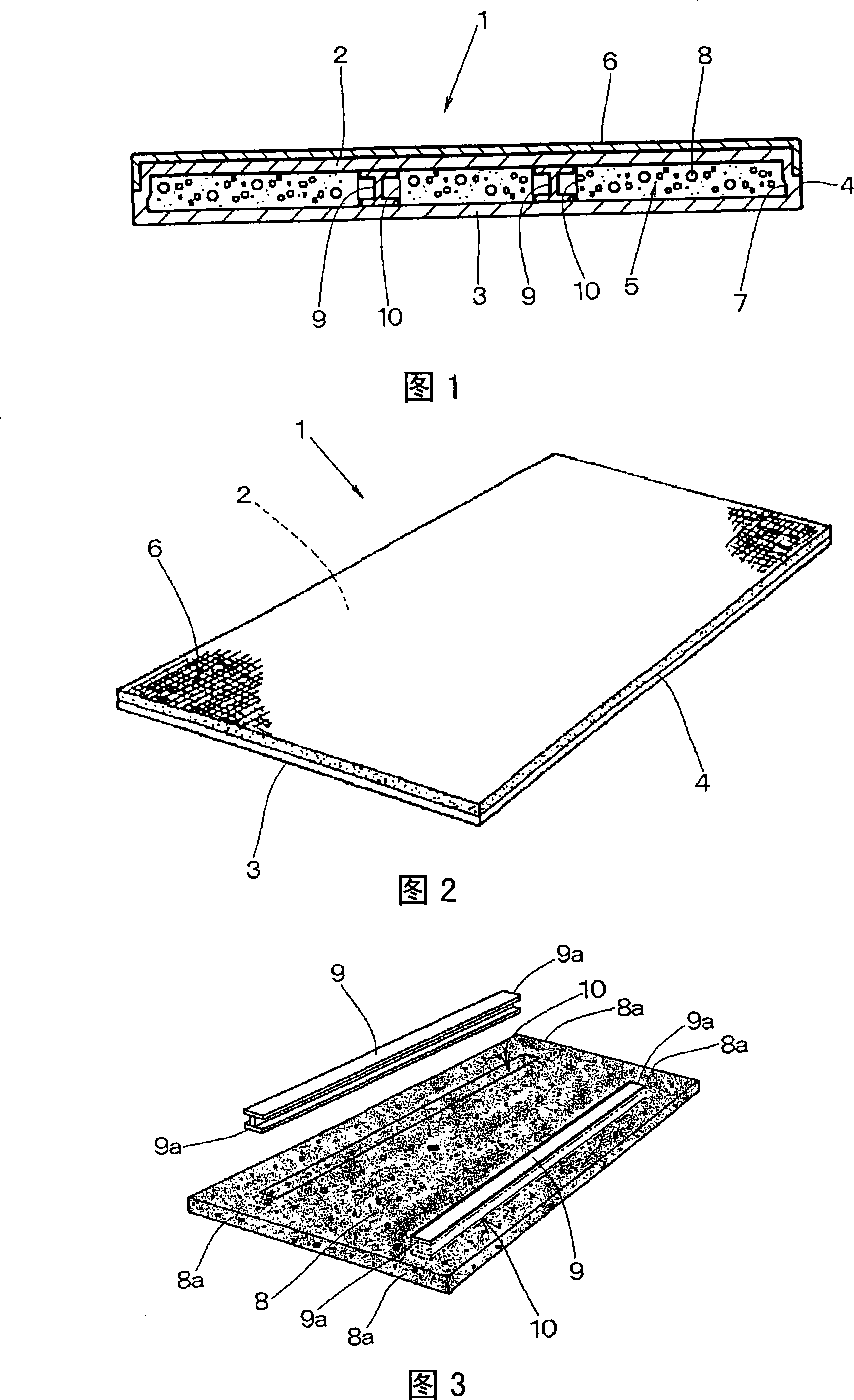

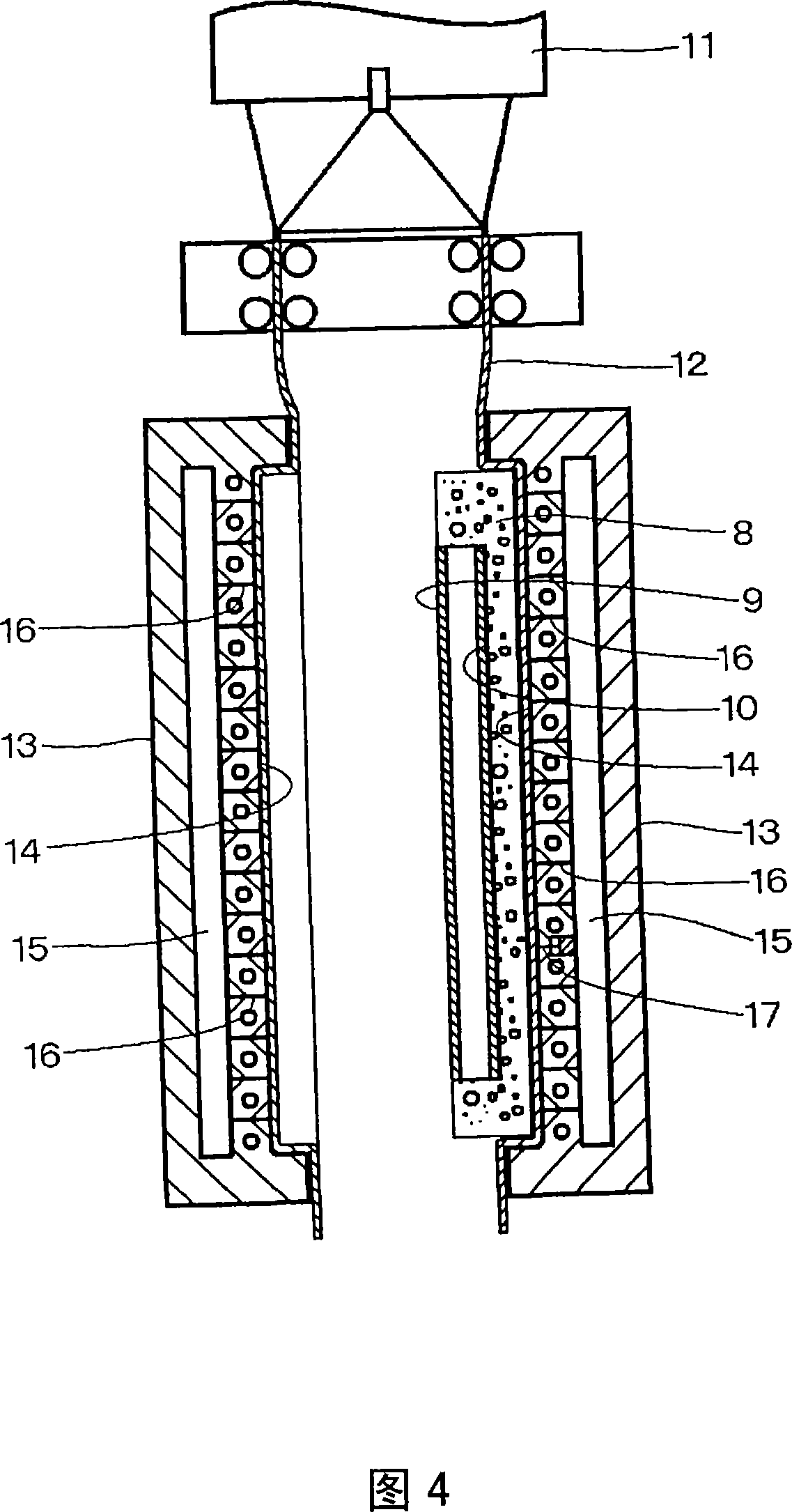

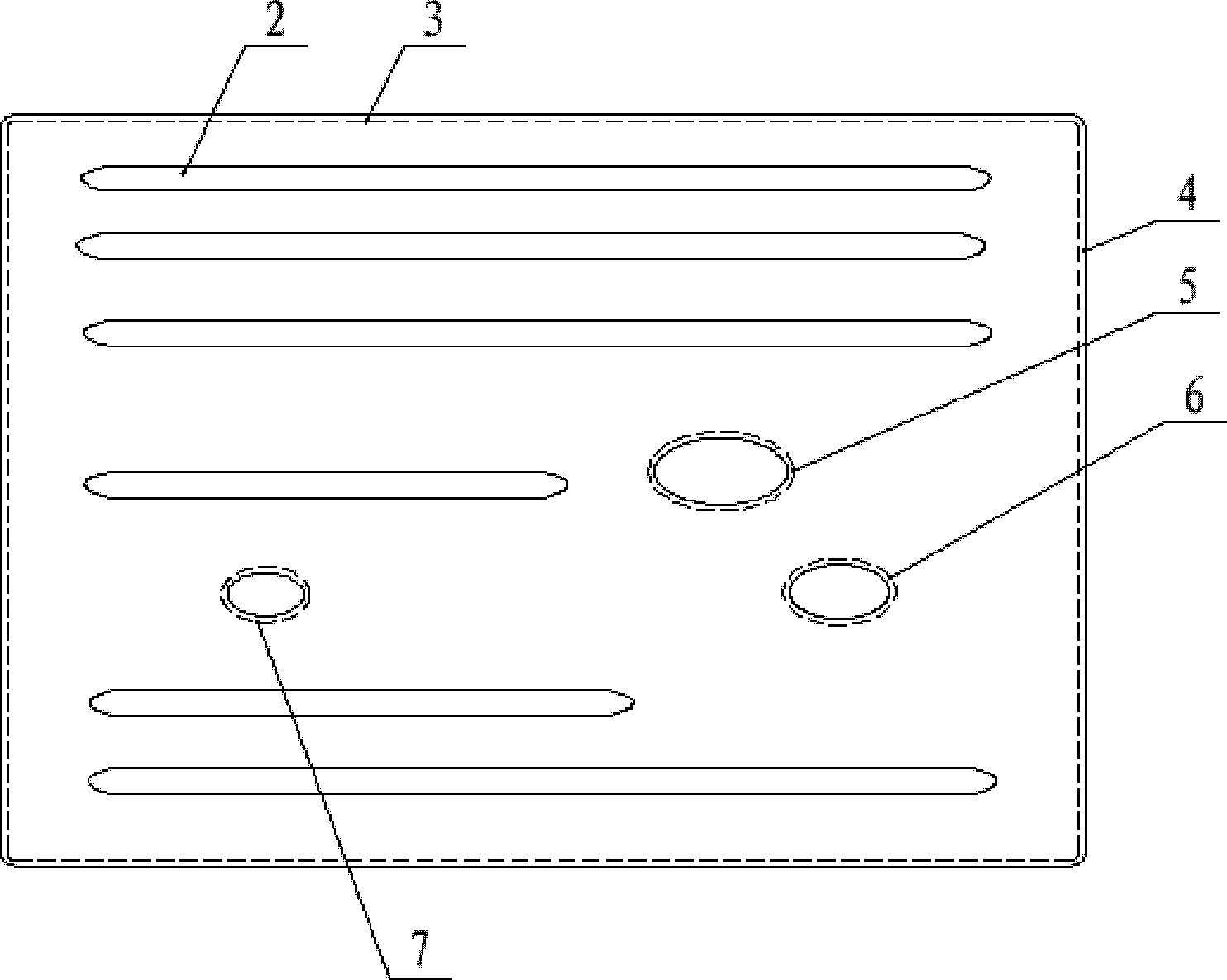

Resin panel and method of producing the same

ActiveCN101184602ADecide the positionSimplify the forming processConstruction materialThin material handlingDouble wallStructural engineering

[Object] Provided is a resin panel produced such that the positioning of a reinforcing material can be precisely done, rattling movement is prevented and distortion by molding shrinkage is not caused because the reinforcing materials are maintained in the foam. [Solving Means] A resin panel 1 is a hollow double-wall structure including a front wall 2, a back wall 3 and a peripheral wall 4 joining the front wall 2 and back wall 3 together. The peripheral wall 4 of the resin panel 1 has a welded part 7 on its entire periphery. Within a hollow part 5 is inner packed a foam 8 made of a thermoplastic resin that is formed in advance in the substantially the same shape as the shape of the space within the hollow part 5. The foam 8 is welded on the inner wall faces of the front wall 2 and back wall 3 of the resin panel 1. In the foam 8 are formed accommodation parts 10, 10 for accommodating reinforcing materials 9, 9. The reinforcing materials 9, 9 are lengthwise. The foam 8 intervenes between the ends of both of the reinforcing materials 9, 9 and the peripheral wall 4.

Owner:KYORAKU CO LTD

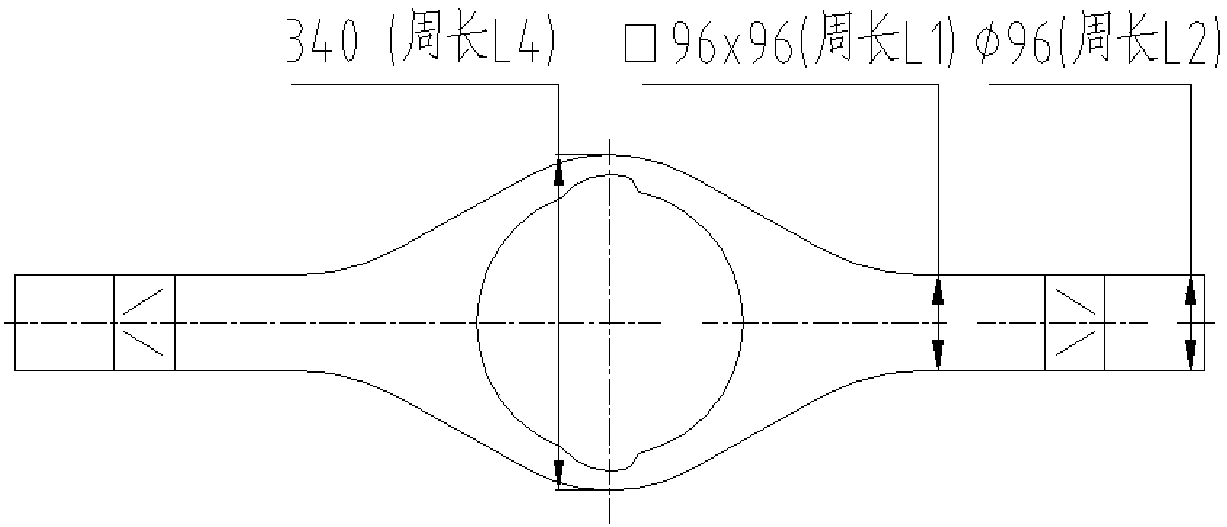

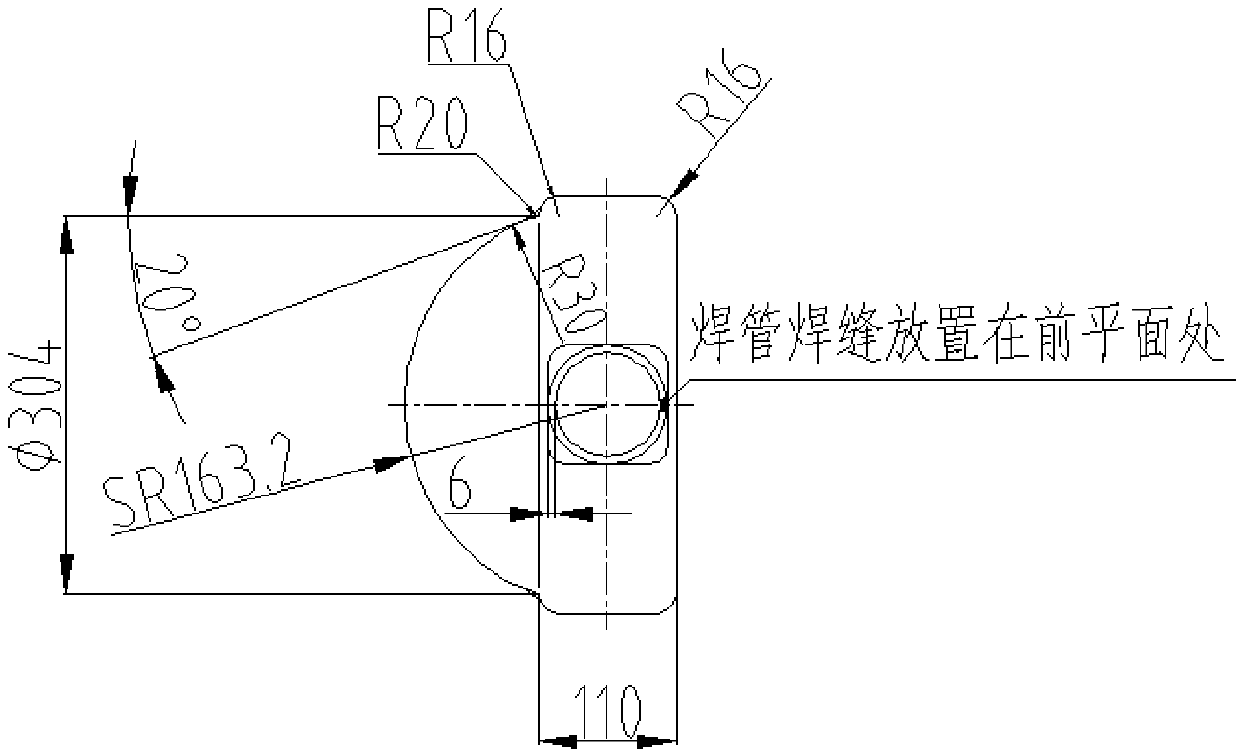

Annealing-free driving bridge shell hydraulic forming method using high-strength welded pipe

PendingCN107639144AReasonable distribution of wall thicknessHigh strengthVehicle componentsRolling resistance optimizationPipe fittingHigh intensity

The invention discloses an annealing-free driving bridge shell hydraulic forming method using a high-strength welded pipe. A welded pipe blank is subjected to two times of end portion pushing and diameter reducing process, two times of middle part hydraulic bulging process and one liquid filling and pressing and shaping process to prepare a bridge shell. The first hydraulic bulging process adoptsa sliding bulging mold with a back pressure punch, the bulging volume is up to 1.8 times of pipe expansion rate, the thinning rate is not more than 10%, and the middle part of the pipe blank after forming is an axisymmetric cylinder. The second hydraulic bulging process adopts a sliding bulging mold with a fixed mold, the middle part of the pipe blank after forming is a non-axisymmetric cylinder shaped part, and the thinning rate is not more than 10%. The third liquid filling and pressing and shaping process prepares the preformed pipe blank into a bridge shell pipe fitting with flat front part and spherical rear part. A bridge shell product is prepared after cutting off an additional front cover. The annealing-free driving bridge shell hydraulic forming method using the high-strength welded pipe retains the advantages of light weight, high strength and high material utilization rate of the bridge shell hydraulic forming process, has the characteristics of simplified forming process, high production efficiency and the like, and can achieve the purpose of replacing the traditional bridge shell stamping and welding process.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

Forming method and forming mold of semi-closed sheet part

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

Aluminium alloy welding wire containing TiB2 particles

ActiveCN111112875ASolve the problem of low welding strength and easy thermal crackingImprove thermal stabilityWelding/cutting media/materialsSoldering mediaMetallurgyMaterials science

The invention discloses an aluminium alloy welding wire containing TiB2 particles. The aluminium alloy welding wire comprises the following elements by weight: 1.1%-3.1% of Zn, 4.1%-4.9% of Mg, 1.3%-1.7% of Cu, 0.02%-0.3% of Zr, 0.03%-0.3% of Cr, 0.01%-0.4% of Fe, 0.01%-0.3% of Si, 0.01%-0.4% of Mn, no more than 6% of TiB2 particles and the balance Al, wherein the diameter of the TiB2 particles is11 micrometers-30 micrometers.

Owner:SHANGHAI JIAO TONG UNIV

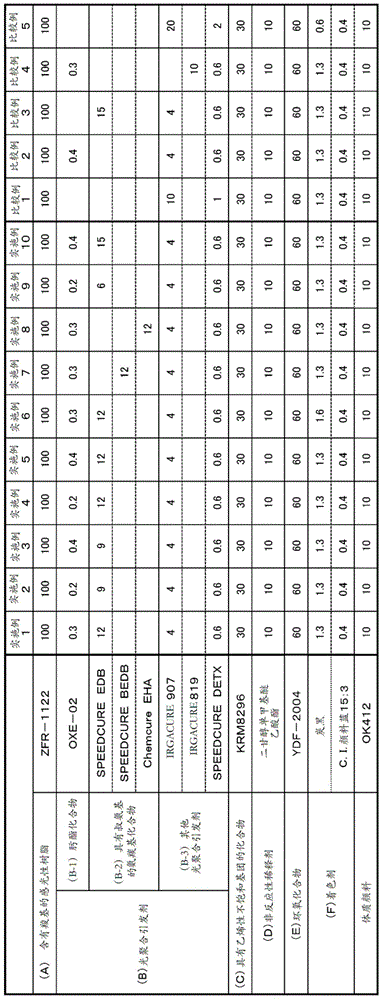

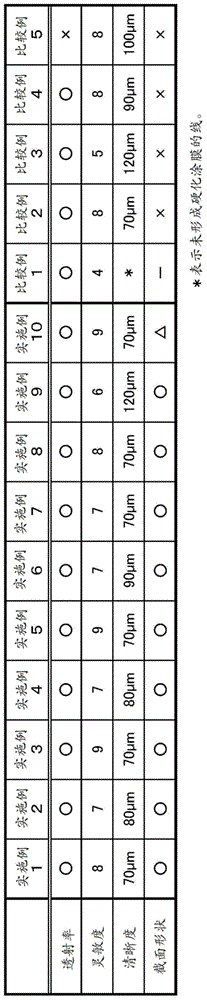

Photosensitive resin composition

InactiveCN104076603AAffect the transmittanceAffect sensitivityPrinted circuit detailsPrinted circuit aspectsReactive diluentOxime

A photosensitive resin composition includes a carboxyl group-containing photosensitive resin, a photopolymerization initiator, a compound having an ethylenic unsaturated group, a non-reactive diluent, and an epoxy compound. The photopolymerization initiator includes an oxime ester compound and an aminocarbonyl compound having a tertiary amino group.

Owner:TAMURA KK

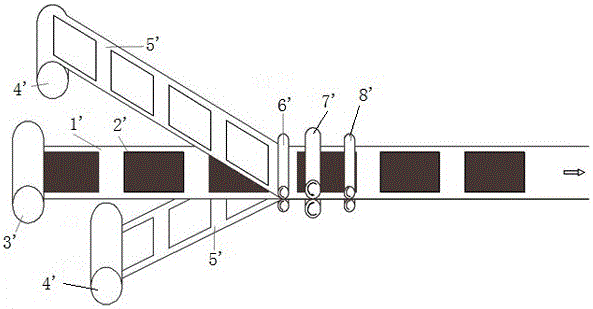

A preparation method of a fuel cell membrane electrode with a sealed frame

ActiveCN104617310BGuaranteed accuracyGuaranteed reliabilityCell electrodesPolymer scienceCell membrane

The invention discloses a method for preparing a fuel cell membrane electrode with a sealing frame. The process is simple and easy to realize. The method comprises the following steps: feeding a polymer electrolyte membrane and a sealing frame material with a layer of hot melt adhesive into a rolling device of a hot pressing platform, jointing the sealing frame material to edges of two sides of the polymer electrolyte membrane through heating rolling, and laminating a gas diffusion layer coated with a catalytic layer on two sides of the polymer electrolyte membrane so as to form a membrane electrode component. In the preparation process, a catalyst liquid is directly coated on the gas diffusion layer instead of the polymer electrolyte membrane, so that damage to a catalytic layer is reduced, the situation that later process is affected by swelling deformation of the membrane in the spraying process is avoided, the formation procedure can be simplified, continuous large-scale production of GDE and MEA can be conveniently achieved, and the production efficiency is greatly improved.

Owner:KUNSHAN SUNLAITE NEW ENERGY +1

Continuous manufacturing method for vacuum insulation material

InactiveCN106457605ASimplify the forming processReduce loss rateThermal insulationPress rollersEngineeringVacuum chamber

The present invention relates to a continuous manufacturing method for a vacuum insulation material. The method includes a first step of putting a porous insulation material into an inner envelope having air permeability, three sides thereof being closed and one side thereof being open, and then sealing the inner envelope; a second step of flattening an upper broad side of the inner envelope; a third step of compressing the inner envelope flattened in the second step; a fourth step of sealing all sides of the inner envelope compressed in the third step, except for one side, with an outer envelope material having a shielding property, and packaging the sealed inner envelope; and a fifth step of sealing the one side of the inner envelope not sealed in the third step by putting the inner envelope sealed in the fourth step into a vacuum chamber and performing a vacuum operation to obtain a predetermined pressure.

Owner:(株)庆东ONE

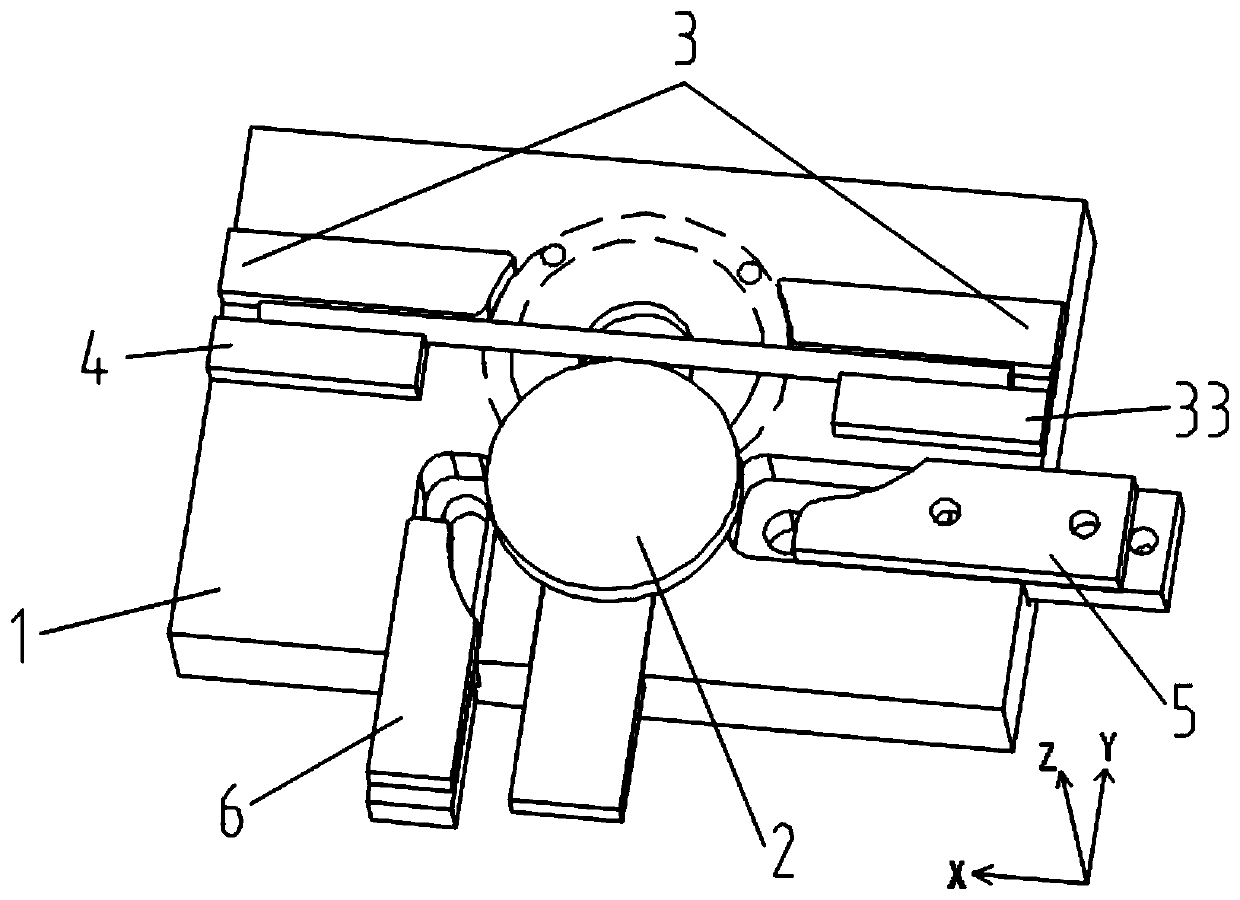

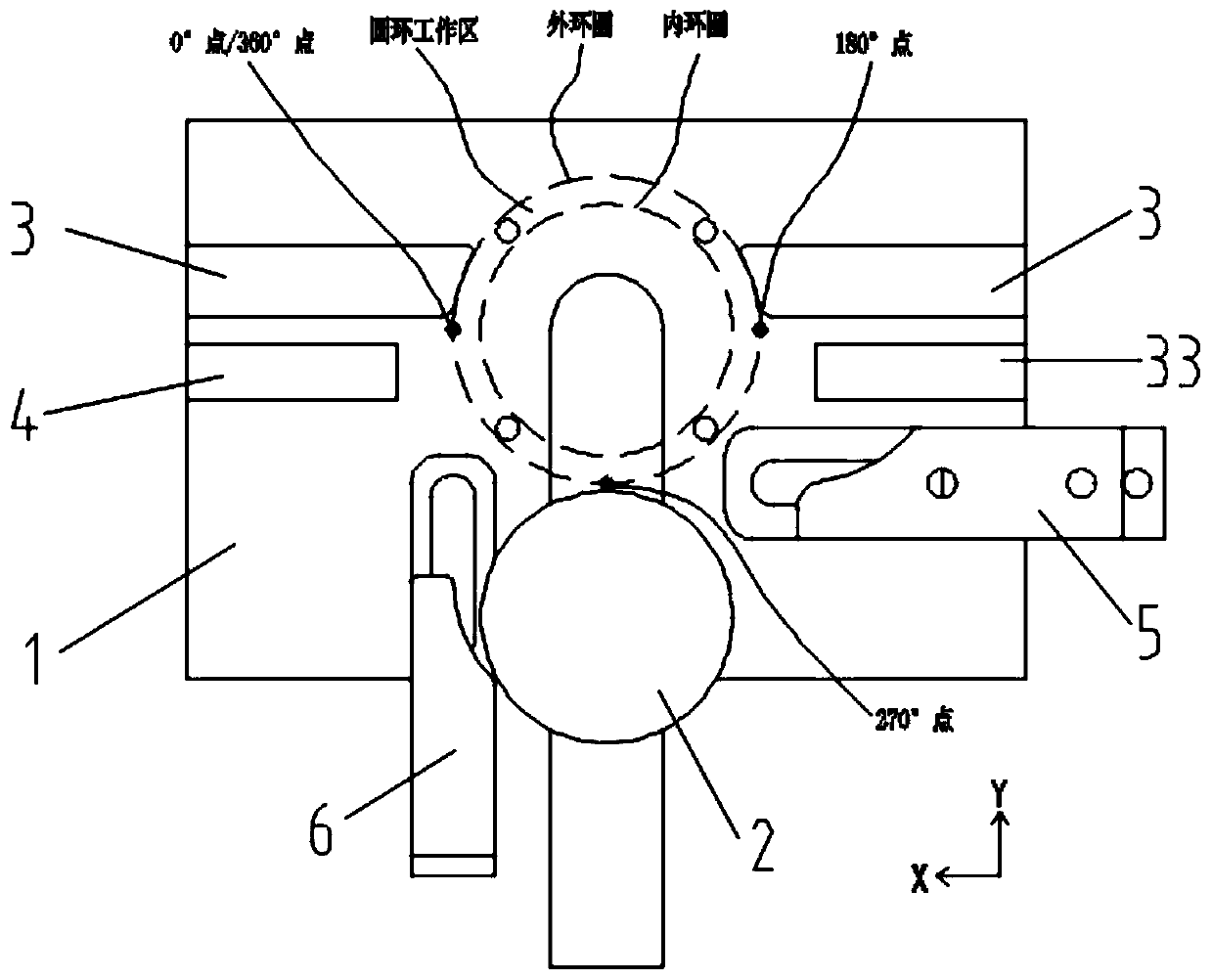

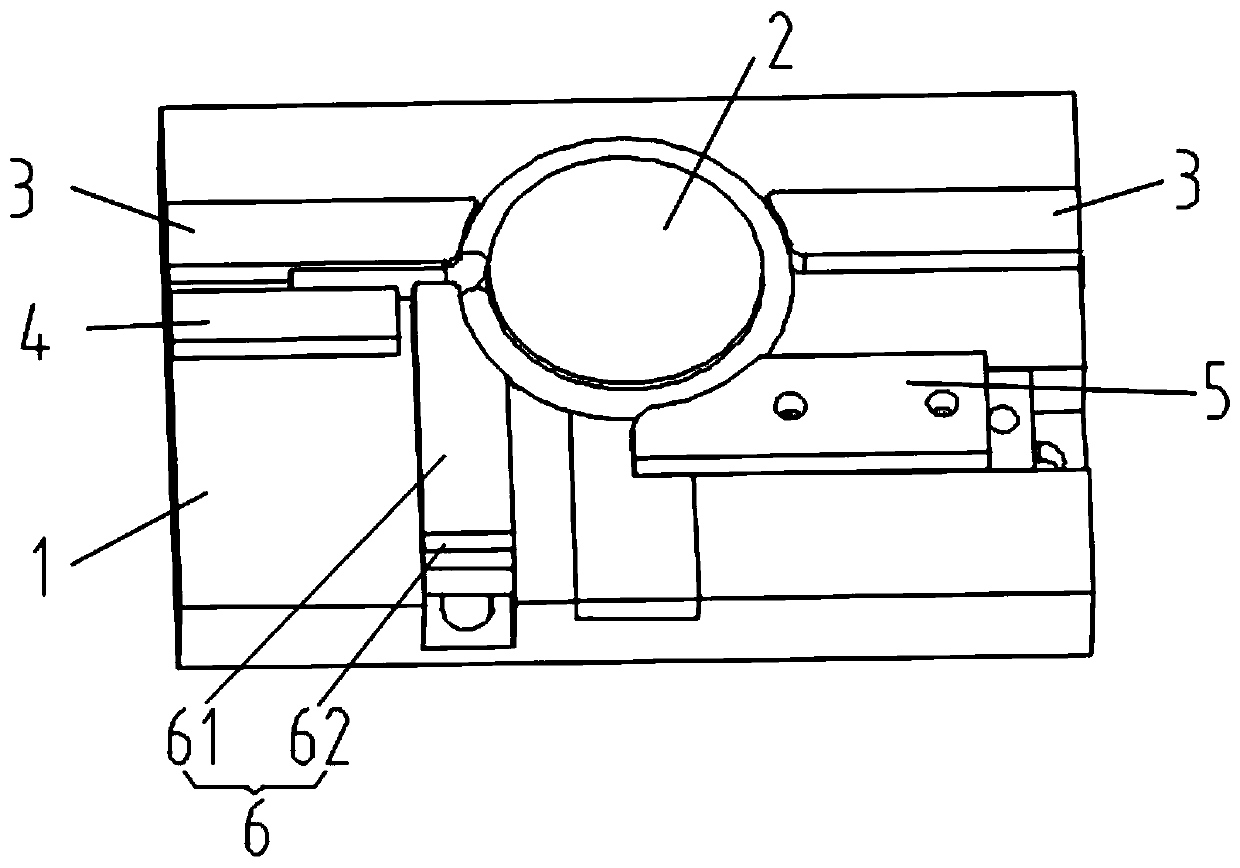

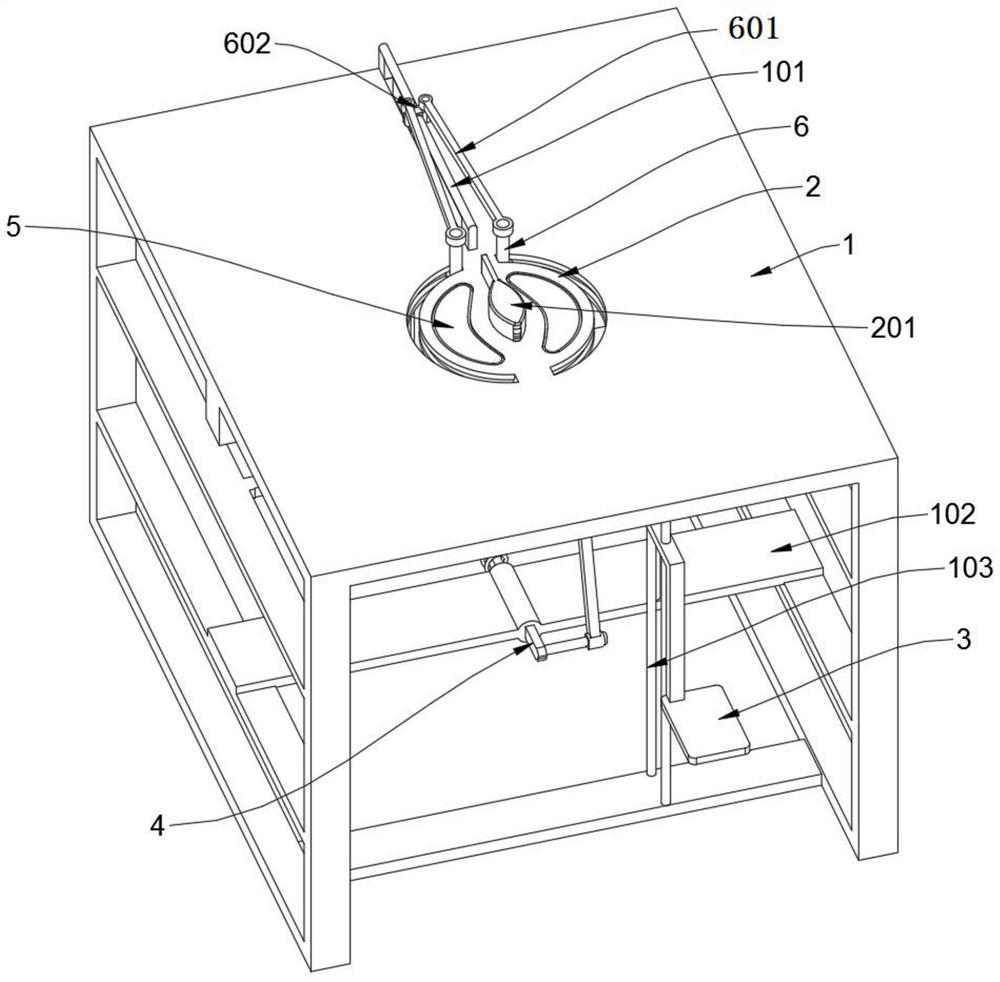

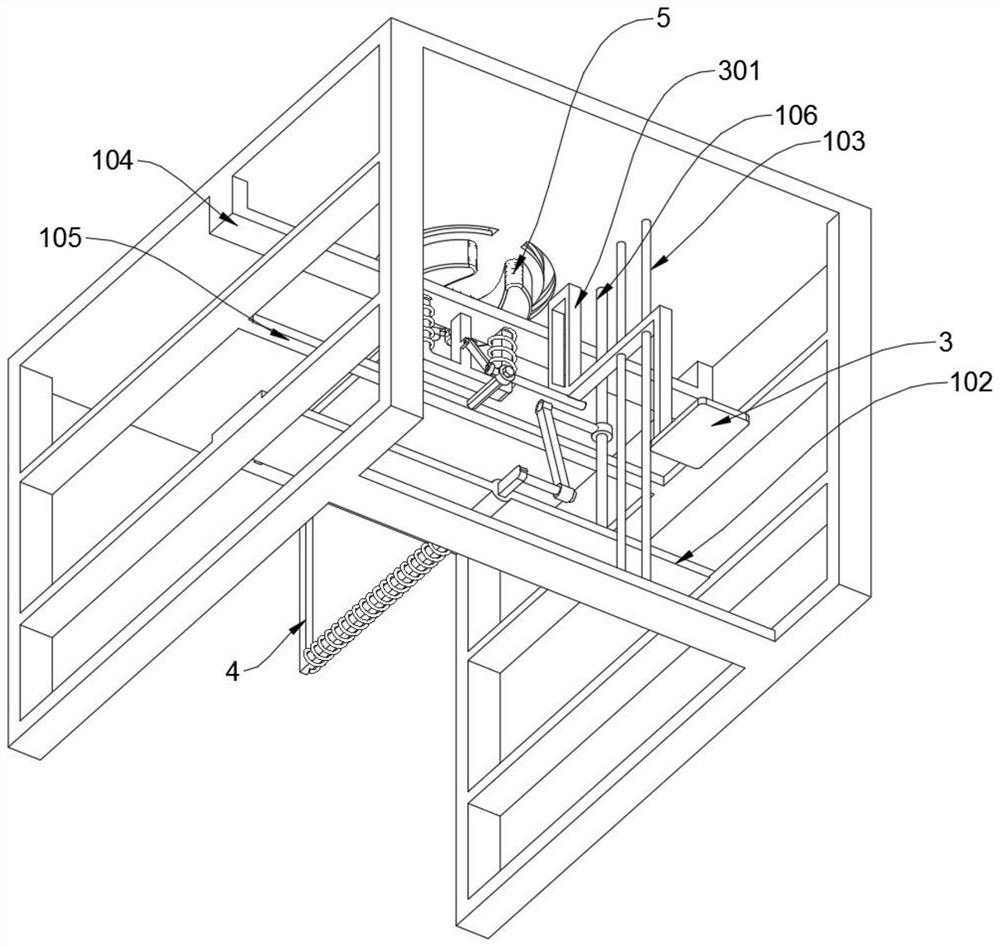

Multi-step continuous bending device of arc-shaped components

ActiveCN110814158ARealize compression moldingEasy to bendMetal-working feeding devicesPositioning devicesStructural engineeringMechanical engineering

The invention discloses a multi-step continuous bending device of arc-shaped components. The multi-step continuous bending device comprises a base. A round die pressing assembly is slidingly arrangedon the base in the Y direction, semi-ring setting assemblies are arranged on the portions, on the two sides of the round die pressing assembly, of the base in the X direction correspondingly, startingend positioning blocks are arranged on the sides, close to the round die pressing assembly, of the semi-ring positioning assemblies in the X direction, and a passageway allowing the components to penetrate is formed between the semi-ring setting assemblies and the starting end positioning blocks in the X direction. A three-fourth-ring die pressing assembly is slidingly arranged on the other sideof the round die pressing assembly in the X direction. The multi-step continuous bending device has the beneficial effects that the component bending procedures are simple and convenient to implement,the device is suitable for forming the components of different specifications, and the bending modules are simple in structure and compatible with multi-shape forming of the components.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

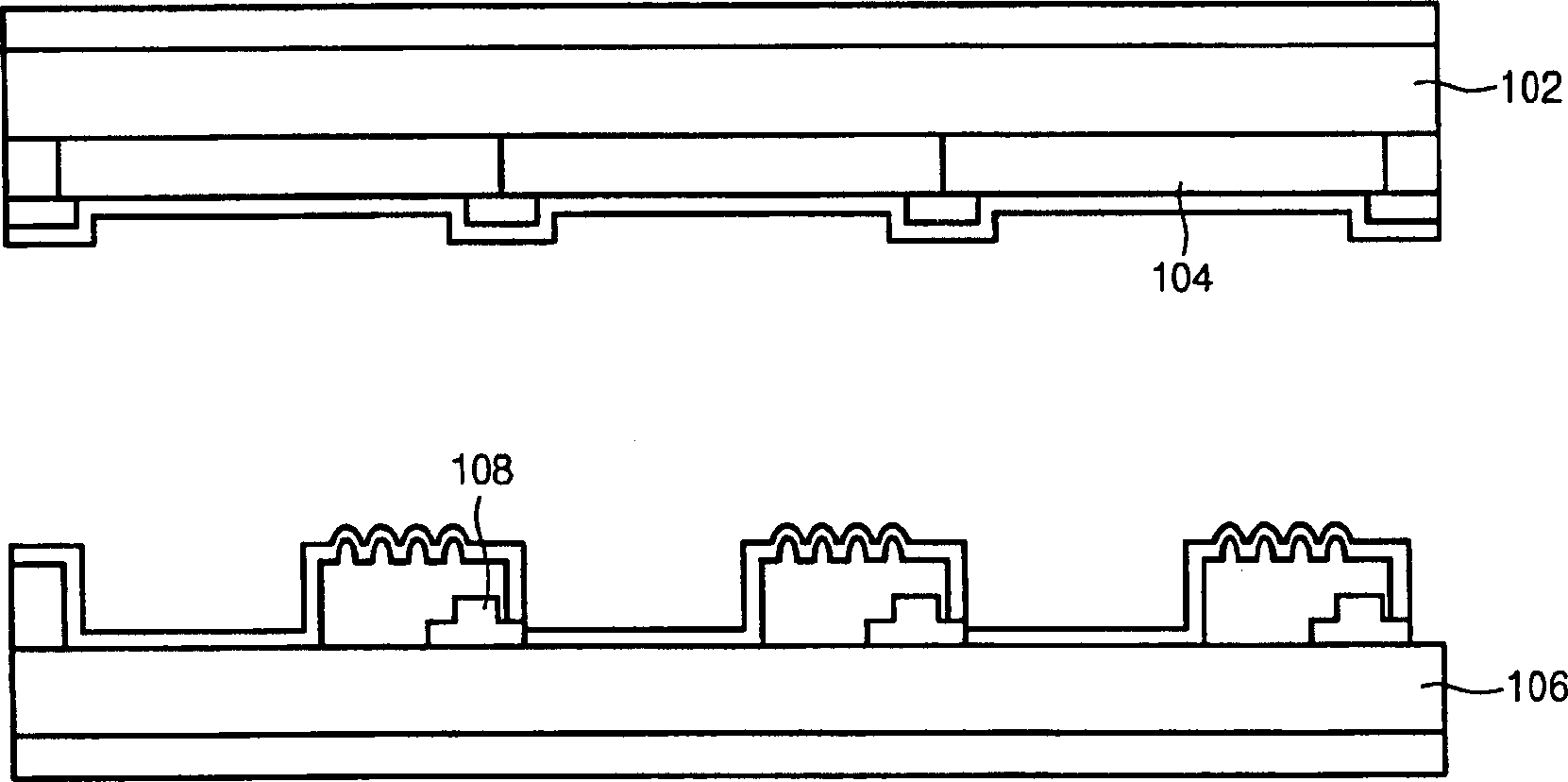

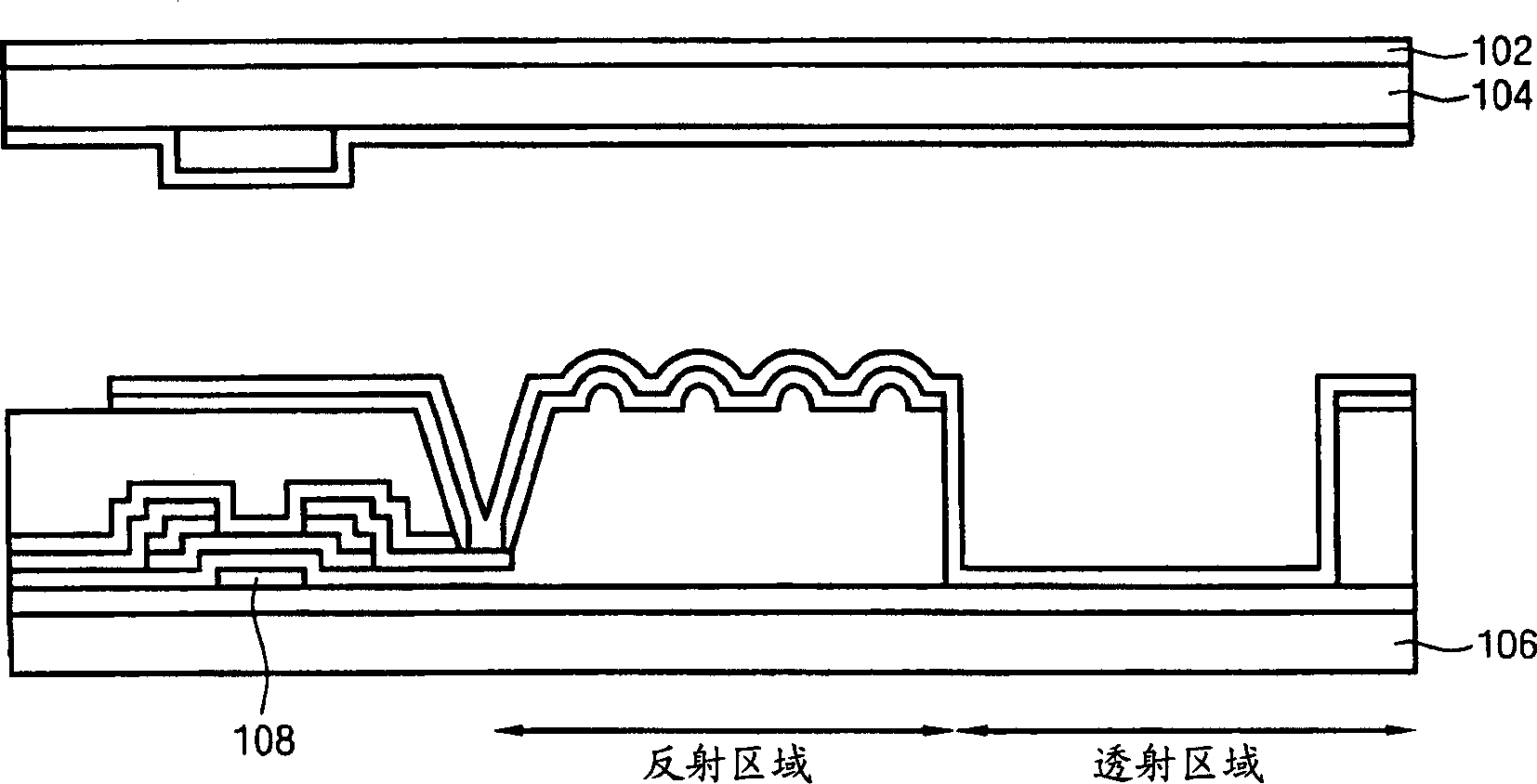

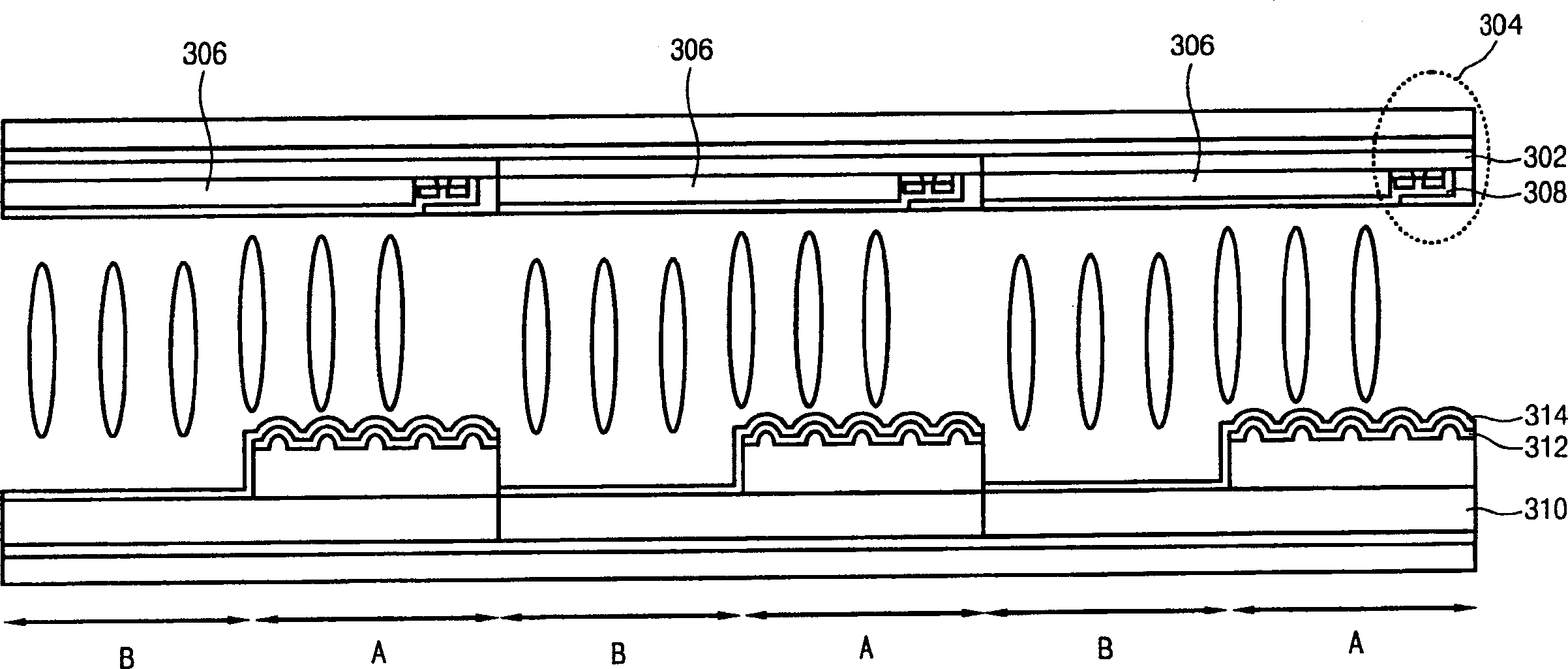

Half-transmitting LCD and its mfg.method

InactiveCN1651999ASimplify the forming processTransistorSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

The invention relates to a semi-transparent liquid crystal display apparatus and a manufacture method. The reflection part is formed into a liquid crystal mode drive with a simple working procedure, which is capable of inducing the transmitting type and semi-transparent type in the same array substrate. The invention provides an upper substrate, a thin film transistor is formed on the switch area of the upper substrate. A color filter is formed via coating a color resin on the thin film transistor and the development, a shading film for shading the leakage current on the thin film transistor is formed on the color filter. By utilizing the lower substrate with a reflection part and a transmitting part formed by the resin coating and the formed patterns, the formed embossed patterns procedures and the upper substrate leaving specific interval. A reflection plate is formed on the reflection part. And the transparent electrode is formed on the reflection plate.

Owner:BOE HYDIS TECH

Forming method for cylindrical shell piece with flanged holes

The invention relates to a forming method for a cylindrical shell piece with flanged holes, which is manufactured and invented to aim at a fuel tank of an airplane. The forming method for the cylindrical shell piece with flanged holes comprises the steps of paving and pasting a rubber pad on the outer side of an element to form a combined body, forming the combined body by rolling and bending, correcting the shape of the element and the flanged holes through a detachable combined type tire, and resolving the combined type tire after the correction. The forming method avoids the interference phenomenon of the element and a die during the disassembly, thus the element can not transform after being disassembled, and the unnecessary correcting processes are reduced.

Owner:XIAN AIRCRAFT IND GROUP

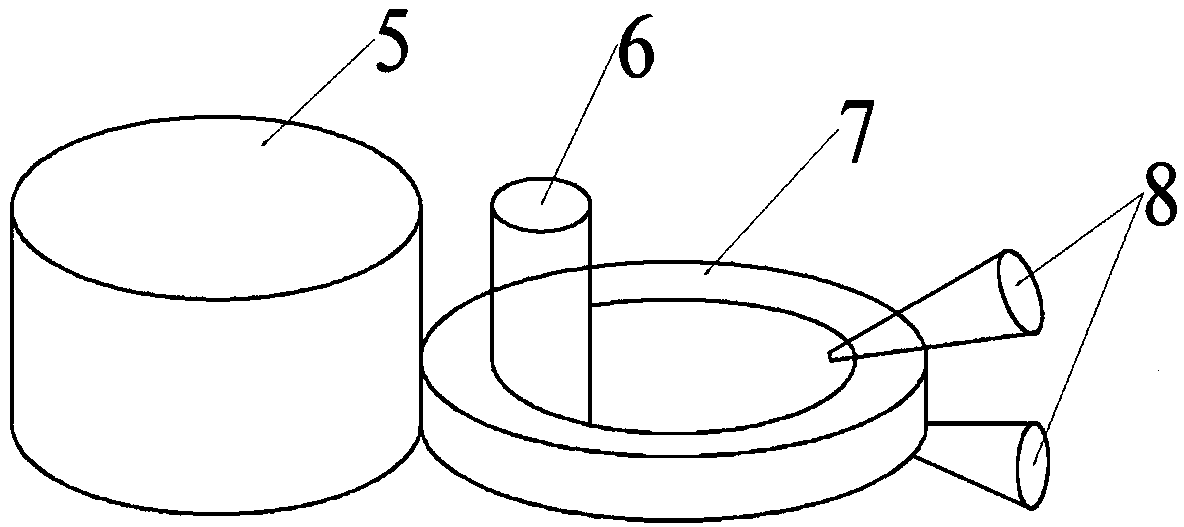

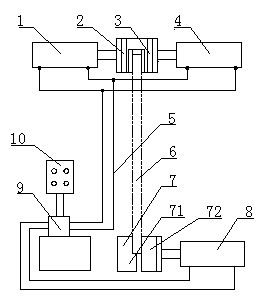

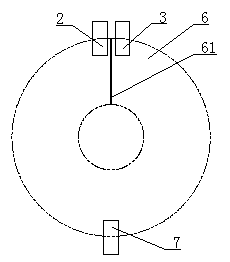

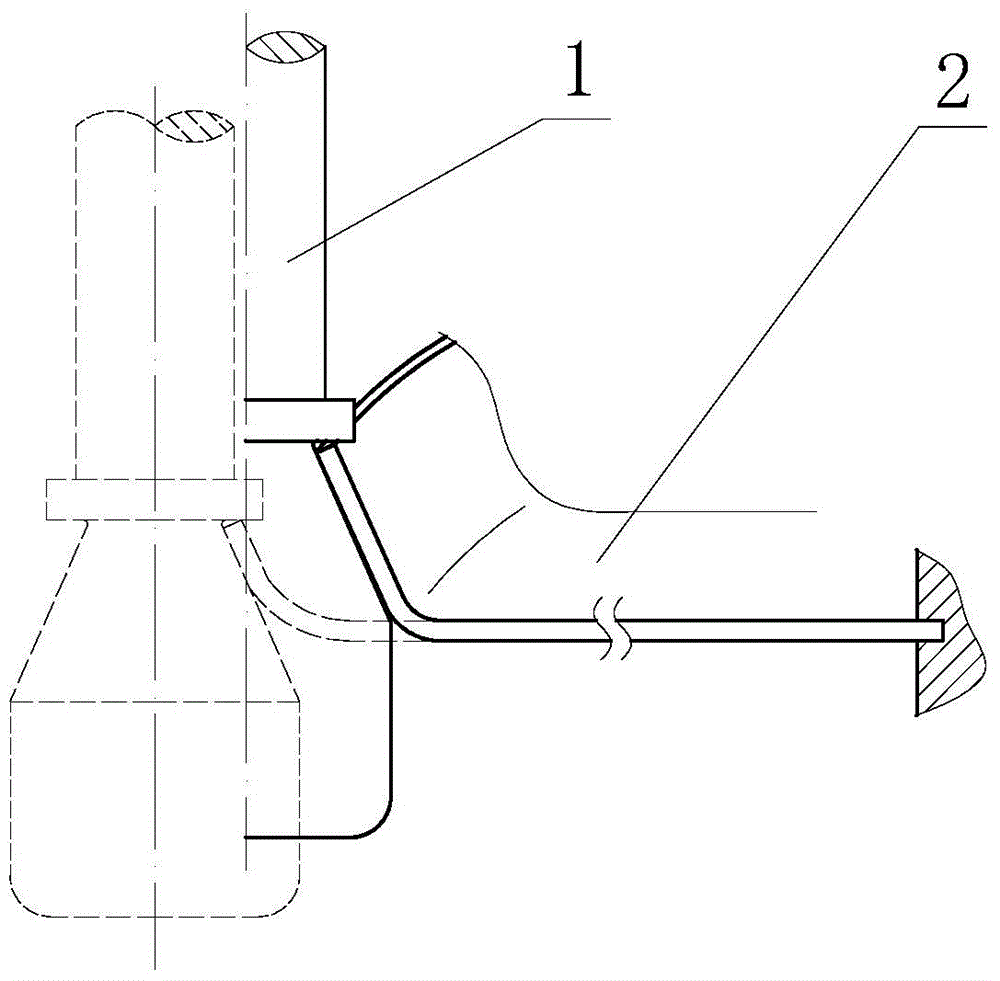

Helical blade forming device

The invention discloses a helical blade forming device, which comprises a left hydraulic cylinder (1), a left chuck (2), a right chuck (3), a right hydraulic cylinder (4), a lower chuck (7), a lower hydraulic cylinder (8), a hydraulic station (9) and an electric cabinet (10). The lower chuck (7) comprises a fixed fixture block (71) and a movable fixture block (72); the left chuck (2) is connected with a projecting shaft of the left hydraulic cylinder (1); the right chuck (3) is connected with a projecting shaft of the right hydraulic cylinder (4); the movable fixture block (72) is connected with a projecting shaft of the lower hydraulic cylinder (8); the hydraulic station (9) is respectively connected with the left hydraulic cylinder (1), the right hydraulic cylinder (4) and the lower hydraulic cylinder (8) by an oil pipe (5) to form a hydraulic control loop; the electric cabinet (10) is connected with the hydraulic station (9) by a lead to form an electric control loop. The helical blade forming device disclosed by the invention is simple in operation, safe and reliable, high in processing precision and capable of remarkably improving the work efficiency.

Owner:HUANGSHI ZHIYUN ELECTROMECHANICAL TECH INST

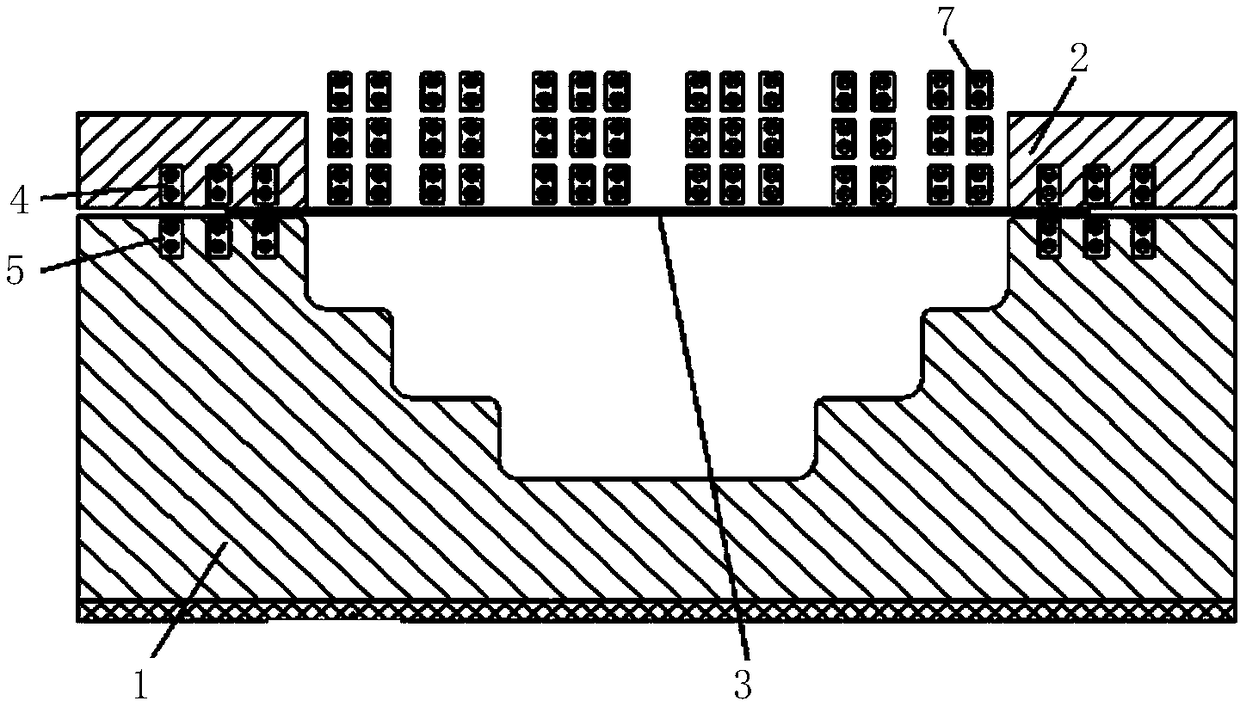

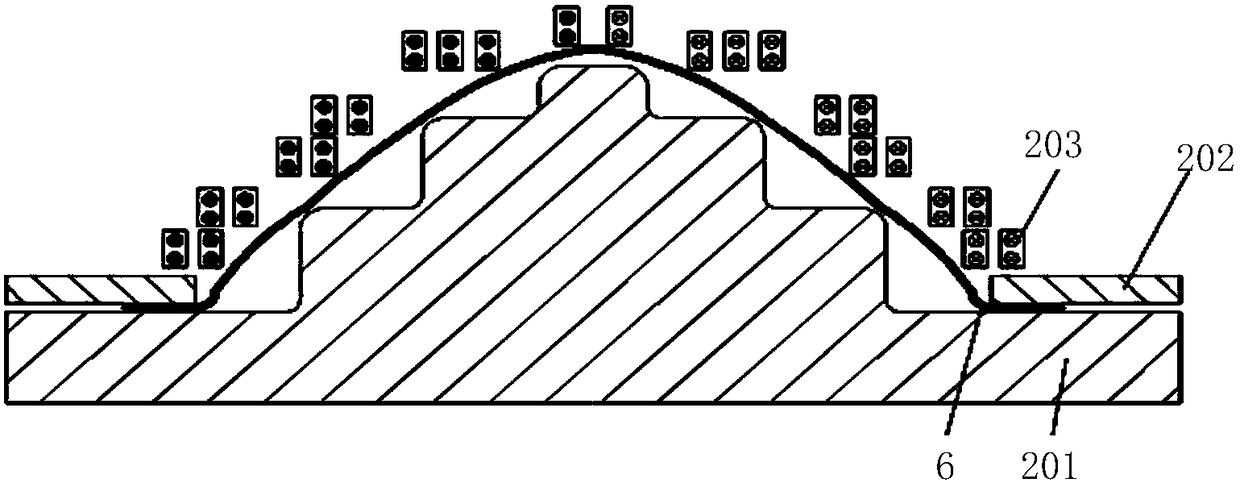

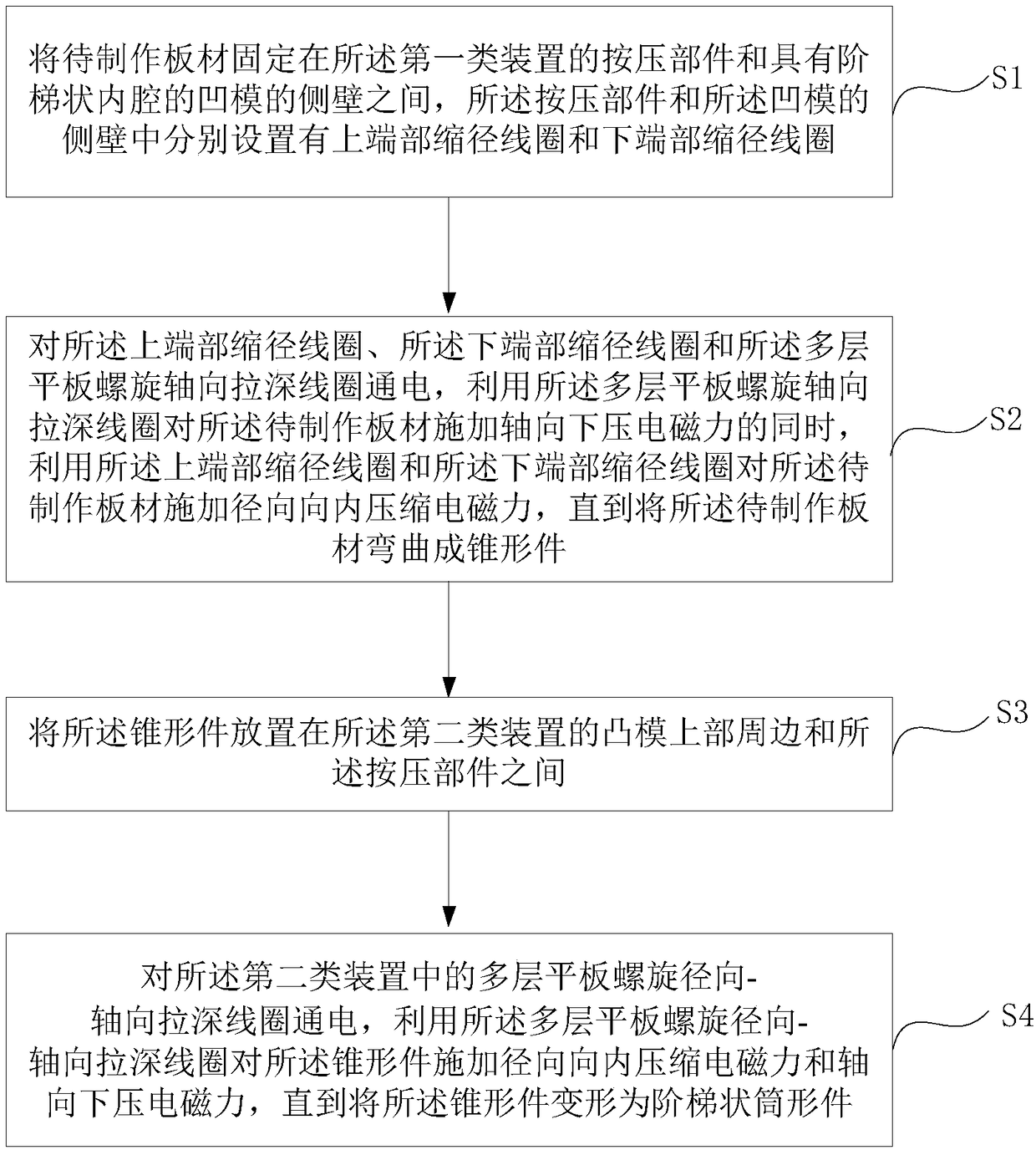

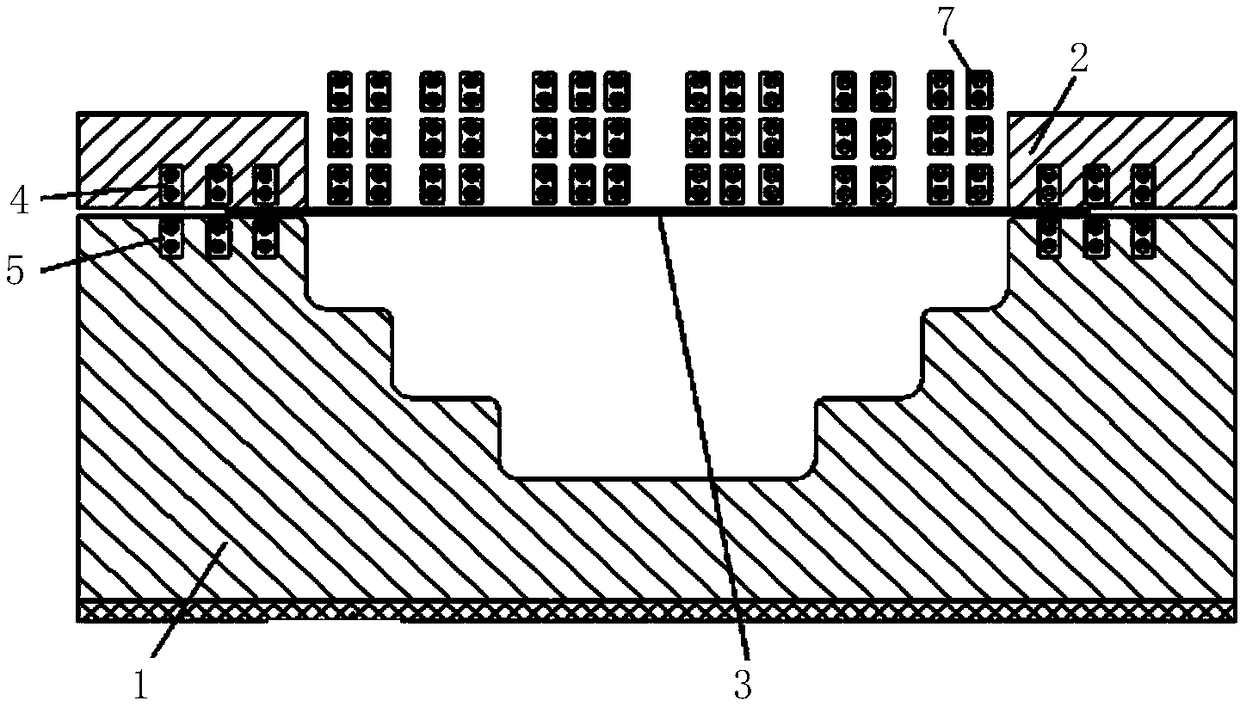

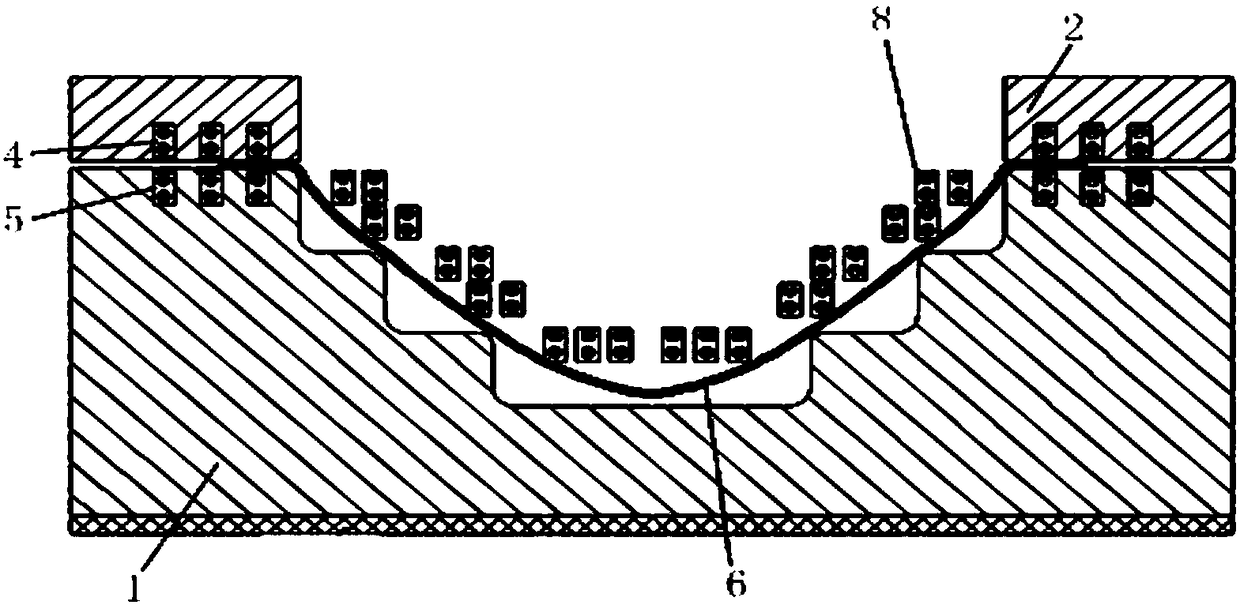

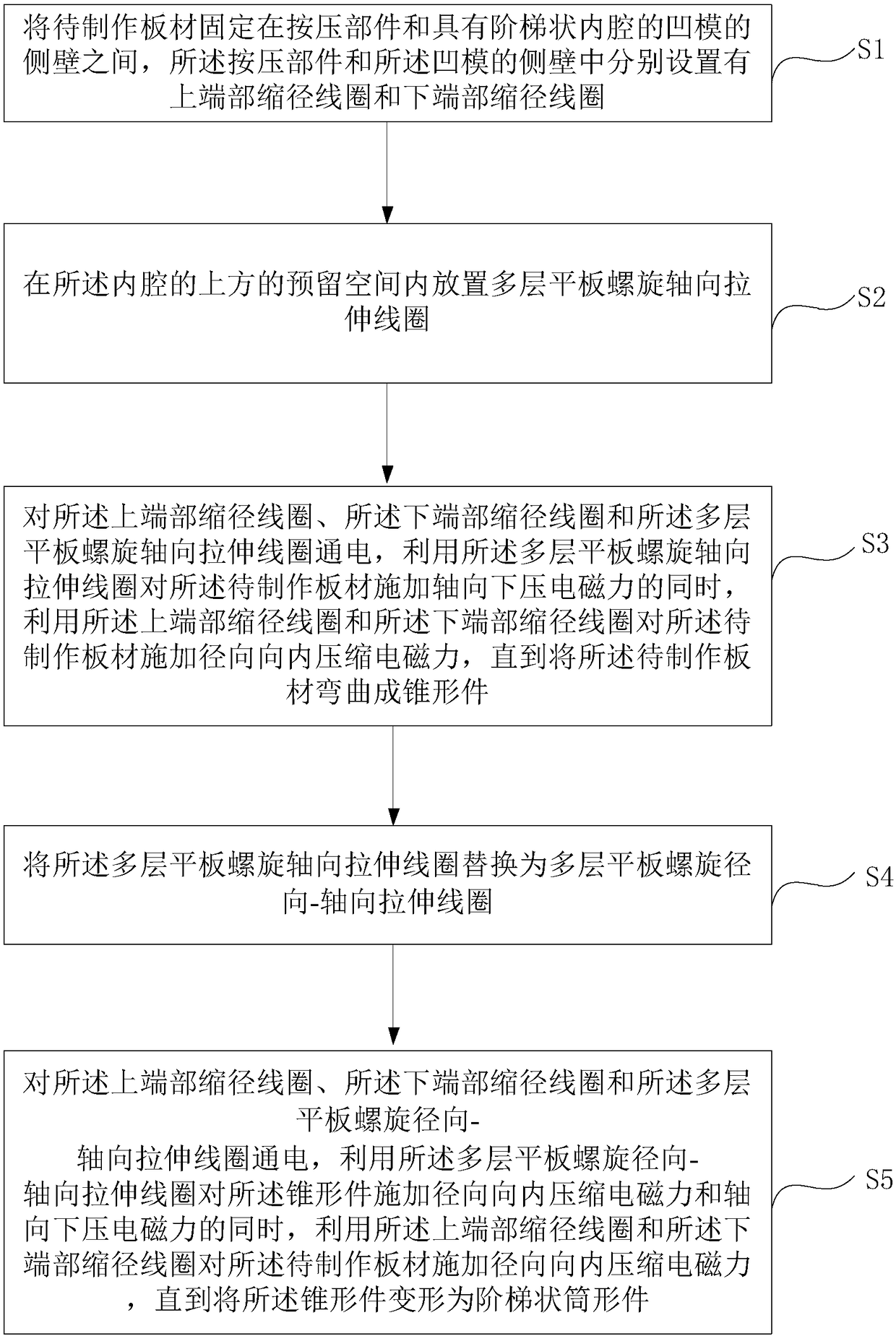

Ladder-shaped cylindrical part producing equipment and method based on magnetic field force drive

ActiveCN108127015APrevent wrinkling and instabilityAvoid tearingShaping toolsMagnetic tension forceEngineering

The invention discloses ladder-shaped cylindrical part producing equipment and method based on magnetic field force drive. The ladder-shaped cylindrical part producing equipment includes a first typedevice and a second type device; the first type device includes a concave mold with a ladder-shaped inner cavity, pressing parts are arranged on the upper portion of the side wall of the concave mold,upper-end-portion reducing coils and lower-end-portion reducing coils are arranged in the pressing parts and the side wall of the concave mold respectively, and multi-layer panel spiral axial drawingcoils for generating axial press-down electromagnetic force on to-be-produced plates to form cone-shaped parts are further arranged above the inner cavity of concave mold; the second type device includes a convex mold with a ladder-shaped surface, pressing parts are arranged at the periphery of the upper portion of the convex mold, and multi-layer panel spiral radial-axial drawing coils are further arranged above the convex mold. By the adoption of the ladder-shaped cylindrical part producing equipment and method based on the magnetic field force drive, wrinkling, unstability and tearing canbe avoided when ladder-shaped cylindrical parts are shaped, the drawing height and the quality of products are improved, and a shaping technology is simplified.

Owner:GUANGDONG UNIV OF TECH

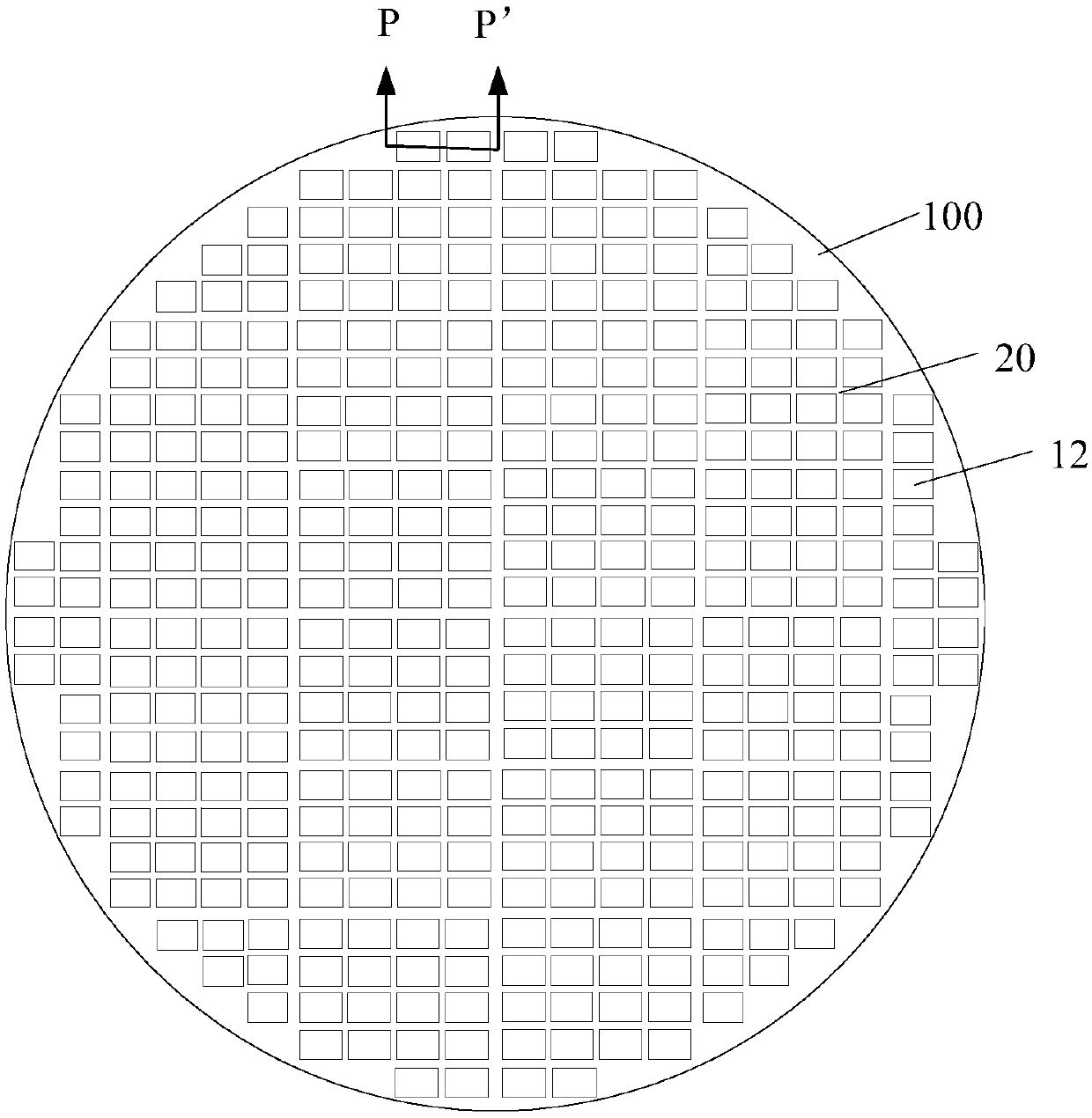

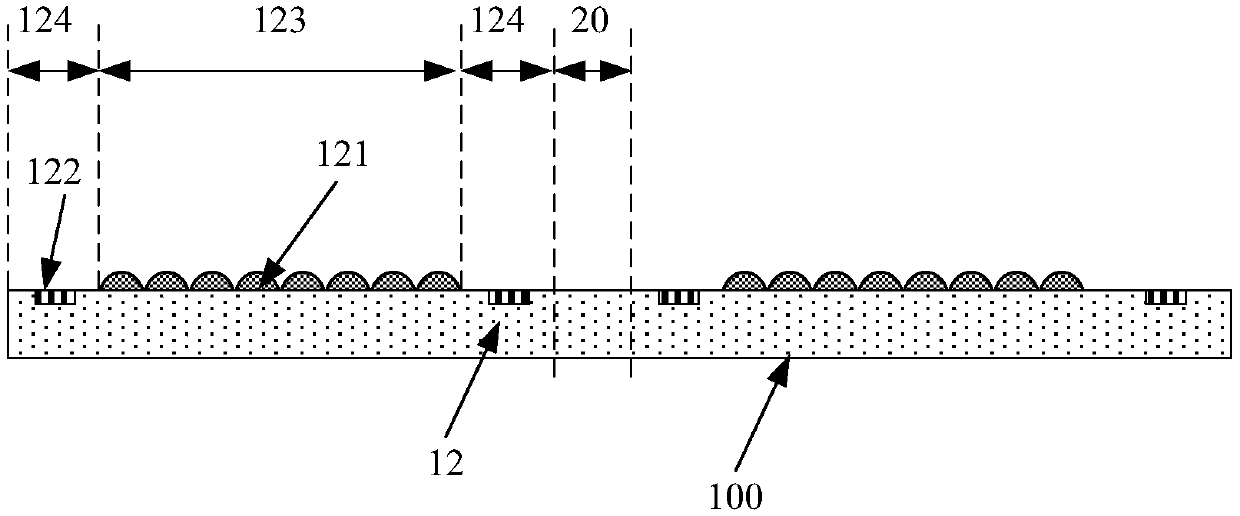

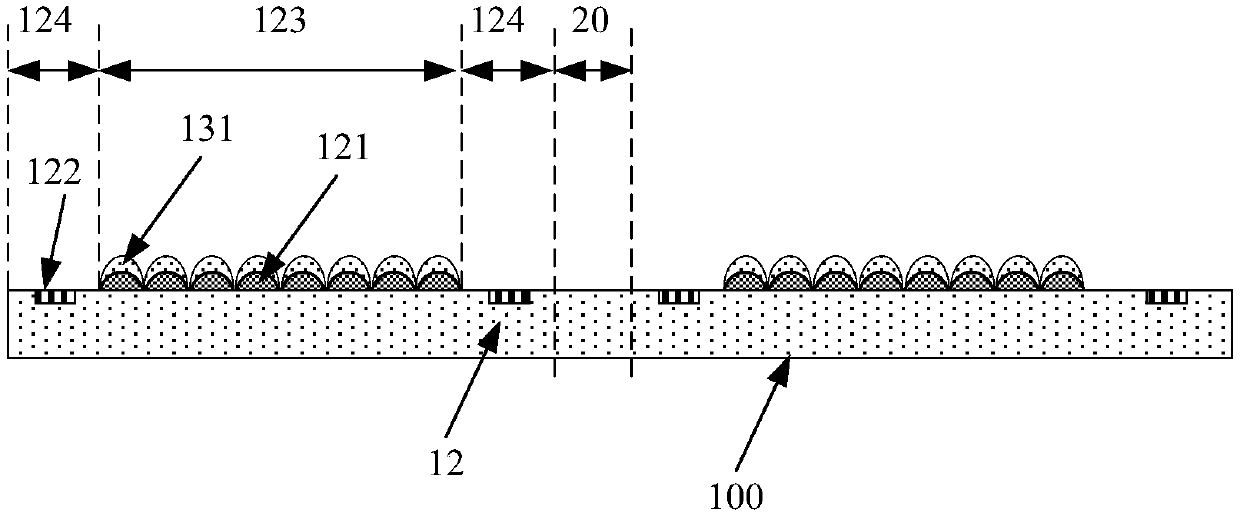

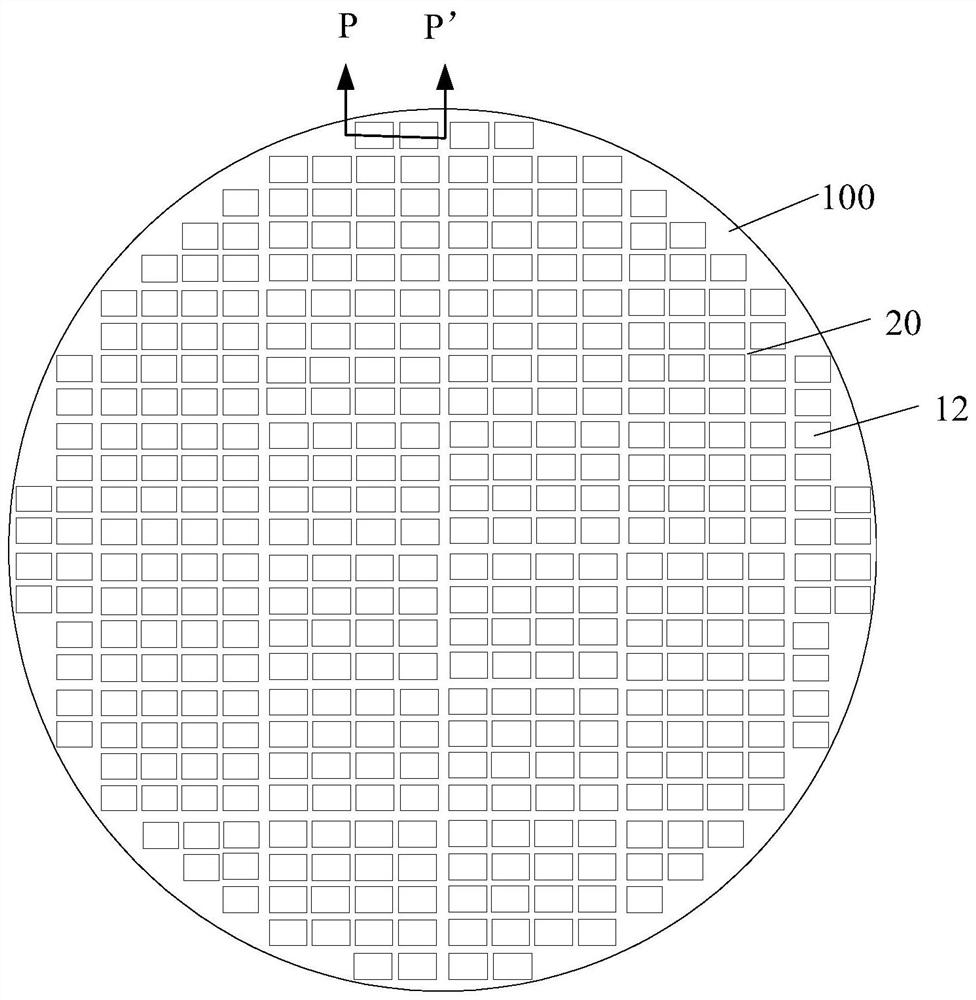

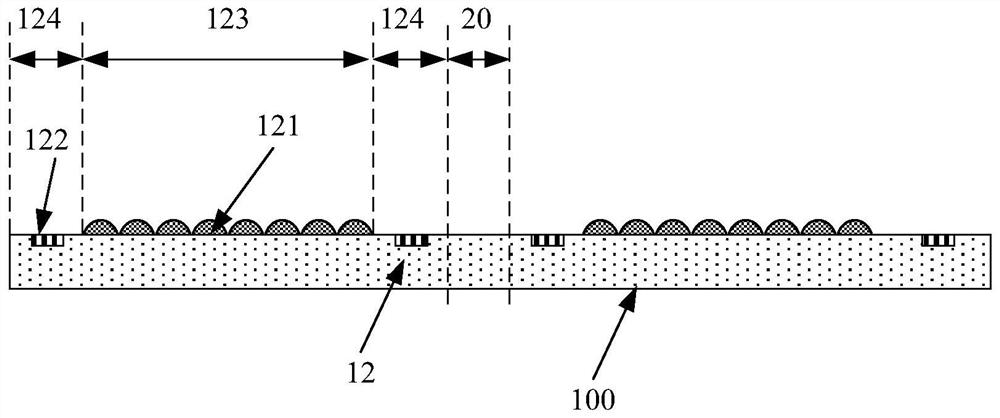

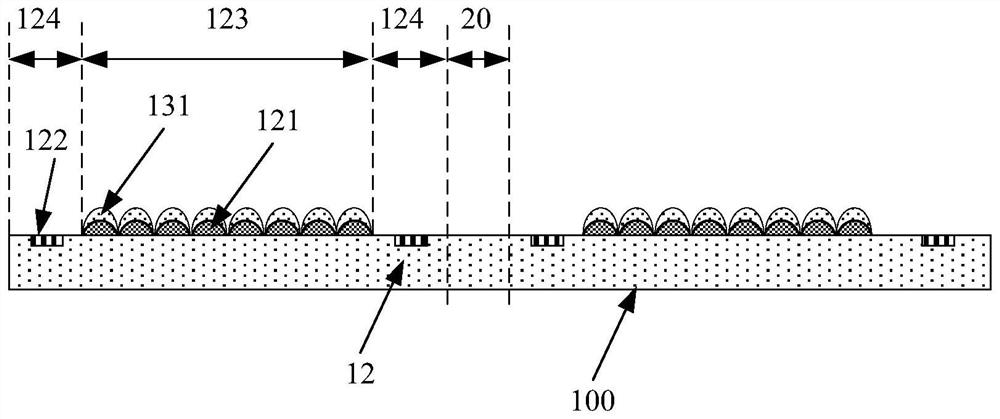

A packaging method and a packaging structure of an image sensing chip

ActiveCN109103208AReduce the difficulty of packagingAdequate bond strengthSolid-state devicesRadiation controlled devicesMultiple injectionBonding process

The invention discloses a packaging method and a packaging structure of an image sensing chip. According to the method, in the process of bonding the transparent cover plate and the substrate, the first adhesive film layer of the transparent cover plate is completely photosensitive and non-photosensitive, so that a cavity-free structure is formed between the transparent cover plate and the image sensing chip, the adhesive strength between the transparent cover plate and the image sensing chip is ensured to be sufficient, so as to carry out an injection molding process on a subsequent single image sensing chip and a substrate. In the process of forming the plastic sealing layer, the adhesive strength between the transparent cover plate and the image sensing chip is strong, and the plastic sealing layer can be directly formed at one time without carrying out multiple injection molding processes, which not only simplifies the forming process of the plastic sealing layer, but also eliminates the need to control the first adhesive film layer only at the periphery of the photosensitive region, reduces the bonding accuracy of the image sensing chip and the light-transmitting cover plate,and further reduces the packaging difficulty of the image sensing chip.

Owner:CHINA WAFER LEVEL CSP

Device and method for manufacturing stepped cylindrical part based on multi-directional magnetic field force driving

The invention discloses a device and method for manufacturing a stepped cylindrical part based on multi-directional magnetic field force driving. The device comprises a female die with a stepped innercavity; pressing parts are arranged at the upper part of the side wall of the female die and are used for being coordinated with the side wall of the female die to fix a plate to be manufactured; upper end part reducing coils and lower end part reducing coils are arranged in the pressing parts and the side wall of the female die correspondingly and are used for generating the radial inward compression electromagnetic force on the plate to be manufactured; a reserved space is formed in the upper part of the inner cavity of the female die and is internally provided with multi-layer slab spiralaxial deep drawing coils or multi-layer slab spiral radial-axial deep drawing coils, wherein the multi-layer slab spiral axial deep drawing coils are used for generating the axial downward piezoelectric magnetic force on the plate to be manufactured so as to form a conical part, and the multi-layer slab spiral radial-axial deep drawing coils are used for simultaneously generating the radial inwardcompression electromagnetic force and the axial downward piezoelectric magnetic force on the conical part. The device and the method has the advantages that wrinkling instability and pull cracks in forming process of the stepped cylindrical part can be avoided, the drawing height and the product quality can be improved, and the forming process can be simplified.

Owner:GUANGDONG UNIV OF TECH

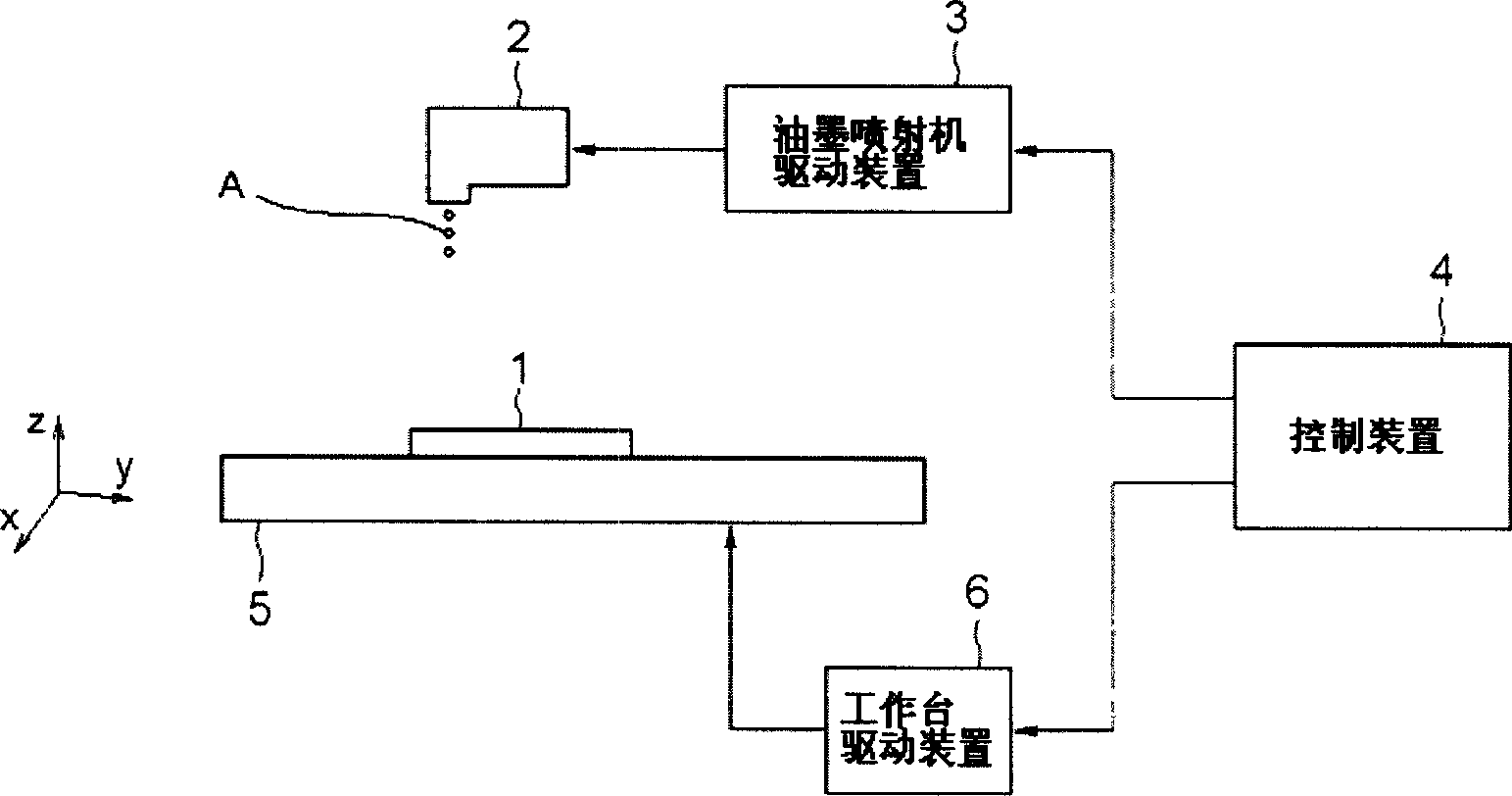

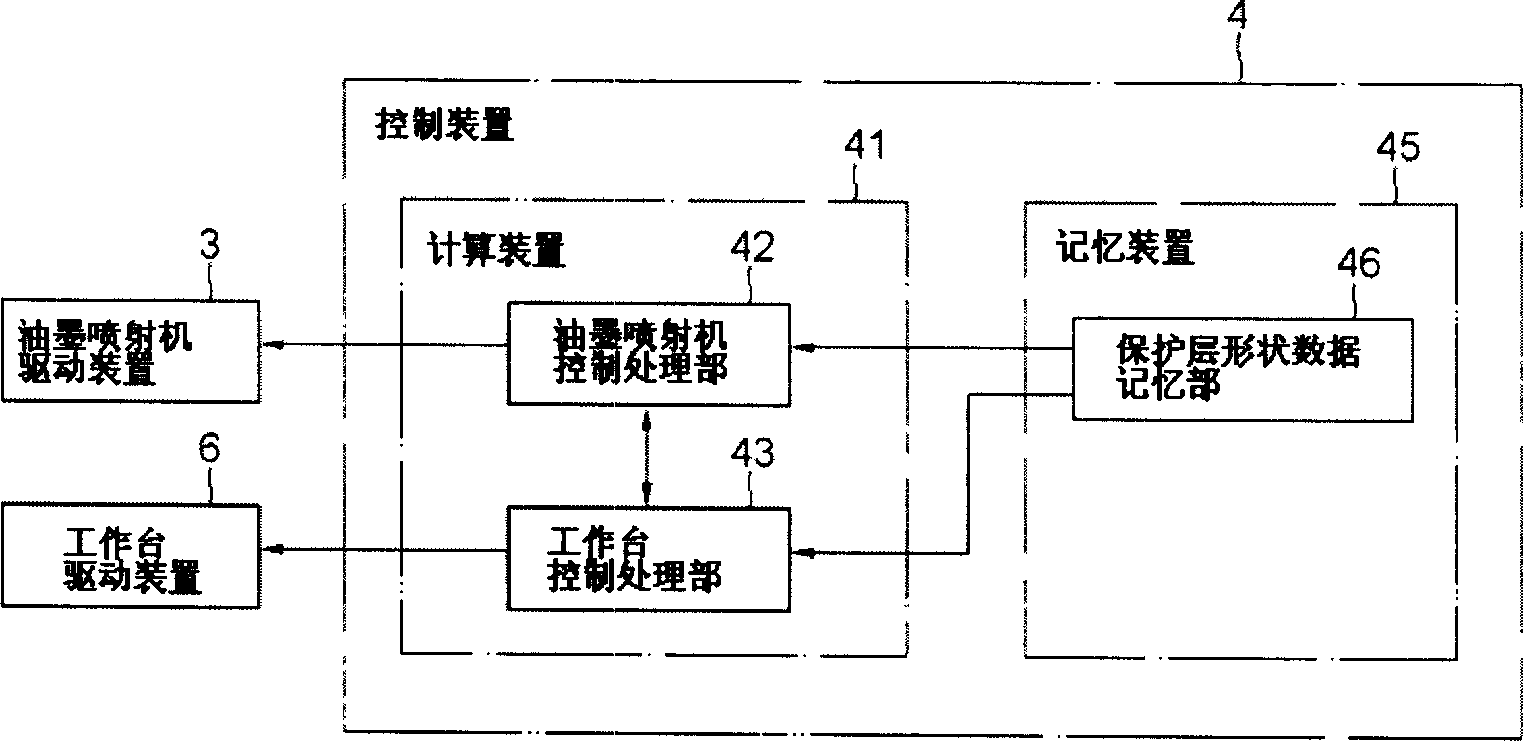

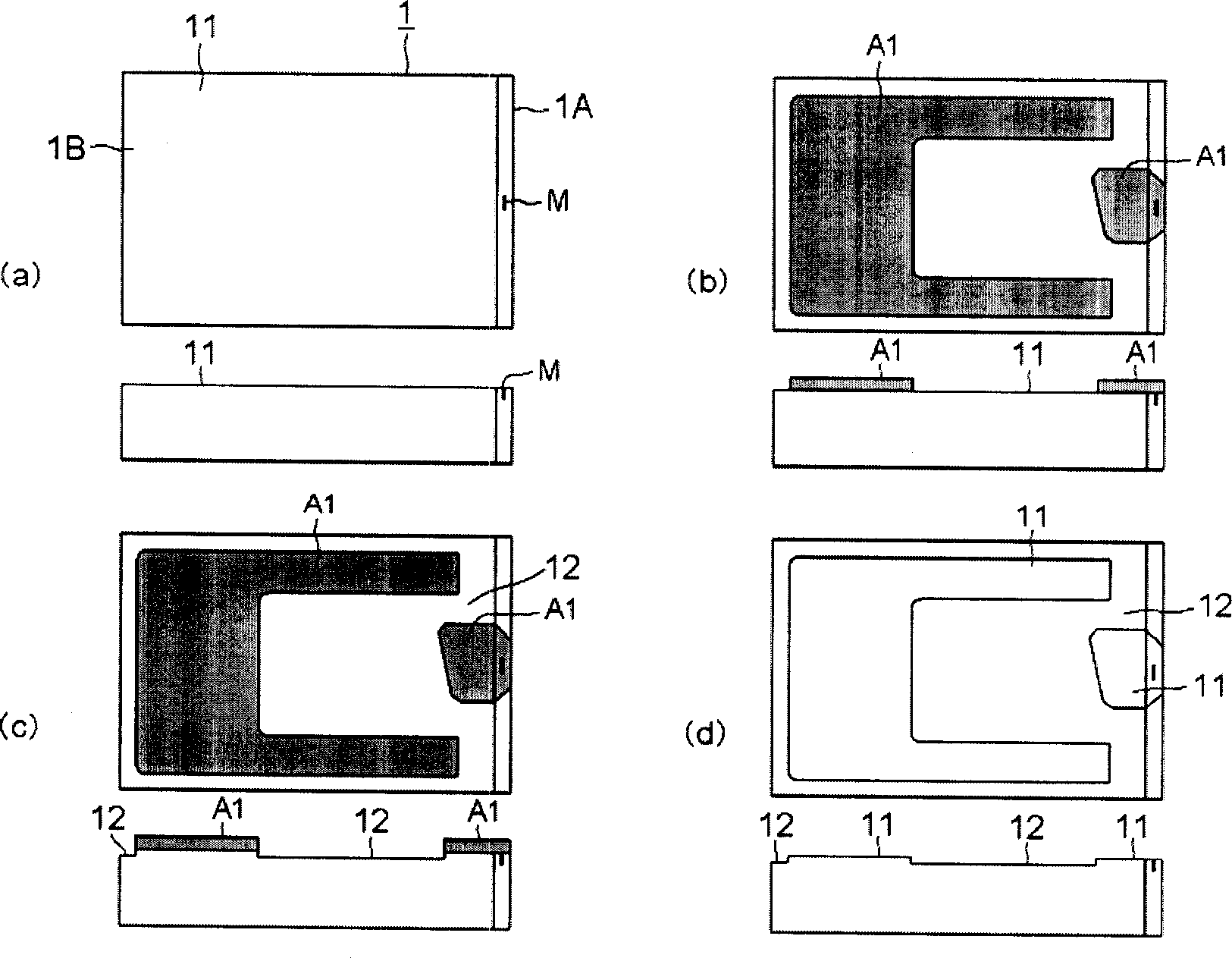

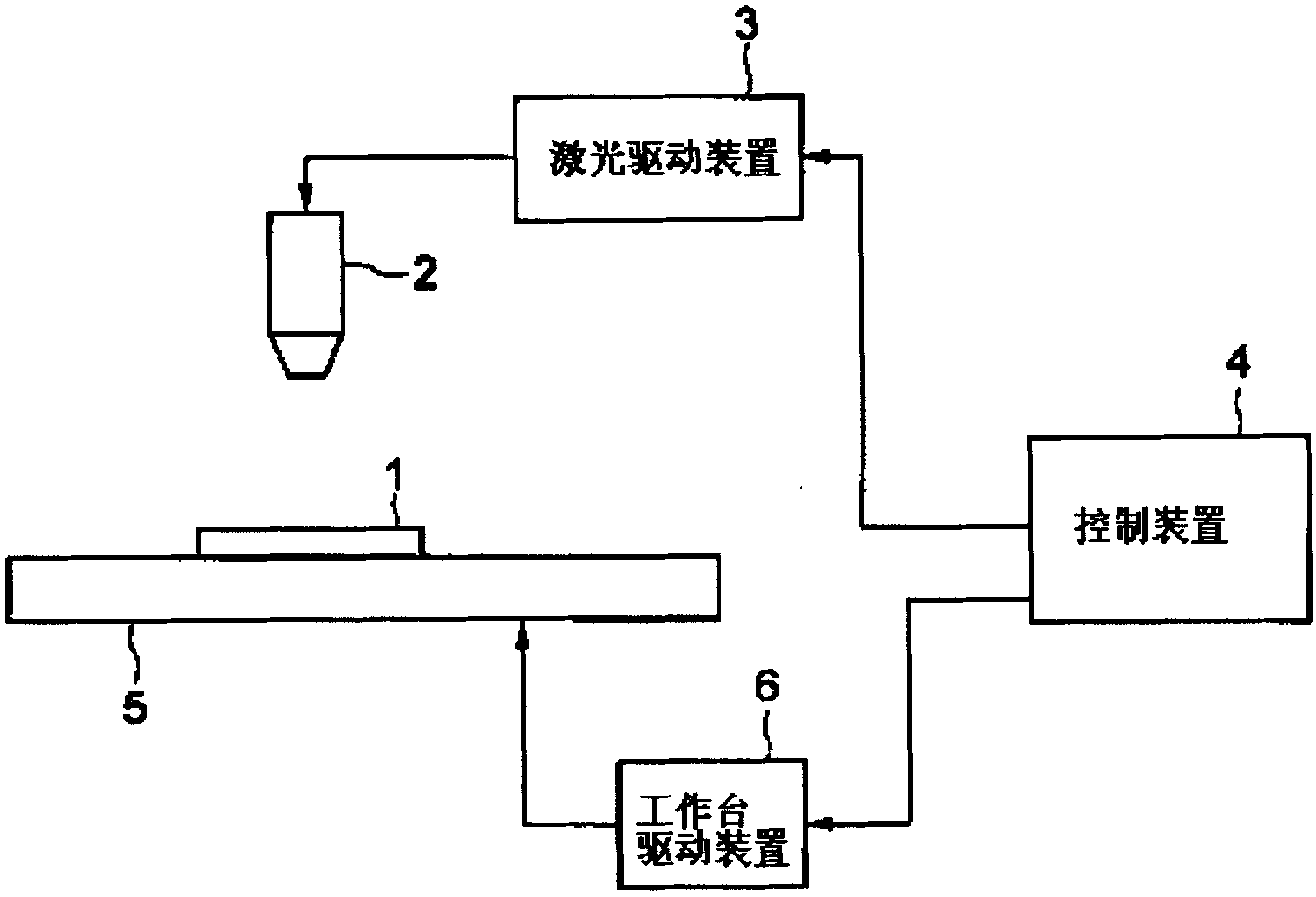

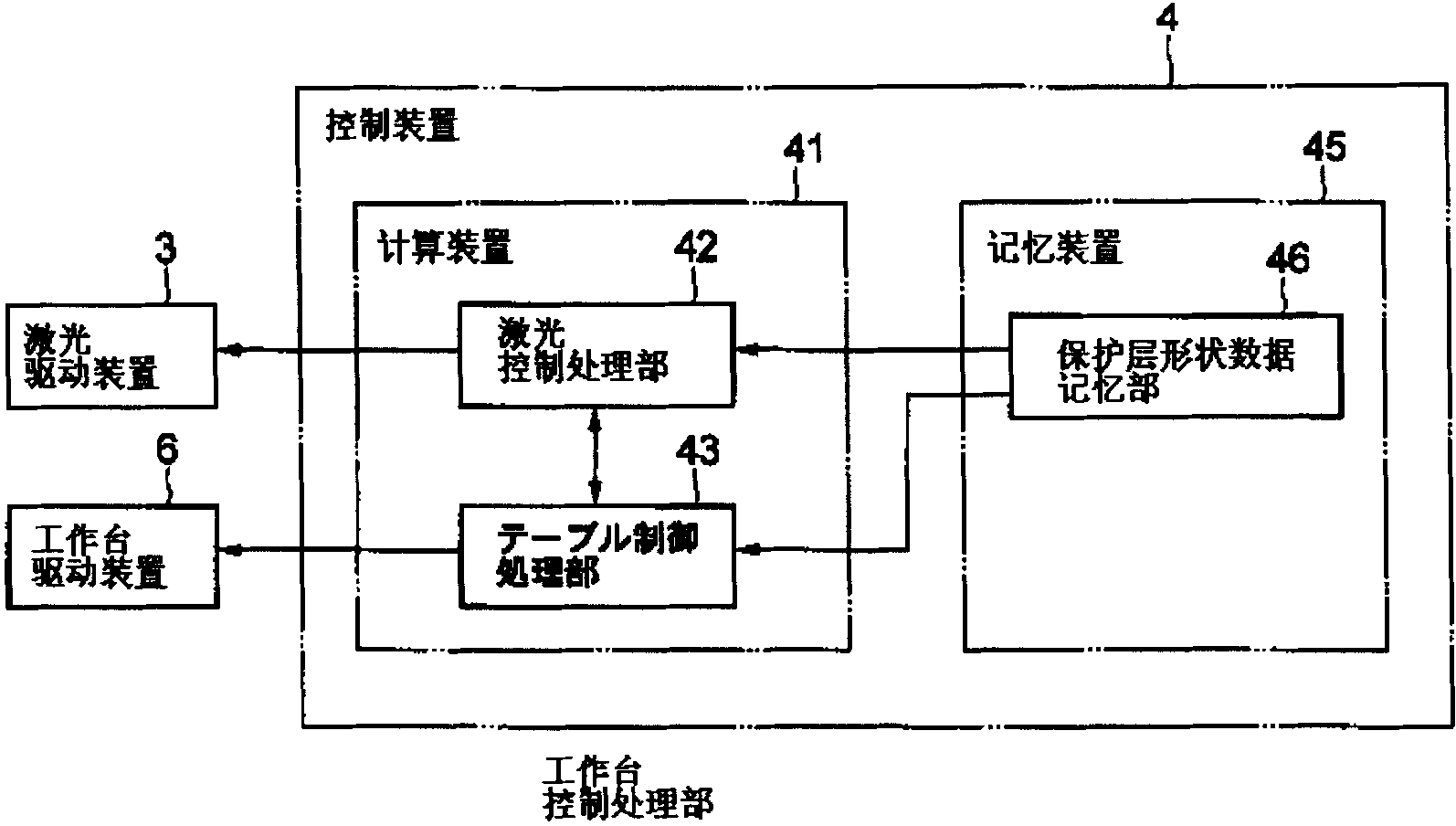

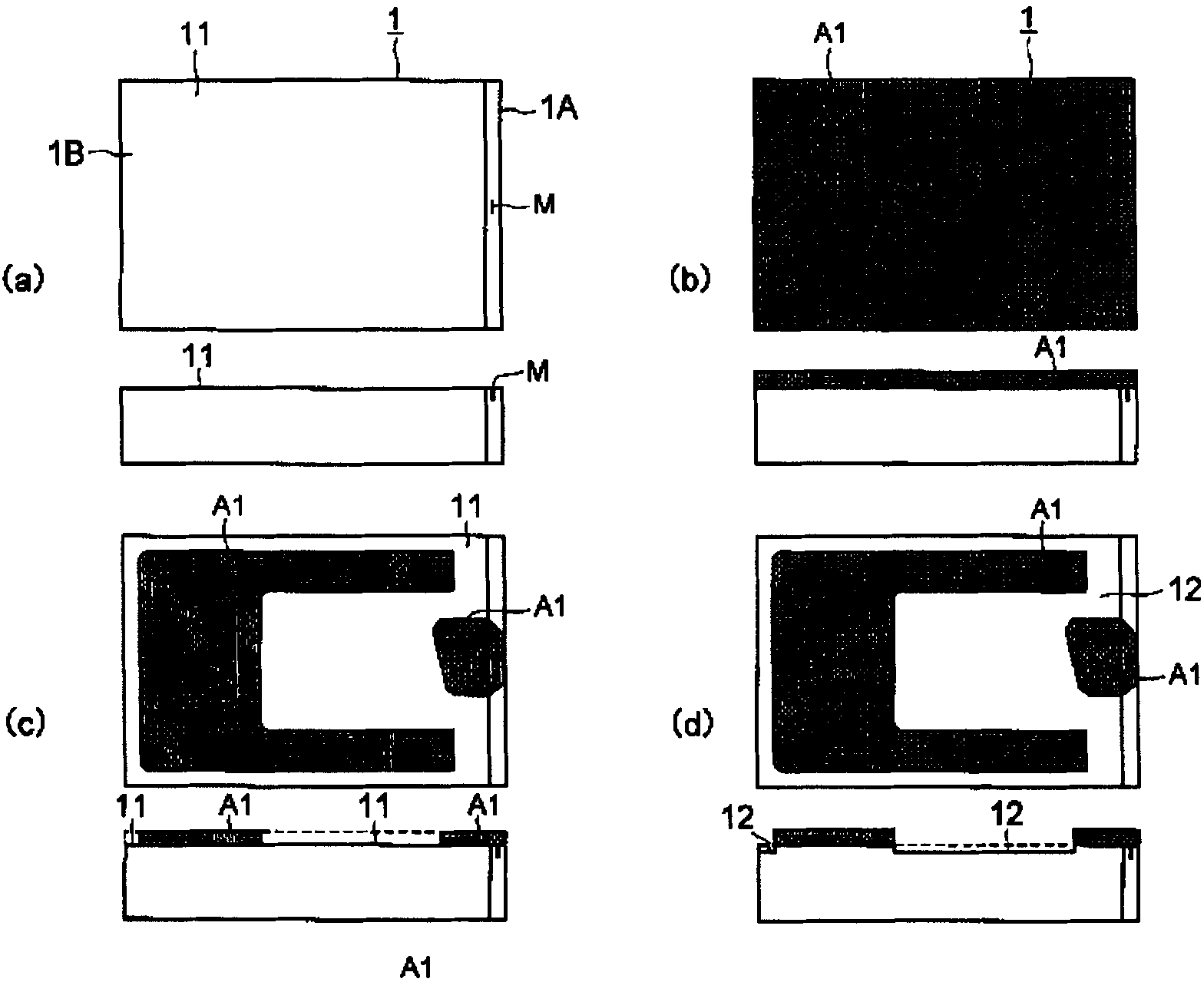

Method and apparatus for forming surface shape, method and apparatus for forming flying surface shape of magnetic head

InactiveCN1825436ASimplify the forming processReduce processing timeFluid-dynamic spacing of headsRecord information storageEngineeringMechanical engineering

An apparatus for forming a surface shape includes a resist forming device for forming a resist of a predetermined shape on a predetermined surface of the etching object, and an etching device for performing etching to the predetermined surface of the etching object on which the resist is formed. The resist forming device includes a resist discharging device for forming a resist of a predetermined shape by discharging a resist material to the predetermined surface of the etching object. The appararus can form a surface shape of an etching object in a short time at low cost, and to make the surface shape to be formed highly accurate.

Owner:SAE MAGNETICS (HK) LTD

Flexible die forming method with approximatively equal wall thickness for variable-diameter part

The invention provides a flexible die forming method with approximatively equal wall thickness for a variable-diameter part, which relates to a flexible die forming method of a variable-diameter part. The invention is used for solving the problems of wall thickness reduction and uneven distribution of the wall thickness because of one-step forming, which exist in the forming of a traditional variable-diameter part. The method comprises the following main steps of: putting a cylinder blank into a die cavity of a die and putting a mandrel into the cylinder blank; filling a sticky and elastic plastic material; sealing; combining the die; jointing the cylinder blank and the die cavity of the die tightly under the pressure action of the sticky and elastic plastic material inside the cylinder blank and the pressure of the die and forming; sinking the die and taking out the formed variable-diameter part; and removing the mandrel and eliminating the residual sticky and elastic plastic material inside the variable-diameter part. The wall thickness of the variable-diameter part manufactured by the method is even, the forming limit of the variable-diameter part is enhanced, the distribution of the wall thickness of the variable-diameter part is improved, the surface quality of the variable-diameter part is enhanced, and the manufacturing cost of the variable-diameter part is also lowered. The method is used for forming the variable-diameter part.

Owner:HARBIN INST OF TECH

Method and apparatus for forming surface shape, method and apparatus for forming flying surface shape of magnetic head

InactiveCN1822109BSimplify the forming processReduce manufacturing costManufacture head surfaceFluid-dynamic spacing of headsMechanical engineeringLaser beams

The invention provides a surface shape forming apparatus, comprising: a resist forming means for forming the resist of a prescribed shape to a prescribed surface of an etching object (1), and an etching means for subjecting the prescribed surface of the etching object (1) in which the resist is formed to etching processing, wherein the resist forming means is equipped with a resist sticking means for sticking a resist material to the prescribed surface of the etching object (1), and a laser irradiation means (2) for irradiating the stuck resist material with a laser beam which moves according to a command of a controller to remove a part of the resist material, so as to form the material to the prescribed shape. The surface shape forming apparatus can form the surface shape of the etching object in a short period of time at a low cost and realize high accuracy of the surface shape to be formed.

Owner:SAE MAGNETICS (HK) LTD

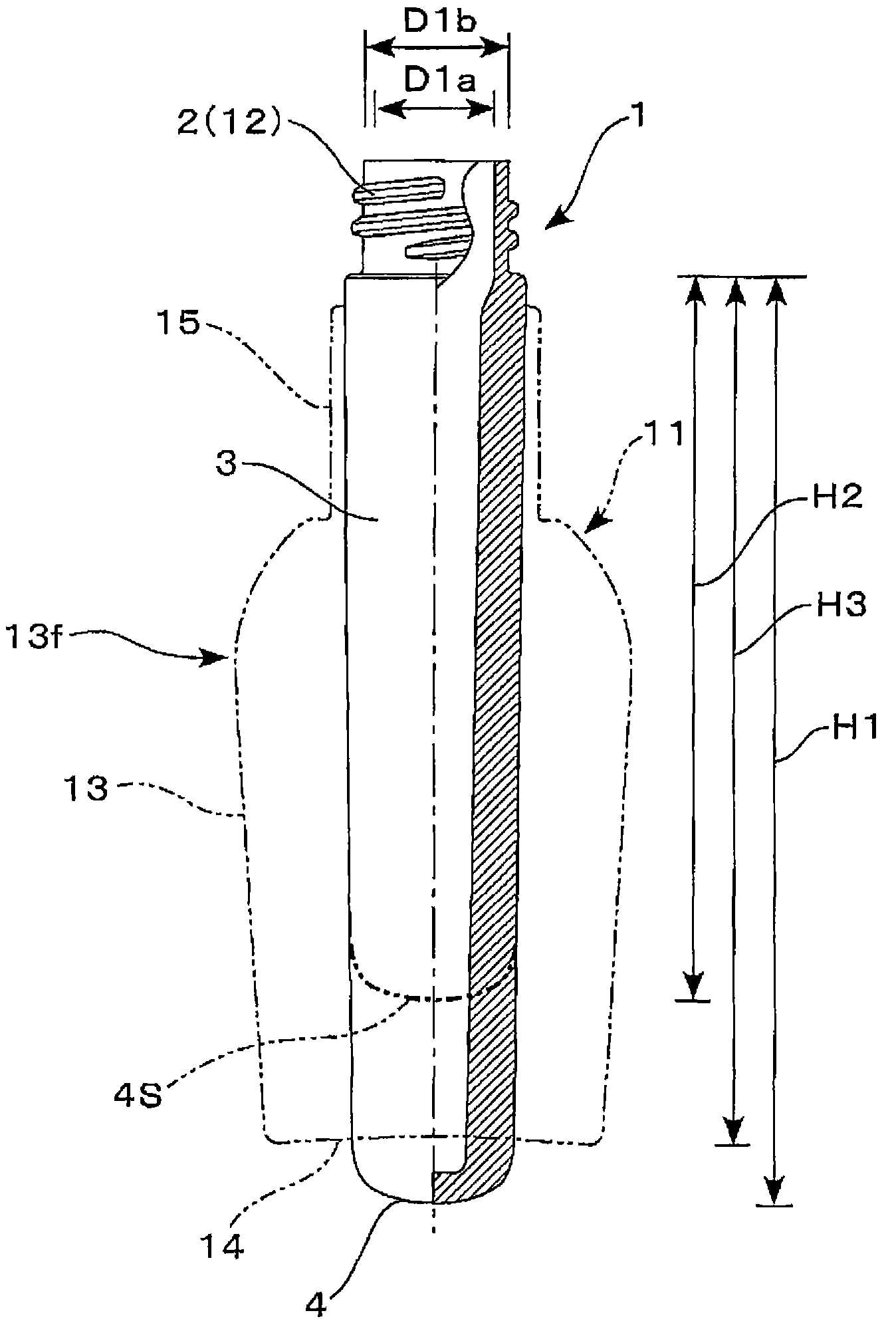

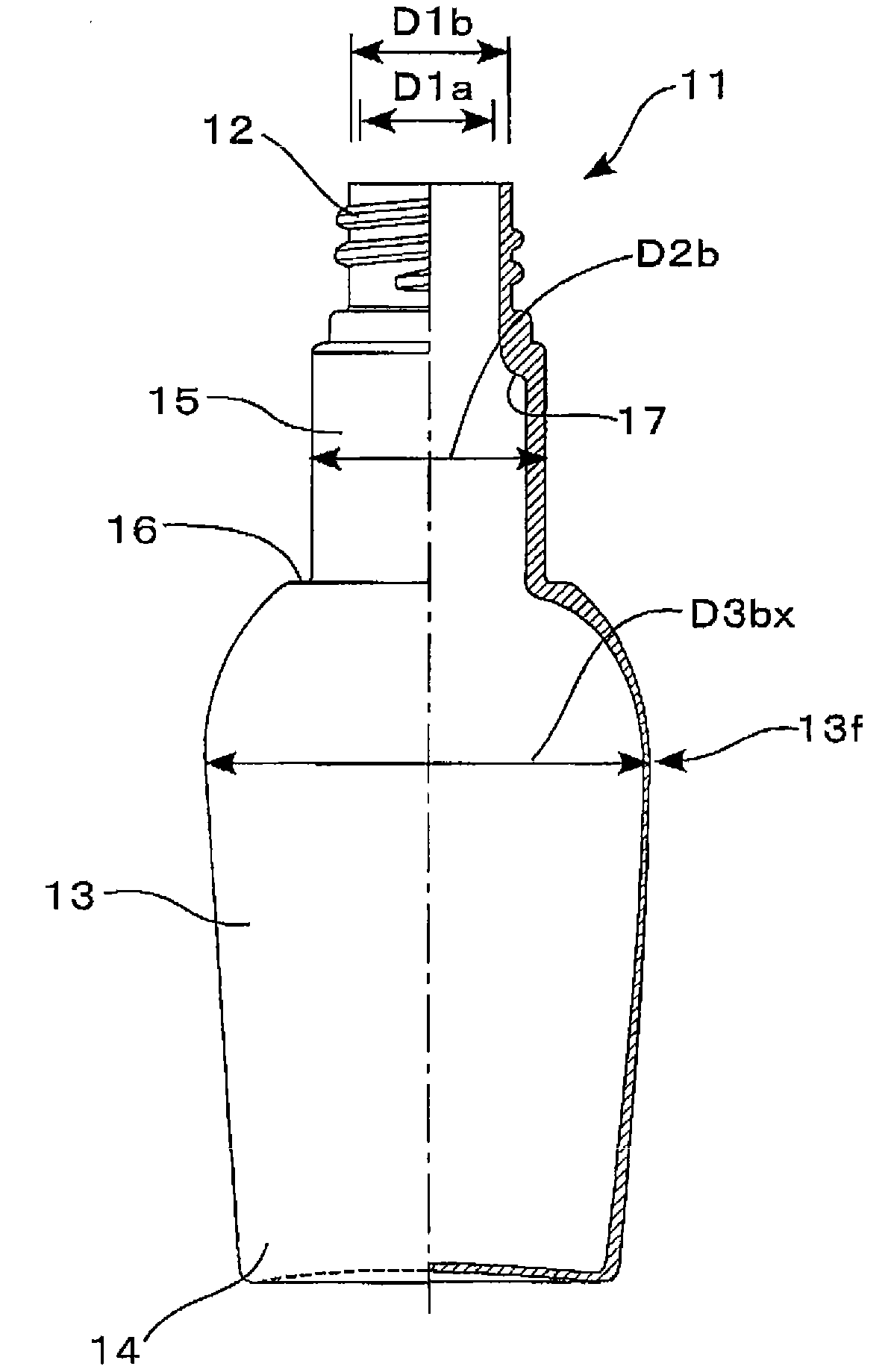

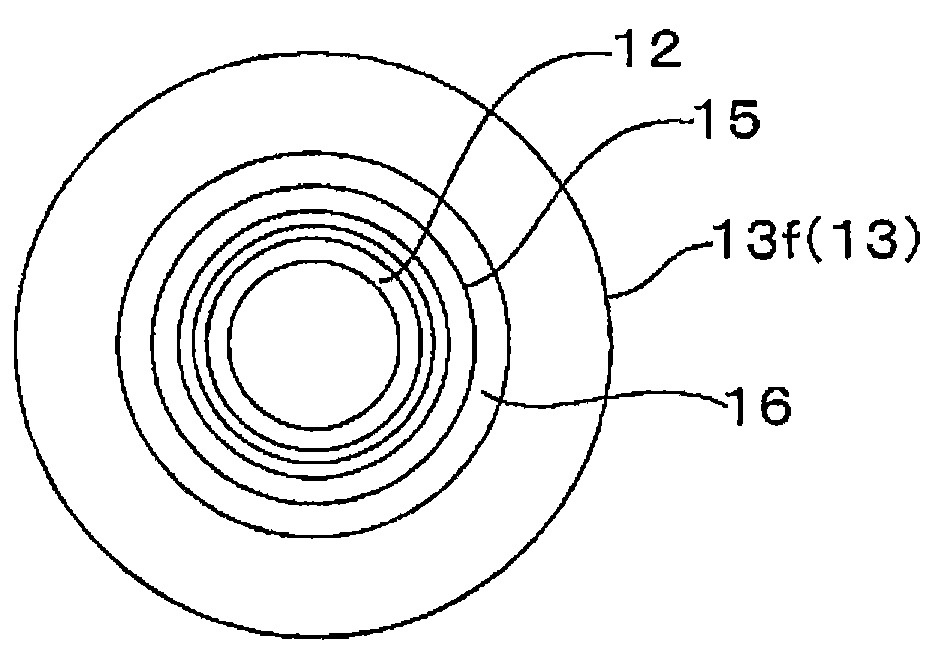

Method of molding synthetic resin bottle body

ActiveCN101541509BWeight increaseFull wall thicknessDomestic articlesRigid containersBlow moldingInjection moulding

A technical problem to be solved by this invention is to create a biaxially drawing and blow molding process that can fully make up for a restricted upper limit to the preform body wall thickness. An object of this invention is to provide a biaxially drawn, blow molded bottle which is narrow-mouthed and yet has a substantially expanded body. In principle, the molding process of this invention to solve the technical problems comprises three steps of : (1) injection molding a preform in the shape of a test tube taller than the bottle wherein the preform has a cylindrical mouth opening portion disposed in an upper part of the preform, and wherein the mouth opening portion of the preform serves also as a mouth opening portion of the bottle product; (2) thermally shrinking the preform from an initial height so that portions other than the mouth opening portion of the preform would have a height that is smaller than that of the bottle; and (3) setting this thermally shrunk preform in a blow mold and biaxially drawing and blow molding the preform into the bottle.

Owner:YOSHINO KOGYOSHO CO LTD

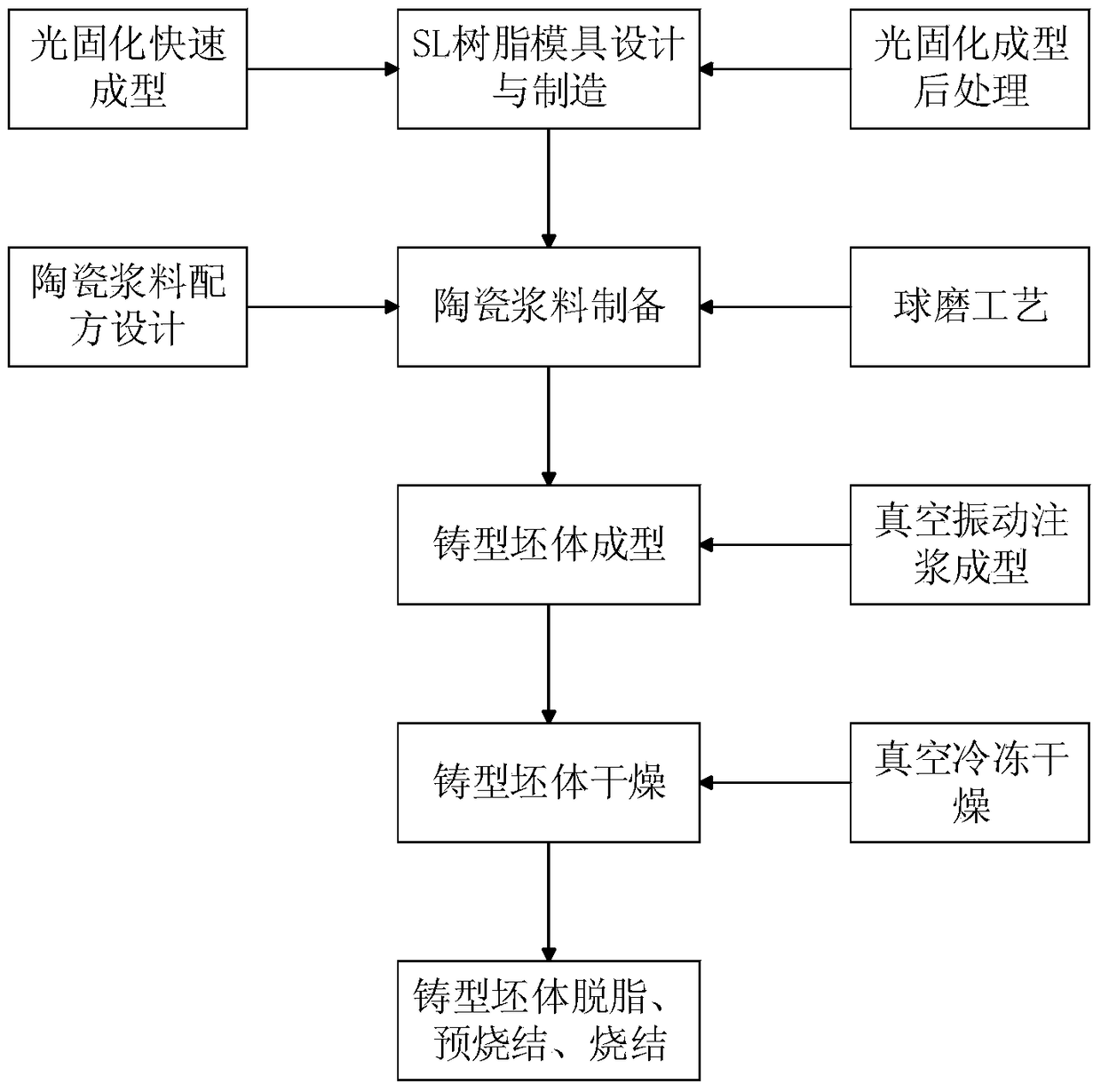

A rapid preparation method of calcium oxide-based ceramic casting mold for complex parts manufacturing

ActiveCN105732007BHigh mutual position accuracyGuaranteed dimensional accuracyCeramic shaping apparatusCasting moldAtmosphere

The invention discloses a fast preparation method of a calcium oxide based ceramic casting mold for manufacturing complex parts, and belongs to the fast precise casting field. The method comprises the following steps: manufacturing a ceramic casting mold biscuit by adopting calcium carbonate powder and moderate mineralizing agent as raw materials, degreasing the biscuit, placing in a vacuum sintering furnace together with moderate metallic calcium to perform the reaction sintering, and then placing the casting mold in an atmosphere sintering furnace to finally sinter. The metallic calcium simple substance is reacted with carbon dioxide produced by decomposing calcium carbonate to produce calcium oxide so as to improve the compactness of the ceramic casting mold. The moderate mineralizing agent is used for promoting the sintering of the ceramic casting mold, and the hydration resistance of the ceramic casting mold is improved. The calcium oxide based integral ceramic casting mold prepared through above method has excellent high-temperature comprehensive performance, solves the technical problem that the aluminum oxide based ceramic casting mold is hard for core removal and high in rejection index, and is especially suitable for the fast manufacturing of complex parts.

Owner:XI AN JIAOTONG UNIV

Hammering forging equipment based on handheld clamp

InactiveCN111906235ASimplify the forming processEfficient and convenient forgingForging press detailsCircular discHand parts

The invention discloses hammering forging equipment based on a handheld clamp, and relates to the technical field of forging equipment. The equipment solves the problems that according to existing hammering forging equipment, the hammering forging equipment is driven, and a hand needs to exert force to repeatedly wing a hammer to conduct repeated hammering, so that the labor intensity is high, andthe operation is arduous. The hammering forging equipment based on the handheld clamp comprises an operation platform; the operation platform comprises a rail shaft rod, a first I-shaped plate, a vertical supporting positioning shaft, a transverse supporting hanging plate, a second I-shaped plate, a thickened vertical supporting shaft and a hexagonal prism rod; and the whole operation platform isof a square structure, a circular groove is formed in the center of the operation platform in a penetrating mode, a disc base is welded to the interior of the circular groove in a supporting mode, and the transverse supporting hanging plate is welded to the middle of the bottom of the operation platform. According to the equipment, handle rods are subjected to forming operation through a bendingmode, so that compared with traditional manual hammering forging forming, the mode has the beneficial effects that the hammer swinging step for repeatedly hammering can be omitted, and the labor intensity of two hands is reduced.

Owner:王凯伦

A packaging method and packaging structure for an image sensor chip

ActiveCN109103208BReduce the difficulty of packagingAdequate bond strengthSolid-state devicesRadiation controlled devicesMultiple injectionSingle image

The present application discloses a packaging method and packaging structure of an image sensor chip, wherein, in the packaging method of the image sensor chip, during the bonding process of the transparent cover plate and the substrate, the first part of the transparent cover plate is An adhesive film layer completes the photosensitive area and the non-photosensitive area, so that a cavity-free structure is formed between the light-transmitting cover plate and the image sensor chip, ensuring sufficient adhesion between the light-transmitting cover plate and the image sensor chip Therefore, during the subsequent injection molding process of a single image sensor chip and substrate to form a plastic seal layer, due to the strong bonding strength between the light-transmitting cover plate and the image sensor chip, multiple injection moldings are not required The plastic sealing layer can be directly formed at one time, which not only simplifies the forming process of the plastic sealing layer, but also does not need to control the first adhesive film layer only on the periphery of the photosensitive area, which reduces the bonding accuracy of the image sensor chip and the light-transmitting cover plate , thereby reducing the packaging difficulty of the image sensor chip.

Owner:CHINA WAFER LEVEL CSP

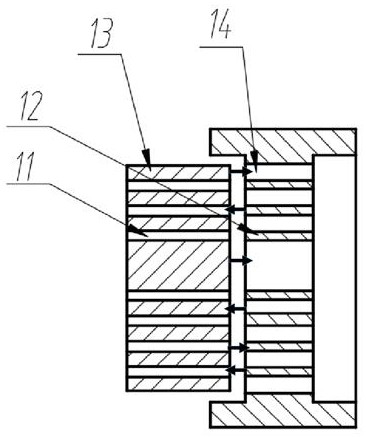

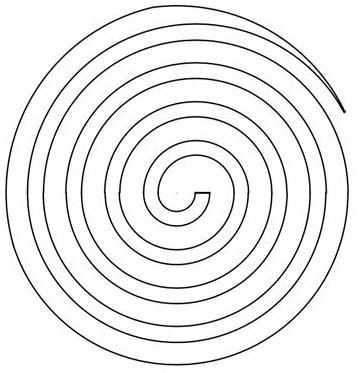

Forming device and processing method of light-alloy wide sheet

ActiveCN112692090ASignificant dynamic recrystallizationImprove refinementExtrusion diesExtrusion control devicesEngineeringMechanical engineering

The invention discloses a forming device of a light-alloy wide sheet. The forming device of the light-alloy wide sheet comprises a die and a punch which are arranged in a corresponding mode, wherein a charging barrel used for storing blank is arranged in the die, the charging barrel is sleeved with a heating coil for heating the blank, and a forming part of a spiral structure is arranged at the bottom of the charging barrel; and multiple force transfer shafts which face the die are connected with the punch, a downward pressing part used for squeezing the blank is arranged on the force transfer shafts, the structure of the downward pressing part is the same as that of the forming part, a solid part of the downward pressing part corresponds to a hollow part of the forming part, thus when the solid part of the downward pressing part squeezes the blank to the interior of the hollow part of the forming part, the solid part of the downward pressing part coincides with the hollow part of the forming part, a hollow part of the downward pressing part and the hollow part of the forming part conduct squeezing separately to form a roll of spiral sheet metal, and the sheet metal is expanded to form the magnesium alloy wide sheet.

Owner:CHONGQING UNIV OF TECH

A Tool Head and Method for Controlling Warping and Deformation of Thin Plates in Formless Progressive Flanging Process

The invention discloses a tool head and method for controlling the buckling deformation in a thin plate die-free gradual edge turning process. A long cylindrical body is arranged at the upper end of the tool head. The lower end of the long cylindrical body is connected with a disc. The bottom face of the disc is connected with a big-end-down circular truncated cone. The diameter of the small end of the circular truncated cone is smaller than that of the disc. The large end of the circular truncated end is connected with a large cylindrical body, wherein the diameter of the large end of the circular truncated end is the same as the diameter of the large cylindrical body. The method includes the following steps that an inclined face of the circular truncated cone of the tool head makes contact with the edge of a plate material, and a gap of 2 mm to 3 mm is formed between the bottom face of the disc and the upper surface of the plate material; the tool head horizontally extrudes the edge of the plate material to make the plate material bent upwards till the plate material makes contact with the bottom face of the disc; the tool head moves along the periphery of the plate material so that the same deformation can happen to an edge to be turned; the tool head is lifted, the steps are repeatedly executed, and performing is completed; the edge to be preformed is shaped through the side wall of the large cylindrical body of the tool head, and a vertical turned edge is obtained. The tool head and method have the advantages that deformation of the plate material is controlled through the combination of the tool head and a program, the longitudinal upwarp in the die-free gradual edge turning forming process can be eliminated, and the tool head and method are easy to obtain and implement and feasible.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com