Method and apparatus for forming surface shape, method and apparatus for forming flying surface shape of magnetic head

A flying surface, magnetic head technology, used in the manufacture of magnetic head surface, magnetic recording head, magnetic recording and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

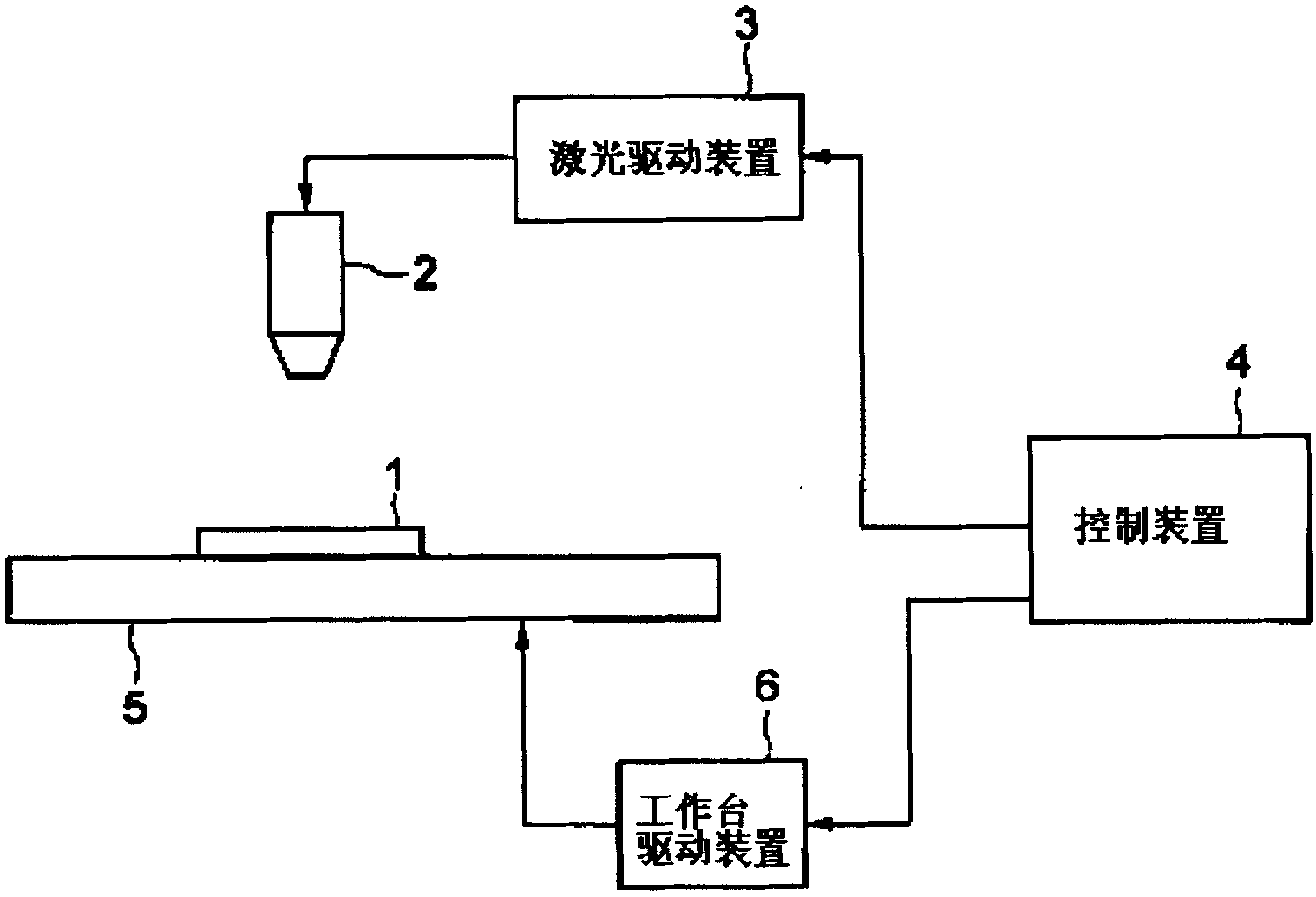

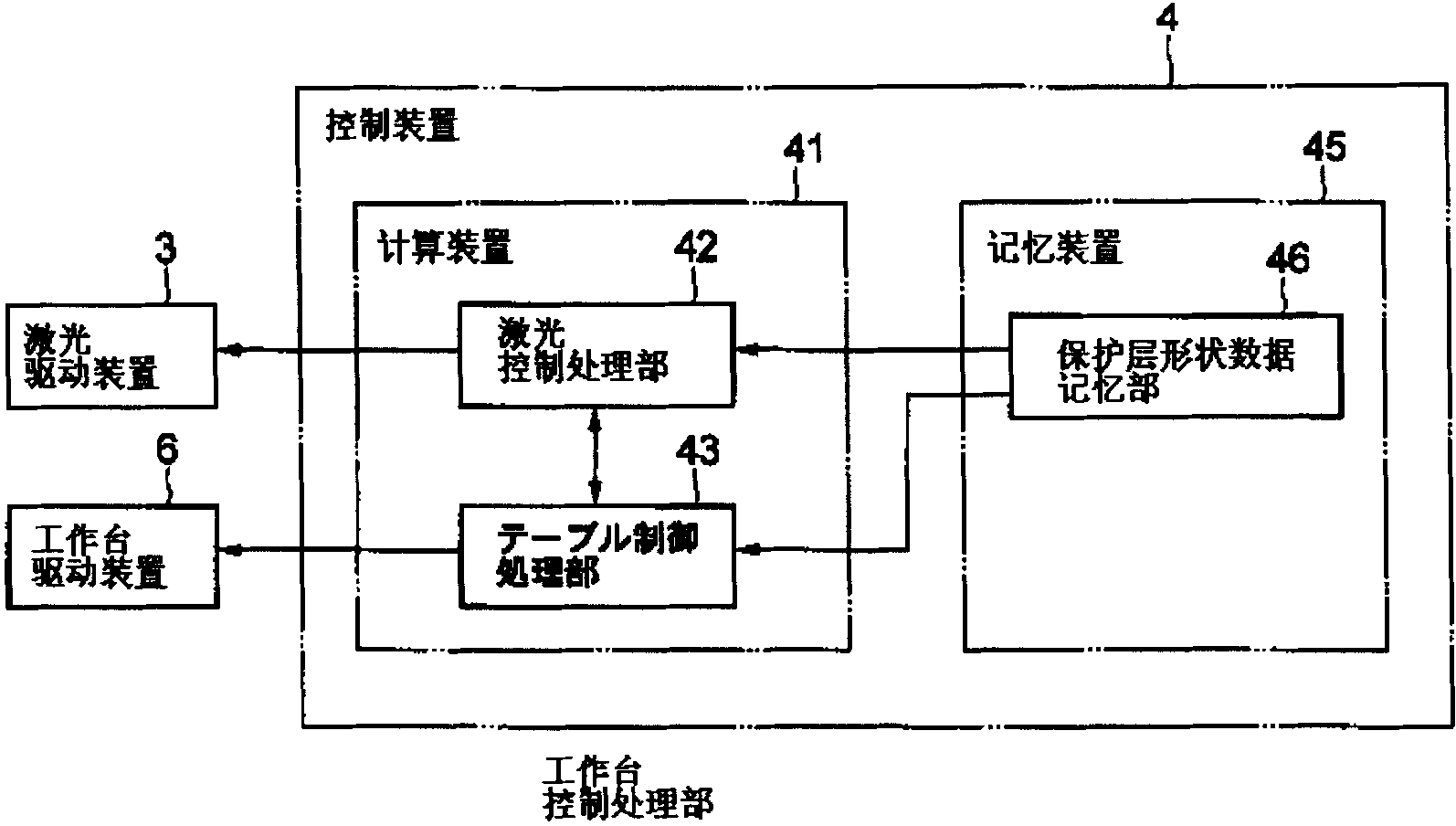

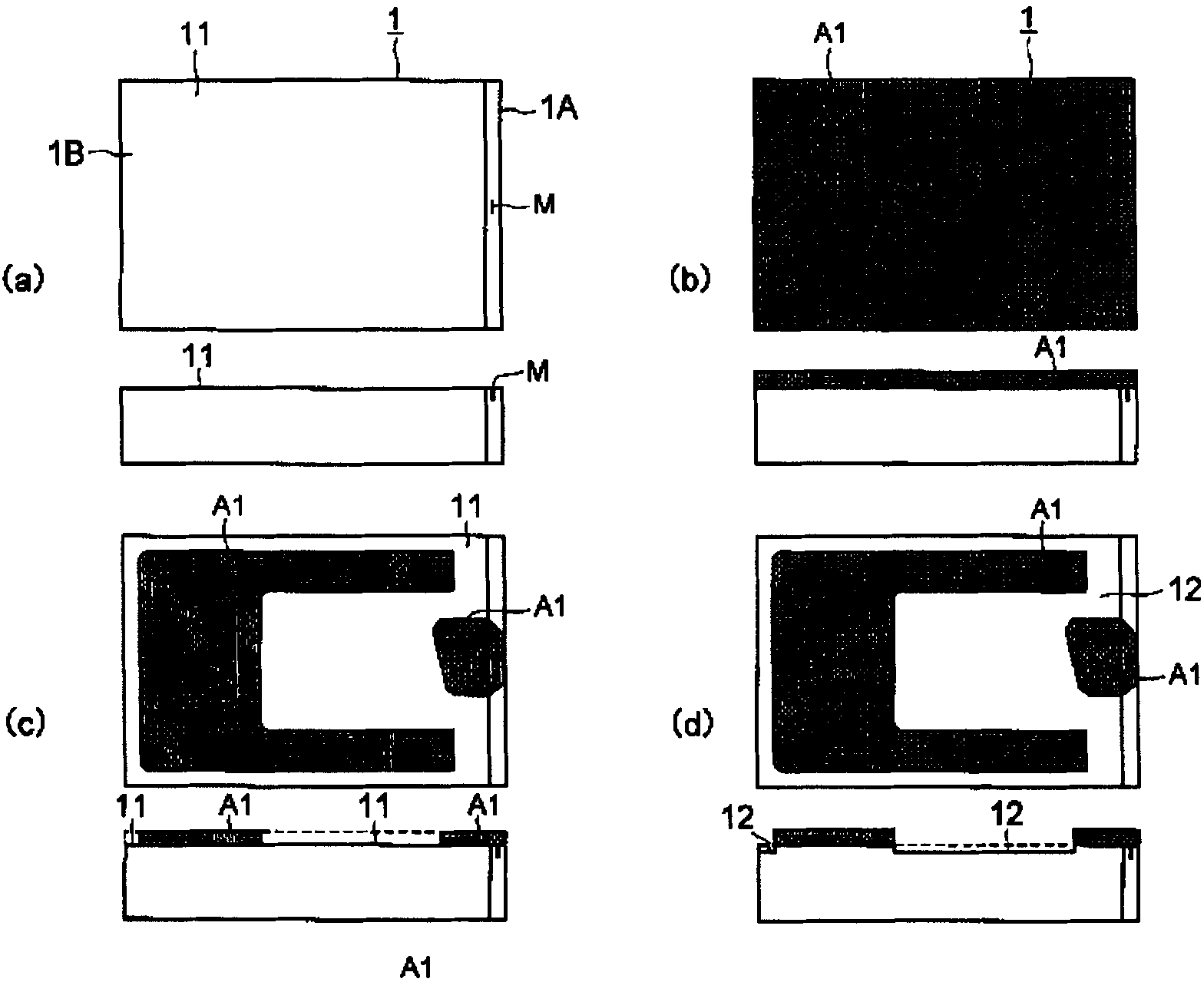

[0041] The first embodiment of the present invention is as Figure 1 to Figure 5 shown. figure 1 It is a block diagram showing the structure of the magnetic head flying surface forming device. figure 2 It is a functional block diagram showing the structure of the control device. Figure 3 to Figure 4 It is an explanatory diagram showing the state when the flying surface of the magnetic head is formed. Figure 5 It is a flow chart of the operation of the surface shape forming device.

[0042] [composition]

[0043] combine figure 1 As shown, the structure of the magnetic head flying surface forming device (surface shape forming device) of the present invention will be described. The flying surface forming device includes: a protective layer coating device (protective layer attaching device (protective layer forming device), not shown) for applying a protective layer material to the magnetic head 1; a laser beam for irradiating the attached protective layer material with...

Embodiment 2

[0077] Next, combine Figure 6 to Figure 9 A second embodiment of the present invention will be described. Figure 6 It is a block diagram showing the structure of the magnetic head flying surface forming apparatus. Figure 7 to Figure 8 It is an explanatory diagram showing the state when the flying surface of the magnetic head is formed. Figure 9 It is the flow chart of the operation of the flight surface forming device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com