Forming device and processing method of light-alloy wide sheet

A molding device and technology of light alloys, applied in metal processing equipment, metal extrusion control equipment, manufacturing tools, etc., can solve the problems of limited grain refinement ability, rising production cost, uneven structure, etc., and achieve continuous stability. The effect of production cycle, production efficiency improvement and uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

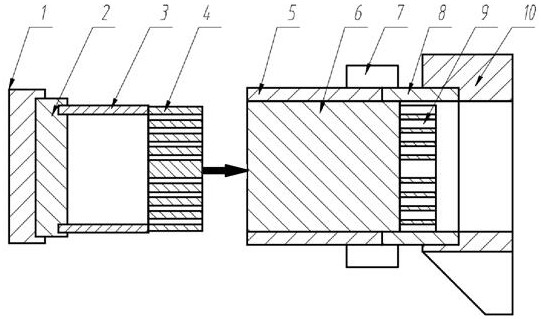

[0037] This example: see figure 1 and figure 2 , a forming device for a light alloy wide thin plate, including a correspondingly arranged die 8 and a punch 2, the die 8 is provided with a barrel 5 for storing a blank 6, and the bottom of the barrel 5 is provided with a spiral structure Formed part 9; the punch 2 is connected with a plurality of power transmission shafts 3 facing the die 8, wherein the power transmission shaft 3 is a cylindrical structure, and more than one power transmission shaft 3 and the lower pressure part 4 are detachable Connect, arrange like this, conveniently take out the sheet material that forms from punch 2.

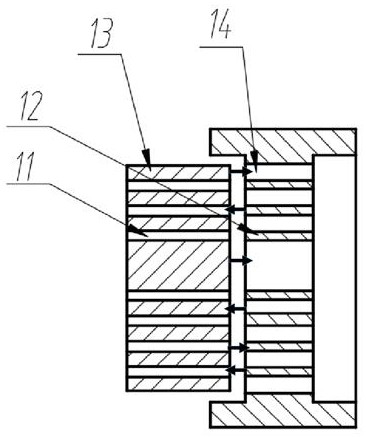

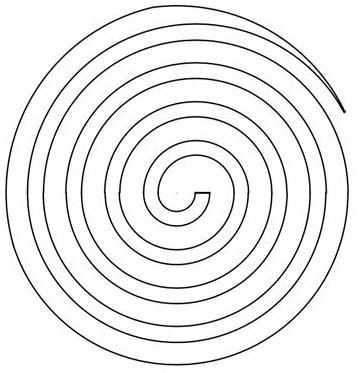

[0038] The power transmission shaft 3 is provided with a lower pressing part 4 for extruding the billet 6, see image 3and Figure 4 , the structure of the pressing part 4 is the same as that of the forming part 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com