Thermal deformation strengthening method for rare earth magnesium alloy

A technology of rare earth magnesium and thermal deformation, which is applied in the field of metal material forming and processing, can solve problems such as grain refinement, and achieve the effects of improving mechanical properties, easy control, and improving plasticity

Inactive Publication Date: 2017-08-29

SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

View PDF7 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The most typical conventional thermal deformation treatment is a single isothermal hot extrusion, but it is difficult to refine the grains below 10μm

In previous studies, some theoretical methods for large plastic deformation were proposed, such as equal angular extrusion method, cumulative rolling and high-pressure torsion method, etc. to obtain microstructures with fine grains, even reaching submicron and nanometer levels; However, these methods are only suitable for the preparation of small-scale materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Login to View More

Abstract

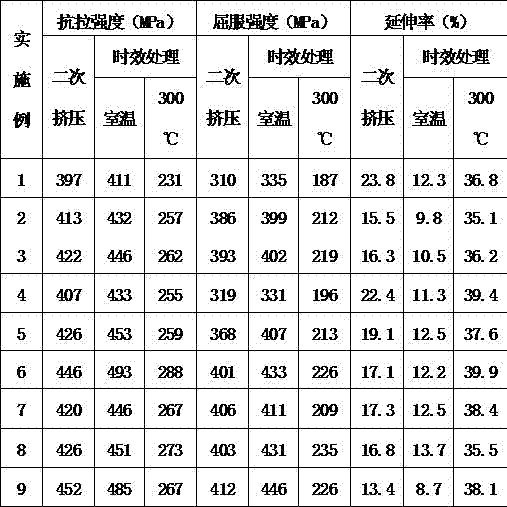

The invention discloses a thermal deformation strengthening method for a rare earth magnesium alloy. The thermal deformation strengthening method comprises the following steps: carrying out homogenization treatment on ingot blanks obtained by gravity casting of a metal mold at a temperature of 525 DEG C for 10 to 24 hours, then cooling with water and removing skins of the ingot blanks; preheating the ingot blanks subjected to skin removal at a temperature of 400 to 500 DEG C for 0.5 to 2 hours, carrying out hot extrusion with an extrusion ratio of (5 to 30) to 1 and an extrusion speed of 0.1 to 10m / min, and keeping the temperature of an extrusion die and an extruding container at 380 to 420 DEG C; carrying out secondary hydrostatic extrusion on bars subjected to the hot extrusion, wherein the preheating temperature of the bars is 200 to 250 DEG C, the extrusion temperature is 200 DEG C, the extrusion ratio is (4 to 10) to 1, the extrusion speed is 1 to 6m / min and a cooling mode is water cooling; preserving heat of the magnesium alloy bars subjected to the hydrostatic extrusion at a temperature of 450 to 560 DEG C for 10 to 24 hours, then carrying out water quenching solution treatment, carrying out heat preservation at a temperature of 180 to 250 DEG C for 10 to 48 hours and carrying out aging heat treatment. The method disclosed by the invention has the advantages that simplicity and easiness in control are realized; difficult-to-deform metal materials can be produced, continuous mass production can be realized, production cost is reduced effectively and mechanical properties of the rare earth magnesium alloy can be substantially improved.

Description

A kind of hot deformation strengthening method of rare earth magnesium alloy technical field The invention relates to the field of metal material forming and processing, in particular to a thermal deformation strengthening method of a rare earth magnesium alloy, which improves the plasticity of the material while maintaining the high strength of the material by controlling the extrusion process and parameters. Background technique Due to its low density, high specific strength, and good creep resistance and shock resistance and energy absorption, magnesium alloys have broad application prospects in the fields of national defense, aerospace, and automobile manufacturing. It is well known that traditional Mg-Al-Zn and Mg-Zn-Zr alloys have low strength, although in these alloys, the addition of rare earth elements (Ce, La, Nd and Y) can form a stable second The two phases make this type of magnesium alloy have high strength and good creep resistance at a temperature of 200°C ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22F1/06C22C23/06

CPCC22F1/06C22C23/06

Inventor 黎小辉唐国翌宋国林

Owner SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com