A rapid preparation method of calcium oxide-based ceramic casting mold for complex parts manufacturing

A ceramic casting, calcium oxide-based technology, used in ceramic molding machines, manufacturing tools, etc., can solve the manufacturing needs of difficult and complex structural parts, shorten the design and manufacturing cycle, reduce manufacturing costs, and improve density and sintering performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

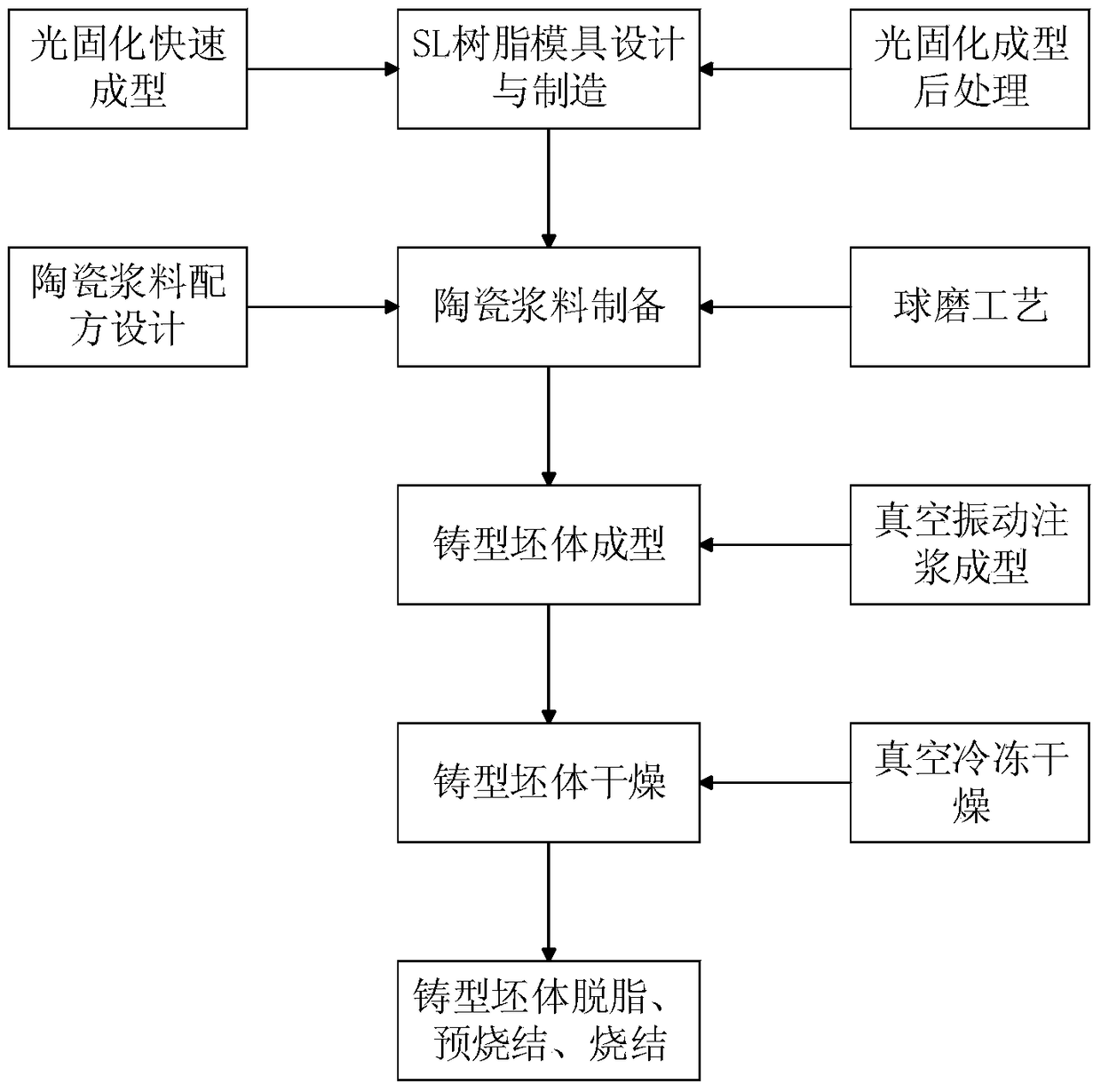

[0040] see figure 1 The present invention discloses a method for rapidly preparing calcium oxide-based ceramic molds suitable for the manufacture of complex parts, comprising the following steps:

[0041] 1) Use a light-curing rapid prototyping machine to manufacture burnable light-curable resin molds;

[0042] 2) Using a gel injection molding method, uniformly mix ceramic powder, monomer, crosslinking agent, dispersant, plasticizer and deionized water to prepare a high-solid, low-viscosity ceramic slurry;

[0043] 3) Pour the ceramic slurry into the cavity of the resin mold under vacuum and vibration environment, and under the induction of catalyst and initiator, the ceramic slurry is solidified to obtain the ceramic casting mold green body; the ceramic casting mold is removed by vacuum freeze-drying method. Moisture in the green body; put the dried ceramic casting green body into the atmospheric degreasing furnace to degrease, and burn off the organic matter in the green bo...

Embodiment 1

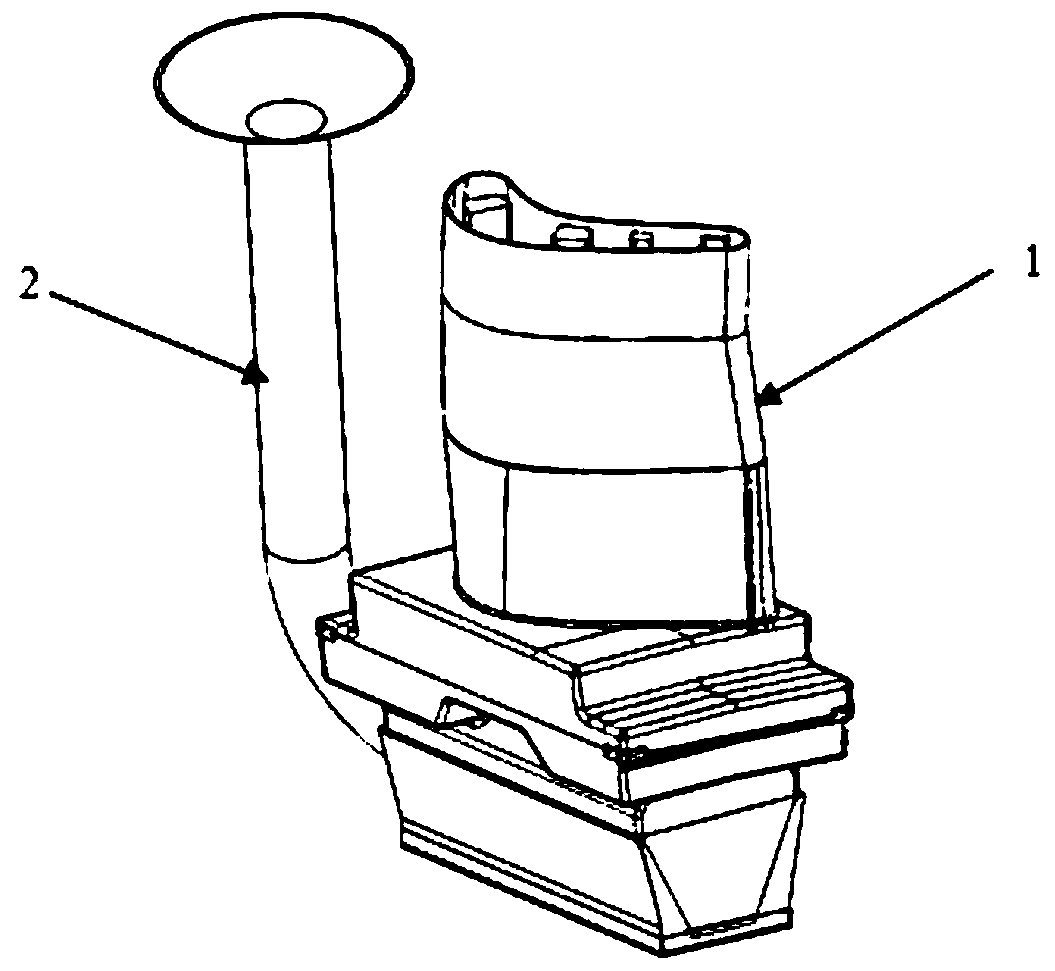

[0047] 1. Manufacture of burnable photocurable resin molds

[0048] The burnable resin mold contains a complex inner cavity and shape structure, and at least can form an integrated cooling channel. The specific manufacturing process is: first, use UG and other 3D modeling software to design an integral mold model of a certain type of blade of an airline ,Such as figure 2As shown, 1 is the SL resin mold shell; 2 is the ceramic slurry gate; export the model data as an STL format file, then use Magics software to add necessary supports to the model, and obtain the final SLC format file after layering processing, Then import the file into the light-curing rapid prototyping machine (XJRP-SPS600B), and scan the liquid photosensitive resin DSM Somos14120 under the drive of the laser head mechanical arm. The scanning path is controlled by the graphic data of each layer. Layers of liquid resin (about 0.1mm) are solidified due to polymerization and reaction, and continue until all lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com