A new flexible spline and wave generator assembly for harmonic gear transmission

A wave generator and harmonic gear technology, applied in the field of flex splines and wave generator components, can solve problems such as difficulty in obtaining machining accuracy, affecting the accuracy of ball movement trajectory, and failure of outer ring fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

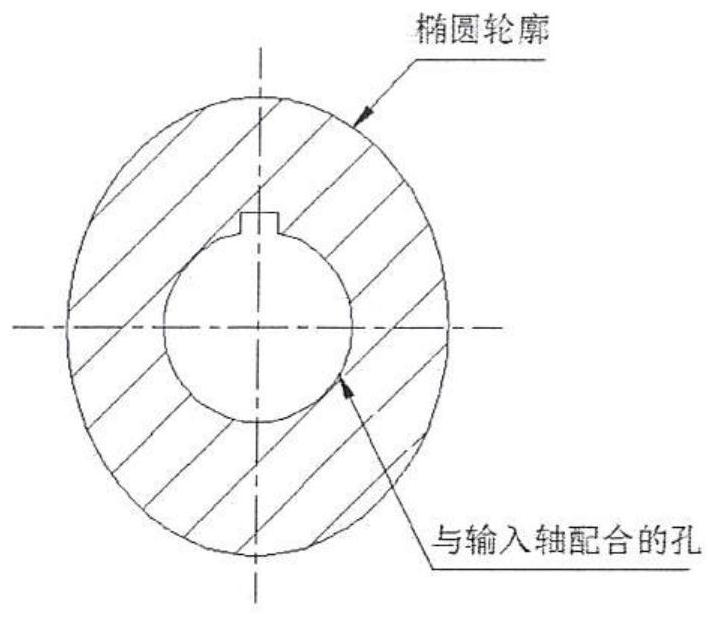

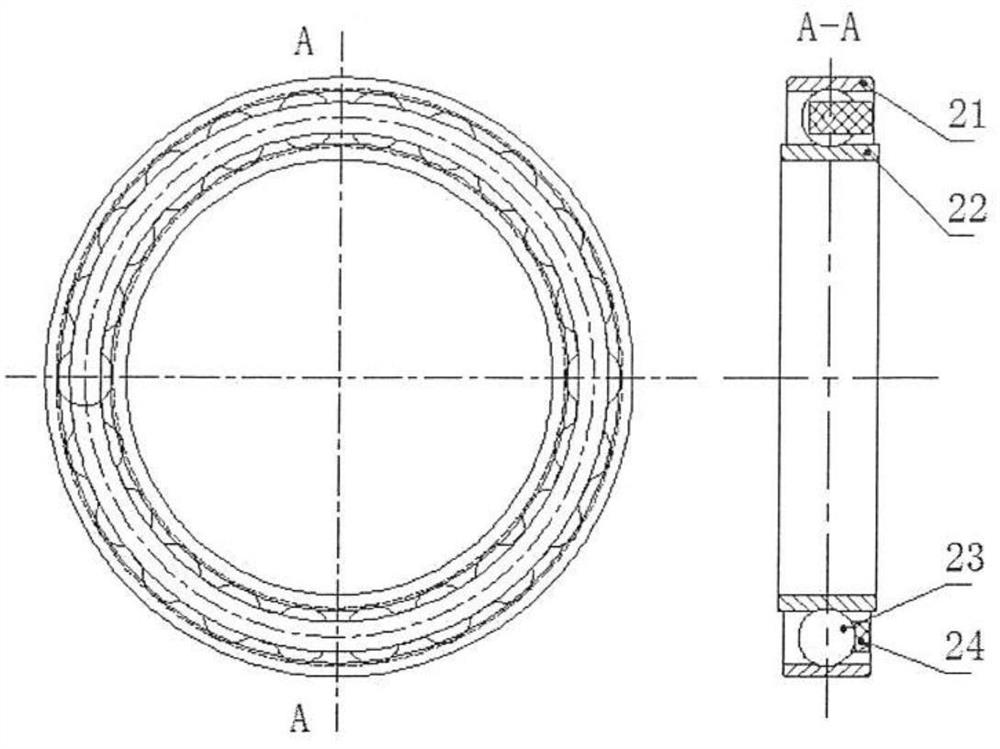

[0071] Embodiment 1. Special-shaped inner ring flexible ball bearing

[0072] Such as Figure 9 As shown, the special-shaped inner ring flexible ball bearing is used Figure 6 The special-shaped inner ring 92 shown, figure 2 In the flexible ball bearing in which the outer ring 91 and the balls 93 are assembled together in the prior art shown, the cage 94 evenly separates the balls along the circumferential direction. The special-shaped inner ring 92 is obtained by removing the inner ring of the flexible ball bearing of the current technology, and directly processing the groove of the inner ring of the flexible ball bearing of the current technology on the camshaft. The cross-sectional shape of the groove and the rib of the special-shaped inner ring 92 is Ellipse; the outer ring 91 is the same or similar to the outer ring of the prior art flexible ball bearing. The channel section of the outer ring 91 and the special-shaped inner ring 92 can be selected as Figure 7 (A) si...

Embodiment 2

[0075] Embodiment 2. A new type of flexible spline and wave generator assembly including special-shaped double-ring flexible ball bearings

[0076] Figure 10 It can be seen that the new flexspline and wave generator assembly including the special-shaped double-ring flexible ball bearing is actually a special-shaped double-ring flexible ball bearing (therefore, the two will be called without distinction in the following), and the special-shaped double-ring flexible ball bearing It has all the functions of flexspline and wave generator components. The special-shaped outer ring is a flexible ring with flexspline teeth on the outer surface. The special-shaped inner ring is a shaft-connected inner ring. The raceway is directly processed on the camshaft and the cross-section of the raceway is The shape is oval, and the holes and grooves on the special-shaped inner ring can be connected with the drive shaft. Special-shaped double-ring flexible ball bearing 10 ready-to-use Figure ...

Embodiment 3

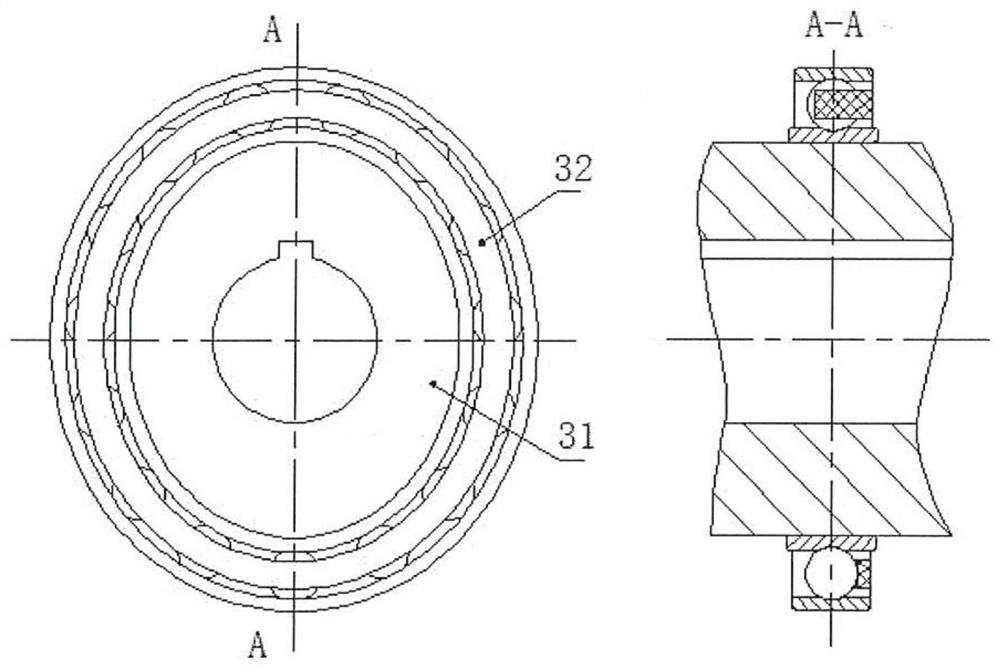

[0080] Embodiment 3. A new type of flexible spline and wave generator assembly including a special-shaped double-ring flexible roller bearing

[0081] Figure 11 It can be seen that the new flexspline and wave generator assembly including the special-shaped double-ring flexible roller bearing is the special-shaped double-ring flexible roller bearing (therefore, the two will be called without distinction in the following), and the special-shaped double-ring flexible roller The sub-bearing has all the functions of the flexspline and wave generator assembly. The special-shaped outer ring is a flexible ring with flexspline teeth on the outer surface. The special-shaped inner ring is a shaft-connected inner ring. The raceway is directly processed on the camshaft and the raceway The cross-sectional shape is ellipse, and the holes and grooves on the special-shaped inner ring can be connected with the transmission shaft. Special-shaped double-ring flexible roller bearing 11 ready-to-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com