Punching and electric spark combined micro arrayed through hole machining method and device

A processing method and electric spark technology are applied in the field of micro-array through-hole processing, which can solve the problems of reduced processing efficiency and accuracy, easy formation of taper, and large corrosion, and achieves improved mutual position accuracy, increased hardness and strength, and reduced manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

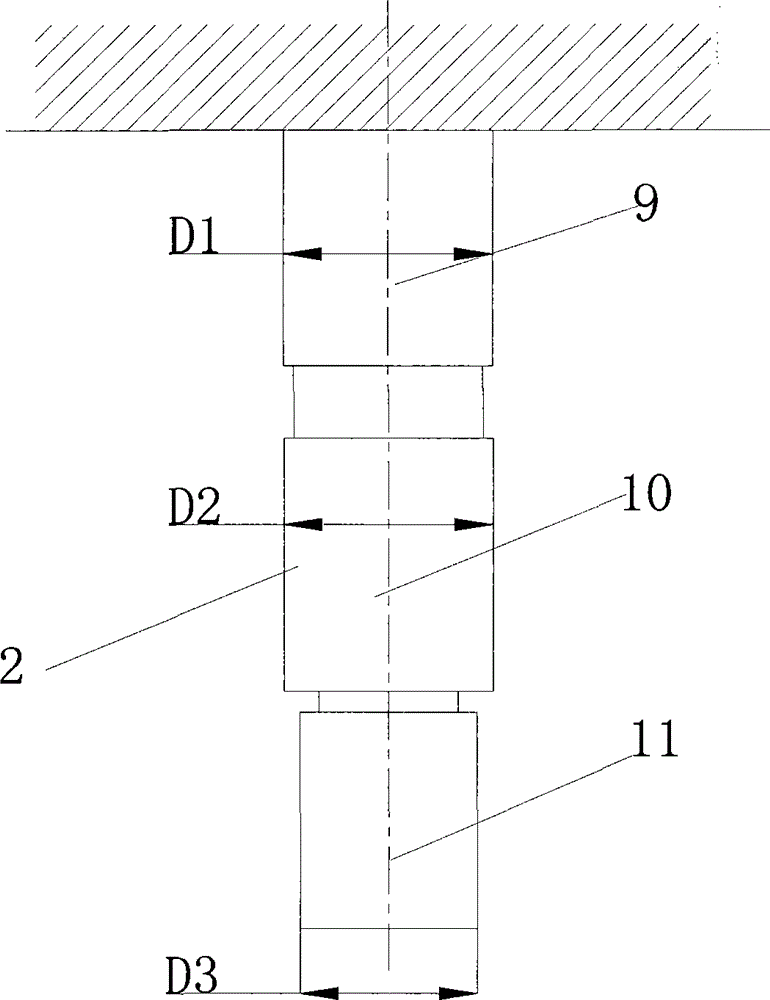

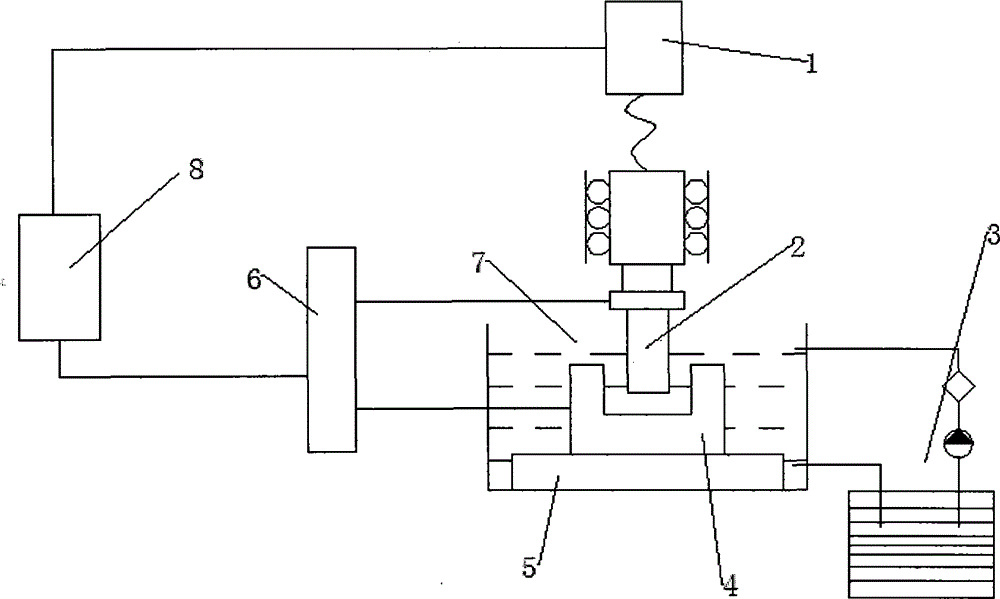

[0027] Such as figure 1 As shown, the forming die 2 used in the micro-array through-hole processing method based on punching and EDM is a three-stage type, which consists of electrodes 11, punches 10 and grinding tools 9 from top to bottom, and the electrode diameter is D3 , There is the following relationship between the punch diameter D2 and the abrasive tool diameter D1: D3<D2<D1, and D2=D3+(2~6μm), D1=D2+(0.05~0.5μm), electrode length L3, punch length There is the following relationship between L2, grinding tool length L1 and workpiece thickness t: L3=5 / 6×t, L2=(1.01~0.99)×t, L1=(1.01~1)×t; coated electrode 11 and the grinding tool 9, uniformly deposit a layer of metal layer with good wear resistance on the outer surface of the punch 10 by electrolytic deposition, and the thickness of the deposited metal layer is 1-20 μm; coat th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com