Spindle box structure with five-surface machining

A headstock and surface machining technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of poor rough machining rigidity, inconvenient use, low work efficiency, etc., and achieve high mutual position accuracy and convenience. Maintenance and use, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention provides a spindle box structure with five-sided processing, which is convenient for operation, convenient assembly and disassembly, reduces production cost and improves work efficiency. The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

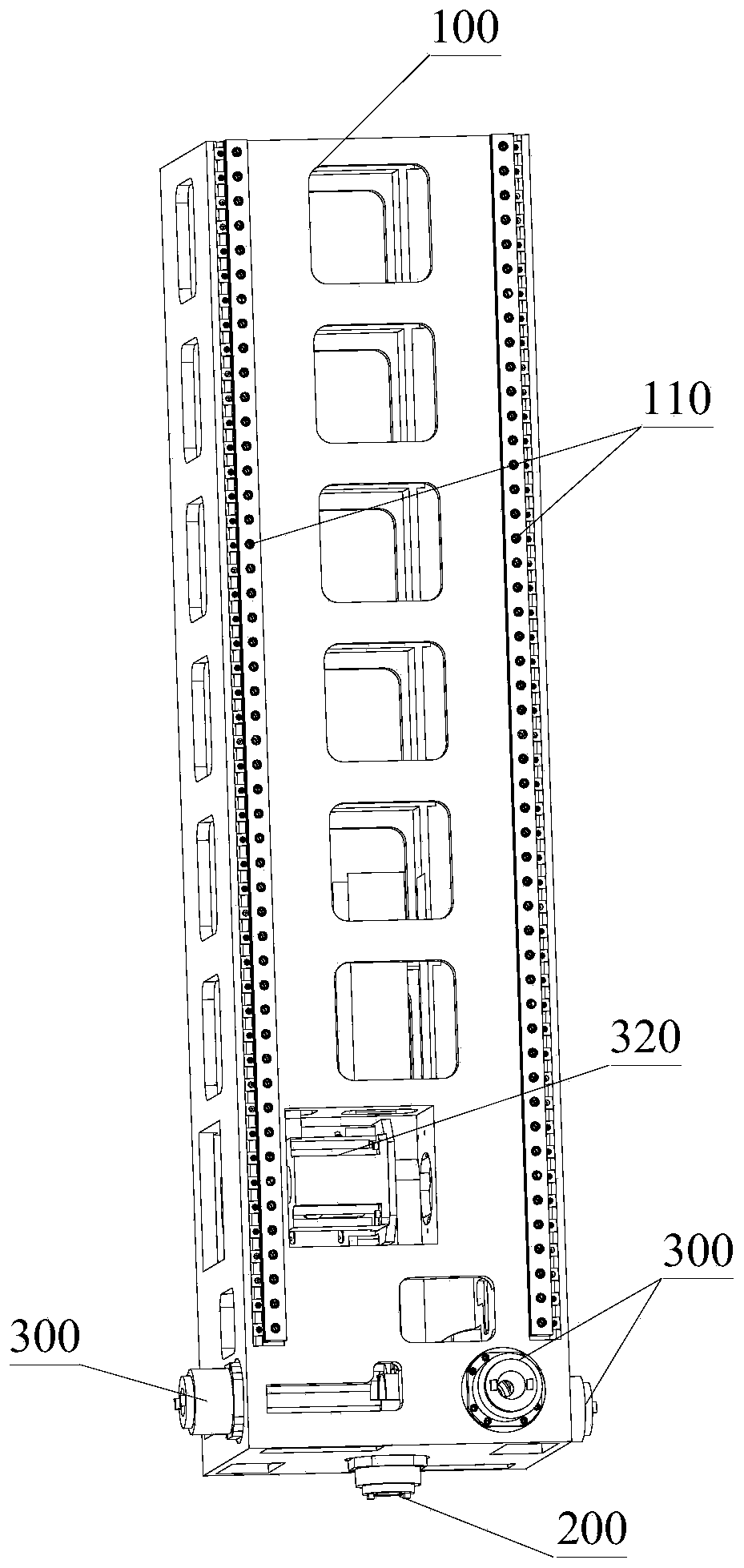

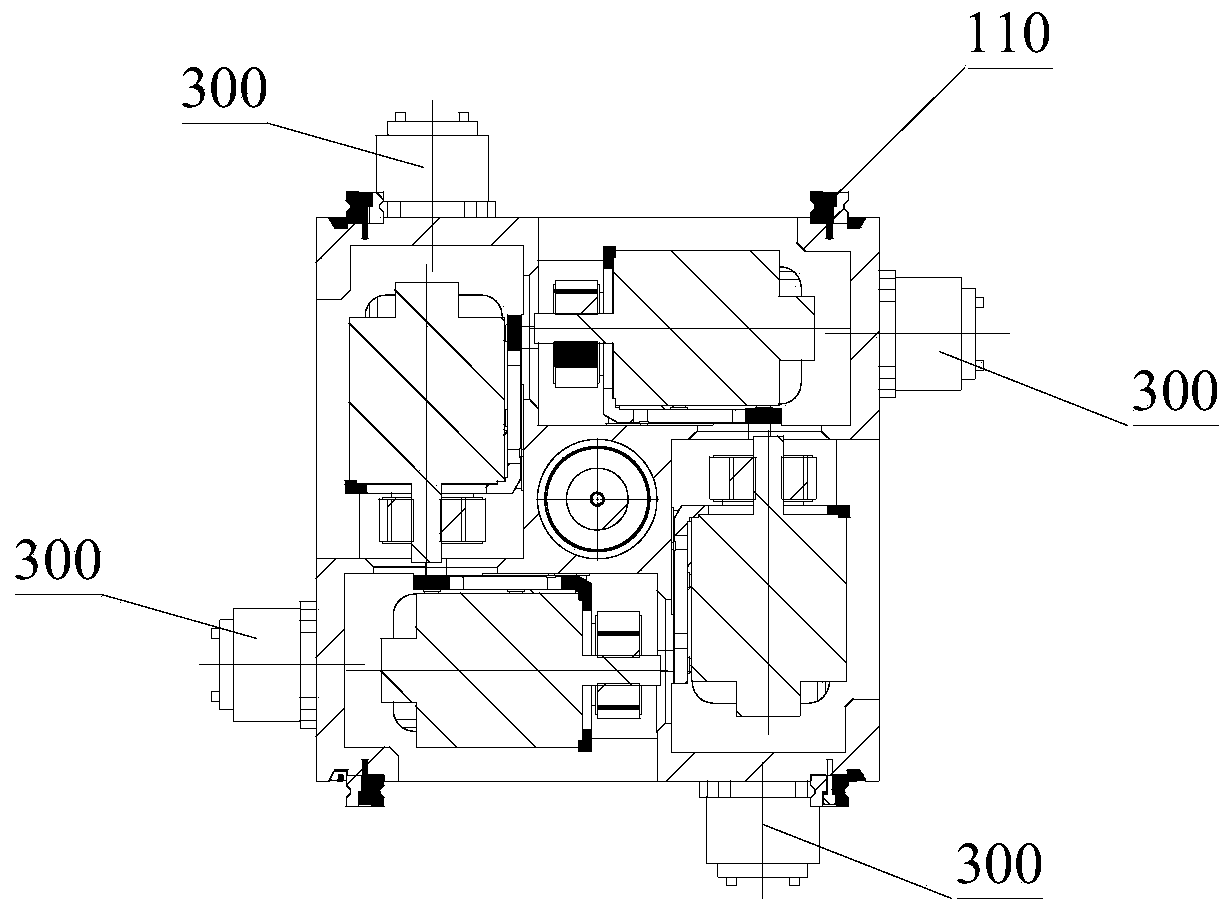

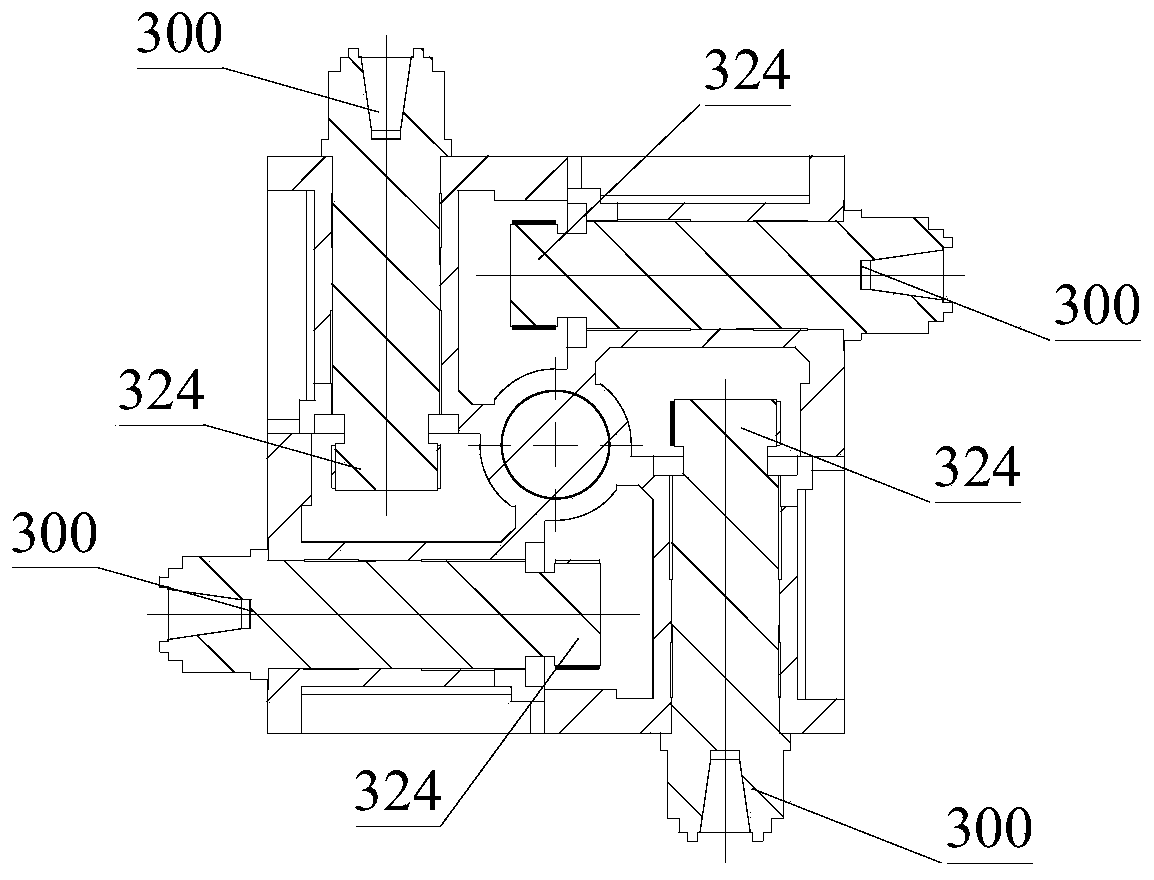

[0027] Such as figure 1 , Figure 5 As shown, the headstock structure provided by the present invention has a five-sided machining, including a headstock 100 and a plurality of spindles arranged on the headstock 100. The plurality of spindles include a central spindle 200 and four side spindles 300. The central spindle 200 Set on the bottom surface of the headstock 100, the outer end protrudes from the headstock 100 and is provided with a direct-connected cutter cylinder, and the inner end is connected with the central spindle motor 210 in the headstock 100 through a coupling 220, which can take its coolant from the tool Cooling blades and par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com