Forming method and forming mold of semi-closed sheet part

A forming mold and semi-closed technology, applied in the field of sheet metal forming, can solve the problems of corrugation, angle value out-of-tolerance, unevenness and other problems on the surface of parts, and achieve the effect of optimizing forming tooling, reducing correction procedures and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

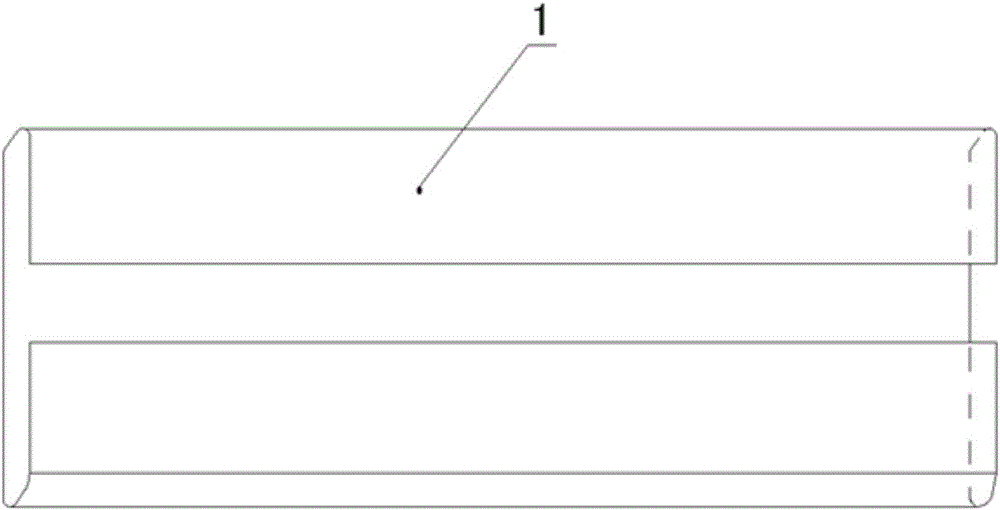

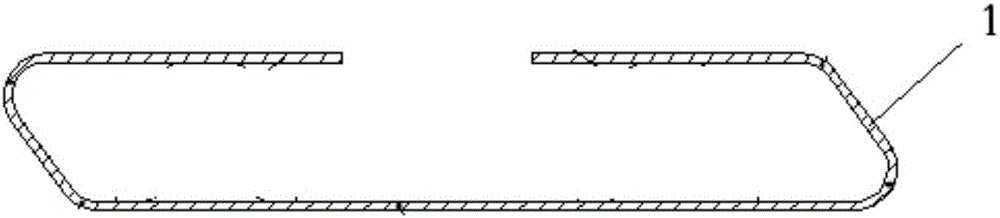

[0019] See attached picture, figure 1 It is a schematic diagram of a semi-closed thin plate part. According to the structural design of the aircraft, the material grade of the part is LY12CZ state, the thickness of the plate is 1mm, and the height of the whole part is 20mm (such as figure 1 with figure 2 shown). The semi-closed structure formed by the flanges of part 1 is a blind spot for correction, and the size cannot be controlled. The surface quality of the parts after manual forming is poor, and the parts cannot be removed smoothly after forming. Therefore, the forming of the part and the unloading after forming are the problems that the present invention strives to solve.

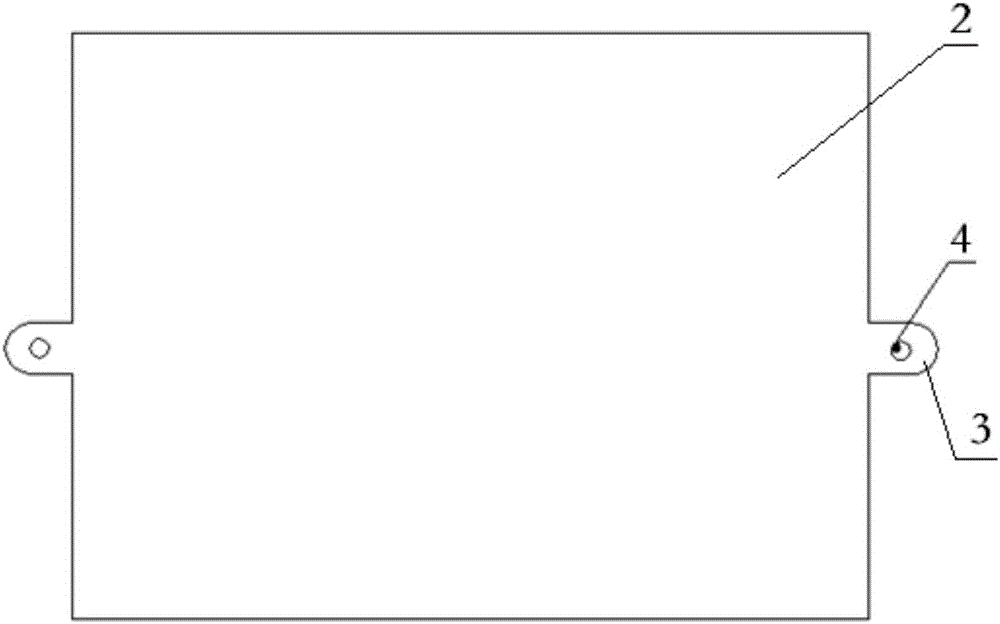

[0020] First, there must be a forming mold, which contains a base 6 and an inner tire. The base is provided with a concave cavity that matches the shape of the bottom of the part 1. The two ends of the cavity are provided with the first part for forming the part. A positioning hole 11, the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com