Patents

Literature

36results about How to "Realize continuous large-scale production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing fuel cell membrane electrode with sealing frame

ActiveCN104617310ARealize continuous large-scale productionAvoid damageCell electrodesPolymer electrolytesPtru catalyst

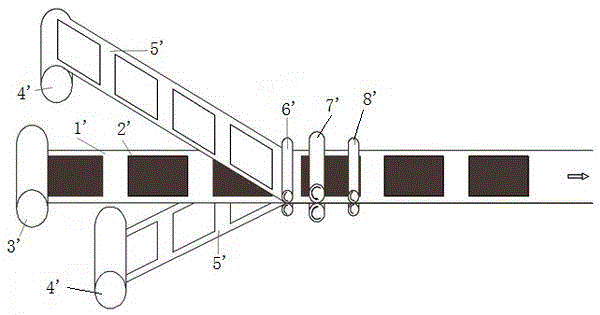

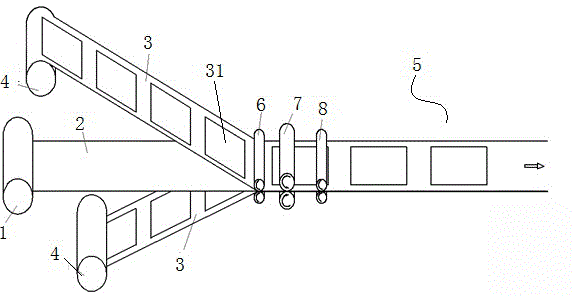

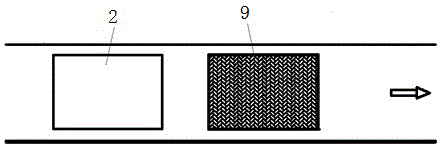

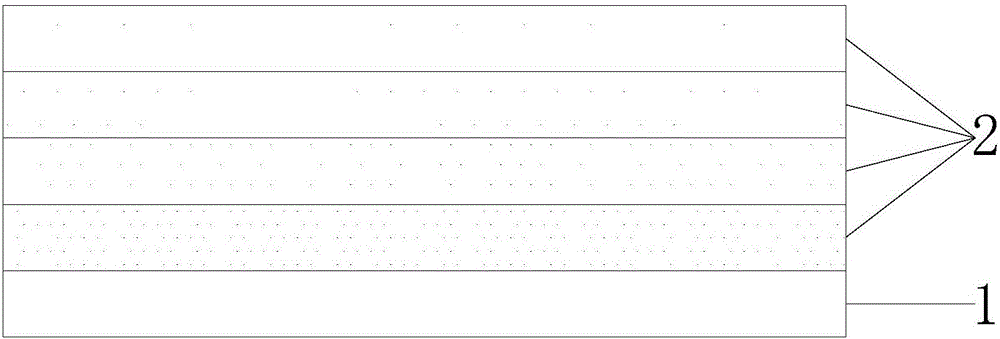

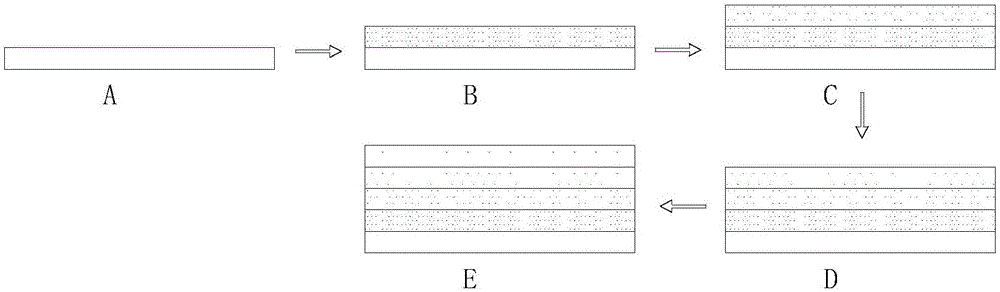

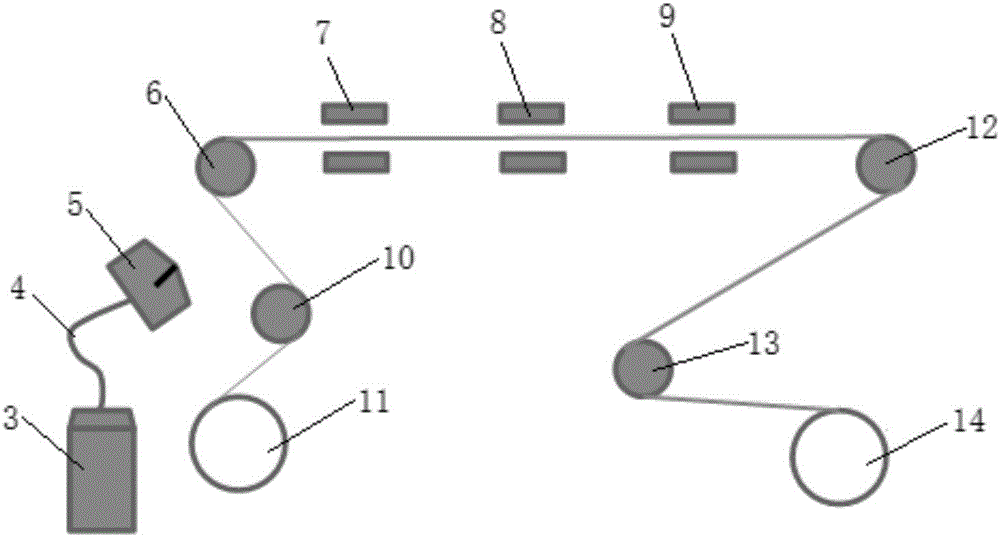

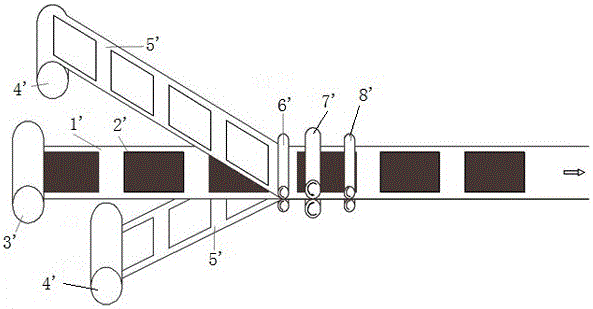

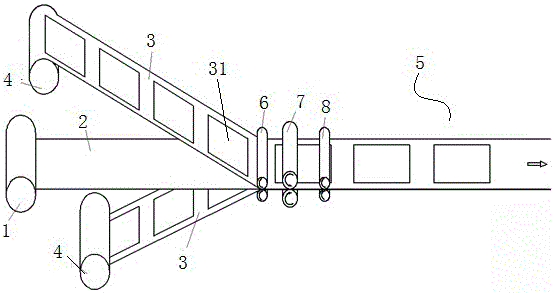

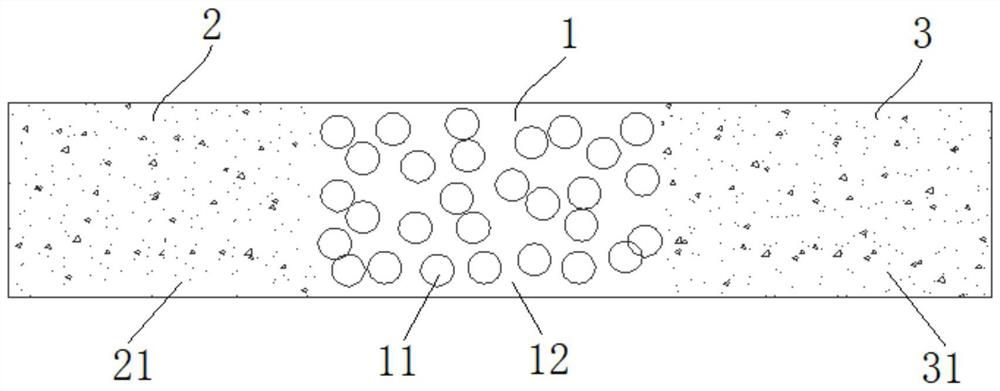

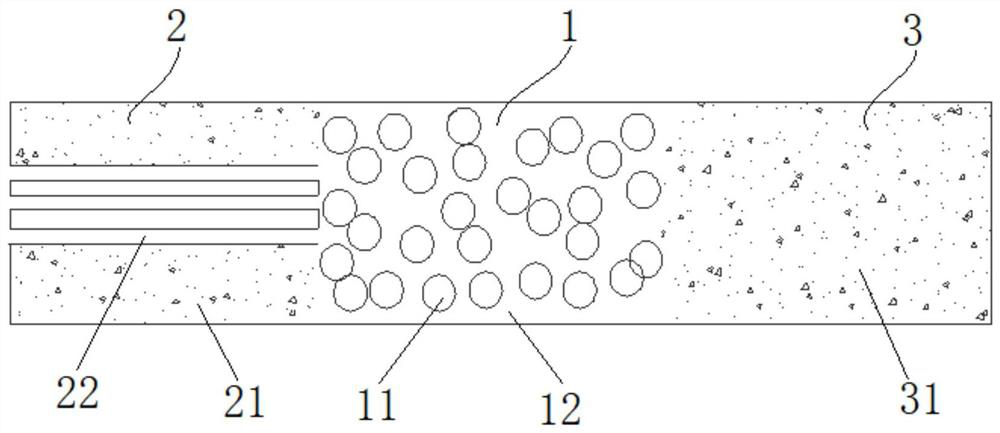

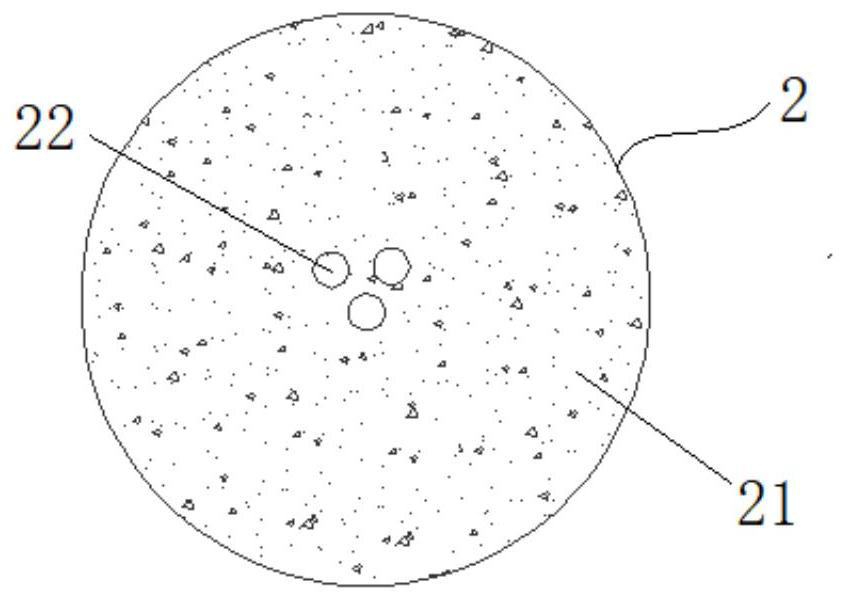

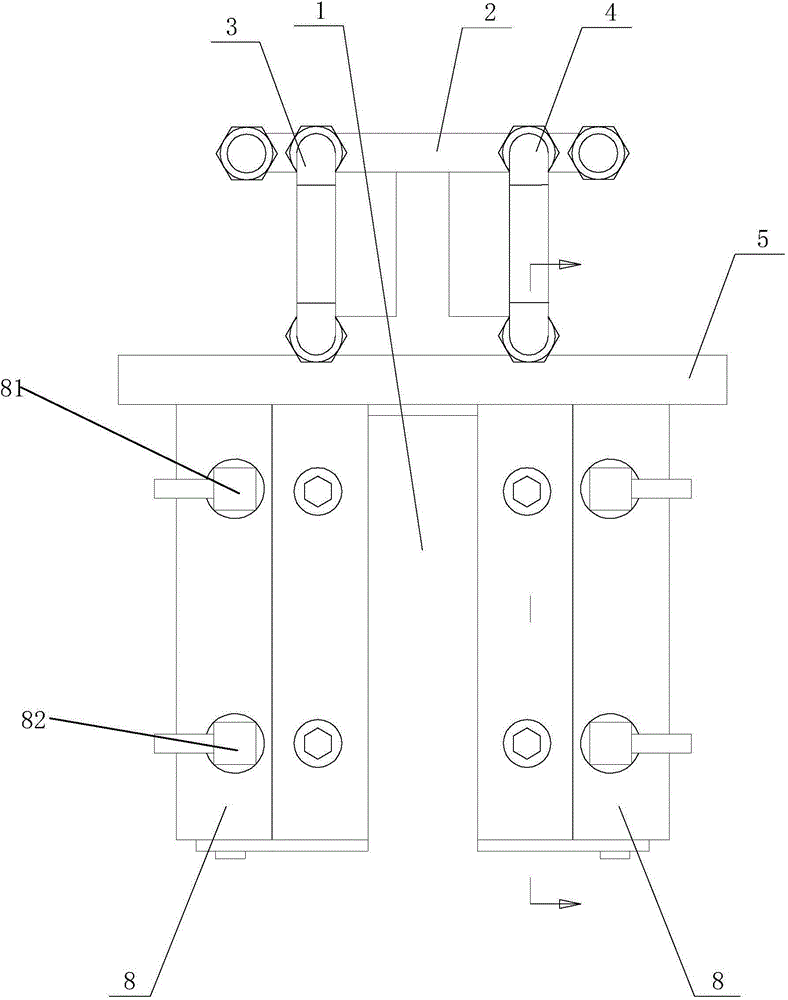

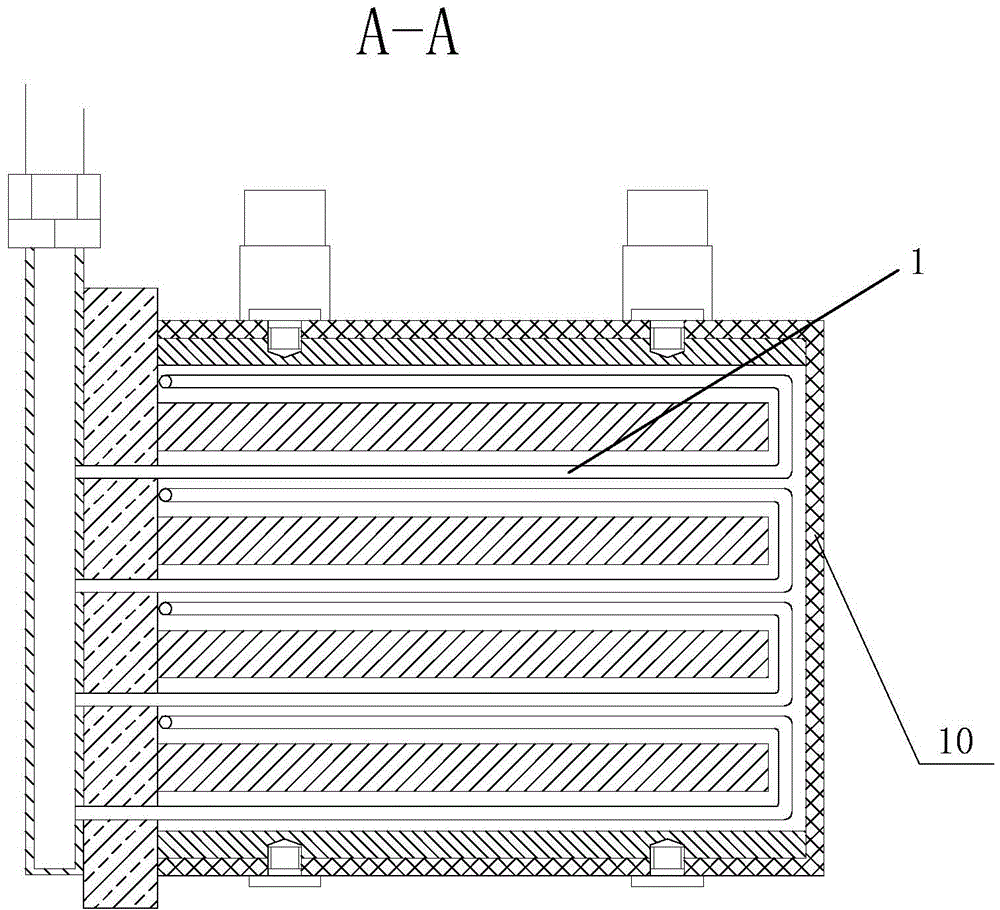

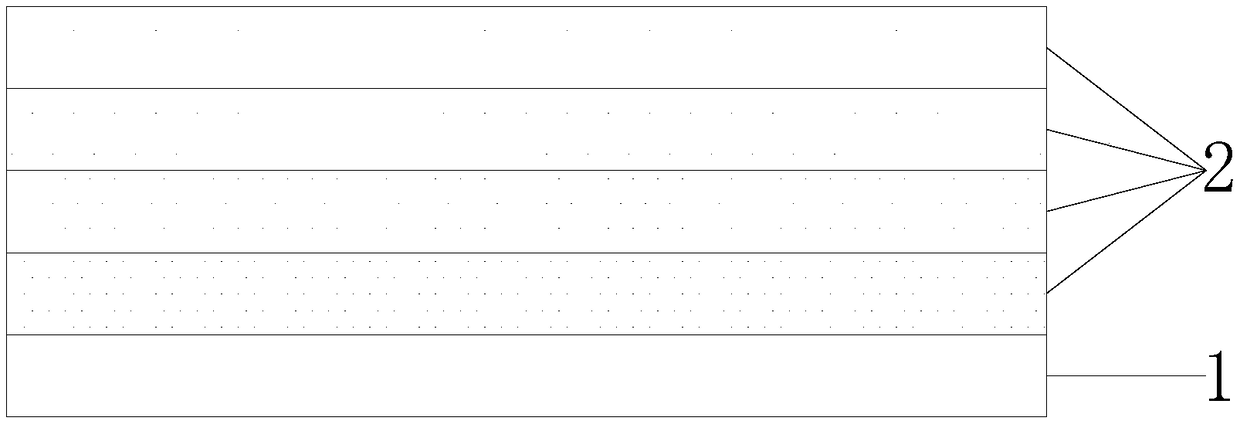

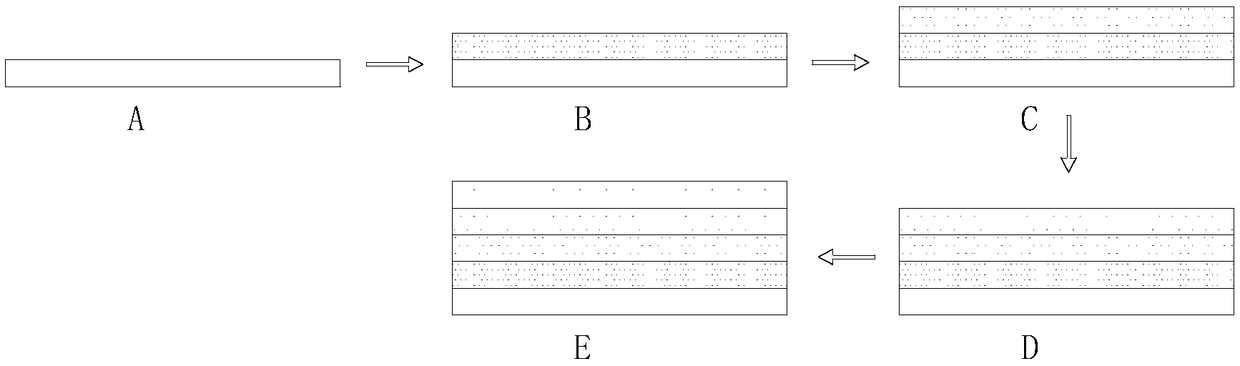

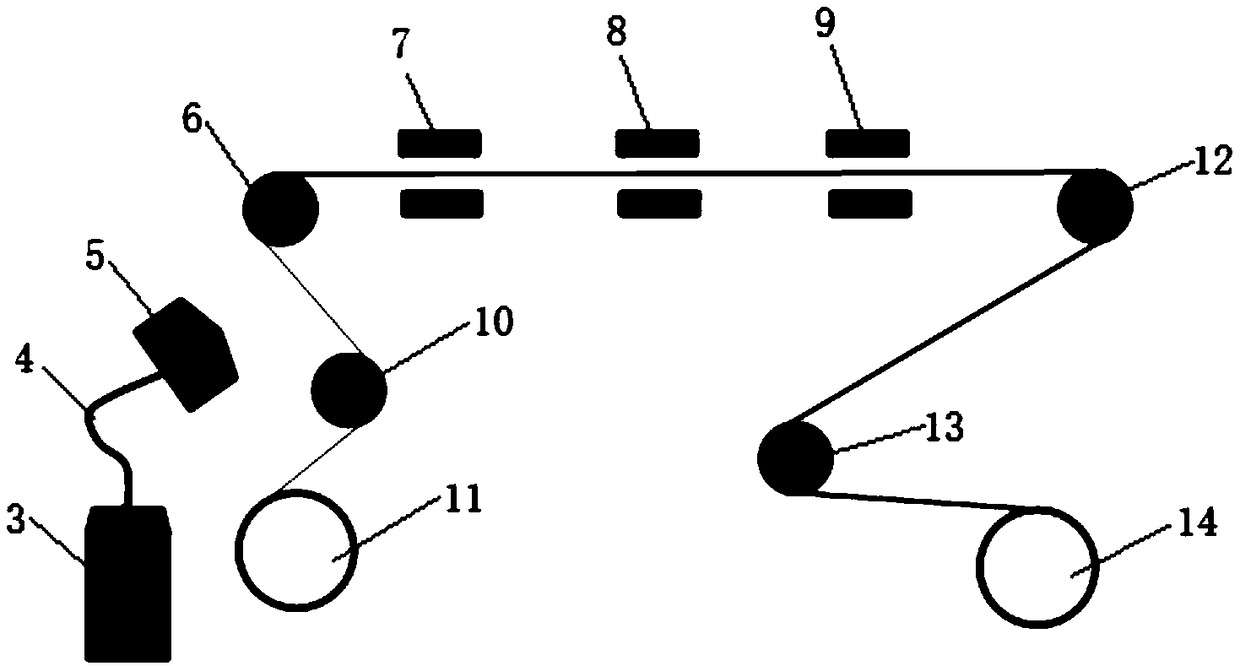

The invention discloses a method for preparing a fuel cell membrane electrode with a sealing frame. The process is simple and easy to realize. The method comprises the following steps: feeding a polymer electrolyte membrane and a sealing frame material with a layer of hot melt adhesive into a rolling device of a hot pressing platform, jointing the sealing frame material to edges of two sides of the polymer electrolyte membrane through heating rolling, and laminating a gas diffusion layer coated with a catalytic layer on two sides of the polymer electrolyte membrane so as to form a membrane electrode component. In the preparation process, a catalyst liquid is directly coated on the gas diffusion layer instead of the polymer electrolyte membrane, so that damage to a catalytic layer is reduced, the situation that later process is affected by swelling deformation of the membrane in the spraying process is avoided, the formation procedure can be simplified, continuous large-scale production of GDE and MEA can be conveniently achieved, and the production efficiency is greatly improved.

Owner:KUNSHAN SUNLAITE NEW ENERGY +1

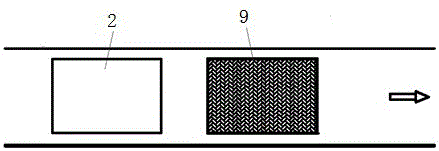

Beta-carotene microcapsule and preparation technology thereof

ActiveCN104719894AUnique emulsificationImprove stabilityNatural dyesFood shapingVegetable oilOrganosolv

The invention relates to a beta-carotene microcapsule and a preparation technology thereof. The technology comprises the following steps: mixing corn starch which contains beta-carotene crystals and microhole ocentyl succinic anhydride and serves as a core material, an oil phase consisting of plant oil, an antioxidant and the like and a water phase consisting of a wall material, an antioxidant, a dispersant, water and the like according to a ratio, homogenizing to prepare microemulsion, and performing spray drying to prepare beta-carotene microcapsule powder. In a preparation process, no organic solvent needs to be added, and an obtained product keeps the bioactivity, is stable to the photo-thermal property and is extremely high dissolvability in cold water; processing, transportation and storage are facilitated; the safety, the flowability, the taste and the water solubility of the product are greatly improved; the beta-carotene microcapsule is a high-quality health food and food pigment raw material. The yield of the beta-carotene microcapsule prepared by the technology is high, and the preparation method is suitable for batch preparation of the beta-carotene microcapsules; continuous large-scale production is realized.

Owner:武汉志邦化学技术有限公司

High-content krill oil microcapsules and preparation technology thereof

ActiveCN104824651AGood moisture absorptionGood moisturizing effectFood ingredient as encapsulating agentEdible oils/fatsAntioxidantEngineering

The invention relates to high-content krill oil microcapsules and a preparation technology thereof. The technology comprises the following steps: by taking krill oil and microporous starch as core materials, adding a small amount of xanthan gum into oil phase; and by taking chitosan oligosaccharide and oxidized starch as wall materials, mixing an oil-phase antioxidant, a water-phase antioxidant, an emulsifier, a dispersant and the like in proportion to prepare micro-emulsion, and performing spray drying to prepare krill oil microcapsule powder. The obtained krill oil microcapsule product contains 10-30 percent of phosphatide and keeps biological activity, improves the light-heat stability, acid-alkali stability and the like of krill oil, has good solubility in cold water, and is relatively easy to process, transport and store, safety, fluidity and water solubility are greatly improved, the application range of krill oil is enlarged, and the krill oil is an excellent health-food raw material, and is widely applied to dairy products, beverages, health-care products, baking, tablets and the like. The yield of the krill oil microcapsule powder prepared according to the technology is high, the phosphatide content of the product is high, and the technology is suitable for mass preparation of krill oil microcapsule powder and realizes continuous large-scale production.

Owner:武汉志邦化学技术有限公司

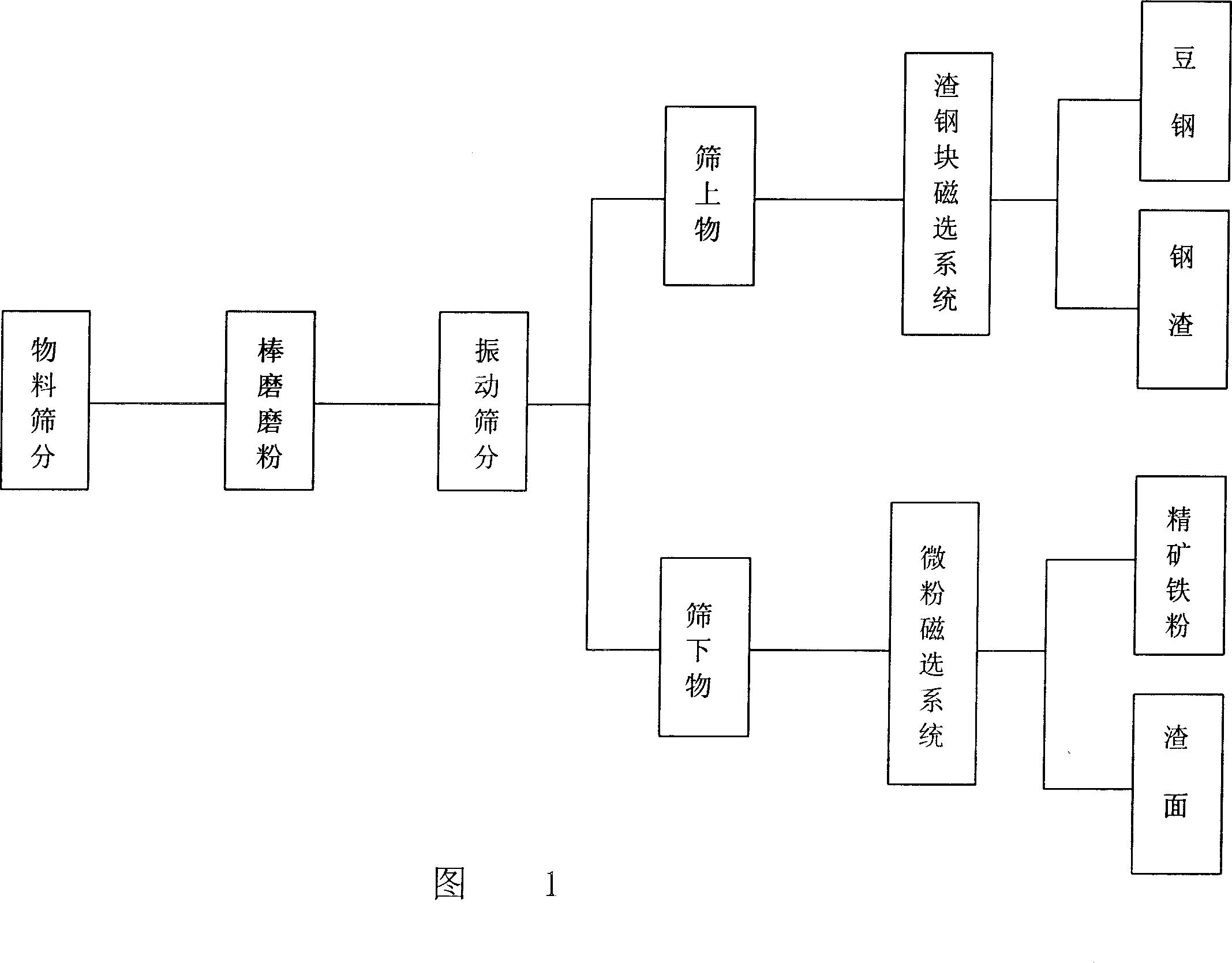

Process for treating slag steel

The invention discloses a rod milling-magnetic cobbing disposing technology of steel-smelting slag in the metallurgical resource synthetic utility technological domain, which comprises the following steps: sieving materials; milling powder; vibrating to screen; magnetting; separating refined ore powder and slag; magnetting the screen material; separating soy steel and steel block slag.

Owner:ANYANG IRON & STEEL GRP

Halogen-free flame-retardant polyethylene functional material for aluminum-plastic composite board and preparation thereof

InactiveCN101280083AComply with the requirements of the directiveMeet the production process requirementsAntioxidantVolumetric Mass Density

The invention discloses a halogen-free flame-retardant polyethylene functional material for APCP and the preparation method of the material. The material has the following components and contents (based on weight proportion): 25-40% of polyethylene, 2.5-25% of modified polyethylene, 32-50% of brucite powders, 0.1-10.0% of silicone flame retardants, 0.5-3.5% of coupling agent, 0.5-8.5% of synergist, and 0.25-1.5% of antioxidant. The technical performance indicators of the material of the invention are as follows: 12.5 to19.5MPa for tensile yield strength, 30 to 230% for ultimate elongation, 15.5 to24.5 MPa for bending strength, 19.0 to 25.0KJ / m2 for notch impact strength, 85 to 95 DEG C for Vicat softening temperature, 1.25 to 1.37 g / cm3 for density, 32 to 36% for oxygen index, and 0.25 to 1.50g / 10min for melt flow rate; besides, the environmental protection index of the material meets the International Safety Standards IEC62321, in line with the requirements of ROHS Directive. The preparation method of the invention is to use vacuum exhaust-type parallel twin-screw extruding hot-cutting and granulating technology to prepare the material. The raw materials of the invention can be easily obtained and the technology is easy to control; besides, the material of the invention has the advantages of excellent comprehensive performance and cost ratio, as well as good flame-retardant properties and thermal stability, which can be extruded and molded through injection and can realize large-scale continuous production.

Owner:HUNAN KEOCT MATERIALS +1

Method for continuously preparing graphene nanoplatelets by means of grinding stripping

The invention belongs to the technical field of graphene, and particularly relates to a method for continuously preparing graphene nanoplatelets by means of grinding stripping.The method comprises the steps that crystallized organic matter is uniformly dispersed in a graphite precursor through solvent dispersion, deformation force produced through repeated crystallization of the crystallized organic matter is utilized for enabling the graphite layer frame distance to be increased, and intercalated graphite is formed; the intercalated graphite is sent to a grinding stripping machine, the stripping and grinding effect of shear force formed in the mutual friction process of media and the graphite material is utilized, the intercalated graphite is stripped, and graphene nanoplatelets are formed; screening separation is conducted on stripped graphite through a vibrating screening machine, unstripped graphite is screened out to be stripped again, and the uniformly distributed graphene nanoplatelets are obtained.The number of layers of the prepared graphene nanoplatelets ranges from 10 to 100, the crystal structure is complete, the high-quality graphene nanoplatelets are produced in an efficient, low-cost and continuous mode under a high shear condition, the preparation process is green and environmentally friendly, and a significant market value is achieved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

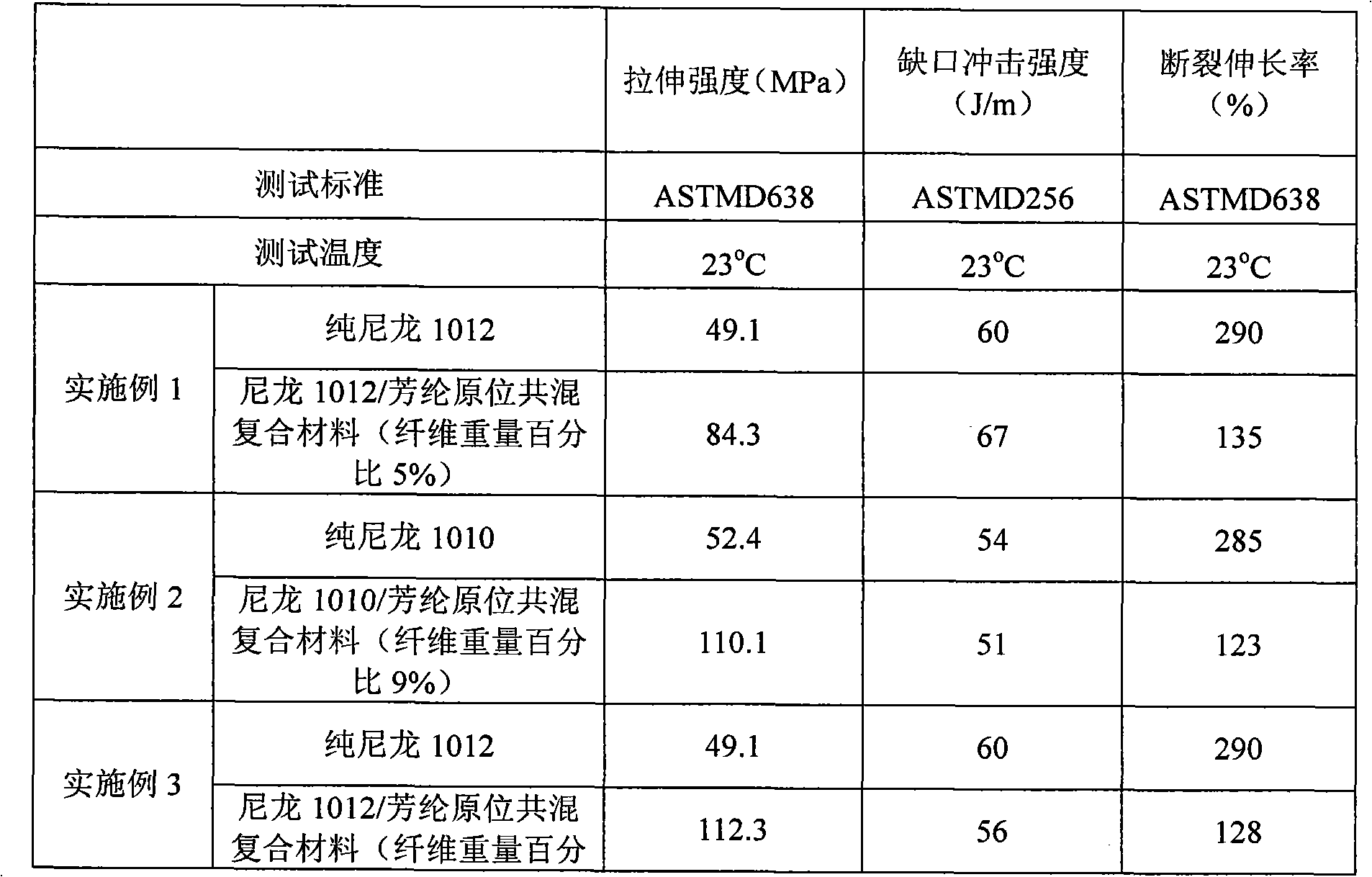

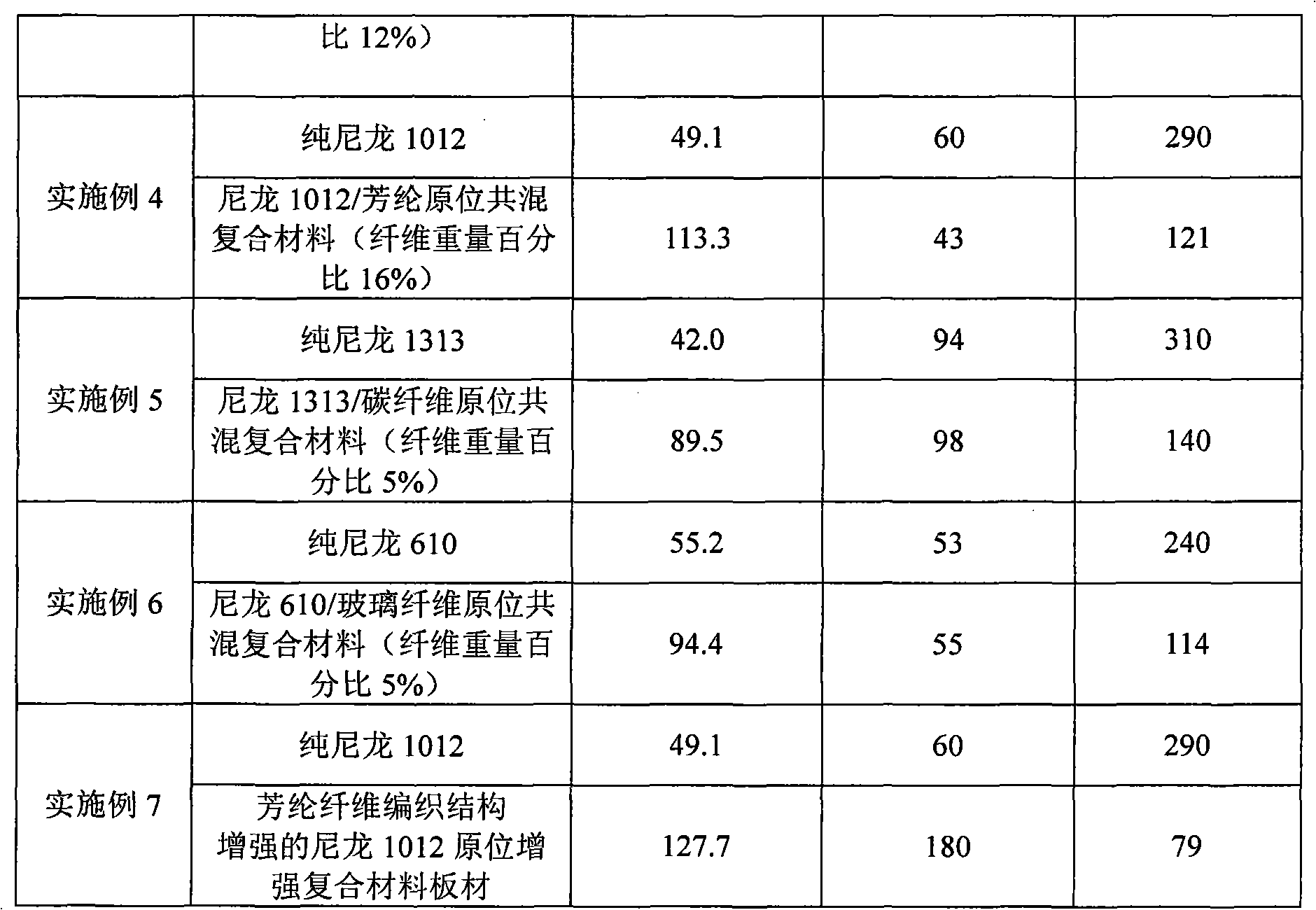

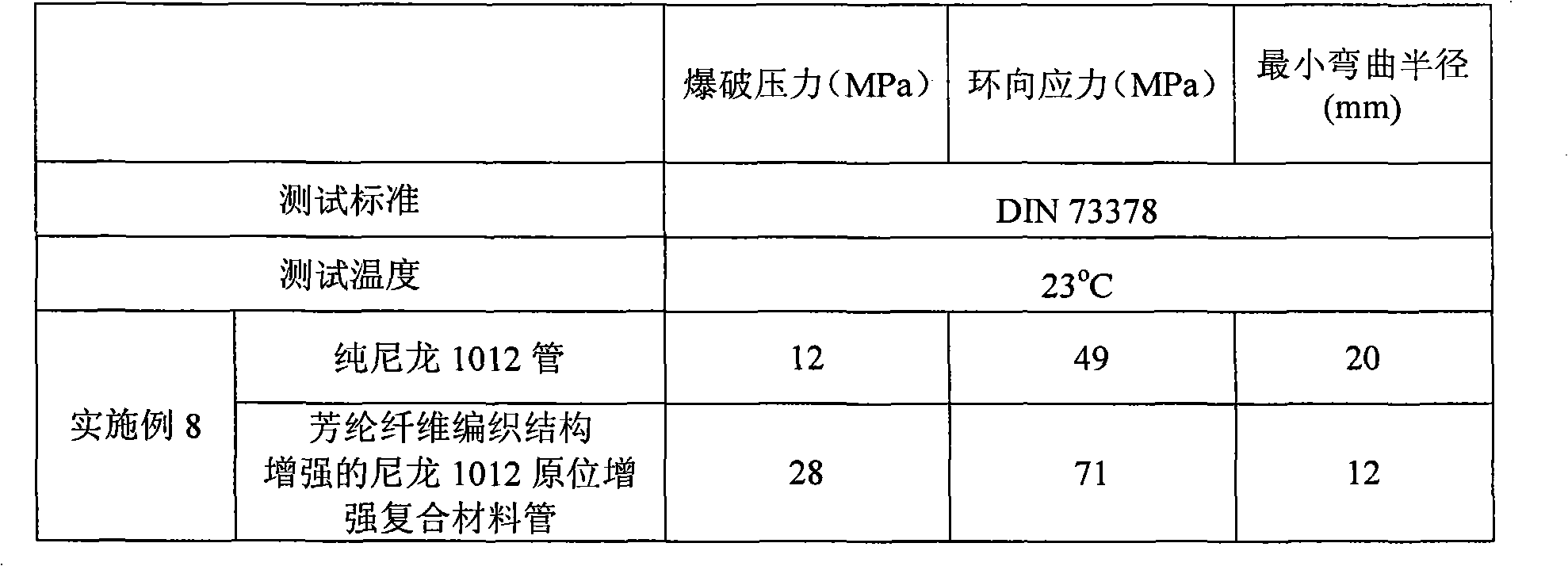

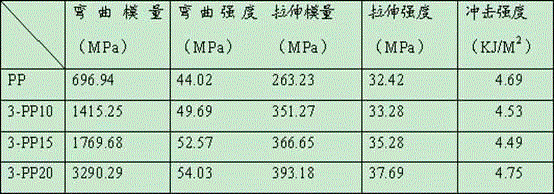

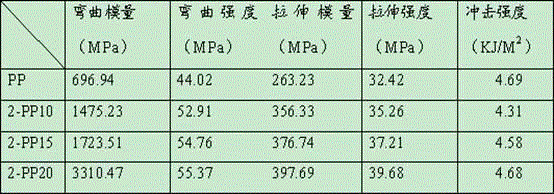

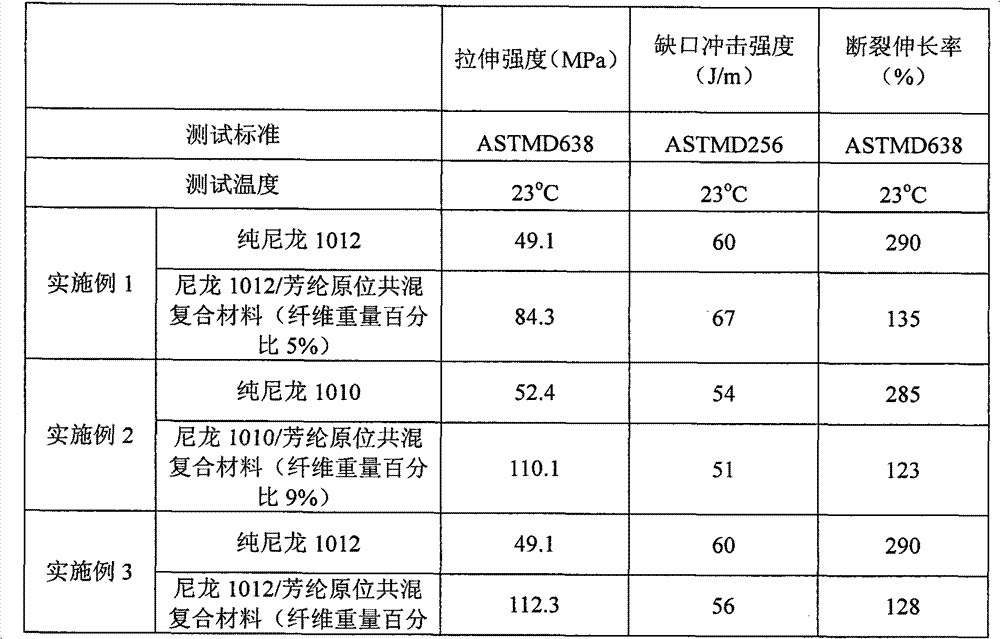

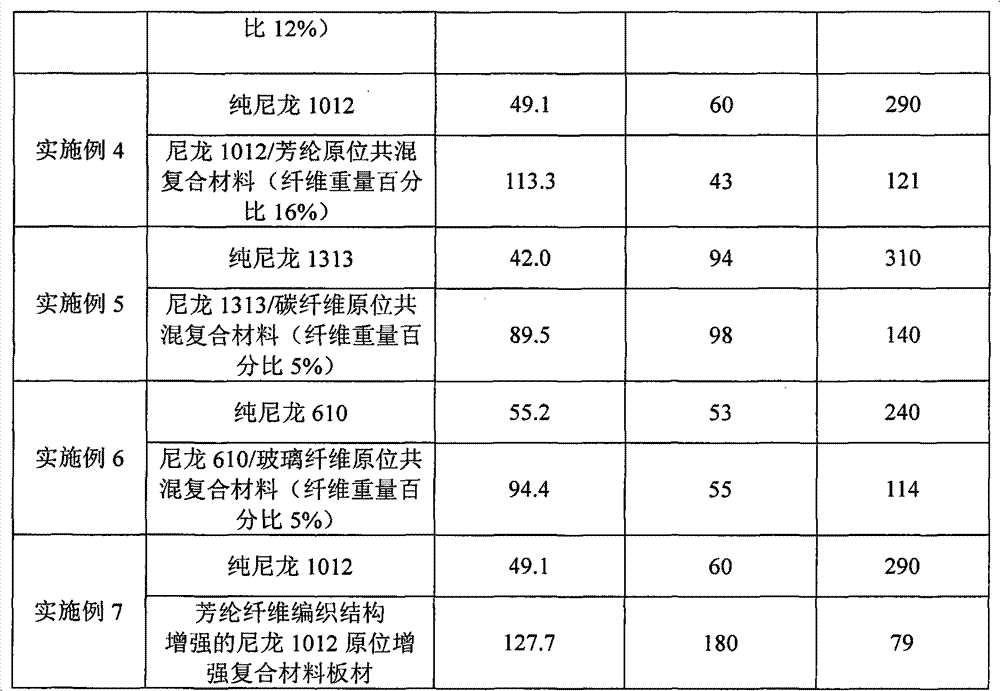

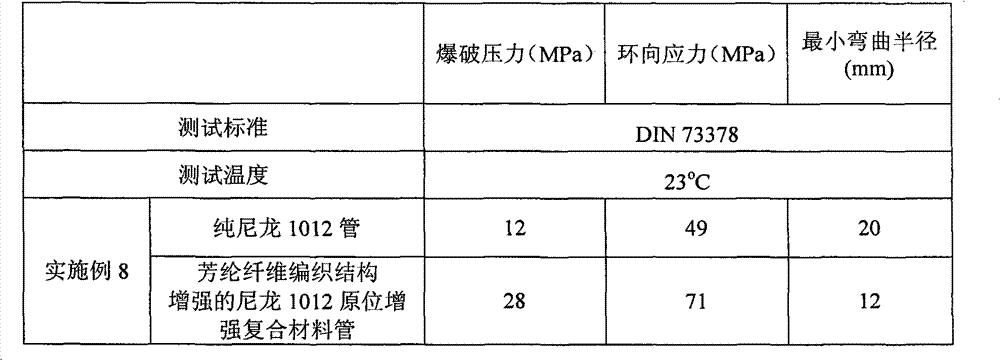

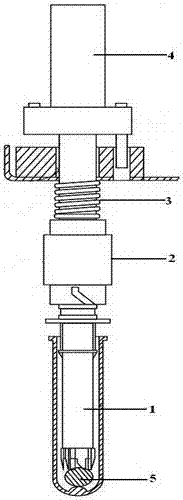

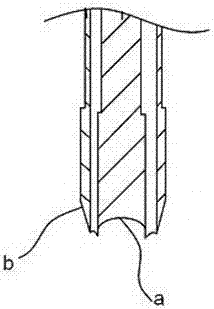

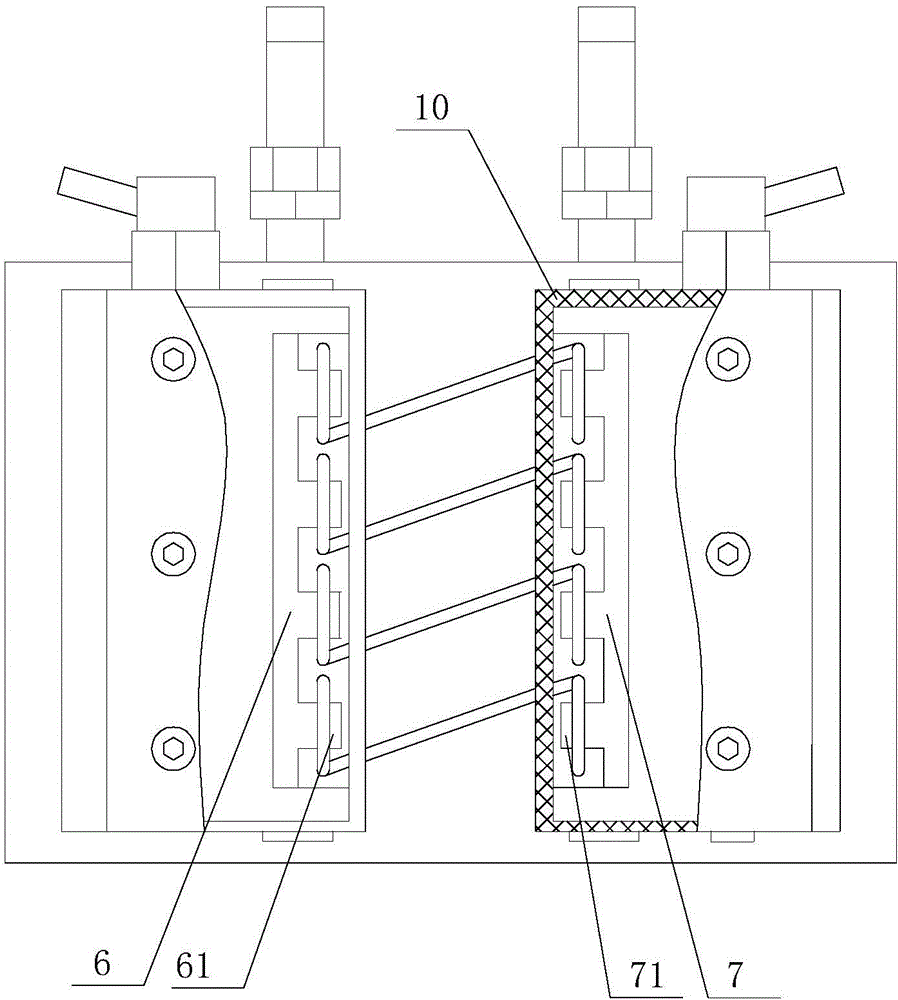

Fiber/long-carbon-chain nylon in-situ composite material and preparation method

The invention relates to a fiber composite material, and particularly relates to a fiber / long-carbon-chain nylon in-situ composite material and a preparation method. The fiber / long-carbon-chain nylon in-situ composite material comprises the components: 1-20wt% of high-performance fiber and 80-99wt% of long-carbon-chain nylon salt, preferably 5-16wt% of high-performance fiber and 84-95wt% of long-carbon-chain nylon salt, wherein the high-performance fiber is selected from at least one of aramid fiber, carbon fiber and fiberglass. The preparing process is simple; and the strength and toughness of the prepared fiber / long-carbon-chain nylon composite material are significantly improved as compared with those of the pure long-carbon-chain nylon prepared by the same process.

Owner:INST OF CHEM CHINESE ACAD OF SCI

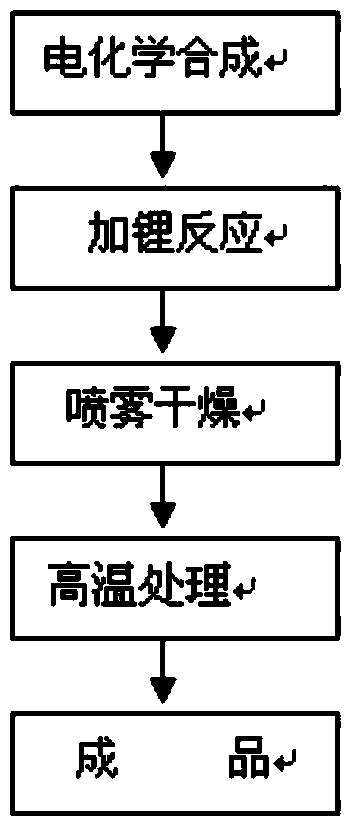

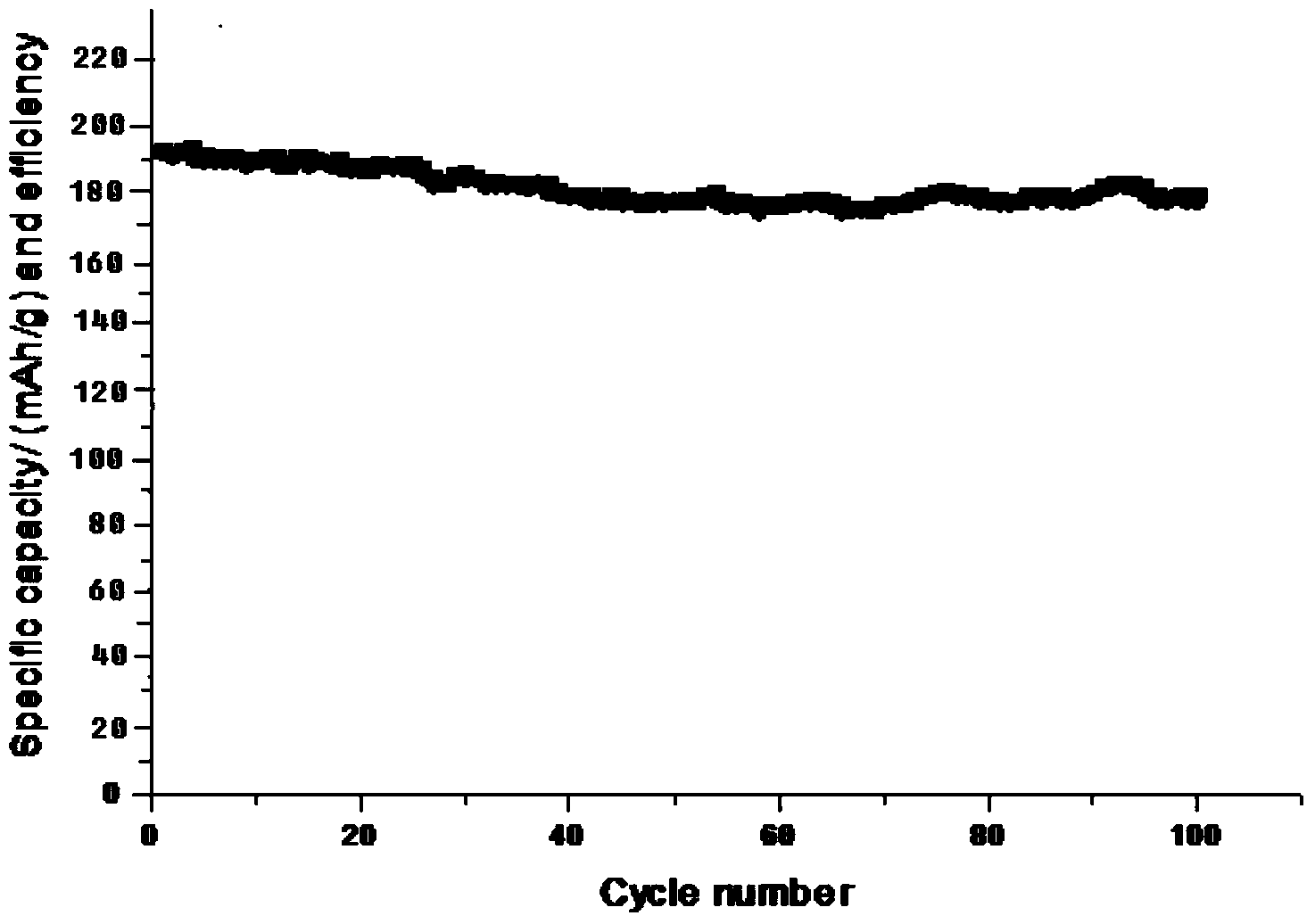

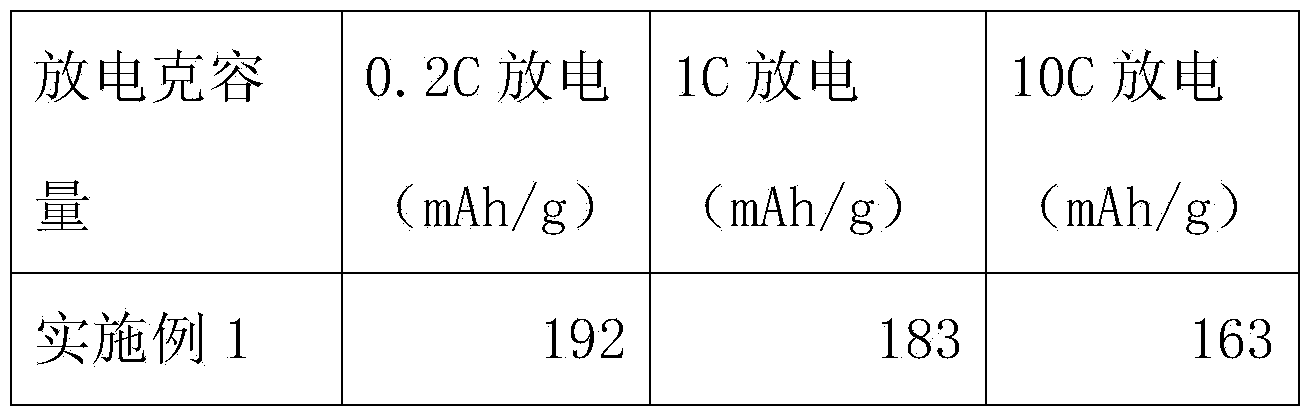

Electrochemical preparation method of ternary anode material

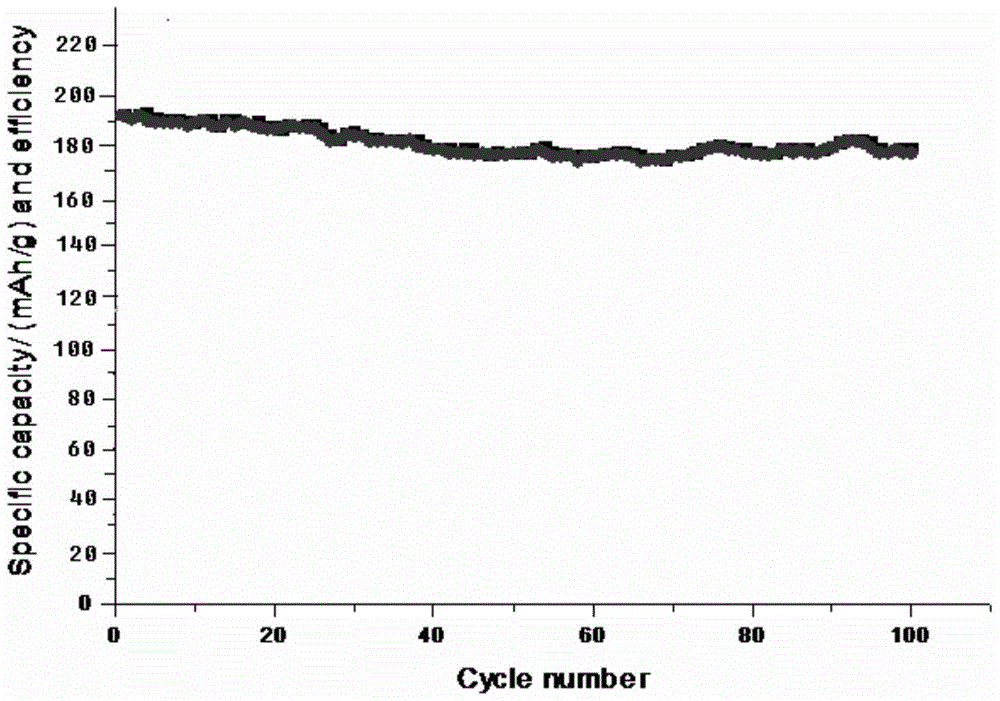

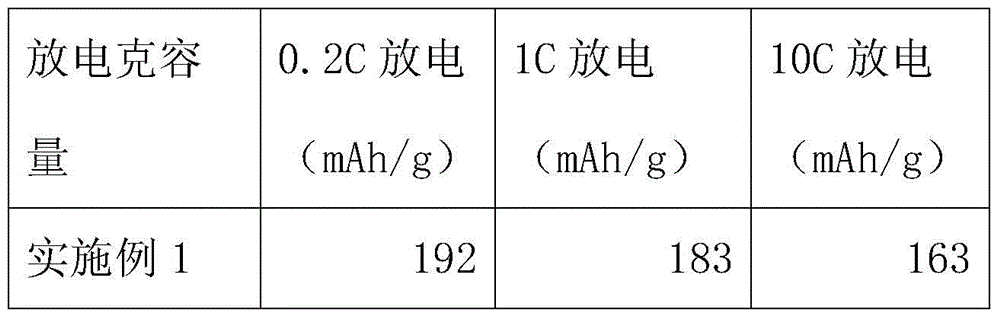

ActiveCN104409723AImprove discharge capacityImprove cycle stabilityElectrolysis componentsCell electrodesChemical synthesisElectrolysis

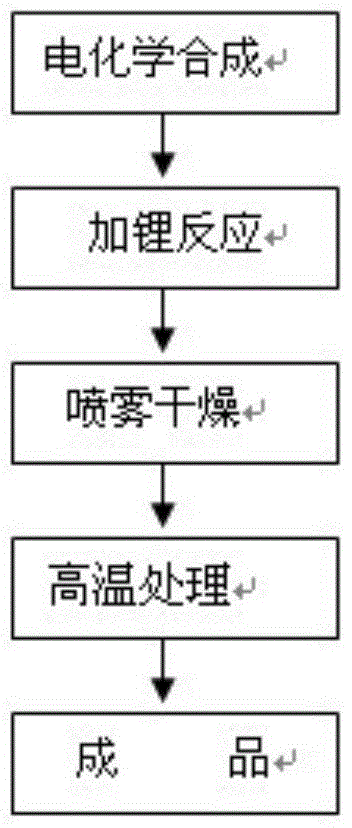

The invention discloses an electrochemical preparation method of a ternary anode material. According to the method disclosed by the invention, pure nickel, cobalt and manganese metals and electric energy are used as raw materials and a green electrochemical synthesis method is adopted for synthesizing a nickel, cobalt and manganese salt compound by means of electrolysis at normal pressure and normal temperature, and the ternary anode material-LiNixCoyMnzO2 can be obtained after lithium addition reaction, spray-drying and high-temperature treatment, wherein x is greater than 1 and less than 1, y is greater than 0 and less than 0.8, z is greater than 0 and less than 1, and x+y+z is equal to 1. Compared with the prior art, the electrochemical preparation method disclosed by the invention can be used for reducing the cost of raw materials and energy consumption, simplifying the process, also reducing the environmental pollution and improving the product performances. An electrochemical synthesis technology adopted by the method is an environmentally-friendly chemical process, the pure metals are used as anode materials and no impurities are introduced, so that the concentration controllability and the high purity of nickel ions, cobalt ions and manganese ions are guaranteed; meanwhile, the zero emission of wastewater to the environment is realized, and the continuous large-scale production can be realized.

Owner:WUHU HUAXINNUO ELECTROCHEM TECH

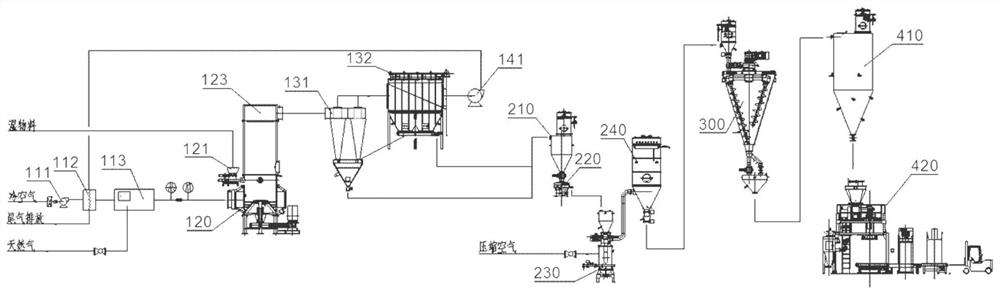

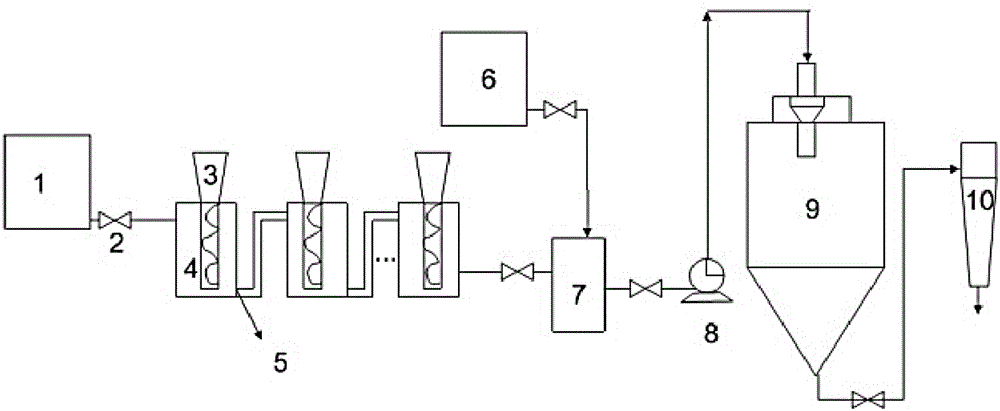

Continuous treatment system and method for basic magnesium carbonate wet material

PendingCN113188292ARealize continuous large-scale productionRealize fully automated operationDrying solid materials with heatMagnesium carbonatesGas solidFiltration

The invention discloses a continuous treatment system and method for a basic magnesium carbonate wet material. The system comprises a drying device and a crushing device, wherein the drying device comprises a thermal medium unit, a rotary flash drying tower and a first dust remover; and the crushing device comprises a first surge bin, a vibrating screen positioned at the lower part of the first surge bin, a jet mill connected with the vibrating screen, and a second dust remover connected with the upper part of the jet mill, wherein the drying device adopts a rotary flash drying tower to dry a wet material, and then the wet material is conveyed to the first dust removal device for gas-solid separation; after gas separation, the solid is cached through a first surge bin in the crushing device and enters a vibrating screen for coarse filtration, then a jet mill is adopted for crushing, and the crushed material is subjected to gas-solid separation through a second dust remover. According to the invention, the continuous treatment of drying and crushing the basic magnesium carbonate wet material can be realized, the continuity and stability of the production process are ensured, and the whole treatment process is environment-friendly.

Owner:CHINA ENFI ENGINEERING CORPORATION

Multilayer electromagnetic shielding film and preparation method thereof

ActiveCN106739324AGood electromagnetic shieldingHigh mechanical strengthSynthetic resin layered productsCarbon nanotubeElectromagnetic shielding

The invention discloses a multilayer electromagnetic shielding film and a preparation method thereof. According to the multilayer electromagnetic shielding film, shielding layers are arranged from the outermost layer to the sub-bottom layer and the bottom layer is a resin insulating layer; the resin insulating layer is a pure resin layer; each of the shielding layers is of a layered structure formed by adding conductive filler to matrix resin. The conductive filler comprises one or more of nickel powder, silver powder, a carbon nanotube and graphene. In two adjacent shielding layers, The adding amount of the conductive filler of the lower shielding layer is greater than that of the lower shielding layer. The electromagnetic shielding property of the multilayer electromagnetic shielding film prepared by the invention is excellent, and the mechanical strength and toughness are good; meanwhile, the production process is simple, the cost is low, and full continuous scaled production can be achieved.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

A kind of electrochemical preparation method of ternary cathode material

ActiveCN104409723BImprove discharge capacityImprove cycle stabilityElectrolysis componentsCell electrodesChemical synthesisElectrolysis

The invention discloses an electrochemical preparation method of a ternary anode material. According to the method disclosed by the invention, pure nickel, cobalt and manganese metals and electric energy are used as raw materials and a green electrochemical synthesis method is adopted for synthesizing a nickel, cobalt and manganese salt compound by means of electrolysis at normal pressure and normal temperature, and the ternary anode material-LiNixCoyMnzO2 can be obtained after lithium addition reaction, spray-drying and high-temperature treatment, wherein x is greater than 1 and less than 1, y is greater than 0 and less than 0.8, z is greater than 0 and less than 1, and x+y+z is equal to 1. Compared with the prior art, the electrochemical preparation method disclosed by the invention can be used for reducing the cost of raw materials and energy consumption, simplifying the process, also reducing the environmental pollution and improving the product performances. An electrochemical synthesis technology adopted by the method is an environmentally-friendly chemical process, the pure metals are used as anode materials and no impurities are introduced, so that the concentration controllability and the high purity of nickel ions, cobalt ions and manganese ions are guaranteed; meanwhile, the zero emission of wastewater to the environment is realized, and the continuous large-scale production can be realized.

Owner:WUHU HUAXINNUO ELECTROCHEM TECH

A kind of industrial device and method for continuous production of graphene powder

Owner:XIAMEN KNANO GRAPHENE TECH CORP

Ethyl lauroyl arginate hydrochloride microcapsule and preparation technology thereof

InactiveCN105054220AReduce solubilityImprove solubilityBiocideFood preservationAnticaking agentArginine ethylester

The present invention relates to an ethyl lauroyl arginate hydrochloride microcapsule and preparation technology thereof. The preparation technology is prepared by: using ethyl lauroyl arginate hydrochloride as core materials; using starch sodium octenyl succinate and cyclodextrin as wall materials, proportionally mixing the wall materials with anticaking agents, dispersants and aqueous phase antioxidants, and homogenizing and spray drying the mixture to obtain ethyl lauroyl arginate hydrochloride microcapsule powder. There is no need to add any organic solvents in the preparation process of the ethyl lauroyl arginate hydrochloride microcapsule, and the function activity of obtained products can be kept; and the ethyl lauroyl arginate hydrochloride microcapsule is characterized by increased solubility at low temperature and greatly improved usability and water solubility. The ethyl lauroyl arginate hydrochloride microcapsule is more conducive to processing, transportation and storage, and is excellent antiseptic materials. The ethyl lauroyl arginate hydrochloride microcapsule produced by the preparation technology is high in yield, and suitable for large-scale preparation to realize the continuous and large-scale production.

Owner:武汉志邦化学技术有限公司

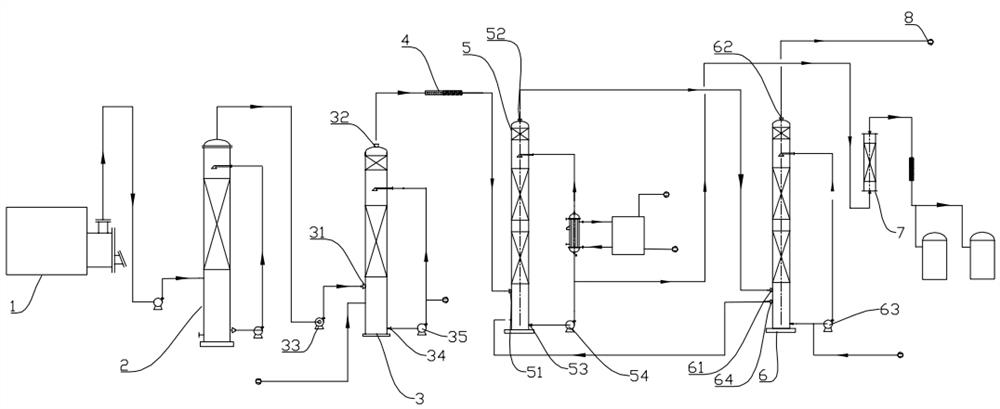

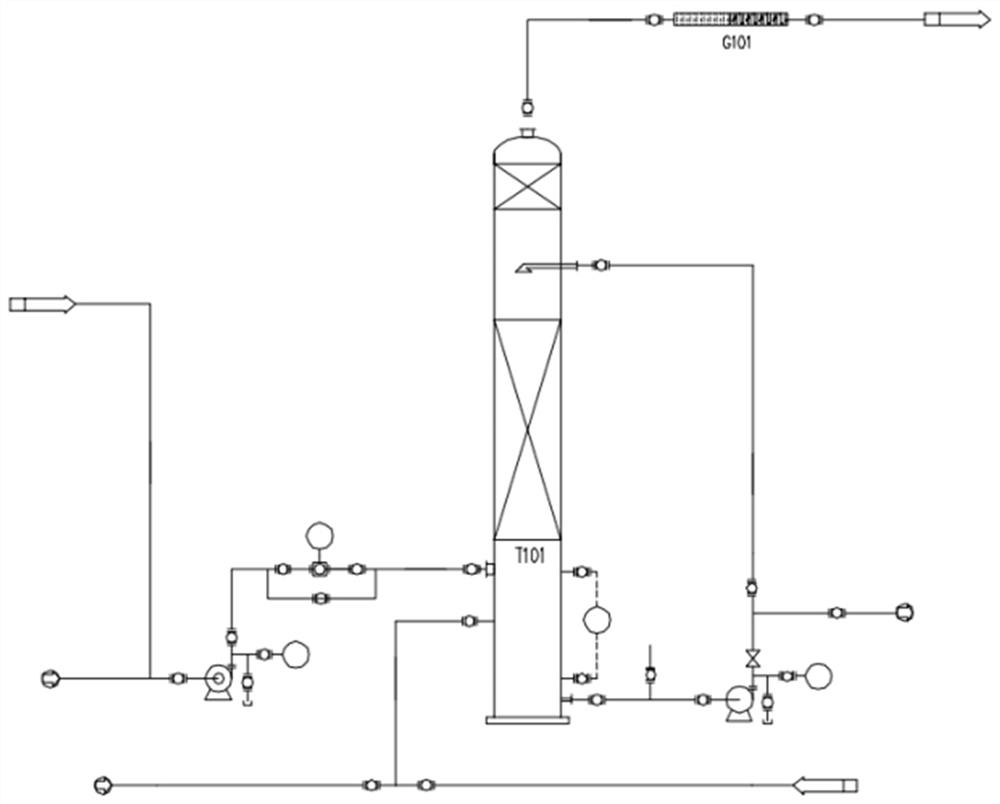

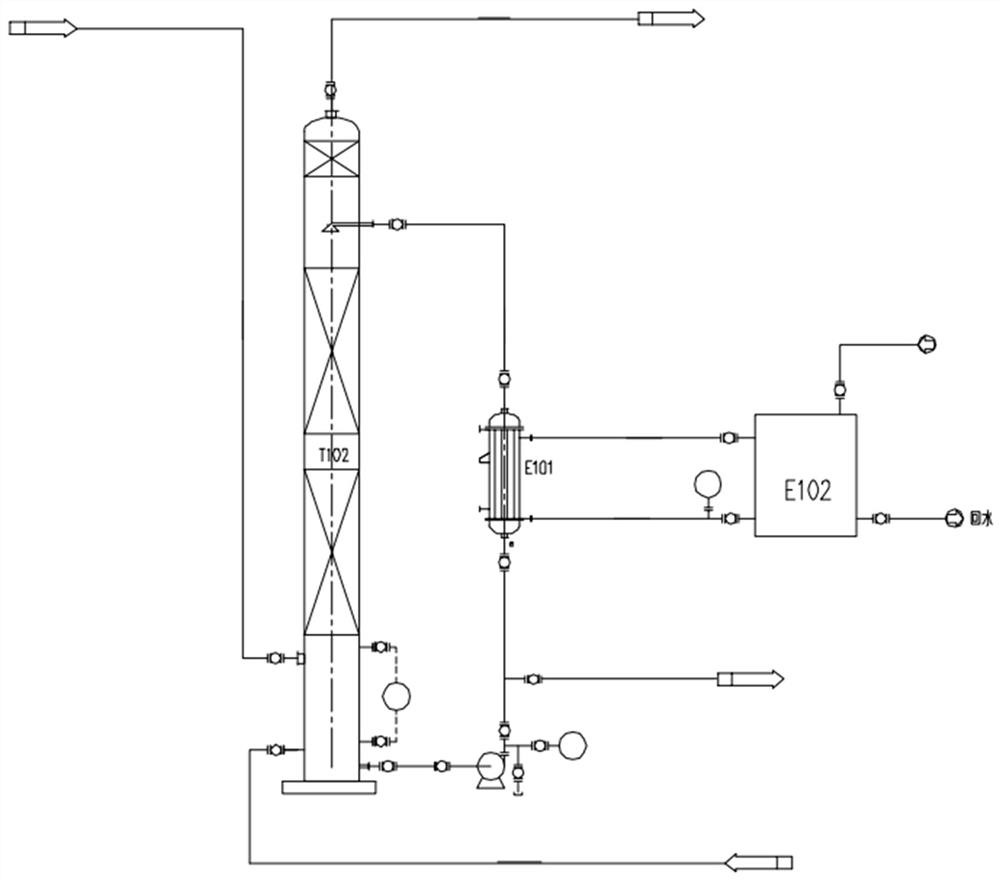

Method and production system for producing reagent hydrochloric acid by using tail gas of Mannheim furnace

ActiveCN113620249AOvercome weaknessRealize continuous large-scale productionChlorine/hydrogen-chloride purificationChemical industryFluid phasePhysical chemistry

The invention provides a method and a production system for producing reagent hydrochloric acid by using tail gas of a Mannheim furnace. The method comprises the following steps that tail gas discharged from a Mannheim furnace enters a sulfuric acid washing tower, impurity gas is absorbed by concentrated sulfuric acid, and gas discharged by the sulfuric acid washing tower sequentially passes through a first-stage washing tower, a first-stage filter, a second-stage washing tower, a third-stage washing tower and a second-stage filter, wherein the lower portion of the third-stage washing tower is communicated with the second-stage washing tower through a liquid phase pipeline so as to make the third-stage washing tower supplement liquid into the second-stage washing tower through a pipeline, a heat exchanger is additionally arranged on a circulating channel outside the second-stage washing tower and is communicated with a refrigerator, and circulating water of the heat exchanger is cooled to be lower than 5 DEG C by the refrigerator. According to the invention, at a low temperature, circulating water in a second-stage washing tower can circularly absorb hydrogen chloride gas all the time, so that the final hydrochloric acid concentration can be close to 36%, the hydrogen chloride gas absorption capacity is improved, and the concentration of the finally obtained reagent hydrochloric acid is further improved.

Owner:河北卓泰肥业有限公司

A preparation method of a fuel cell membrane electrode with a sealed frame

ActiveCN104617310BGuaranteed accuracyGuaranteed reliabilityCell electrodesPolymer scienceCell membrane

The invention discloses a method for preparing a fuel cell membrane electrode with a sealing frame. The process is simple and easy to realize. The method comprises the following steps: feeding a polymer electrolyte membrane and a sealing frame material with a layer of hot melt adhesive into a rolling device of a hot pressing platform, jointing the sealing frame material to edges of two sides of the polymer electrolyte membrane through heating rolling, and laminating a gas diffusion layer coated with a catalytic layer on two sides of the polymer electrolyte membrane so as to form a membrane electrode component. In the preparation process, a catalyst liquid is directly coated on the gas diffusion layer instead of the polymer electrolyte membrane, so that damage to a catalytic layer is reduced, the situation that later process is affected by swelling deformation of the membrane in the spraying process is avoided, the formation procedure can be simplified, continuous large-scale production of GDE and MEA can be conveniently achieved, and the production efficiency is greatly improved.

Owner:KUNSHAN SUNLAITE NEW ENERGY +1

Natural carotene microcapsule and preparation method thereof

PendingCN112075630AImprove protectionImprove emulsion stabilityFood preservationFood ingredientsBiotechnologyVegetable oil

The invention discloses a natural carotene microcapsule. The natural carotene microcapsule comprises the following components in parts by weight: 8-18 parts of a core material, 22-75 parts of a wall material, 10-20 parts of vegetable oil, 3-7 parts of d-sodium erythorbate, 1.6-2.2 parts of sodium tripolyphosphate, 1.2-1.8 parts of citric acid and 20-26 parts of maltodextrin, wherein the core material is natural carotene; and the wall material is starch sodium octenylsuccinate, xylitol, tannic acid and zein. The natural carotene microcapsule is high in embedding rate and good in stability, andcan solve the technical problem of low embedding rate of the natural carotene microcapsule in the prior art. The technical scheme of the invention also provides a preparation method of the natural carotene microcapsule.

Owner:武汉星辰现代生物工程有限公司

A kind of preparation technology of β-carotene microcapsule

ActiveCN104719894BUnique emulsificationImprove stabilityNatural dyesFood coatingSolubilityBeta-Carotene

The invention relates to a beta-carotene microcapsule and a preparation technology thereof. The technology comprises the following steps: mixing corn starch which contains beta-carotene crystals and microhole ocentyl succinic anhydride and serves as a core material, an oil phase consisting of plant oil, an antioxidant and the like and a water phase consisting of a wall material, an antioxidant, a dispersant, water and the like according to a ratio, homogenizing to prepare microemulsion, and performing spray drying to prepare beta-carotene microcapsule powder. In a preparation process, no organic solvent needs to be added, and an obtained product keeps the bioactivity, is stable to the photo-thermal property and is extremely high dissolvability in cold water; processing, transportation and storage are facilitated; the safety, the flowability, the taste and the water solubility of the product are greatly improved; the beta-carotene microcapsule is a high-quality health food and food pigment raw material. The yield of the beta-carotene microcapsule prepared by the technology is high, and the preparation method is suitable for batch preparation of the beta-carotene microcapsules; continuous large-scale production is realized.

Owner:武汉志邦化学技术有限公司

Cooling filter tip and low-temperature cigarette with same

PendingCN112369659AAdd smoke flavorGood suction experienceCigar manufactureTobacco smoke filtersPhysicsAerosolize

The invention discloses a cooling filter tip and a low-temperature cigarette with the same. The cooling filter tip comprises a particle section, a first filter section and a second filter section, theparticle section comprises particles used for reducing the smoke temperature and / or increasing the smoke flavor, the first end of the particle section is connected with the first end of the first filtering section, and the second end, opposite to the first end of the particle section, of the particle section is connected with the first end of the second filtering section; a first bundle column used for allowing smoke to pass through and blocking particles is arranged in the first filtering section, and the second end, opposite to the first end of the first filtering section, of the first filtering section is used for being connected with an atomized tobacco matrix section; a second bundle column used for allowing smoke to pass through and blocking particles is arranged in the second filtering section, and the second end, opposite to the first end of the second filtering section, of the second filtering section is used for allowing smoke to pass through and flow into the mouth of a user. The low-temperature cigarette comprises a cooling filter tip and an atomized tobacco substrate section connected with the cooling filter tip. According to the invention, the smoke temperature can be reduced and / or the smoke flavor can be increased.

Owner:HUBEI CHINA TOBACCO IND

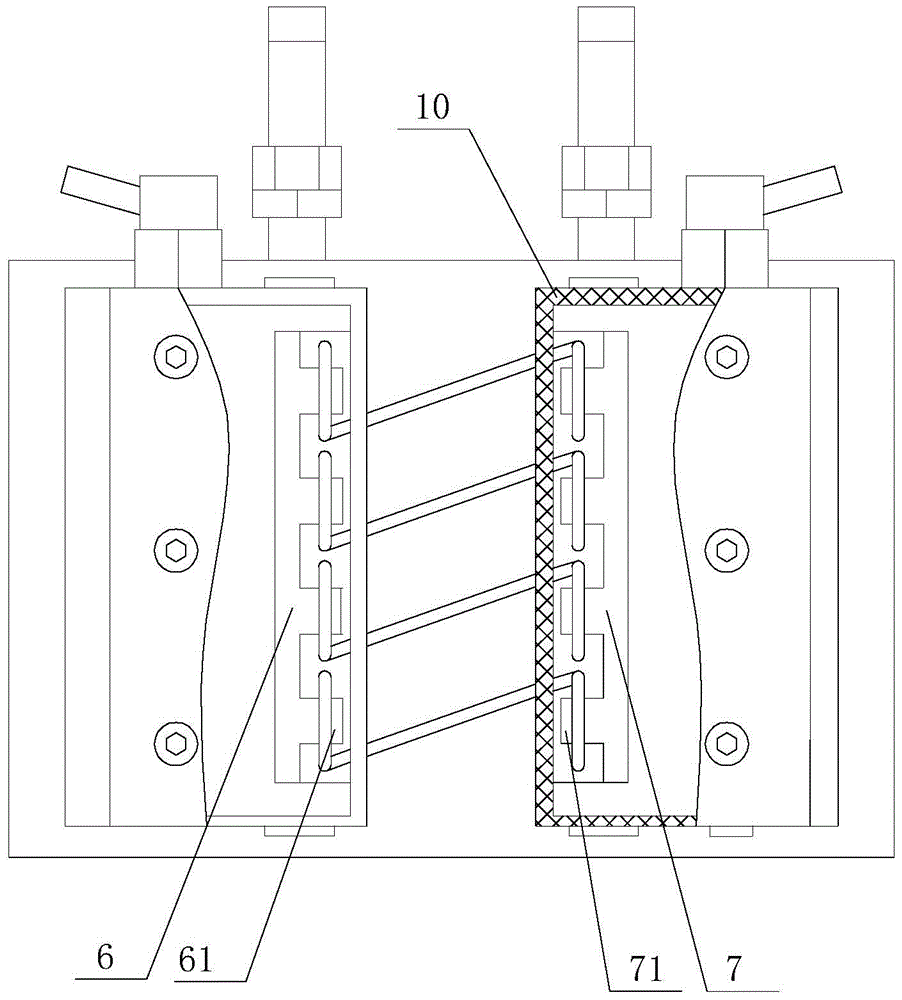

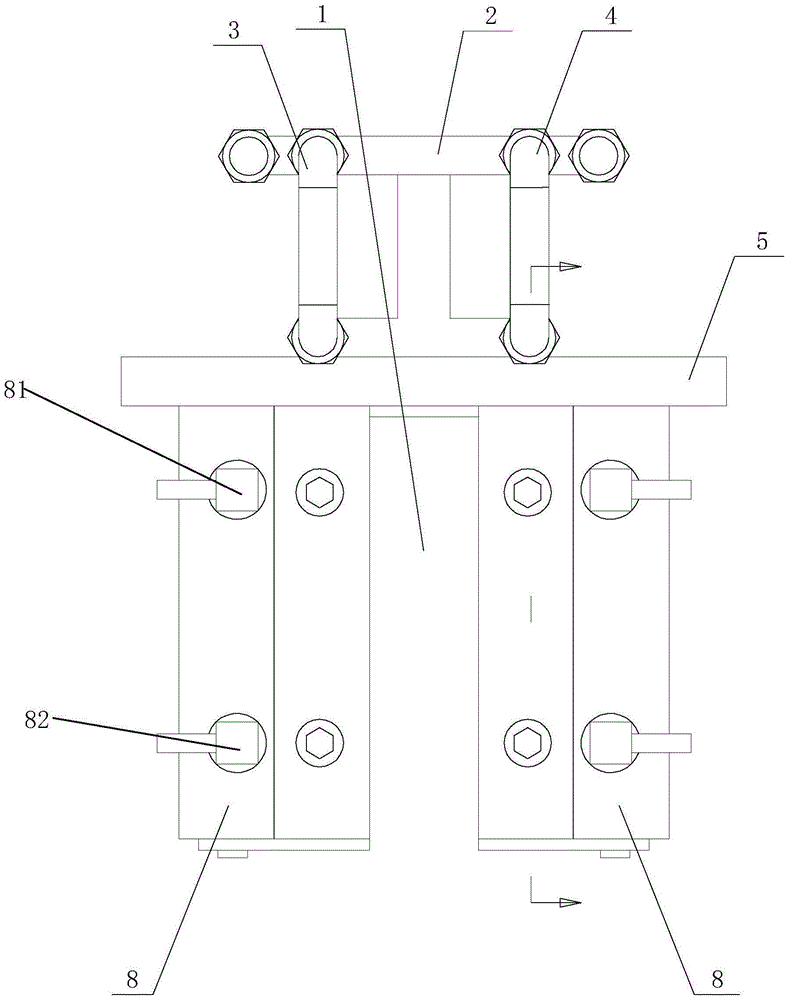

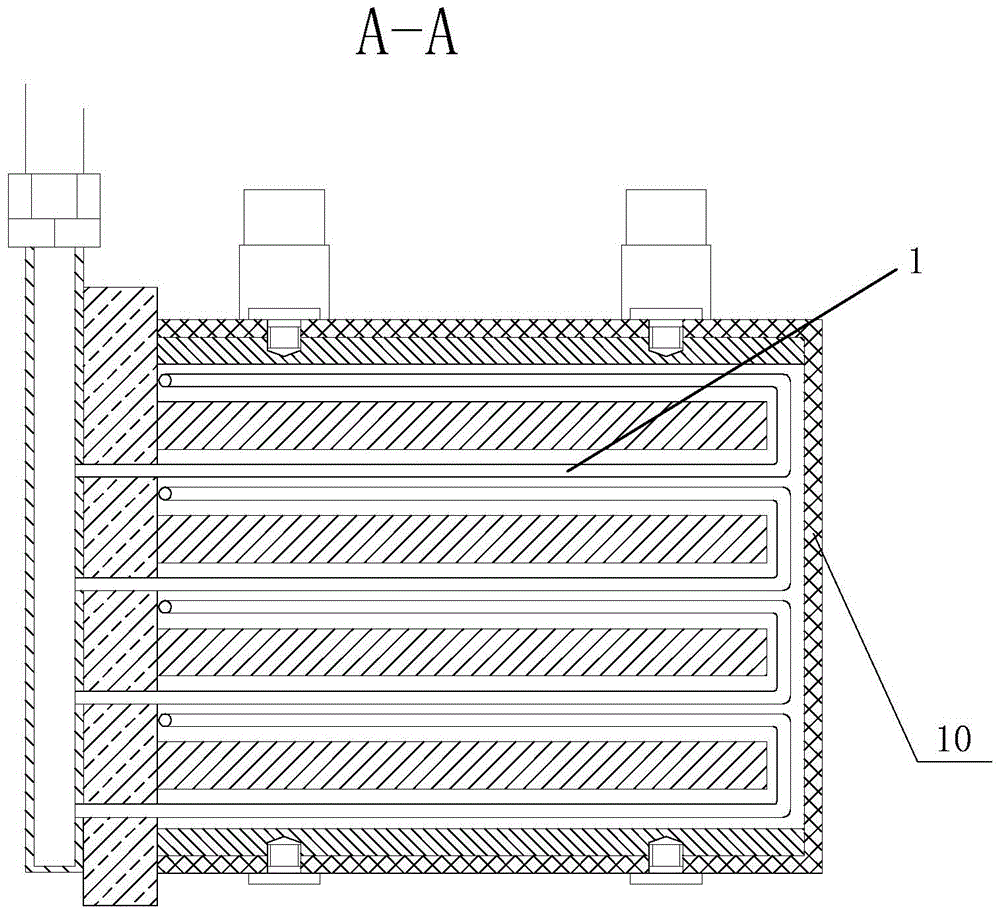

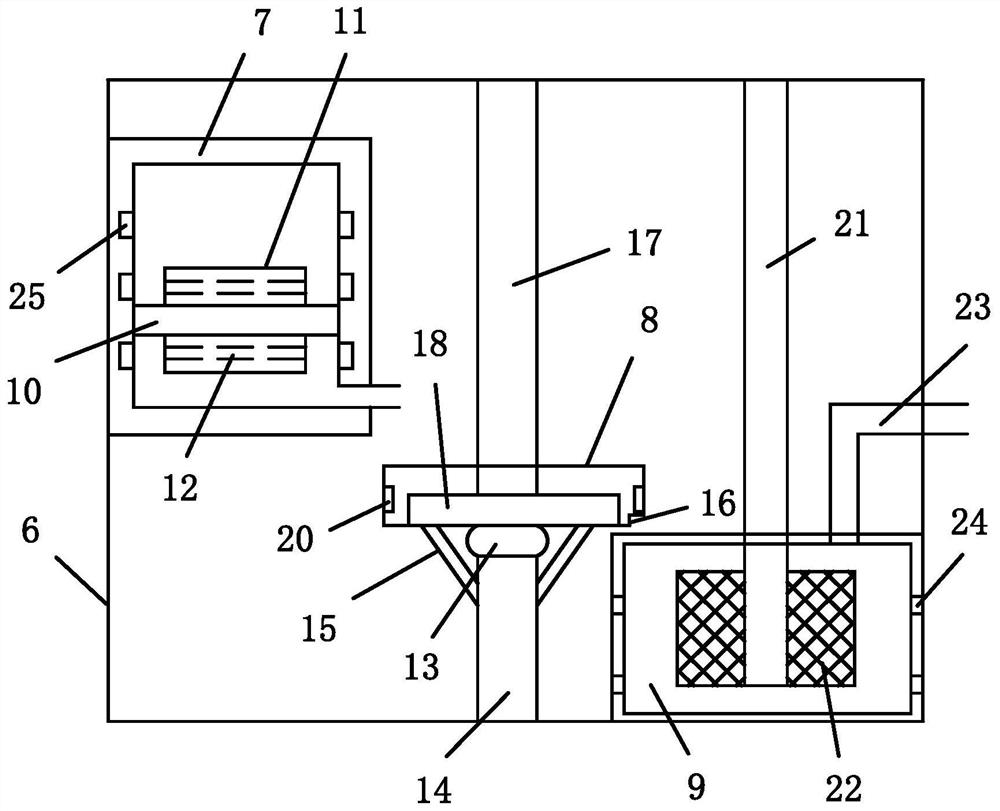

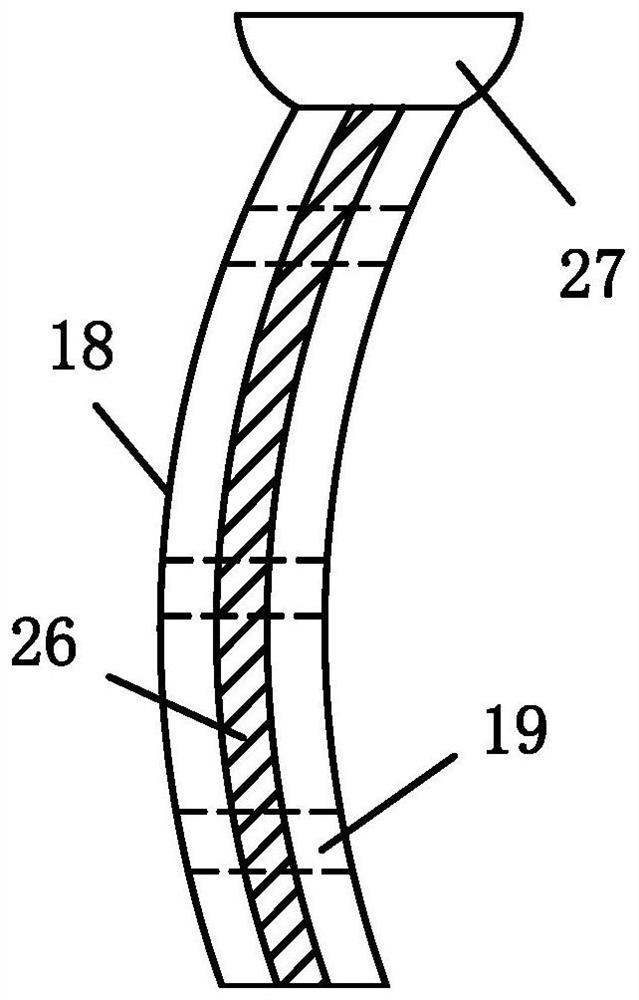

High frequency quenching sensor

ActiveCN104894340BRealize continuous large-scale productionGuaranteed uniformityIncreasing energy efficiencyQuenching devicesInductorGraphite

The invention discloses a high-frequency quenching inductor. The high-frequency quenching inductor comprises a cooling liquid inlet pipeline, a cooling liquid outlet pipeline, a first graphite block, a second graphite block and at least one hollow coil. The first graphite block is provided with at least one boss, and the second graphite block is provided with at least one matched boss. The bosses and the matched bosses are in one-to-one correspondence and are arranged symmetrically. The starting ends of the hollow coils are communicated with the cooling liquid inlet pipeline, extend to the matched bosses after winding around the bosses by one circle and are communicated with the cooling liquid outlet pipeline after winding around the matched bosses by one circle. Portions, respectively winding around the bosses and the matched bosses, of the hollow coils are U-shaped. The high-frequency quenching inductor has the advantages that uniformity in induction quenching of components and uniformity in product quality are guaranteed, continuous mass production of heat treatment of small shaft type or spring components is achieved, and production efficiency is improved remarkably.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Huperzine A production method suitable for industrial production

InactiveCN105949123AReduce the temperatureLarge amount of waterOrganic chemistryChemical industryFiltrationSolvent

The invention provides a huperzine A production method suitable for industrial production and relates to a huperzine A production method. The huperzine A production method comprises the following specific steps of pretreatment of raw materials, extraction, centrifugation, ultra-filtration, nano-filtration, PH value regulation, concentration, microwave drying and smashing. The huperzine A production method adopts a membrane technology for separation and purification. Compared with other purification modes such as macroporous resin adsorption and solvent extraction, the huperzine A production method has the advantages of being safe, environmentally friendly and capable of saving energy, only using a pure water solvent, not adopting an organic solvent and the like, the operation is simple, the product is safe, environmentally friendly, good and inexpensive, and continuous large-scale industrial production can be achieved.

Owner:JIANGXI HAIFU BIOENG

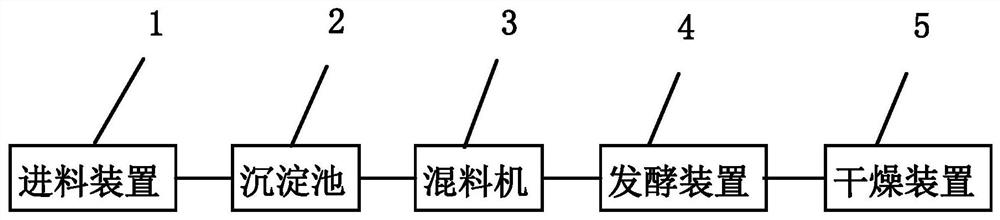

A production equipment and process for producing organic fertilizer from sludge

ActiveCN110950693BRealize continuous large-scale productionImprove bioprotective activityBio-organic fraction processingMicroorganism based treatmentSludgeProcess engineering

The invention discloses a production equipment for producing organic fertilizer from sludge, which comprises a feeding device for feeding the sludge; a sedimentation tank connected with the feeding device and used for stirring the sludge raw materials and then precipitating; mixing The feeder is connected with the sedimentation tank, and is used to add ingredients to the sludge raw material and stir evenly; the fermentation device, connected with the mixer, is used to ferment the mixed raw materials; the drying device is used to dry the fermented raw materials , to get organic fertilizer. The invention can improve the deficiencies of the prior art and improve the efficiency of sludge recycling.

Owner:广州绿邦环境技术有限公司 +1

A kind of preparation method of edible fulvic acid salt

The invention discloses a preparation method of edible fulvic acid salt, and belongs to the technical field of chemical engineering. The method is characterized in that a mode of combining an oxidization degradation activation technology and a molecular weight cutting grading technology is used for using medical stone and young coal as raw materials; oxidization and activation are performed through a green oxidizing agent system; then, the novel mineral-based fulvic acid salt is obtained through film filtering purification and enriching; the prepared product has high purity, high activity, high water solubility and few other impurities; the characteristics of safety, environment protection, no irritation, no side effect, direct eating performance, long shelf life and the like are realized; in addition, the operation is relatively simple; the extraction rate is high; the continuous scaled production can be realized.

Owner:KUNMING UNIV OF SCI & TECH

Fiber/long-carbon-chain nylon in-situ composite material and preparation method

The invention relates to a fiber composite material, and particularly relates to a fiber / long-carbon-chain nylon in-situ composite material and a preparation method. The fiber / long-carbon-chain nylon in-situ composite material comprises the components: 1-20wt% of high-performance fiber and 80-99wt% of long-carbon-chain nylon salt, preferably 5-16wt% of high-performance fiber and 84-95wt% of long-carbon-chain nylon salt, wherein the high-performance fiber is selected from at least one of aramid fiber, carbon fiber and fiberglass. The preparing process is simple; and the strength and toughness of the prepared fiber / long-carbon-chain nylon composite material are significantly improved as compared with those of the pure long-carbon-chain nylon prepared by the same process.

Owner:INST OF CHEM CHINESE ACAD OF SCI

A method for continuously preparing graphene using a rotary homogenizer

ActiveCN105645394BWeaken the force between layersFacilitate strippingGrapheneCrystal structureGraphite

The invention belongs to the technical field of graphene and particularly relates to a method for preparing graphene continuously by using a rotary homogenizer. Graphite and a nano phase-change material are mixed uniformly and then are mixed with an intercalator, the mixture is heated at the temperature of 40-80 DEG C, the nano phase-change material is changed into liquids from a solid state, gaps are formed among graphitic layers, the intercalator is expediently intercalated in a layered structure of graphite, the interlayer acting force of the graphite is weakened, stripping of the graphite is facilitated, intercalated graphite is sent to the rotary homogenizer, graphite is continuously sheared and stripped by means of shearing force produced during rotary stirring, the graphite is stripped layer by layer, damage of the mechanical shearing force to a graphene crystal structure is prevented, and the graphene with uniformly distributed layers is prepared. The yield of the graphene prepared with the method is high, the graphene has 10-100 layers and has few structure defects, high-quality graphene is prepared rapidly and continuously, the production cost of the high-quality graphene is greatly reduced, large-scale production of graphene is promoted, and the graphene has remarkable market application value.

Owner:陕西富安长德信息科技有限公司

High-frequency quenching inductor

ActiveCN104894340ARealize continuous large-scale productionGuaranteed uniformityIncreasing energy efficiencyQuenching devicesGraphiteInductor

The invention discloses a high-frequency quenching inductor. The high-frequency quenching inductor comprises a cooling liquid inlet pipeline, a cooling liquid outlet pipeline, a first graphite block, a second graphite block and at least one hollow coil. The first graphite block is provided with at least one boss, and the second graphite block is provided with at least one matched boss. The bosses and the matched bosses are in one-to-one correspondence and are arranged symmetrically. The starting ends of the hollow coils are communicated with the cooling liquid inlet pipeline, extend to the matched bosses after winding around the bosses by one circle and are communicated with the cooling liquid outlet pipeline after winding around the matched bosses by one circle. Portions, respectively winding around the bosses and the matched bosses, of the hollow coils are U-shaped. The high-frequency quenching inductor has the advantages that uniformity in induction quenching of components and uniformity in product quality are guaranteed, continuous mass production of heat treatment of small shaft type or spring components is achieved, and production efficiency is improved remarkably.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Multilayer electromagnetic shielding film and preparation method thereof

ActiveCN106739324BGood electromagnetic shieldingHigh mechanical strengthSynthetic resin layered productsCarbon nanotubeElectromagnetic shielding

The invention discloses a multilayer electromagnetic shielding film and a preparation method thereof. According to the multilayer electromagnetic shielding film, shielding layers are arranged from the outermost layer to the sub-bottom layer and the bottom layer is a resin insulating layer; the resin insulating layer is a pure resin layer; each of the shielding layers is of a layered structure formed by adding conductive filler to matrix resin. The conductive filler comprises one or more of nickel powder, silver powder, a carbon nanotube and graphene. In two adjacent shielding layers, The adding amount of the conductive filler of the lower shielding layer is greater than that of the lower shielding layer. The electromagnetic shielding property of the multilayer electromagnetic shielding film prepared by the invention is excellent, and the mechanical strength and toughness are good; meanwhile, the production process is simple, the cost is low, and full continuous scaled production can be achieved.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

A method for continuously preparing graphene microsheets by grinding and exfoliating

The invention belongs to the technical field of graphene, and particularly relates to a method for continuously preparing graphene nanoplatelets by means of grinding stripping.The method comprises the steps that crystallized organic matter is uniformly dispersed in a graphite precursor through solvent dispersion, deformation force produced through repeated crystallization of the crystallized organic matter is utilized for enabling the graphite layer frame distance to be increased, and intercalated graphite is formed; the intercalated graphite is sent to a grinding stripping machine, the stripping and grinding effect of shear force formed in the mutual friction process of media and the graphite material is utilized, the intercalated graphite is stripped, and graphene nanoplatelets are formed; screening separation is conducted on stripped graphite through a vibrating screening machine, unstripped graphite is screened out to be stripped again, and the uniformly distributed graphene nanoplatelets are obtained.The number of layers of the prepared graphene nanoplatelets ranges from 10 to 100, the crystal structure is complete, the high-quality graphene nanoplatelets are produced in an efficient, low-cost and continuous mode under a high shear condition, the preparation process is green and environmentally friendly, and a significant market value is achieved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

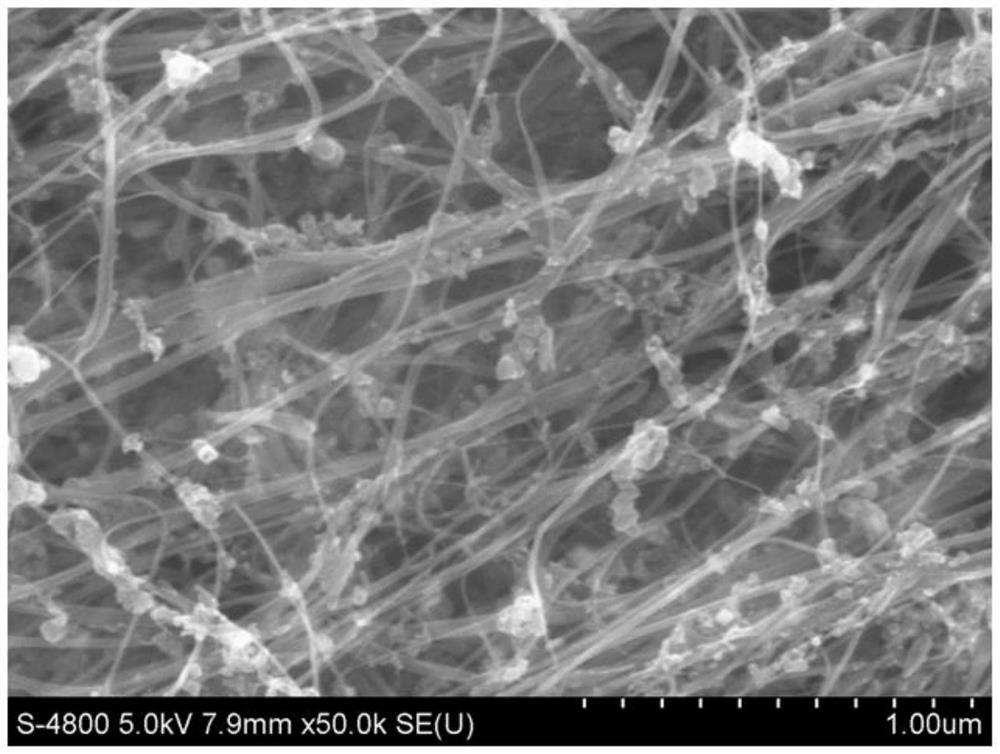

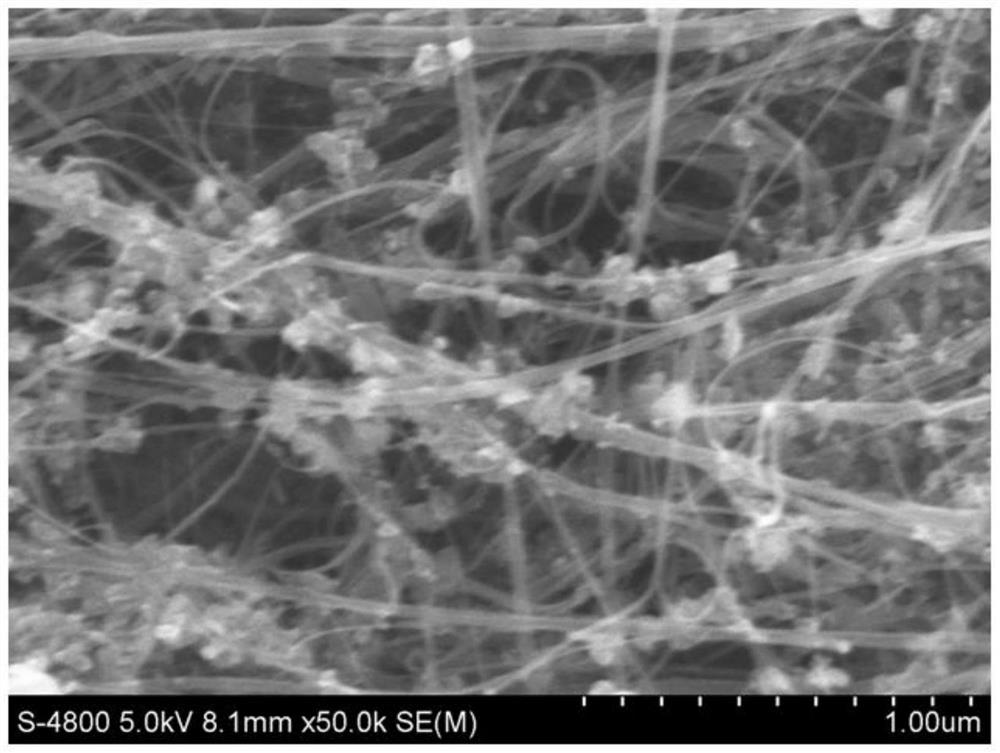

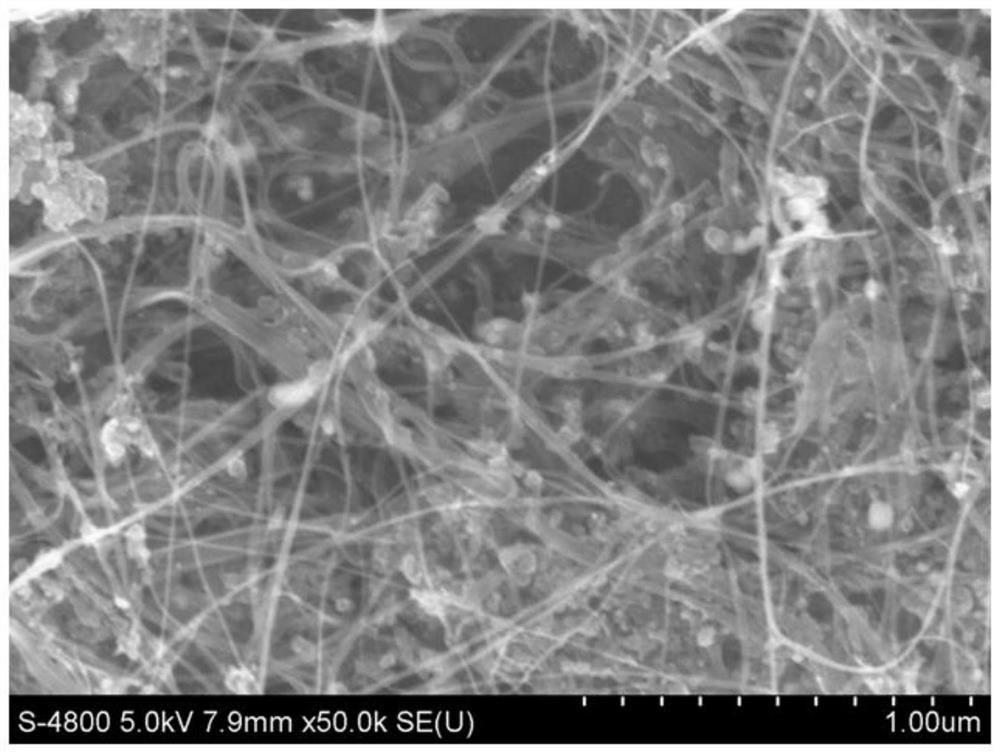

Silicon oxide composite boron-doped carbon nanotube film as well as preparation method and application thereof

PendingCN113013387ASimple processGood self-supporting performanceCell electrodesSecondary cellsSilicic acidSilicon oxide

The invention discloses a silicon oxide composite boron-doped carbon nanotube film and a preparation method and application thereof, and the preparation method comprises the following steps: 1, completely sealing a vertical CVD furnace, continuously introducing Ar, heating the vertical CVD furnace to 1100-1200 DEG C, and carrying out heat preservation; 2, weighing ethanol, ferrocene and thiophene according to a mass ratio of 95:1.5:1, and mixing to obtain a mixed solution; adding 1-3wt.%, preferably 2wt.%, of boric acid as a boron source for reaction and 0.2-1wt.% of ethyl orthosilicate as a silicon source for reaction into the mixed solution, uniformly dispersing, and transferring to a microsyringe at the top end of the vertical CVD furnace as a precursor solution; and 3, closing Ar, continuously introducing 600-1000 sccm of H2 as a reaction gas, injecting the precursor solution into a vertical CVD furnace by an injection pump through an ultrasonic atomization device at the top of the vertical CVD furnace, and obtaining the silicon oxide composite boron-doped carbon nanotube film 5-10 minutes after the reaction is started. The silicon oxide composite boron-doped carbon nanotube film obtained by the invention has high electrochemical performance.

Owner:TIANJIN UNIV

A kind of extraction method of high-purity mogroside V

ActiveCN110669095BAvoid damageImprove extraction efficiencyGlycoside steroidsBiotechnologyReflux extraction

Owner:广西壮族自治区科学技术情报研究所

A kind of high-content krill oil microcapsules and its preparation process

ActiveCN104824651BGood moisture absorptionGood moisturizing effectFood ingredient as encapsulating agentEdible oils/fatsSolubilityAntioxidant

The invention relates to high-content krill oil microcapsules and a preparation technology thereof. The technology comprises the following steps: by taking krill oil and microporous starch as core materials, adding a small amount of xanthan gum into oil phase; and by taking chitosan oligosaccharide and oxidized starch as wall materials, mixing an oil-phase antioxidant, a water-phase antioxidant, an emulsifier, a dispersant and the like in proportion to prepare micro-emulsion, and performing spray drying to prepare krill oil microcapsule powder. The obtained krill oil microcapsule product contains 10-30 percent of phosphatide and keeps biological activity, improves the light-heat stability, acid-alkali stability and the like of krill oil, has good solubility in cold water, and is relatively easy to process, transport and store, safety, fluidity and water solubility are greatly improved, the application range of krill oil is enlarged, and the krill oil is an excellent health-food raw material, and is widely applied to dairy products, beverages, health-care products, baking, tablets and the like. The yield of the krill oil microcapsule powder prepared according to the technology is high, the phosphatide content of the product is high, and the technology is suitable for mass preparation of krill oil microcapsule powder and realizes continuous large-scale production.

Owner:武汉志邦化学技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com