A method for continuously preparing graphene using a rotary homogenizer

A technology of graphene and homogenizer, which is applied in the field of graphene, can solve the problems of non-continuous production, large lattice defects, and low quality, and achieve the effects of improving utilization rate, weakening interlayer force, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

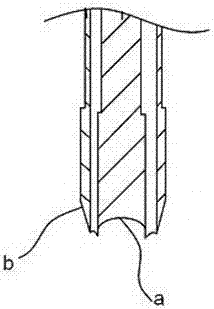

[0028] (1) Combine flake graphite with nano Na 2 HPO 4 12H 2 O is added to the high-speed mixer by weight ratio 100:1 ~ 10, mixed and dispersed at a speed of 1500rpm for 15min, so that the nano phase change material is evenly dispersed in the graphite layered structure to obtain a premix;

[0029] (2) The premix obtained in step (1) was dispersed and mixed with the intercalation agent hexamethylenediamine at 60°C for 30 minutes to obtain an intercalation graphite mixture; the weight ratio of the premix to the intercalation agent was 100: 1. The nano-phase change material distributed in the graphite layered structure melts and changes from solid to liquid, so that gaps appear between graphite layers, which is conducive to the intercalation agent interspersed in the graphite layered structure and weakens the interlayer force of graphite , which is conducive to the stripping of graphite;

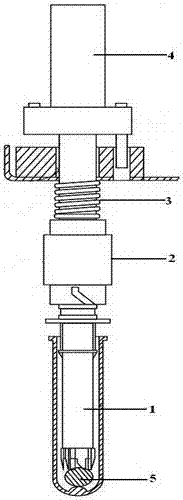

[0030] (3) Add the intercalated graphite mixture obtained in step (3) into a rotary homo...

Embodiment 2

[0034] (1) Combine expanded graphite with nano CH 3 COONa·3H 2 O is added to the high-speed mixing mixer at a weight ratio of 100:4, mixed and dispersed for 30min at a speed of 800rpm, so that the nano phase change material is evenly dispersed in the graphite layered structure to obtain a premix;

[0035] (2) Disperse and mix the premix obtained in step (1) with the intercalation agent m-xylylenediamine for 40 minutes at 60°C to obtain an intercalation graphite mixture; the weight ratio of the premix to the intercalation agent is 100 : 2, the nano-phase change material distributed in the graphite layered structure melts and changes from solid to liquid, so that there is a gap between the graphite layers, which is conducive to the intercalation agent interspersed in the graphite layered structure and weakens the interlayer effect of graphite Force, which is conducive to the peeling of graphite;

[0036] (3) Add the intercalated graphite mixture obtained in step (3) into a rot...

Embodiment 3

[0040] (1) Combining pyrolytic graphite with nano-Na 2 SO 4 10H 2 O is added to the high-speed mixing mixer at a weight ratio of 100:6, mixed and dispersed for 20min at a speed of 1000rpm, so that the nano phase change material is evenly dispersed in the graphite layered structure to obtain a premix;

[0041] (2) Disperse and mix the premix obtained in step (1) with the intercalation agent 2,2,4-trimethyl-1,6-hexanediamine at 50°C for 30 minutes to obtain the intercalated graphite mixture ; The weight ratio of the premix and the intercalation agent is 100:3, and the nano phase change material distributed in the graphite layered structure melts and changes from a solid state to a liquid state, so that gaps appear between the graphite layers, which is conducive to the intercalation agent interspersed in In the layered structure of graphite, the interlayer force of graphite is weakened, which is conducive to the peeling of graphite;

[0042] (3) Add the intercalated graphite m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com