A method for removing sulfur and sodium from ternary precursor

A precursor, ternary technology, applied in chemical instruments and methods, electrical components, nickel compounds, etc., can solve the problem of high sodium content and sulfur content, achieve high-efficiency content, reduce content, and weaken the effect of interlayer force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

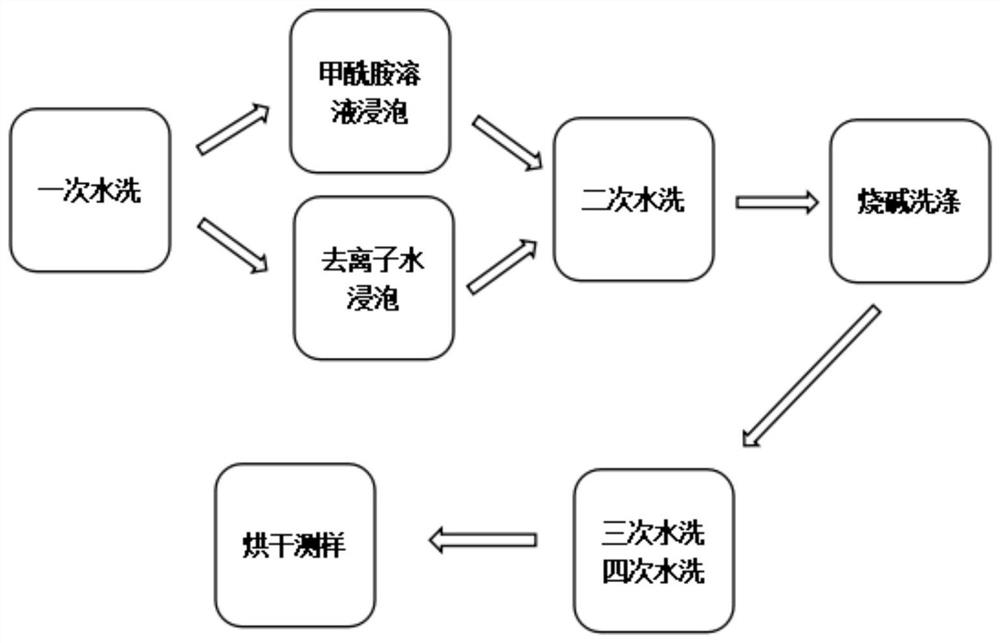

Method used

Image

Examples

Embodiment 1

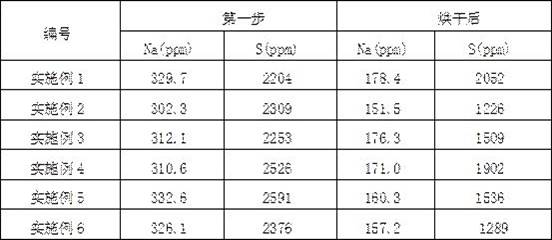

[0028] Example 1: Step 1: 1 t of newly produced NCM523 ternary precursor raw material with a particle size greater than 8 μm is separated from solid and liquid by a filter press and washed;

[0029] The second step: unload the sample treated in the first step to a storage area of 1 m 3 In a slurry tank of pure water, stir and soak for 3 h;

[0030] Step 3: Wash the samples treated in the second step with pure water once and once with caustic soda solution with a concentration of 0.35 mol / L;

[0031] Step 4: Wash the sample treated in the third step with pure water, dry it and send it for Na and S inspection;

Embodiment 2

[0032] Example 2: Step 1: 1 t of newly produced solid granular NCM523 ternary precursor raw material with a particle size larger than 8 μm is separated from solid and liquid by a filter press and washed;

[0033] The second step: unload the sample treated in the first step to contain 1 m 3 , in a slurry tank with a volume concentration of 30% formamide aqueous solution, stirring and soaking for 3 h;

[0034] Step 3: Wash the samples treated in the second step with pure water once and once with caustic soda solution with a concentration of 0.35 mol / L;

[0035] Step 4: Wash the sample treated in the third step with pure water and dry it for Na, S inspection;

Embodiment 3

[0036] Example 3: Step 1: 1 t of newly produced solid granular NCM523 ternary precursor raw material with a particle size of 10±0.5 μm is separated from solid and liquid by a filter press and washed;

[0037] The second step: wash the sample treated in the first step with a caustic soda solution with a concentration of 0.35 mol / L, and the washing temperature is 50°C;

[0038] The third step: wash the sample treated in the second step with pure water and dry it for Na, S inspection;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com