Fiber/long-carbon-chain nylon in-situ composite material and preparation method

An in-situ composite material and long carbon chain technology, which is applied in the field of fiber composite materials to achieve good industrialization prospects, improved dispersion and excellent strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

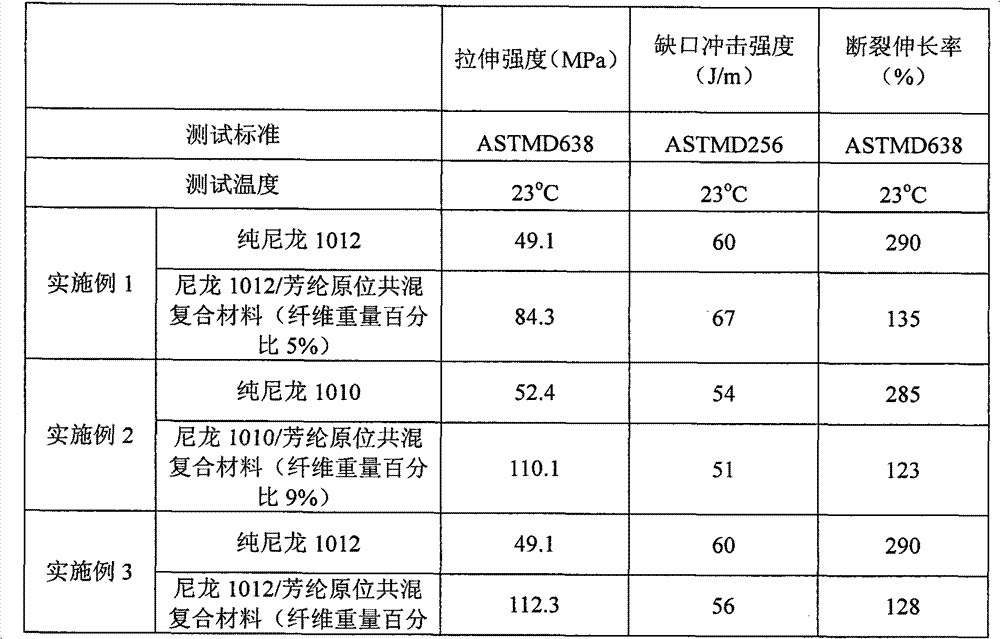

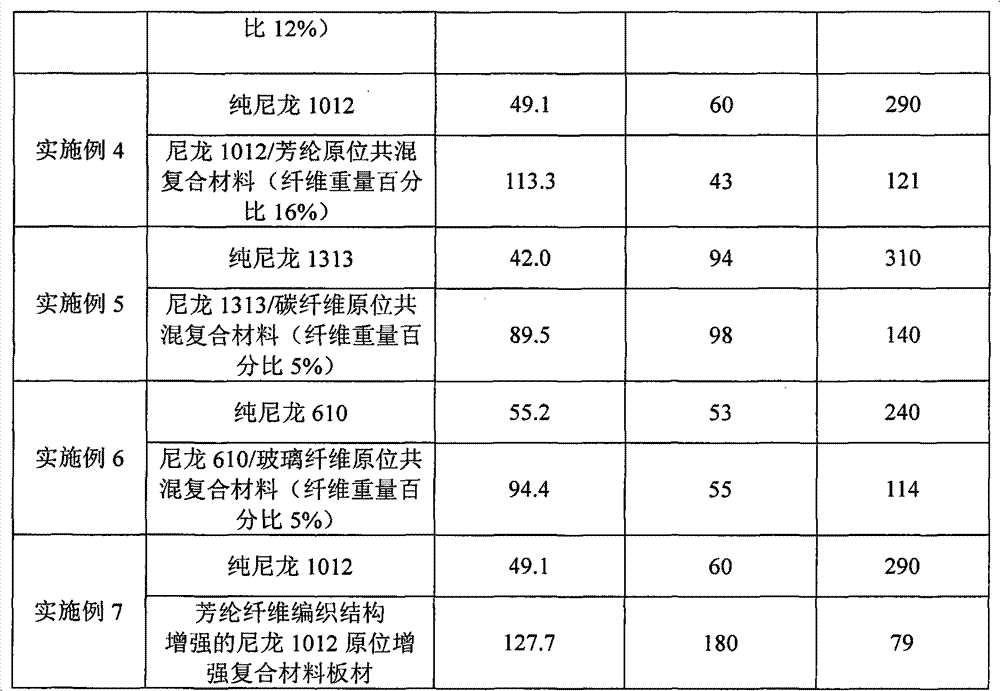

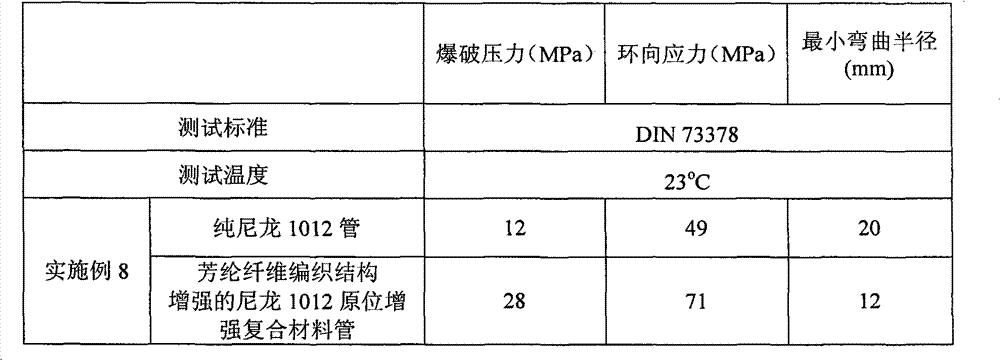

Examples

Embodiment 1

[0041] 1. Preparation of nylon 1012 salt: weigh 1Kg of dodecanedibasic acid, 4Kg of 99.5% ethanol, and mix to obtain an ethanol solution of dodecanedibasic acid; weigh 0.96Kg of decanediamine, 1Kg of 99.9% ethanol, and mix to prepare Obtain the ethanol solution of decanediamine; heat the obtained ethanol solution of dodecanedibasic acid to 35°C, and then add it dropwise into the stirred reactor containing the ethanol solution of decanediamine, and the dropping time is 20 minutes Put it into an ice-water bath after standing still for 15 minutes, collect the precipitated suspended matter, wash with ethanol to obtain nylon 1012 salt, and dry it in a vacuum oven for 48 hours;

[0042] 2. Fiber pretreatment: take aramid staple fiber (produced in Japan, model 968) with a length of 1 mm and a diameter of 13 μm, soak it in acetone for 3 hours, take it out and dry it in vacuum at 80°C for 12 hours;

[0043] 3. Polycondensation reaction: 95 parts by weight of nylon 1012 salt and 5 parts...

Embodiment 2

[0045] 1. Preparation of nylon 1010 salt: Weigh 1Kg of sebacic acid and 4Kg of 99.9% ethanol, and mix them to obtain an ethanol solution of sebacic acid. Weigh 0.96Kg of decanediamine, 1Kg of 99.9% ethanol, and mix to obtain an ethanol solution of decanediamine; heat the obtained ethanol solution of sebacic acid to 35° C., and then add it dropwise to a stirred tank containing decanediamine ethanol In the reactor of the solution, the dripping time is 20 minutes; after standing for 15 minutes, put it into an ice-water bath, collect the precipitated suspended matter, obtain nylon 1010 salt, and dry it in a vacuum oven for 48 hours;

[0046] 2. Fiber pretreatment: take aramid staple fiber (produced in Japan, model 968) with a length of 1 mm and a diameter of 13 μm, soak it in acetone for 3 hours, take it out and dry it in vacuum at 80°C for 12 hours;

[0047] 3. Polycondensation reaction: 91 parts by weight of nylon 1010 salt and 9 parts by weight of aramid fiber were mixed in a h...

Embodiment 3

[0049] 1. Preparation of nylon 1012 salt: Weigh 1 Kg of dodecanedibasic acid and 4 Kg of 99.9% ethanol, and mix them to obtain an ethanol solution of dodecanedibasic acid. Weigh 0.96Kg of decanediamine and 1Kg of 99.9% ethanol, and mix them to obtain an ethanol solution of decanediamine. Heat the ethanol solution of dodecanedibasic acid to 35°C, then add it dropwise into a stirred reactor containing ethanol solution of decanediamine, and the adding time is 20 minutes; after standing for 15 minutes, put it in ice In a water bath, the precipitated suspended matter was collected to obtain nylon 1012 salt, and dried in a vacuum oven for 48 hours;

[0050] 2. Fiber pretreatment: take aramid staple fiber (produced in Japan, model 968) with a length of 1 mm and a diameter of 13 μm, soak it in acetone for 3 hours, take it out and dry it in vacuum at 80°C for 12 hours;

[0051] 3. Polycondensation reaction: 88 parts by weight of nylon 1012 salt and 12 parts by weight of aramid fiber w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com